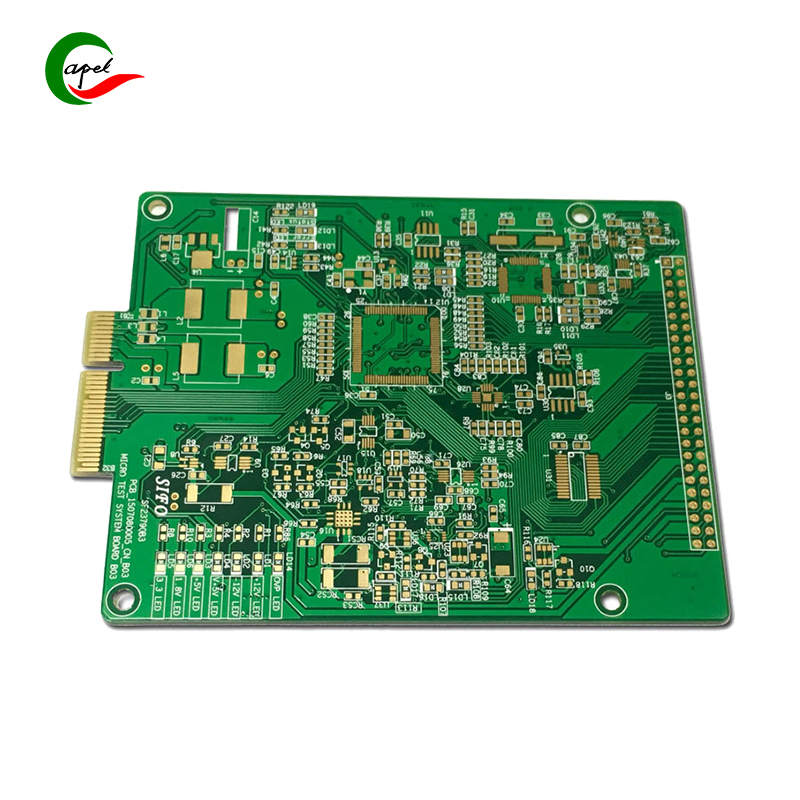

Multilayer PCBs Prototyping Manufacturers Quick Turn Pcb Boards

Matla a Ts'ebetso ea PCB

| Che. | Morero | Lipontšo tsa tekheniki |

| 1 | Lera | 1-60(lera) |

| 2 | Boholo ba sebaka sa ho sebetsa | 545 x 622 limilimithara |

| 3 | Botenya bo fokolang | 4(lera)0.40mm |

| 6(lera) 0.60mm | ||

| 8(lera) 0.8mm | ||

| 10(lera)1.0mm | ||

| 4 | Bophara bo fokolang ba mola | 0.0762 limilimithara |

| 5 | Sebaka se fokolang | 0.0762 limilimithara |

| 6 | Mocheso o fokolang oa ho bula | 0.15 limilimithara |

| 7 | Sekoti lebota botenya ba koporo | 0.015 limilimithara |

| 8 | Metallized aperture tolerance | ± 0.05 limilimithara |

| 9 | Mamello e se nang metale aperture | ± 0.025mm |

| 10 | Ho mamellana le lesoba | ± 0.05 limilimithara |

| 11 | Mamello ya dimensional | ± 0.076 limilimithara |

| 12 | Borokho bo fokolang ba solder | 0.08 limilimithara |

| 13 | Insulation resistance | 1E+12Ω (e tloaelehileng) |

| 14 | Karolelano ea botenya ba poleiti | 1:10 |

| 15 | Tšisinyeho ea mocheso | 288 ℃ (makhetlo a 4 ka metsotsoana e 10) |

| 16 | E khopamisitsoe ebile e kobehile | ≤0.7% |

| 17 | Matla a khahlanong le motlakase | ~1.3KV/mm |

| 18 | Matla a thibelang ho hlobola | 1.4N/mm |

| 19 | Solder hanela boima | ≥6H |

| 20 | Ho lieha ha lelakabe | 94V-0 |

| 21 | Taolo ea impedance | ±5% |

Re etsa Multilayer PCBs prototyping ka boiphihlelo ba lilemo tse 15 ka botsebi ba rona

