6 Lera HDI PCB FR4 Potoloho Boards Pcb Khauta menoana

Matla a Ts'ebetso ea PCB

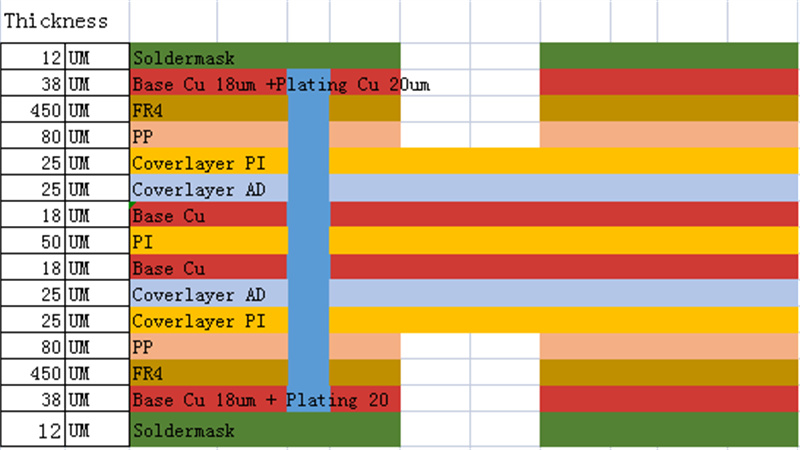

| Che. | Morero | Lipontšo tsa tekheniki |

| 1 | Lera | 1-60(lera) |

| 2 | Boholo ba sebaka sa ho sebetsa | 545 x 622 limilimithara |

| 3 | Botenya bo fokolang | 4(lera)0.40mm |

| 6(lera) 0.60mm | ||

| 8(lera) 0.8mm | ||

| 10(lera)1.0mm | ||

| 4 | Bophara bo fokolang ba mola | 0.0762 limilimithara |

| 5 | Sebaka se fokolang | 0.0762 limilimithara |

| 6 | Mocheso o fokolang oa ho bula | 0.15 limilimithara |

| 7 | Sekoti lebota botenya ba koporo | 0.015 limilimithara |

| 8 | Metallized aperture tolerance | ± 0.05 limilimithara |

| 9 | Mamello e se nang metale aperture | ± 0.025mm |

| 10 | Ho mamellana le lesoba | ± 0.05 limilimithara |

| 11 | Mamello ya dimensional | ± 0.076 limilimithara |

| 12 | Borokho bo fokolang ba solder | 0.08 limilimithara |

| 13 | Insulation resistance | 1E+12Ω (e tloaelehileng) |

| 14 | Karolelano ea botenya ba poleiti | 1:10 |

| 15 | Tšisinyeho ea mocheso | 288 ℃ (makhetlo a 4 ka metsotsoana e 10) |

| 16 | E khopamisitsoe ebile e kobehile | ≤0.7% |

| 17 | Matla a khahlanong le motlakase | ~1.3KV/mm |

| 18 | Matla a thibelang ho hlobola | 1.4N/mm |

| 19 | Solder hanela boima | ≥6H |

| 20 | Ho lieha ha lelakabe | 94V-0 |

