Li-PCB tsa mekato e 16 li fana ka ho rarahana le ho feto-fetoha ha maemo ho hlokoang ke lisebelisoa tsa sejoale-joale tsa elektroniki. Moralo o nang le tsebo le khetho ea tatellano ea stacking le mekhoa ea khokahano ea li-interlayer li bohlokoa ho fihlela ts'ebetso e nepahetseng ea boto. Sengoliloeng sena, re tla hlahloba lintlha, litataiso, le mekhoa e metle ea ho thusa baqapi le baenjiniere ho theha liboto tsa potoloho tse sebetsang hantle le tse tšepahalang tsa 16.

1.Ho Utloisisa Lintho tsa Motheo tsa 16 lera PCBs Stacking Tatelano

1.1 Tlhaloso le sepheo sa ho bokella tatellano

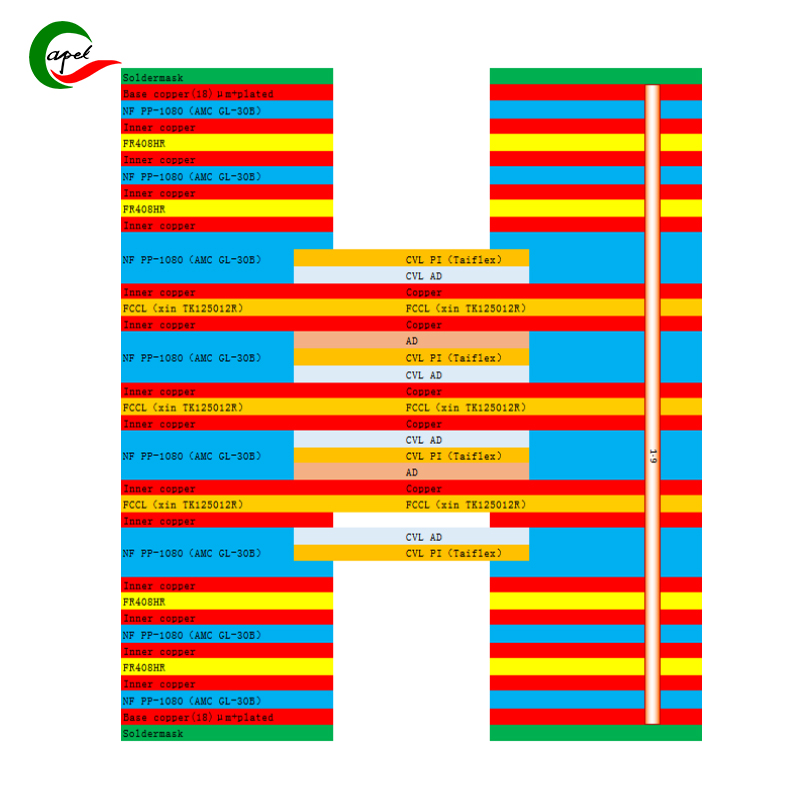

Tatelano ea stacking e bolela tlhophiso le tatellano eo ka eona lisebelisoa tse kang koporo le li-insulating layers li entsoeng laminated hammoho ho theha boto ea potoloho ea li-multi-layer. The stacking tatelano e etsa qeto ea ho behoa ha lihlopha tsa lipontšo, matla a matla, lihlopha tsa fatše, le likarolo tse ling tsa bohlokoa ho qubu.

Sepheo se seholo sa tatellano ea stacking ke ho finyella thepa e hlokahalang ea motlakase le ea mechine ea boto. E na le karolo ea bohlokoa ho khethollang ho se sebetse ha boto ea potoloho, botšepehi ba matšoao, kabo ea matla, tsamaiso ea mocheso, le bokhoni ba tlhahiso. Tatelano ea stacking e boetse e ama ts'ebetso ka kakaretso, ho ts'epahala, le ho etsoa ha boto.

1.2 Lintlha tse amang moralo oa tatellano ea stacking: Ho na le lintlha tse 'maloa tse lokelang ho nahanoa ha u rala tatellano ea tatellano ea

16-layer PCB:

a) Litlhoko tsa motlakase:Moralo oa lifofane tsa lets'oao, matla le lifofane tse fatše li lokela ho ntlafatsoa ho netefatsa botsitso bo nepahetseng ba lets'oao, taolo ea impedance, le phokotso ea tšitiso ea motlakase.

b) Litlhoko tsa mocheso:Ho behoa ha matla le lifofane tsa fatše le ho kenngoa ha li-vias tsa mocheso ho thusa ho senya mocheso ka katleho le ho boloka mocheso o nepahetseng oa ho sebetsa oa karolo.

c) Litšitiso tsa tlhahiso:Tatelano ea stacking e khethiloeng e lokela ho ela hloko bokhoni le mefokolo ea ts'ebetso ea tlhahiso ea PCB, joalo ka ho fumaneha ha lintho tse bonahalang, palo ea likarolo, karo-karolelano ea ho cheka,le ho nepahala ha tlhophiso.

d) Ntlafatso ea Litšenyehelo:Khetho ea lisebelisoa, palo ea mekhahlelo, le ho rarahana ha li-stack-up li lokela ho lumellana le tekanyetso ea morero ha ho ntse ho netefatsa ts'ebetso e hlokahalang le ho tšepahala.

1.3 Mefuta e tloaelehileng ea tatellano ea tatellano ea tatellano ea li-circuits tsa 16-layer: Ho na le tatellano e tloaelehileng ea stacking bakeng sa 16-layer.