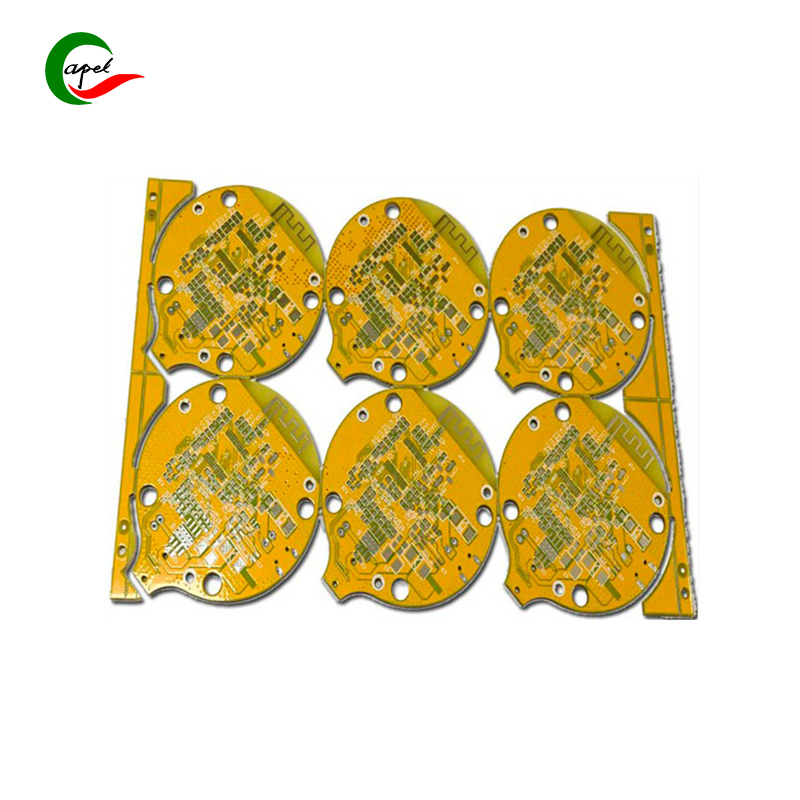

4 lera Flex-Rigid Boards

8 lera Rigid-Flex PCBs

8 lera HDI PCBs

Lisebelisoa tsa Teko le Tlhahlobo

Teko ea microscope

Tlhahlobo ea AOI

Teko ea 2D

Teko ea Impedance

Teko ea RoHS

Flying Probe

Horizontal Tester

Ho Kobeha Teste

Ts'ebeletso ea rona ea li-prototyping tsa Multilayer PCBs

. Fana ka tšehetso ea tekheniki Pele ho thekiso le ka mor'a thekiso;

. Tloaelo ho fihla ho mekhahlelo e 40, 1-2days Phetoho e potlakileng ea prototyping, Theko ea likarolo, Kopano ea SMT;

. E fana ka lisebelisoa tse peli tsa Bongaka, Taolo ea Liindasteri, Likoloi, Lifofane, Lisebelisoa tsa Bareki, IOT, UAV, Lipuisano joalo-joalo.

. Lihlopha tsa rona tsa baenjiniere le bafuputsi ba ikemiselitse ho phethahatsa litlhoko tsa hau ka ho nepahala le ka botsebi.

Multilayer PCB e fana ka tšehetso e tsoetseng pele ea tekheniki lebaleng la likoloi

1. Sistimi ea boithabiso ea koloi: PCB ea li-multi-layer e ka ts'ehetsa mesebetsi e mengata ea puisano ea molumo, video le waelese, ka hona e fana ka boiphihlelo bo bongata ba boithabiso ba koloi. E ka amohela mekhahlelo e mengata ea potoloho, ea kopana le litlhoko tse fapaneng tsa ts'ebetso ea molumo le livideo, 'me ea ts'ehetsa phetisetso ea lebelo le holimo le lits'ebetso tsa khokahano ea waelese, joalo ka Bluetooth, Wi-Fi, GPS, jj.

2. Sistimi ea polokeho: PCB e nang le likarolo tse ngata e ka fana ka ts'ebetso e phahameng ea ts'ireletso le ts'epahalo, 'me e sebelisoa ho litsamaiso tsa polokeho tse sebetsang le tse sa sebetseng. E ka kopanya li-sensor tse fapaneng, likarolo tsa taolo le limmojule tsa puisano ho hlokomela mesebetsi e joalo ka temoso ea ho thulana, braking ea othomathiki, ho khanna ka bohlale, le ho thibela bosholu. Moralo oa PCB ea mekhahlelo e mengata e netefatsa puisano e potlakileng, e nepahetseng le e ts'epahalang le khokahanyo har'a li-module tse fapaneng tsa sistimi ea polokeho.

3. Sistimi ea thuso ea ho khanna: PCB e nang le likarolo tse ngata e ka fana ka ts'ebetso e nepahetseng ea matšoao a holimo le phetiso ea data e potlakileng bakeng sa lits'ebetso tsa thuso ea ho khanna, joalo ka ho paka ka boiketsetso, ho lemoha letheba le sa boneng, taolo ea cruise e feto-fetohang le litsamaiso tsa thuso ea ho boloka lane, joalo-joalo.