| 21 | Taolo ea impedance | ±5% |

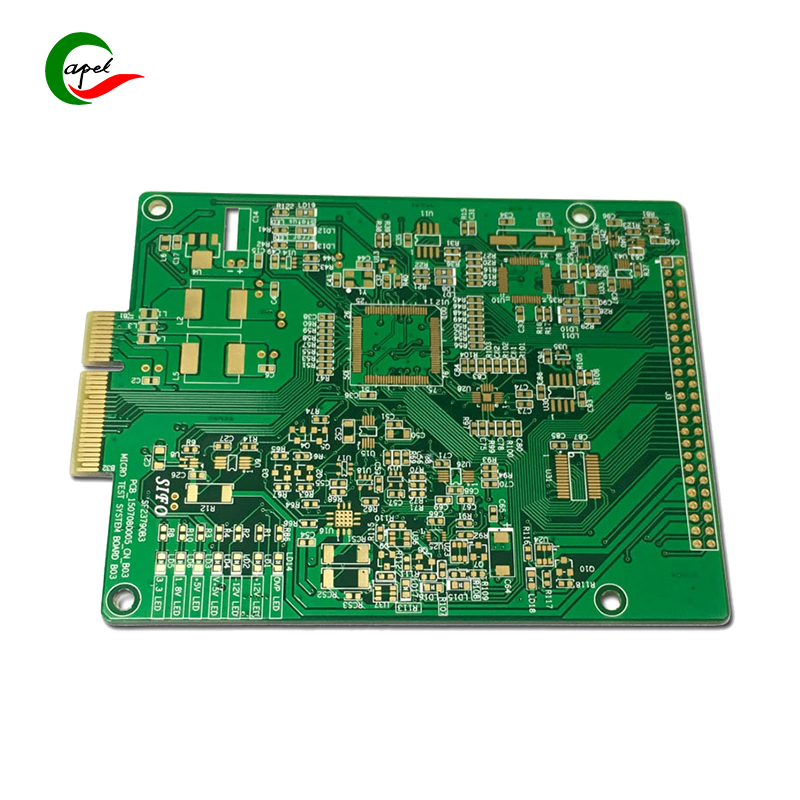

Re etsa 6 layer HDI PCB ka boiphihlelo ba lilemo tse 15 ka botsebi ba rona

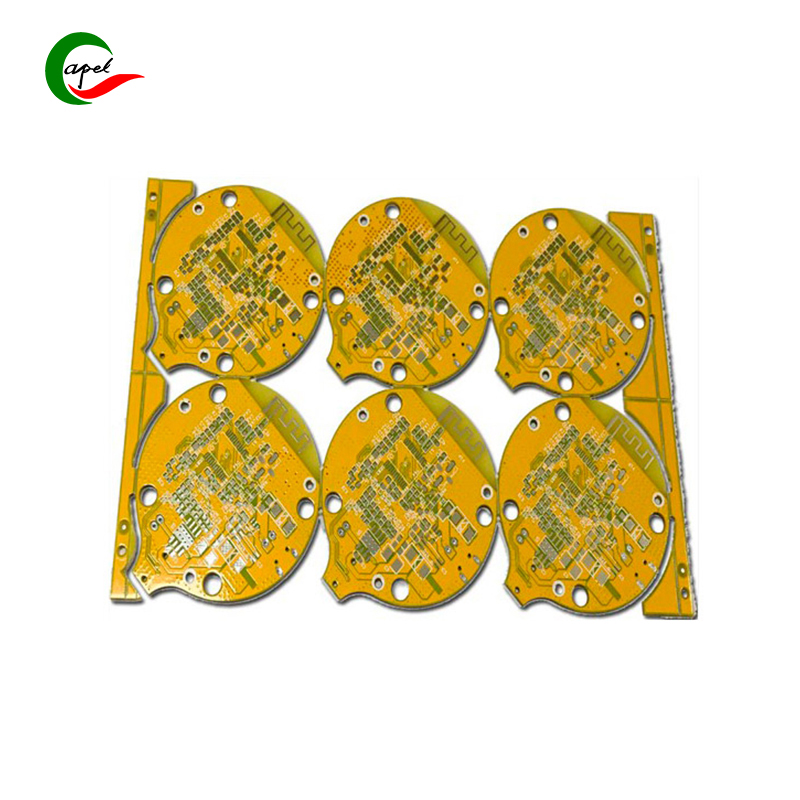

4 lera Flex-Rigid Boards

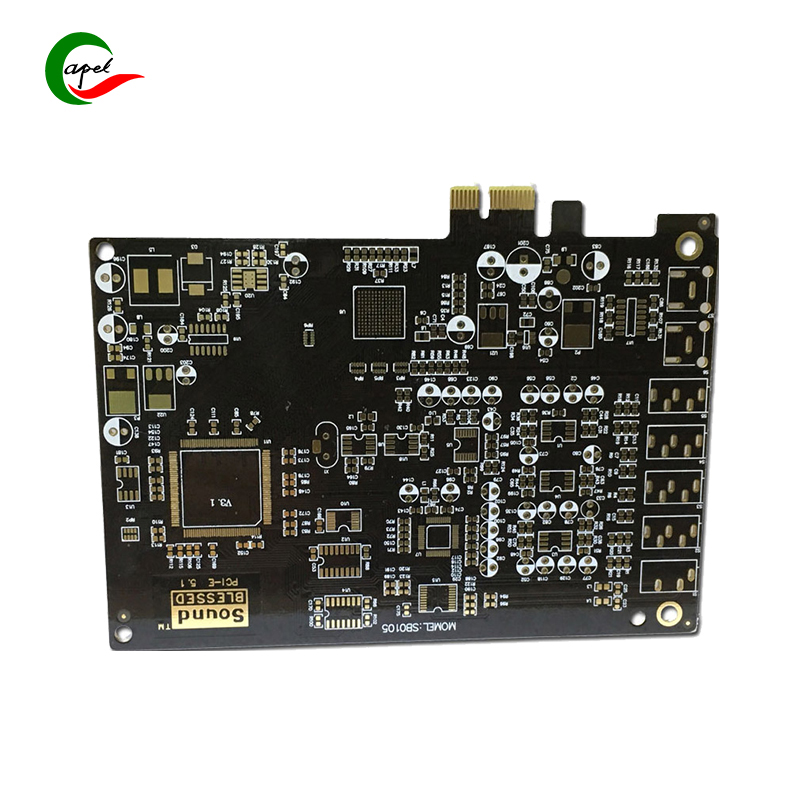

8 lera Rigid-Flex PCBs

8 lera HDI Printed Circuit Boards

Lisebelisoa tsa Teko le Tlhahlobo

Teko ea microscope

Tlhahlobo ea AOI

Teko ea 2D

Teko ea Impedance

Teko ea RoHS

Flying Probe

Horizontal Tester

Ho Kobeha Teste

Tšebeletso ea rona ea 6 ea HDI PCB

. Fana ka tšehetso ea tekheniki Pele ho thekiso le ka mor'a thekiso;

. Tloaelo ho fihla ho mekhahlelo e 40, 1-2days Phetoho e potlakileng ea prototyping, Theko ea likarolo, Kopano ea SMT;

. E fana ka lisebelisoa tse peli tsa Bongaka, Taolo ea Liindasteri, Likoloi, Lifofane, Lisebelisoa tsa Bareki, IOT, UAV, Lipuisano joalo-joalo.

. Lihlopha tsa rona tsa baenjiniere le bafuputsi ba ikemiselitse ho phethahatsa litlhoko tsa hau ka ho nepahala le ka botsebi.

6 layer HDI PCB ts'ebeliso e khethehileng ho Likoloi

1. ADAS (Advanced Driver Assistance System): Mekhoa ea ADAS e itšetlehile ka li-sensor tse ngata tse kang lik'hamera, li-radar le li-lidar ho thusa bakhanni ho tsamaea le ho qoba ho thulana. HDI PCB ea 6-layer e sebelisoa ho li-module tsa ADAS ho amohela likhokahano tsa sensor tse phahameng haholo le ho netefatsa phetisetso ea mats'oao e tšepahalang bakeng sa ho lemoha ntho e nepahetseng le tlhokomeliso ea mokhanni.