PCB, ho itšetlehile ka tshebetso e lakatsehang le litlhoko. Mehlala e meng e tloaelehileng e kenyelletsa:

a) Ho latellana ha stacking:Tatelano ena e kenyelletsa ho beha likarolo tsa matšoao ka mokhoa o ts'oanang lipakeng tsa matla le matla a fatše ho fihlela ponts'o e ntle ea ponts'o, "crosstalk" e fokolang, le phepelo e leka-lekaneng ea mocheso.

b) Tatelano ea stacking:Ka tatellano ena, likarolo tsa lipontšo li latellana ka tatellano pakeng tsa matla le likarolo tsa fatše. E fana ka taolo e kholo holim'a tlhophiso ea lera 'me e molemo bakeng sa ho kopana le litlhoko tse khethehileng tsa botšepehi ba matšoao.

c) Taelo e kopaneng ea stacking:Sena se kenyelletsa motsoako oa li-symmetric le litaelo tse latellanang tsa stacking. E lumella ho itloaetsa le ho ntlafatsa sebopeho sa likarolo tse itseng tsa boto.

d) Tatelano ea stacking e sa utloahaleng:Tatelano ena e beha likarolo tse hlokolosi tsa matšoao haufi le sefofane sa fatše bakeng sa tšireletso e ntle ea lerata le ho itšehla thajana.

2. Lintlha tsa bohlokoa bakeng sa Khetho ea tatellano ea tatellano ea PCB ea 16 layer:

2.1 Botšepehi ba pontšo le lintlha tsa botšepehi ba matla:

Tatelano ea stacking e na le phello e kholo ho botšepehi ba pontšo le botšepehi ba matla a boto. Ho beoa ka nepo ha lets'oao le lifofane tsa motlakase / tsa fatše ho bohlokoa ho fokotsa kotsi ea ho khopama ha mats'oao, lerata le tšitiso ea motlakase. Lintlha tsa bohlokoa li kenyelletsa:

a) Ho beoa ha lesela la matšoao:Likarolo tsa matšoao a lebelo le phahameng li lokela ho behoa haufi le sefofane sa fatše ho fana ka tsela e tlaase ea ho khutlela morao le ho fokotsa ho kopanya lerata. Likarolo tsa matšoao le tsona li lokela ho raloa ka hloko ho fokotsa skew le bolelele ba ho tsamaisana.

b) Kabo ea lifofane tsa motlakase:Tatelano ea stacking e lokela ho netefatsa hore ho na le phepelo e lekaneng ea sefofane sa matla ho tšehetsa botšepehi ba matla. Matla a lekaneng le lifofane tsa fatše li lokela ho behoa ka mokhoa o hlophisitsoeng ho fokotsa ho theoha ha motlakase, ho khaotsa ho thibela le ho kopanya lerata.

c) Decoupling Capacitors:Ho beoa ka nepo ha li-decoupling capacitor ho bohlokoa ho netefatsa phetiso e lekaneng ea matla le ho fokotsa lerata la phepelo ea motlakase. Tatelano ea stacking e lokela ho fana ka sebaka se haufi le ho ba haufi le li-decoupling capacitor ho matla le lifofane tsa fatše.

2.2 Taolo ea mocheso le ho qhala mocheso:

Tsamaiso e nepahetseng ea mocheso e bohlokoa ho netefatsa ts'epo le ts'ebetso ea boto ea potoloho. Tatelano ea stacking e lokela ho nahanela sebaka se nepahetseng sa lifofane tsa matla le tsa fatše, li-vias tsa mocheso, le mekhoa e meng ea ho pholisa. Lintlha tsa bohlokoa li kenyelletsa:

a) Kabo ea sefofane sa motlakase:Kabo e lekaneng ea matla le lifofane tsa fatše ho pholletsa le stack e thusa mocheso o tobileng hole le likarolo tse bonolo le ho netefatsa hore mocheso o ts'oanang o ajoa ka har'a boto.

b) Litsela tsa mocheso:Tatelano ea stacking e lokela ho lumella mocheso o sebetsang ka ho beha ho thusa ho qhala mocheso ho tloha karolong e ka hare ho ea mokatong o ka ntle kapa sink ea mocheso. Sena se thusa ho thibela libaka tse chesang tse sebakeng sa heno le ho netefatsa hore mocheso o sebetsa hantle.

c) Ho beha likarolo:Tatelano ea stacking e lokela ho nahana ka tlhophiso le ho ba haufi ha likarolo tsa ho futhumatsa ho qoba ho chesa haholo. Ho lumellana hantle ha likarolo tse nang le mekhoa ea ho pholisa joalo ka licheso tsa mocheso kapa li-fan le tsona li lokela ho nkoa.

2.3 Litšitiso tsa tlhahiso le ntlafatso ea litšenyehelo:

Tatelano ea stacking e tlameha ho ela hloko litšitiso tsa tlhahiso le ho ntlafatsa litšenyehelo, kaha li bapala karolo ea bohlokoa ho khoneha le ho khona ho lefella boto. Lintlha li kenyelletsa:

a) Ho fumaneha ha lintho:Tatelano ea stacking e khethiloeng e lokela ho lumellana le boteng ba lisebelisoa le ho lumellana ha tsona le mokhoa o khethiloeng oa ho etsa PCB.

b) Palo ea mekhahlelo le ho rarahana:Tatelano ea stacking e lokela ho raloa ka har'a lithibelo tsa ts'ebetso ea tlhahiso ea PCB e khethiloeng, ho nahanoa ka lintlha tse joalo ka palo ea likarolo, karo-karolelano ea ho cheka, le ho nepahala ha tlhophiso.

c) Ho ntlafatsa litšenyehelo:Tatelano ea stacking e lokela ho ntlafatsa ts'ebeliso ea lisebelisoa le ho fokotsa ho rarahana ha tlhahiso ntle le ho senya ts'ebetso le ts'epahalo e hlokahalang. E lokela ho ikemisetsa ho fokotsa litšenyehelo tse amanang le litšila tsa thepa, ho rarahana ha tšebetso le kopano.

