Liboto tsa potoloho tse hatisitsoeng tsa elektronike tsa likoloi (PCBs) li bapala karolo ea bohlokoa ts'ebetsong ea likoloi tsa kajeno tse tsoetseng pele. Ho tloha ho litsamaiso tsa lienjine tse laolang le lipontšo tsa infotainment ho isa taolong ea likarolo tsa polokeho le bokhoni ba ho khanna bo ikemetseng, li-PCB tsena li hloka moralo o hlokolosi le lits'ebetso tsa tlhahiso ho netefatsa ts'ebetso e nepahetseng le ts'epo.Sengoliloeng sena, re tla kenella ka har'a leeto le rarahaneng la li-PCB tsa elektroniki tsa likoloi, re hlahlobe mehato ea bohlokoa e amehang ho tloha mothating oa pele oa moralo ho fihlela tlhahiso.

1.Ho utloisisa PCB ea elektroniki ea likoloi:

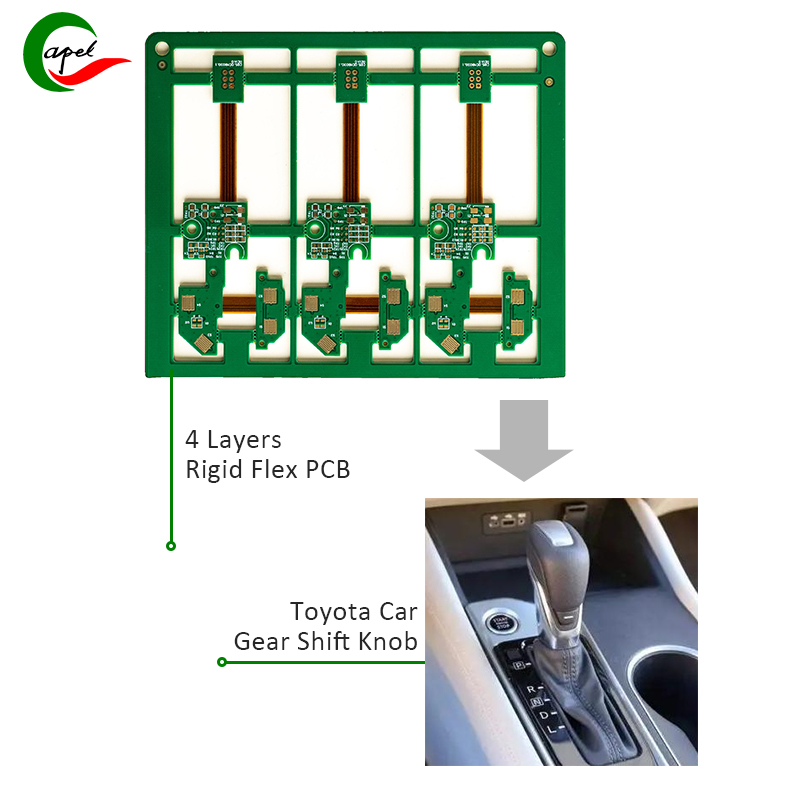

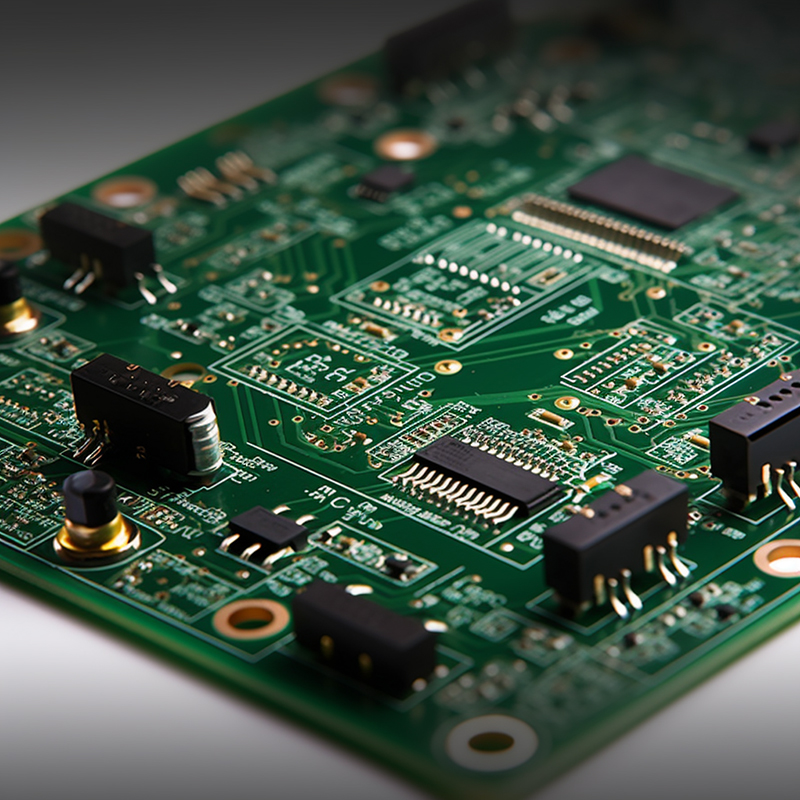

Likoloi tsa elektroniki tsa PCB kapa boto ea potoloho e hatisitsoeng ke karolo ea bohlokoa ea likoloi tsa sejoale-joale. Ba na le boikarabello ba ho fana ka likhokahano tsa motlakase le ts'ehetso bakeng sa litsamaiso tse fapaneng tsa elektroniki ka koloing, joalo ka likarolo tsa taolo ea enjene, sistimi ea infotainment, li-sensor, joalo-joalo. Karolo ea bohlokoa ea li-PCB tsa elektroniki tsa likoloi ke bokhoni ba bona ba ho mamella tikoloho e thata ea likoloi. Likoloi li na le liphetoho tse feteletseng tsa mocheso, ho thothomela le lerata la motlakase. Ka hona, li-PCB tsena li hloka ho tšoarella haholo le ho tšepahala ho netefatsa ts'ebetso e nepahetseng le polokeho. Li-PCB tsa elektronike tsa likoloi li atisa ho etsoa ho sebelisoa software e khethehileng e lumellang baenjiniere ho etsa meralo e finyellang litlhoko tse khethehileng tsa indasteri ea likoloi. Litlhoko tsena li kenyelletsa lintlha tse kang boholo, boima ba 'mele, tšebeliso ea matla, le ho lumellana ha motlakase le likarolo tse ling. Mokhoa oa ho etsa li-PCB tsa elektroniki oa likoloi o kenyelletsa mehato e