2. Infotainment system: Sistimi ea infotainment likoloing tsa sejoale-joale e kopanya mesebetsi e fapaneng joalo ka GPS navigation, playback multimedia, likhetho tsa khokahanyo le likhokahano tsa puisano. HDI PCB ea 6-layer e thusa ho kopanya likaroloana, lihokelo le lihokelo, ho netefatsa puisano e ntle, taolo e tšepahalang le boiphihlelo bo ntlafalitsoeng ba basebelisi.

3. Yuniti ea Taolo ea Enjene (ECU): Karolo ea taolo ea enjene e na le boikarabello ba ho beha leihlo le ho laola mesebetsi e fapaneng ea enjene joalo ka ente ea mafura, nako ea ho tima, le taolo ea mosi. 6-layer HDI PCB e thusa ho amohela potoloho e rarahaneng le puisano e potlakileng lipakeng tsa li-sensor tse fapaneng tsa enjine le li-activator, ho netefatsa taolo e nepahetseng ea enjene le ts'ebetso e nepahetseng.

4. Electronic Stability Control (ESC): Sistimi ea ESC e matlafatsa botsitso le polokeho ea koloi ka ho tsoela pele ho beha leihlo le ho lokisa braking ea lebili le torque ea enjene. 6-layer HDI PCB e bapala karolo ea bohlokoa mojuleng oa ESC, e thusa ho kopanya li-microcontrollers, li-sensor, le li-activator bakeng sa tlhahlobo ea data ea nako ea sebele le taolo e nepahetseng.