2.4 Khokahano ea lera le pontšo ea crosstalk:

Tatelano ea stacking e lokela ho sebetsana le litaba tsa ho tsamaisana le maemo le ho fokotsa matšoao a crosstalk a ka amang botšepehi ba matšoao hampe. Lintlha tsa bohlokoa li kenyelletsa:

a) Symmetrical stacking:Symmetrical stacking ea likarolo tsa matšoao lipakeng tsa matla le matla a fatše ho thusa ho fokotsa ho kopanya le ho fokotsa ho kopana.

b) Litsela tse peli tse fapaneng:Tatelano ea stacking e lokela ho lumella likarolo tsa matšoao hore li tsamaisane hantle bakeng sa ho tsamaisa mats'oao a phapano ka lebelo le phahameng. Sena se thusa ho boloka botsitso ba matšoao le ho fokotsa ho fetelletsa litaba.

c) Karohano ea matšoao:Tatelano ea stacking e lokela ho nahana ka karohano ea matšoao a hlokolosi a analoge le a dijithale ho fokotsa tšitiso le tšitiso.

2.5 Taolo ea Impedans le kopanyo ea RF/microwave:

Bakeng sa lits'ebetso tsa RF/microwave, tatellano ea stacking e bohlokoa ho fihlela taolo e nepahetseng ea impedance le kopanyo. Lintlha tsa bohlokoa li kenyelletsa:

a) Impedans e laoloang:Tatelano ea stacking e lokela ho lumella moralo o laoloang oa impedance, ho nahanoa ka lintlha tse joalo ka bophara ba trace, botenya ba dielectric le tlhophiso ea lera. Sena se netefatsa phatlalatso e nepahetseng ea lets'oao le ho ts'oana ho thibela mats'oao a RF/microwave.

b) Ho beoa ha lesela la lets'oao:Lipontšo tsa RF/microwave li lokela ho behoa ka mokhoa o hlophisehileng haufi le lera le kantle ho fokotsa tšitiso ea mats'oao a mang le ho fana ka phatlalatso e betere.

c) RF Shielding:Tatellano ea ho bokellana e lokela ho kenyelletsa ho beoa ka nepo ha lilara tsa fatše le tse sireletsang ho arola le ho sireletsa mats'oao a RF/microwave hore a se sitisoe.

3.Interlayer Connection Mekhoa

3.1 Ka mekoti, masoba a foufetseng le mekoti e epetsoeng:

Li-Vias li sebelisoa haholo ho boto ea potoloho e hatisitsoeng (PCB) e le mokhoa oa ho hokahanya likarolo tse fapaneng. Ke masoba a phuntsoeng ka likarolo tsohle tsa PCB 'me a pentiloe ho fana ka ts'ebetso ea motlakase. Ka masoba fana ka khokahanyo e matla ea motlakase 'me ho bonolo ho e etsa le ho e lokisa. Leha ho le joalo, li hloka boholo bo boholo ba ho cheka, bo nkang sebaka sa bohlokoa ho PCB le ho fokotsa likhetho tsa ho tsamaisa.

Li-vias tse foufetseng le tse patiloeng ke mekhoa e meng ea ho hokahanya ha interlayer e fanang ka melemo ea ho sebelisa sebaka le ho fetoha ha maemo.

Li-vias tse foufetseng li cheka ho tloha holim'a PCB 'me li felise ka mekhahlelo e ka hare ntle le ho feta likarolong tsohle. Li lumella likhokahano lipakeng tsa mealo e haufi ha li ntse li siea likarolo tse tebileng li sa amehe. Sena se nolofalletsa tšebeliso e nepahetseng ea sebaka sa boto le ho fokotsa palo ea likoti tsa ho phunya. vias patoa, ka lehlakoreng le leng, ke masoba a koaletsoeng ka ho feletseng ka hare ho magato a ka hare ea PCB 'me u se ke ua atolosetsa ho dikarolo ka ntle. Li fana ka likamano pakeng tsa lihlopha tse ka hare ntle le ho ama likarolo tse ka ntle. Li-vias tse patiloeng li na le melemo e mengata ea ho boloka sebaka ho feta ka likoti le li-vias tse foufetseng hobane ha li nke sebaka leha e le sefe ka lera le ka ntle.

Khetho ea ka masoba, vias foufetseng, le vias patoa itšetlehile ka ditlhoko tse itseng tsa moralo PCB. Ka likoti hangata li sebelisoa ka meralo e bonolo kapa moo ho tiea le ho lokisoa e leng lintho tse amehang haholo. Meralong e matla haholo moo sebaka e leng ntho ea bohlokoa, joalo ka lisebelisoa tse ts'oaroang ka letsoho, li-smartphone le lilaptop, ho khethoa li-vias tse sa boneng le tse patiloeng.

3.2 Micropore leHDI theknoloji:

Li-microvias ke masoba a manyenyane a bophara (hangata a ka tlase ho li-micron tse 150) tse fanang ka likhokahano tsa interlayer tse matla haholo ho li-PCB. Ba fana ka melemo ea bohlokoa ho miniaturization, botšepehi ba matšoao le ho feto-fetoha ha litsela.

Li-microvia li ka aroloa ka mefuta e 'meli: li-microvia tsa ka-hole le li-microvia tse foufetseng. Li-Microvias li hahiloe ka likoti tsa ho phunya ho tloha holimo holimo ho PCB le ho fetela ka mekhahlelo eohle. Li-microvias tse foufetseng, joalo ka ha lebitso le bontša, li atoloha feela ho likarolo tse itseng tsa ka hare 'me ha li kenelle likarolong tsohle.