mengata. Sebopeho sa PCB se raliloe pele le ka mokhoa o phethahetseng le ho lekoa ho netefatsa hore moralo o kopana le litlhaloso tse hlokahalang. Moralo o fetisetsoa ho PCB ea 'mele o sebelisa mekhoa e kang etching kapa ho beha thepa ea conductive ho substrate ea PCB. Ka lebaka la ho rarahana ha li-PCB tsa elektroniki tsa likoloi, likarolo tse ling tse kang li-resistor, li-capacitor le li-circuits tse kopaneng hangata li beoa ho PCB ho phethela potoloho ea elektroniki. Likarolo tsena hangata li behiloe holim'a PCB ho sebelisoa mechini e ikemetseng ea ho beha. Tlhokomelo e khethehileng e lefshoa ts'ebetsong ea welding ho netefatsa khokahanyo e nepahetseng le nako e telele. Ka lebaka la bohlokoa ba litsamaiso tsa elektroniki tsa likoloi, taolo ea boleng e bohlokoa indastering ea likoloi. Ka hona, li-PCB tsa elektroniki tsa likoloi li etsa liteko le tlhahlobo e matla ho netefatsa hore li fihlela litekanyetso tse hlokahalang. Sena se kenyelletsa tlhahlobo ea motlakase, ho palama baesekele e futhumatsang, tlhahlobo ea vibrate le tlhahlobo ea tikoloho ho netefatsa ts'epahalo le ho tšoarella ha PCB tlasa maemo a fapaneng.

2.Automotive electronic PCB design process:

Ts'ebetso ea moralo oa lisebelisoa tsa elektroniki tsa PCB e kenyelletsa mehato e 'maloa ea bohlokoa ho netefatsa ho ts'epahala, ts'ebetso le ts'ebetso ea sehlahisoa sa ho qetela.

2.1 Moralo oa moralo: Mohato oa pele oa moralo ke moralo oa moralo.Mohato ona, lienjineri li hlalosa likhokahano tsa motlakase lipakeng tsa likarolo tsa motho ka mong ho latela ts'ebetso e hlokahalang ea PCB. Sena se kenyelletsa ho theha setšoantšo sa moralo se emelang potoloho ea PCB, ho kenyelletsa likhokahano, likarolo, le likamano tsa tsona. Nakong ena, baenjiniere ba nahana ka lintlha tse kang litlhoko tsa matla, litsela tsa matšoao, le ho lumellana le litsamaiso tse ling ka koloing.