5. Powertrain: The Powertrain Control Unit (PCU) e laola ts'ebetso ea enjene, phetisetso le drivetrain bakeng sa ts'ebetso e ntle le katleho. 6-layer HDI PCB e kopanya likarolo tse fapaneng tsa taolo ea matla, li-sensor tsa mocheso le li-interfaces tsa puisano, ho netefatsa phetisetso e nepahetseng ea matla, phapanyetsano ea data e tšepahalang le taolo e sebetsang ea mocheso.

6. Sistimi ea Taolo ea Battery (BMS): BMS e ikarabella ho lekola le ho laola tšebetso, ho tjhaja le ho sireletsa betri ea koloi. HDI PCB ea 6-layer e nolofalletsa moralo o kopanetsoeng le ho kopanngoa ha likarolo tsa BMS, ho kenyelletsa le li-IC tsa ho lekola betri, li-sensor tsa mocheso, li-sensor tsa hajoale, le likhokahano tsa puisano, ho netefatsa taolo e nepahetseng ea betri le ho lelefatsa bophelo ba betri.

6 layer HDI PCB e ntlafatsa theknoloji joang ho Likoloi?

1. Miniaturization: 6-layer HDI PCB e lumella ho beoa ha karolo e phahameng ea sekhahla, ka hona ho hlokomela miniaturization ea litsamaiso tsa elektronike. Sena se bohlokoa indastering ea likoloi moo sebaka se fokolang hangata. Ka ho fokotsa boholo ba PCB, bahlahisi ba ka rala likoloi tse nyane, tse bobebe le tse kopaneng.

2. Ntlafatsa botšepehi ba pontšo: Theknoloji ea HDI e fokotsa bolelele ba matšoao a matšoao 'me e fana ka taolo e ntlafetseng ea impedance.

Sena se ntlafatsa boleng ba lets'oao, se fokotsa lerata mme se matlafatsa sets'oants'o sa lets'oao. Ho netefatsa ts'ebetso ea mats'oao e tšepahalang ho bohlokoa lits'ebetsong tsa likoloi moo phetiso ea data le puisano li leng bohlokoa.

3. Ts'ebetso e ntlafetseng: Likarolo tse ling ho HDI PCB ea 6-layer li fana ka sebaka se eketsehileng sa litsela le mekhoa ea ho hokahanya, e nolofalletsang ts'ebetso e ntlafetseng. Hona joale likoloi li kopanya mefuta e fapaneng ea mesebetsi ea elektroniki, joalo ka lisebelisoa tse tsoetseng pele tsa ho thusa bakhanni (ADAS), lisebelisoa tsa infotainment le likarolo tsa taolo ea enjene. Tšebeliso ea 6-layer HDI PCB e thusa ho kopanngoa ha mesebetsi ena e rarahaneng.

4. Phatlalatso ea data e potlakileng: Mekhoa ea likoloi, e kang mekhoa e tsoetseng pele ea ho tsamaea le puisano pakeng tsa likoloi, e hloka ho fetisoa ha data ka lebelo le phahameng. HDI PCB ea 6-layer e ts'ehetsa lits'ebetso tse phahameng tsa maqhubu bakeng sa phetiso ea data e potlakileng le e sebetsang haholoanyane. Sena se bohlokoa bakeng sa ho etsa liqeto ka nako ea nnete, ho ntlafatsa polokeho le ts'ebetso.

5. Botšepehi bo ntlafetseng: Theknoloji ea HDI e sebelisa li-micro-vias ho fana ka likhokahano tse molemo tsa motlakase ha li ntse li nka sebaka se senyenyane.

Litsela tsena tse nyane li thusa ho ntlafatsa ts'epahalo ka ho fokotsa kotsi ea mats'oao a mats'oao le ho se lumellane. Ho lisebelisoa tsa elektroniki tsa likoloi moo ho ts'epahalang ho leng bohlokoa, li-PCB tsa HDI li netefatsa likhokahano tse matla le tse tšoarellang.

6. Tsamaiso ea mocheso: Ka ho rarahana ho ntseng ho eketseha le tšebeliso ea matla ea lisebelisoa tsa motlakase tsa likoloi, tsamaiso e nepahetseng ea mocheso e bohlokoa. 6-lera HDI PCB tšehetsa ho kenngwa tshebetsong ha vias mogote ho thusa dissipate mocheso le ho laola mocheso.

Sena se lumella litsamaiso tsa likoloi hore li sebetse hantle, leha ho le mocheso o phahameng.