High-density interconnect (HDI) ke thekenoloji e sebelisang li-microvias le mekhoa e tsoetseng pele ea tlhahiso ho finyella boima bo phahameng ba potoloho le ts'ebetso. Theknoloji ea HDI e lumella hore ho behoe likaroloana tse nyenyane le litsela tse thata, tse hlahisang lintlha tse nyenyane tsa sebopeho le botšepehi bo phahameng ba matšoao. Theknoloji ea HDI e fana ka melemo e 'maloa ho feta tekhenoloji ea setso ea PCB mabapi le miniaturization, ntlafatso ea phatlalatso ea matšoao, phokotso ea ho sotha ha matšoao, le ts'ebetso e ntlafalitsoeng. E lumella meralo ea li-multilayer e nang le li-microvias tse ngata, ka hona e khutsufatsa bolelele ba khokahano le ho fokotsa bokhoni ba parasitic le inductance.

Theknoloji ea HDI e boetse e nolofalletsa tšebeliso ea lisebelisoa tse tsoetseng pele tse kang laminates tse phahameng-frequency le likarolo tse tšesaane tsa dielectric, tse bohlokoa bakeng sa lisebelisoa tsa RF / microwave. E fana ka taolo e ntle ea impedance, e fokotsa tahlehelo ea matšoao le ho netefatsa phetisetso e tšepahalang ea lebelo le holimo.

3.3 Lisebelisoa le lits'ebetso tsa khokahano ea Interlayer:

Khetho ea lisebelisoa le mekhoa ea ho hokahanya li-interlayer e bohlokoa ho netefatsa ts'ebetso e ntle ea motlakase, ts'epahalo ea mochini le ho etsoa ha li-PCB. Tse ling tsa lisebelisoa tse sebelisoang hangata tsa khokahano ea li-interlayer le mekhoa ke:

a) Koporo:Koporo e sebelisoa haholo ka mekhahlelo ea conductive le vias tsa PCBs ka lebaka la conductivity lona e babatsehang le solderability. Hangata e pentiloe holim'a sekoti ho fana ka khokahanyo e tšepahalang ea motlakase.

b) Soldering:Mekhoa ea soldering, joalo ka wave soldering kapa reflow soldering, hangata e sebelisoa ho etsa likhokahano tsa motlakase lipakeng tsa masoba ho li-PCB le likarolo tse ling. Sebelisa solder peista ho via le ho sebelisa mocheso ho qhibiliha solder le ho theha kgokelo e ka tšeptjoang.

c) Electroplating:Mekhoa ea ho etsa li-electroplating tse kang electroless copper plating kapa electrolytic copper li sebelisoa ho qhekella ka tsela ho ntlafatsa conductivity le ho netefatsa likhokahano tse ntle tsa motlakase.

d) Ho kopanya:Mekhoa ea ho kopanya, joalo ka li-adhesive bonding kapa thermocompression bonding, e sebelisoa ho kopanya meaho e nang le masela hammoho le ho theha likhokahanyo tse tšepahalang.

e) Lisebelisoa tsa dielectric:Khetho ea thepa ea dielectric bakeng sa stackup ea PCB e bohlokoa bakeng sa likhokahano tsa interlayer. Li-laminates tse phahameng tse kang FR-4 kapa Rogers laminates hangata li sebelisoa ho netefatsa botšepehi ba pontšo e ntle le ho fokotsa tahlehelo ea matšoao.

3.4 Moralo le moelelo o fapaneng:

Moralo oa likarolo tse fapaneng oa "PCB stackup" o khetha thepa ea motlakase le mochini oa likhokahano lipakeng tsa mekhahlelo. Lintlha tse ka sehloohong tsa moralo oa likarolo tse fapaneng li kenyelletsa:

a) Tlhophiso ea lera:Ho hlophisoa ha lipontšo, matla le lifofane tse fatše ka har'a sephutheloana sa PCB ho ama botšepehi ba matšoao, botšepehi ba matla, le tšitiso ea motlakase (EMI). Ho beoa le ho tsamaisana hantle ha likarolo tsa matšoao ka matla le lifofane tsa fatše ho thusa ho fokotsa ho kopanya lerata le ho netefatsa litsela tse tlase tsa ho khutla tsa inductance.

b) Taolo ea tšitiso:Moralo oa likarolo tse fapaneng o lokela ho ela hloko litlhoko tse laoloang tsa ho sitisa, haholo-holo bakeng sa matshwao a dijithale a lebelo le phahameng kapa a RF/microwave. Sena se kenyelletsa khetho e nepahetseng ea lisebelisoa tsa dielectric le botenya ho fihlela sebopeho se lakatsehang.

c) Tsamaiso ea mocheso:Moqapi oa likarolo tse fapaneng o lokela ho nahana ka mokhoa o atlehang oa ho senya mocheso le tsamaiso ea mocheso. Ho beoa hantle ha matla le lifofane tsa fatše, li-vias tsa mocheso, le likarolo tse nang le mekhoa ea ho pholisa (joalo ka licheso tsa mocheso) li thusa ho qhala mocheso le ho boloka mocheso o nepahetseng oa ho sebetsa.

d) Ho tšepahala ha mochine:Moralo oa karolo o lokela ho nahana ka ts'epahalo ea mochini, haholo lits'ebetsong tse ka bang tlas'a khatello ea libaesekele tse futhumetseng kapa khatello ea mochini. Khetho e nepahetseng ea lisebelisoa, mekhoa ea ho kopanya, le tlhophiso ea li-stackup li thusa ho netefatsa botšepehi ba sebopeho le ho tšoarella ha PCB.