2.2 Moralo oa moralo oa PCB: Hang ha moralo oa moralo o phethetsoe, moralo o fetela karolong ea moralo oa PCB.Mohato ona, baenjiniere ba fetolela schematic ho sebopeho sa 'mele sa PCB. Sena se kenyelletsa ho khetholla boholo, sebōpeho, le sebaka sa likarolo ho boto ea potoloho, hammoho le ho tsamaisa litsela tsa motlakase. Moralo oa moralo o tlameha ho nahana ka lintlha tse kang botšepehi ba matšoao, taolo ea mocheso, ho kena-kenana le motlakase (EMI), le tlhahiso. Tlhokomelo e khethehileng e lefshoa ho beoa ha likarolo ho ntlafatsa phallo ea mats'oao le ho fokotsa lerata.

2.3 Khetho ea likarolo le ho beoa: Kamora hore moralo oa pele oa PCB o phetheloe, lienjiniere li tsoela pele ka khetho ea likarolo le ho li beha.Sena se kenyelletsa ho khetha likarolo tse nepahetseng ho latela litlhoko tse kang ts'ebetso, tšebeliso ea matla, boteng le litšenyehelo. Lintlha tse kang likarolo tsa boemo ba likoloi, mefuta e fapaneng ea mocheso le mamello ea ho sisinyeha li bohlokoa ts'ebetsong ea khetho. Likarolo li beoa ho PCB ho latela mehato ea tsona le maemo a khethiloeng nakong ea sethala sa moralo. Ho beoa hantle le ho tsamaisa likarolo ho bohlokoa ho netefatsa kopano e nepahetseng le phallo e nepahetseng ea mats'oao.

2.4 Tlhahlobo ea botšepehi ba pontšo: Tlhahlobo ea botšepehi ba lipontšo ke mohato oa bohlokoa oa moralo oa PCB oa likoloi tsa elektroniki.E kenyelletsa ho lekola boleng le ts'epahalo ea matšoao ha a ntse a ata ka PCB. Tlhahlobo ena e thusa ho tseba mathata a ka bang teng joalo ka phokotso ea lets'oao, crosstalk, menahano, le tšitiso ea lerata. Ho sebelisoa lisebelisoa tse fapaneng tsa ketsiso le tlhahlobo ho netefatsa moralo le ho ntlafatsa sebopeho ho netefatsa botšepehi ba matšoao. Baqapi ba tsepamisa maikutlo linthong tse joalo ka bolelele ba ho latela mohlala, ho bapisa ha impedance, botsitso ba matla, le tsamaiso e laoloang ea impedance ho netefatsa phetisetso e nepahetseng le e se nang lerata.

Tlhahlobo ea botšepehi ba matšoao e boetse e nahanela mats'oao a lebelo le holimo le libaka tsa bohlokoa tsa libese tse teng lits'ebetsong tsa elektroniki tsa likoloi. Ha theknoloji e tsoetseng pele e kang Ethernet, CAN le FlexRay e ntse e sebelisoa ka ho eketsehileng likoloing, ho boloka botšepehi ba matšoao ho ba thata le ho ba bohlokoa.

Ts'ebetso ea tlhahiso ea 3.Automotive electronic PCB:

3.1 Khetho ea thepa: Khetho ea thepa ea elektroniki ea koloi ea PCB e bohlokoa ho netefatsa ho tšoarella, ho ts'epahala le ts'ebetso.Lisebelisoa tse sebelisoang li tlameha ho khona ho mamella maemo a thata a tikoloho a kopaneng le lits'ebetso tsa likoloi, ho kenyelletsa le ho fetoha ha mocheso, ho thothomela, mongobo le ho pepeseha ha lik'hemik'hale. Lisebelisoa tse sebelisoang ka tloaelo bakeng sa li-PCB tsa elektronike tsa likoloi li kenyelletsa FR-4 (Flame Retardant-4) epoxy-based laminate, e nang le motlakase o motle oa motlakase, matla a mochine le ho hanyetsa mocheso o babatsehang. Li-laminate tsa mocheso o phahameng tse kang polyimide li boetse li sebelisoa lits'ebetsong tse hlokang ho fetoha ha mocheso o feteletseng. Khetho ea thepa e boetse e lokela ho nahana ka litlhoko tsa potoloho ea kopo, joalo ka matšoao a lebelo le phahameng kapa lisebelisoa tsa elektronike tsa matla.