Litsamaiso tsena li hloka ts'ebetso e nepahetseng ea matšoao le phetiso ea data ka potlako. Le temoho ka nako le matla a kahlolo, le tšehetso ea botekgeniki ea multi-lera PCB ka kopana ditlhoko tsena.

4. Sistimi ea taolo ea enjene: Sistimi ea taolo ea enjene e ka sebelisa PCB ea mekhahlelo e mengata ho hlokomela taolo e nepahetseng le ho beha leihlo enjene.

E ka kopanya li-sensor tse fapaneng, li-actuator le li-unit tsa taolo ho beha leihlo le ho lokisa maemo a joalo ka phepelo ea mafura, nako ea ho tima le taolo ea enjene ho ntlafatsa ts'ebetso ea mafura le ho fokotsa tlhahiso ea mosi.

5. Mokhoa oa ho khanna motlakase: PCB e nang le likarolo tse ngata e fana ka tšehetso e tsoetseng pele ea theknoloji bakeng sa tsamaiso ea matla a motlakase le phetisetso ea matla ea likoloi tsa motlakase le likoloi tsa lebasetere. E ka ts'ehetsa phetisetso ea matla a phahameng le taolo ea oscillation, ea ntlafatsa ts'ebetso le ts'epahalo ea sistimi ea taolo ea betri, le ho netefatsa mosebetsi o hokahaneng oa li-module tse fapaneng tsamaisong ea ho khanna motlakase.

Liboto tsa potoloho ea Multilayer tšimong ea likoloi FAQ

1. Boholo le boima ba 'mele: Sebaka ka koloing se lekanyelitsoe, kahoo boholo le boima ba boto ea potoloho ea multilayer le tsona ke lintlha tse lokelang ho nahanoa. Mapolanka a maholo haholo kapa a boima a ka fokotsa moralo le ts'ebetso ea koloi, kahoo ho na le tlhokahalo ea ho fokotsa boholo ba boto le boima ba moralo ha ho ntse ho boloka litlhoko tsa ts'ebetso le ts'ebetso.

2. Anti-vibration le ho hanyetsa tšusumetso: Koloi e tla ba le li-vibrations tse sa tšoaneng le liphello nakong ea ho khanna, kahoo boto ea potoloho ea multilayer e hloka ho ba le ho thibela ho sisinyeha hantle le ho hanyetsa tšusumetso. Sena se hloka moralo o utloahalang oa sebopeho se tšehetsang boto ea potoloho le khetho ea lisebelisoa tse loketseng ho netefatsa hore boto ea potoloho e ntse e ka sebetsa ka mokhoa o tsitsitseng tlas'a maemo a thata a litsela.

3. Ho ikamahanya le maemo a tikoloho: Tikoloho ea ho sebetsa ea likoloi e rarahane ebile e fetoha, 'me liboto tsa potoloho tse nang le mekhahlelo e mengata li hloka ho khona ho ikamahanya le maemo a fapaneng a tikoloho, joalo ka mocheso o phahameng, mocheso o tlase, mongobo, joalo-joalo. khetha lisebelisoa tse nang le ho hanyetsa mocheso o phahameng, ho hanyetsa mocheso o tlaase le ho hanyetsa mongobo, le Nka mehato e ts'oanang ea tšireletso ho etsa bonnete ba hore boto ea potoloho e ka sebetsa ka botšepehi libakeng tse sa tšoaneng.

4. Ho lumellana le sebopeho sa sebopeho: Mapolanka a potoloho ea Multilayer a hloka ho lumellana le ho hokahanngoa le lisebelisoa tse ling tsa elektronike le litsamaiso, kahoo moralo o lumellanang oa sebopeho le tlhahlobo ea sebopeho lia hlokahala. Sena se kenyelletsa khetho ea likhokahano, ho latela litekanyetso tsa sehokelo, le tiisetso ea botsitso le ts'epahalo ea matšoao a sehokelo.

6. Liphutheloana tsa chip le lenaneo: ho kenya li-chip le lenaneo li ka 'na tsa ameha ho liboto tsa potoloho tse ngata. Ha ho etsoa moralo, hoa hlokahala ho nahana ka foromo ea sephutheloana le boholo ba chip, hammoho le sebopeho le mokhoa oa ho chesa le ho etsa lenaneo. Sena se tiisa hore chip e tla hlophisoa le ho sebetsa ka nepo le ka ts'epo.