4.Design Guidelines bakeng sa 16-Layer PCB

4.1 Kabo ea lera le kabo:

Ha u rala boto ea potoloho ea mekato e 16, ho bohlokoa ho abela le ho abela likarolo ka hloko ho ntlafatsa ts'ebetso le botsitso ba matšoao. Mona ke tse ling tsa litataiso tsa kabo ea maemo

le kabo:

Lekola palo ea likarolo tsa matšoao tse hlokahalang:

Nahana ka ho rarahana ha moralo oa potoloho le palo ea matšoao a lokelang ho tsamaisoa. Beha likarolo tse lekaneng tsa matšoao ho amohela mats'oao ohle a hlokahalang, ho netefatsa sebaka se lekaneng sa ho tsamaisa le ho qoba ho fetelletsa lintho.tšubuhlellano. Abela lifofane tsa fatše le tsa motlakase:

Abela bonyane likarolo tse peli tse ka hare ho lifofane tse fatše le tsa matla. Sefofane sa fatše se thusa ho fana ka litšupiso tse tsitsitseng bakeng sa matšoao le ho fokotsa tšitiso ea motlakase (EMI). Sefofane sa motlakase se fana ka marang-rang a kabo ea matla a fokolang a fokolang a thusang ho fokotsa ho theoha ha motlakase.

Arohane le likarolo tsa mats'oao a hlokolosi:

Ho itšetlehile ka ts'ebeliso, ho ka 'na ha hlokahala ho arola likarolo tse nang le maikutlo a bonolo kapa a lebelo le phahameng ho tloha ho lihlopha tse lerata kapa tse matla ho thibela ho kena-kenana le ho kopana. Sena se ka etsoa ka ho beha lifofane tsa fatše tse inehetseng kapa tsa motlakase pakeng tsa tsona kapa ho sebelisa likarolo tsa ho itšehla thajana.

Arola ka ho lekana likarolo tsa matšoao:

Abela likarolo tsa matšoao ka ho lekana ho pholletsa le pokello ea boto ho fokotsa khokahano lipakeng tsa matšoao a haufi le ho boloka botsitso ba matšoao. Qoba ho beha likarolo tsa matšoao haufi le tse ling sebakeng se le seng sa stackup ho fokotsa interlayer crosstalk.

Nahana ka matshwao a maqhubu a phahameng:

Haeba moralo oa hau o na le mats'oao a maqhubu a holimo, nahana ka ho beha likarolo tsa mats'oao a maqhubu a holimo haufi le likarolo tse kantle ho fokotsa litlamorao tsa likhoele tsa phetiso le ho fokotsa tieho ea phatlalatso.

4.2 Ho tsamaisa le ho tsamaisa mats'oao:

Moralo oa ho tsamaisa le ho latela mats'oao a bohlokoa ho netefatsa boits'oaro bo nepahetseng le ho fokotsa tšitiso. Mona ke tse ling tsa litataiso bakeng sa tlhophiso le ho tsamaisa mats'oao ho liboto tsa potoloho tse mekato e 16:

Sebelisa mesaletsa e batsi bakeng sa matshwao a phahameng a hona jwale:

Bakeng sa mats'oao a nang le maqhubu a phahameng, joalo ka likhokahano tsa motlakase le fatše, sebelisa mesaletsa e pharaletseng ho fokotsa khanyetso le ho theoha ha motlakase.

Ho bapisa impedance bakeng sa matshwao a lebelo le phahameng:

Bakeng sa matshwao a lebelo le phahameng, etsa bonnete ba hore trace impedance e tsamaellana le tšobotsi e sitisang mohala oa phetisetso ho thibela menahano le phokotso ea mats'oao. Sebelisa mekhoa e laoloang ea moralo oa impedance le lipalo tse nepahetseng tsa bophara ba trace.

Fokotsa bolelele ba ho latella le lintlha tsa crossover:

Boloka bolelele ba ho latella bo le bokhutšoane kamoo ho ka khonehang 'me u fokotse palo ea lintlha tsa crossover ho fokotsa capacitance ea parasitic, inductance, le tšitiso. Ntlafatsa ho beoa ha likarolo 'me u sebelise likarolo tse ikhethileng tsa litsela ho qoba litsela tse telele tse rarahaneng.

Arola mats'oao a lebelo le phahameng le a tlase:

Arola mats'oao a lebelo le phahameng le a tlase ho fokotsa tšusumetso ea lerata ho mats'oao a lebelo le holimo. Beha mats'oao a lebelo le phahameng holim'a likarolo tsa mats'oao tse inehetseng 'me u li boloke hole le likarolo tse matla kapa tse lerata.

Sebelisa lipara tse fapaneng bakeng sa matšoao a lebelo le phahameng:

Ho fokotsa lerata le ho boloka botsitso ba mats'oao bakeng sa mats'oao a phapano a lebelo le phahameng, sebelisa mekhoa e fapaneng ea ho tsamaisa lipara. Boloka li-impedance le bolelele ba lipara tse fapaneng li bapisitsoe ho thibela lets'oao la skew le crosstalk.

4.3 Phatlalatso le kabo ea matla a matla:

Kabo e nepahetseng ea lifofane tsa fatše le tsa motlakase li bohlokoa ho fihlela ts'epo e ntle ea matla le ho fokotsa tšitiso ea motlakase. Mona ke tse ling tsa litataiso bakeng sa likabelo tsa sefofane sa fatše le sa matla holim'a liboto tsa potoloho tse mekato e 16:

Abela lifofane tsa fatše le tsa motlakase tse inehetseng:

Abela bonyane mekhahlelo e 'meli e ka hare bakeng sa lifofane tse inehetseng tsa fatše le tsa motlakase. Sena se thusa ho fokotsa lits'oants'o tsa fatše, ho fokotsa EMI, le ho fana ka tsela e fokolang ea ho khutla bakeng sa lipontšo tsa maqhubu a phahameng.

Lifofane tse arohaneng tsa dijithale le tsa analog:

Haeba moralo o na le likarolo tsa digital le analog, ho kgothaletswa ho ba le lifofane tse fapaneng tsa fatše bakeng sa karolo ka 'ngoe. Sena se thusa ho fokotsa khokahano ea lerata lipakeng tsa likarolo tsa dijithale le analog le ho ntlafatsa botšepehi ba matšoao.