Theknoloji ea tlhahiso ea 3.2 PCB: Theknoloji ea tlhahiso ea PCB e kenyelletsa mekhoa e mengata e fetolang meralo hore e be liboto tsa potoloho tse hatisitsoeng.Ts'ebetso ea tlhahiso hangata e kenyelletsa mehato e latelang:

a) Phetisetso ea Moralo:Moralo oa PCB o fetisetsoa ho software e inehetseng e hlahisang lifaele tsa bonono tse hlokahalang bakeng sa tlhahiso.

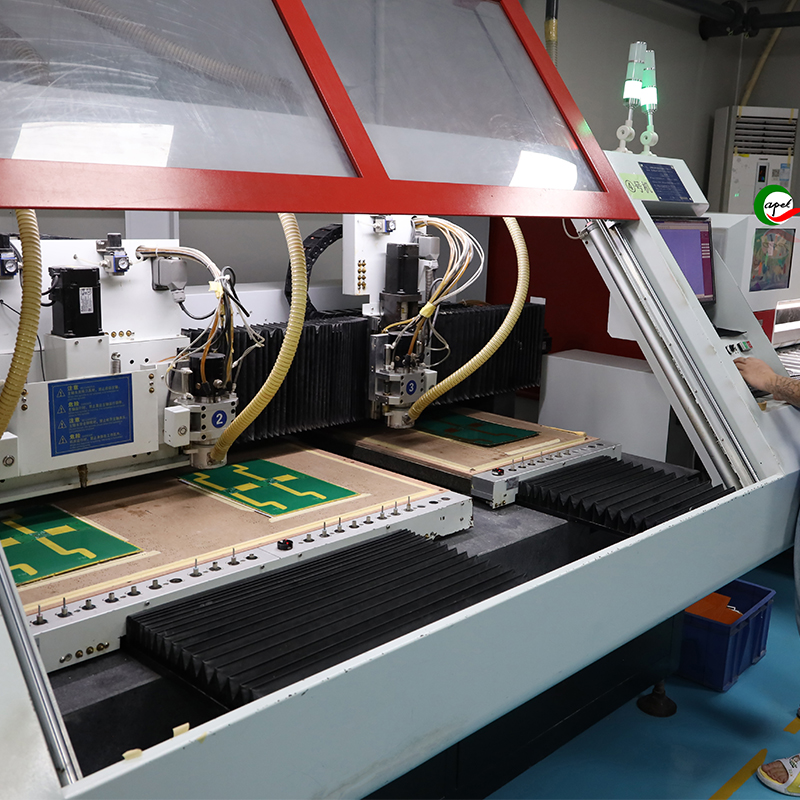

b) Phanele:Ho kopanya meralo e mengata ea PCB ho phanele e le 'ngoe ho ntlafatsa katleho ea tlhahiso.

c) Ho etsa litšoantšo:Apara lesela la lintho tse etsang lifoto holim'a phanele, 'me u sebelise faele ea bonono ho pepesa mokhoa o hlokahalang oa potoloho holim'a phanele e koahetsoeng.

d) Ho hlohlelletsa:Etching ka lik'hemik'hale libaka tse pepenene tsa phanele ho tlosa koporo e sa batleheng, ho siea mesaletsa e lakatsehang ea potoloho.

e) Ho cheka:Ho cheka masoba phanele ho amohela karolo e etellang pele le vias bakeng sa khokahano lipakeng tsa likarolo tse fapaneng tsa PCB.

f) Electroplating:Sekhahla se tšesaane sa koporo se entsoe ka electroplated holim'a phanele ho matlafatsa conductivity ea litsela tsa potoloho le ho fana ka sebaka se boreleli bakeng sa mekhoa e latelang.

g) Kopo ea Mask ea Solder:Sebelisa lera la mask a solder ho sireletsa mesaletsa ea koporo ho tsoa ho oxidation le ho fana ka insulation lipakeng tsa mesaletsa e haufi. Mask ea solder e boetse e thusa ho fana ka phapang e hlakileng ea pono lipakeng tsa likarolo tse fapaneng le mesaletsa.

h) Ho hatisa skrineng:Sebelisa mokhoa oa ho hatisa skrine ho hatisa mabitso a likarolo, li-logos le lintlha tse ling tse hlokahalang ho PCB.