Beha lifofane tsa fatše le tsa motlakase haufi le lifofane tsa lipontšo:

Beha lifofane tsa fatše le tsa motlakase haufi le lifofane tsa lipontšo tseo li li fepang ho fokotsa sebaka sa loop le ho fokotsa ho nka lerata.

Sebelisa litsela tse ngata bakeng sa lifofane tsa motlakase:

Sebelisa li-vias tse ngata ho hokela lifofane tsa matla ho arolelana matla le ho fokotsa ts'ebetso ea sefofane sa matla. Sena se thusa ho fokotsa ho theoha ha motlakase le ho ntlafatsa ts'ebetso ea motlakase.

Qoba melala e moqotetsane lifofaneng tsa motlakase:

Qoba melala e moqotetsane ka har'a lifofane tsa matla kaha li ka baka tšubuhlellano ea hona joale le ho eketsa ho hanyetsa, ho baka ho theoha ha motlakase le ho se sebetse hantle ha sefofane sa motlakase. Sebelisa likhokahano tse matla lipakeng tsa libaka tse fapaneng tsa lifofane tsa motlakase.

4.4 Thermal pad le ka ho bea:

Ho beoa ho nepahetseng ha liphahlo tsa mocheso le li-vias ho bohlokoa ho tlosa mocheso hantle le ho thibela likarolo ho tsoa ho chesa haholo. Mona ke tse ling tsa litataiso bakeng sa pad ea mocheso le ka ho behoa ho liboto tsa potoloho tse 16:

Beha pampiri ea mocheso tlas'a lisebelisoa tse hlahisang mocheso:

Hlalosa karolo e hlahisang mocheso (e kang amplifier ea matla kapa IC ea matla a phahameng) 'me u behe pad ea mocheso ka tlas'a eona ka ho toba. Lisebelisoa tsena tsa mocheso li fana ka tsela e tobileng ea mocheso ho fetisetsa mocheso ho lera le ka hare la mocheso.

Sebelisa lisebelisoa tse ngata tsa mocheso bakeng sa ho qhala mocheso:

Sebelisa multiple mogote vias ho hokela lera mogote le lera ka ntle ho fana ka sebetsang hantle mocheso dissipation. Li-vias tsena li ka behoa ka mokhoa o tsitsitseng ho pota-potile letlapa la mocheso ho finyella esita le kabo ea mocheso.

Nahana ka impedance ea mocheso le layer stackup:

Ha ho qaptjoa vias mogote, nahana ka mogote impedance ya boto lintho tse bonahalang le lera stackup.Optimize ka boholo le sebaka ho fokotsa ho hanyetsa mogote le maximize dissipation mocheso.

4.5 Ho beoa ha Karolo le Botšepehi ba Lipontšo:

Ho beha karolo ka nepo ho bohlokoa ho boloka botsitso ba matšoao le ho fokotsa tšitiso. Mona ke tse ling tsa litataiso tsa ho beha likarolo ho boto ea potoloho ea mekato e 16:

Likarolo tse amanang le sehlopha:

Likarolo tse amanang le sehlopha tseo e leng karolo ea sistimi e nyane kapa tse nang le tšebelisano e matla ea motlakase. Sena se fokotsa bolelele ba tatellano mme se fokotsa ho fokotseha ha lets'oao.

Boloka likarolo tsa lebelo le holimo haufi:

Beha likarolo tsa lebelo le phahameng, tse kang li-oscillator tse phahameng-frequency kapa microcontrollers, haufi le tse ling ho fokotsa bolelele ba ho latela le ho netefatsa botšepehi bo nepahetseng ba pontšo.

Fokotsa bolelele ba mohlala oa matšoao a bohlokoa:

Fokotsa bolelele ba ho latela matšoao a bohlokoa ho fokotsa tieho ea phatlalatso le ho fokotsa matšoao. Beha likarolo tsena haufi le moo ho ka khonehang.

Likarolo tse arohaneng tse hlokolosi:

Likarolo tse arohaneng tse utloang lerata, joalo ka li-analog kapa li-sensor tsa boemo bo tlase, ho tsoa ho matla a phahameng kapa a lerata ho fokotsa tšitiso le ho boloka botsitso ba matšoao.

Nahana ka li-decoupling capacitors:

Beha li-decoupling capacitor haufi le lithapo tsa motlakase tsa karolo ka 'ngoe ho fana ka matla a hloekileng le ho fokotsa ho fetoha ha motlakase. Li-capacitor tsena li thusa ho tsitsisa phepelo ea motlakase le ho fokotsa khokahano ea lerata.

5.Simulation and Analysis Tools for Stack-Up Design

5.1 3D software ea mohlala le ketsiso:

3D modelling le software ea ketsiso ke sesebelisoa sa bohlokoa bakeng sa moralo oa li-stackup hobane e lumella baqapi ho etsa litšoantšo tse hlakileng tsa PCB stackups. Software e ka bona likarolo, likarolo, le litšebelisano tsa bona tsa 'mele. Ka ho etsisa stackup, baqapi ba ka tseba mathata a ka bang teng joalo ka lipontšo tsa crosstalk, EMI, le litšitiso tsa mochini. E boetse e thusa ho netefatsa tlhophiso ea likarolo le ho ntlafatsa moralo oa PCB ka kakaretso.

5.2 Lisebelisoa tsa tlhahlobo ea botšepehi ba matšoao:

Lisebelisoa tsa tlhahlobo ea botšepehi ba matšoao li bohlokoa bakeng sa ho sekaseka le ho ntlafatsa ts'ebetso ea motlakase ea li-stackups tsa PCB. Lisebelisoa tsena li sebelisa li-algorithms tsa lipalo ho etsisa le ho sekaseka boits'oaro ba matšoao, ho kenyeletsoa taolo ea impedance, lipontšo tsa matšoao, le khokahano ea lerata. Ka ho etsa papiso le tlhahlobo, baqapi ba ka tseba lintlha tse ka bang teng tsa bots'epehi ba matšoao qalong ea ts'ebetso ea moralo le ho etsa liphetoho tse hlokahalang ho netefatsa phetiso ea mats'oao e tšepahalang.

5.3 Lisebelisoa tsa tlhahlobo ea mocheso:

Lisebelisoa tsa tlhahlobo ea mocheso li bapala karolo ea bohlokoa moralong oa li-stackup ka ho sekaseka le ho ntlafatsa taolo ea mocheso oa li-PCB. Lisebelisoa tsena li etsisa phallo ea mocheso le kabo ea mocheso ka har'a sekhahla se seng le se seng sa stack. Ka ho etsa mohlala ka mokhoa o nepahetseng oa ho senya matla le litsela tsa ho fetisa mocheso, baqapi ba ka tseba libaka tse chesang, ba ntlafatsa ho beoa ha lihlopha tsa koporo le li-vias tsa mocheso, 'me ba netefatse hore ho na le pholiso e nepahetseng ea likarolo tsa bohlokoa.

5.4 Moralo bakeng sa tlhahiso:

Moralo oa tlhahiso ea lintho ke karolo ea bohlokoa ea moralo oa stackup. Ho na le lisebelisoa tse fapaneng tsa software tse fumanehang tse ka thusang ho netefatsa hore sephutheloana se khethiloeng se ka etsoa ka nepo. Lisebelisoa tsena li fana ka maikutlo mabapi le monyetla oa ho fihlela pokello e lakatsehang, ho nahanoa ka lintlha tse kang ho fumaneha ha thepa, botenya ba lera, ts'ebetso ea tlhahiso, le litšenyehelo tsa tlhahiso. Ba thusa baqapi ho etsa liqeto tse nang le tsebo ho ntlafatsa stacking ho nolofatsa tlhahiso, ho fokotsa kotsi ea tieho, le ho eketsa chai.

6.Mohato-ka-Mohato oa Moqapi oa Li-PCB tsa 16-Layer

6.1 Pokello ea litlhoko tsa pele:

Mohato ona, bokella litlhoko tsohle tse hlokahalang bakeng sa moralo oa PCB oa 16-layer. Utloisisa tšebetso ea PCB, ts'ebetso e hlokahalang ea motlakase, litšitiso tsa mochini, le litataiso life kapa life tse ikhethileng tsa moralo kapa maemo a lokelang ho lateloa.

6.2 Kabo ea likarolo le tlhophiso:

Ho ea ka litlhoko, aba likarolo ho PCB le ho etsa qeto ea tlhophiso ea bona. Nahana ka lintlha tse kang botšepehi ba pontšo, ho nahanela mocheso le mathata a mochine. Likarolo tsa sehlopha tse ipapisitseng le litšoaneleho tsa motlakase le ho li beha ka leano botong ho fokotsa tšitiso le ho ntlafatsa phallo ea mats'oao.

6.3 Moralo oa li-stack-up le kabo ea mekhahlelo:

Etsa qeto ea moralo oa li-stack-up bakeng sa PCB ea mekato e 16. Nahana ka lintlha tse kang dielectric constant, thermal conductivity, le cost ho khetha thepa e nepahetseng. Abela lipontšo, matla, le lifofane tsa fatše ho latela litlhoko tsa motlakase. Beha lifofane tsa fatše le tsa matla ka symmetrically ho netefatsa stack e leka-lekaneng le ho ntlafatsa botšepehi ba lipontšo.

6.4 Ts'ebetso ea mats'oao le ntlafatso ea litsela:

Mothating ona, matšoao a mats'oao a tsamaisoa lipakeng tsa likarolo ho netefatsa taolo e nepahetseng ea impedance, botšepehi ba matšoao, le ho fokotsa phallo ea matšoao. Ntlafatsa tsela ho fokotsa bolelele ba mats'oao a bohlokoa, qoba ho tšela mesaletsa e bobebe, 'me u boloke karohano lipakeng tsa matshwao a lebelo le phahameng le a tlase. Sebelisa lipara tse fapaneng le mekhoa e laolehileng ea ho tsamaisa li-impedance ha ho hlokahala.

6.5 Lihokelo tsa Interlayer le ka ho bea:

Etsa moralo oa ho beoa ha li-vias tse hokahanyang lipakeng tsa mekhahlelo. Fumana tse nepahetseng ka mofuta, joalo ka ka lesoba kapa lesoba le foufetseng, ho ipapisitsoe le liphetoho tsa lera le likhokahano tsa likarolo. Ntlafatsa ka sebopeho ho fokotsa ponts'o ea mats'oao, li-impedance discontinuities, le ho boloka esita le ho ajoa ho PCB.

6.6 Netefatso ea ho qetela ea moralo le ketsiso:

Pele ho tlhahiso, netefatso ea ho qetela ea moralo le lipapiso lia etsoa. Sebelisa lisebelisoa tsa papiso ho sekaseka meralo ea PCB bakeng sa botšepehi ba matšoao, botšepehi ba matla, boits'oaro ba mocheso, le tlhahiso. Netefatsa moralo khahlano le litlhoko tsa pele 'me u etse litokiso tse hlokahalang ho ntlafatsa ts'ebetso le ho netefatsa hore o khona ho etsa.

Sebelisana le ho buisana le bankakarolo ba bang joalo ka baenjiniere ba motlakase, baenjiniere ba mechini, le lihlopha tsa tlhahiso nakong eohle ea moralo ho netefatsa hore litlhoko tsohle lia fihlelleha le hore mathata a ka bang teng a rarollotsoe. Kamehla hlahloba le ho pheta-pheta meralo ho kenyelletsa maikutlo le ntlafatso.

7.Industry Mekhoa e Molemo ka ho Fetisisa le Lithuto Tsa Litaba

7.1 Linyeoe tse atlehileng tsa moralo oa PCB oa 16-layer:

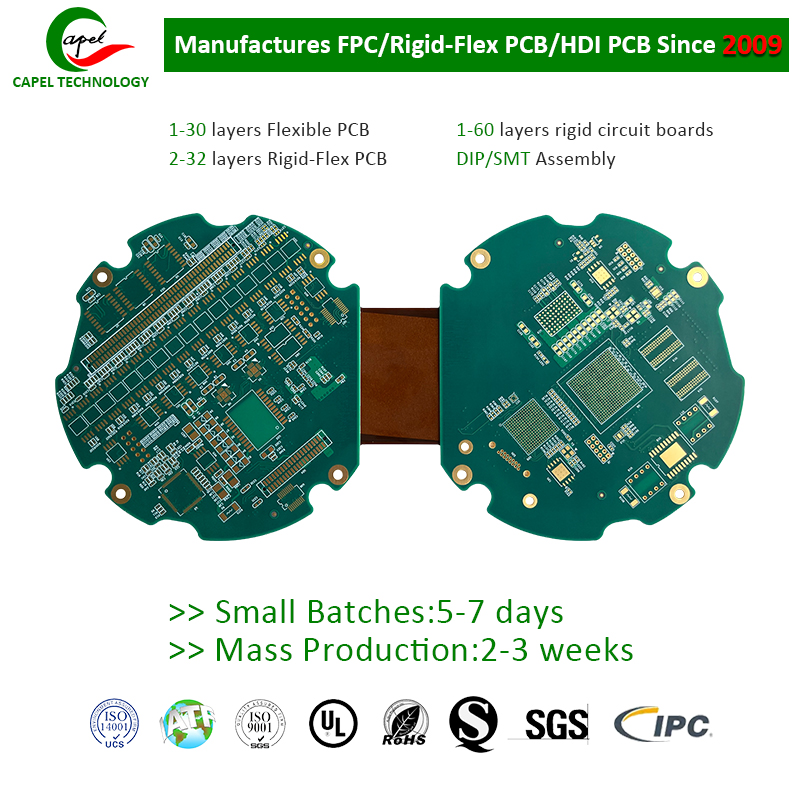

Mohlala oa 1:Shenzhen Capel Technology Co., Ltd. e atlehile ho etsa PCB ea 16-layer bakeng sa lisebelisoa tsa marang-rang tsa lebelo le phahameng. Ka ho hlahloba ka hloko botšepehi ba matšoao le kabo ea matla, ba fihlela ts'ebetso e phahameng mme ba fokotsa tšitiso ea motlakase. Senotlolo sa katleho ea bona ke moralo o ntlafalitsoeng ka botlalo o sebelisang thekenoloji ea taolo ea impedance.

Thuto-pale 2:Shenzhen Capel Technology Co., Ltd. e entse PCB ea mekato e 16 bakeng sa sesebelisoa se rarahaneng sa bongaka. Ka ho sebelisa motsoako oa holim'a metsi le likarolo tsa ho pota-pota, ba fihletse moralo o kopanetsoeng empa o le matla. Ho beha likarolo ka hloko le ho tsamaisa tsela e nepahetseng ho netefatsa hore matšoao a tšepahala le ho tšepahala.

7.2 Ithute ka ho hloleha 'me u qobe maraba:

Thuto-pale 1:Baetsi ba bang ba pcb ba ile ba kopana le lintlha tsa botšepehi ba pontšo ho moralo oa PCB oa 16 oa lisebelisoa tsa puisano. Mabaka a ho hloleha e ne e le ho se nahane ka ho lekaneng ha taolo ea impedance le khaello ea kabo e nepahetseng ea sefofane sa fatše. Thuto e ithutoang ke ho sekaseka ka hloko litlhoko tsa botšepehi ba matšoao le ho tiisa litataiso tsa moralo oa taolo ea impedance.

Thuto-pale 2:Baetsi ba bang ba pcb ba ile ba tobana le mathata a ho etsa thepa le PCB ea eona ea 16 ka lebaka la ho rarahana ha moralo. Tšebeliso e feteletseng ea li-vias tse foufetseng le likarolo tse petelitsoeng tse teteaneng li lebisa mathateng a ho etsa thepa le a kopano. Thuto e ithutiloeng ke ho beha tekano lipakeng tsa ho rarahana ha moralo le ho etsoa ha bokhoni ba moetsi oa PCB ea khethiloeng.

Ho qoba maraba le maraba a moralo oa PCB oa 16-layer, ho bohlokoa ho:

a.Ho utloisisa ka botlalo litlhoko le litšitiso tsa moralo.

b.Litlhophiso tse stacked tse ntlafatsang botšepehi ba lets'oao le kabo ea matla. c.Abela le ho hlophisa likarolo ka hloko ho ntlafatsa ts'ebetso le ho nolofatsa tlhahiso.

d.Ho netefatsa mekhoa e nepahetseng ea ho tsamaisa, joalo ka ho laola impedance le ho qoba tšebeliso e feteletseng ea lifofu.

e.Ho sebelisana le ho buisana ka katleho le bohle ba amehang mosebetsing oa meralo, ho kenyeletsoa lienjiniere tsa motlakase le tsa mechini le lihlopha tsa tlhahiso.

f.Etsa netefatso e felletseng ea moralo le ketsiso ho tseba le ho lokisa litaba tse ka bang teng pele ho tlhahiso.

Nako ea poso: Sep-26-2023

Morao