3.3 Lokisetsa lera la koporo: Pele o theha potoloho ea kopo, likarolo tsa koporo ho PCB li hloka ho lokisoa.Sena se kenyelletsa ho hloekisa bokaholimo ba koporo ho tlosa litšila, li-oxide kapa litšila. Ts'ebetso ea ho hloekisa e ntlafatsa ho khomarela ha lisebelisoa tsa photosensitive tse sebelisoang ts'ebetsong ea ho nka litšoantšo. Ho ka sebelisoa mekhoa e sa tšoaneng ea ho hloekisa, ho akarelletsa ho hohla ka mechine, ho hloekisa lik’hemik’hale le ho hloekisa lero la mali.

3.4 Potoloho ea kopo: Hang ha likarolo tsa koporo li lokisitsoe, potoloho ea kopo e ka etsoa ho PCB.Sena se kenyelletsa ho sebelisa mokhoa oa ho nka litšoantšo ho fetisetsa mokhoa o lakatsehang oa potoloho ho PCB. Faele ea litšoantšo e hlahisoang ke moralo oa PCB e sebelisoa e le tšupiso ea ho pepesa lisebelisoa tsa foto ho PCB ho leseli la UV. Ts'ebetso ena e thatafatsa libaka tse pepenene, ho etsa litsela tse hlokahalang tsa potoloho le liphahlo.

3.5 PCB etching le ho phunya: Ka mor'a ho theha potoloho ea kopo, sebelisa tharollo ea lik'hemik'hale ho tlosa koporo e feteletseng.Thepa ea li-photosensitive e sebetsa joalo ka maske, e sireletsang mesaletsa e hlokahalang ea potoloho ho etching. Ka mor'a moo ho tla tshebetso ya ho cheka ho etsa masoba bakeng sa karolo e etellang pele le vias ho PCB. Likoti li chekoa ho sebelisoa lisebelisoa tse nepahetseng 'me libaka tsa tsona li khethoa ho latela moralo oa PCB.

3.6 Ts'ebeliso ea mask ea solder: Kamora hore ts'ebetso ea etching le ho cheka e phetheloe, PCB e pentiloe ho ntlafatsa ts'ebetso ea mesaletsa ea potoloho.Ratella lera le lesesaane la koporo holim'a bokaholimo ba koporo bo pepesitsoeng. Ts'ebetso ena ea plating e thusa ho netefatsa likhokahano tse tšepahalang tsa motlakase le ho eketsa botsitso ba PCB. Ka mor'a ho roala, ho sebelisoa mask a solder ho PCB. Mask ea solder e fana ka insulation le ho sireletsa mesaletsa ea koporo ho tsoa ho oxidation. Hangata e sebelisoa ka khatiso ea skrine, 'me sebaka seo likarolo li behoang ho sona se siuoa se butsoe bakeng sa soldering.

Teko le tlhahlobo ea 3.7 PCB: Mohato oa ho qetela ts'ebetsong ea tlhahiso ke tlhahlobo le tlhahlobo ea PCB.Sena se kenyelletsa ho lekola ts'ebetso le boleng ba PCB. Liteko tse fapaneng tse joalo ka tlhahlobo ea ho tsoela pele, tlhahlobo ea ho hanyetsa insulation, le tlhahlobo ea ts'ebetso ea motlakase li etsoa ho netefatsa hore PCB e kopana le lintlha tse hlokahalang. Tlhahlobo ea pono e boetse e etsoa ho hlahloba liphoso leha e le life tse kang marikhoe a makgutshwane, a bulang, a sa nepahalang, kapa a nang le mathata a ho bea dikarolo.

Ts'ebetso ea ho etsa lisebelisoa tsa elektroniki tsa PCB e kenyelletsa letoto la mehato ho tloha ho khetho ea thepa ho isa tekong le tlhahlobong. Mohato o mong le o mong o na le karolo ea bohlokoa ho netefatsa ho ts'epahala, ts'ebetso le ts'ebetso ea PCB ea ho qetela. Baetsi ba tlameha ho latela litekanyetso tsa indasteri le mekhoa e metle ho netefatsa hore li-PCB li fihlela litlhoko tse thata tsa lits'ebetso tsa likoloi.

4. Lits'oants'o tse ikhethileng tsa koloi: ho na le lintlha tse ikhethileng tsa koloi tse lokelang ho nahanoa ha ho etsoa moralo le

ho etsa li-PCB tsa likoloi.

4.1 Ho senya mocheso le tsamaiso ea mocheso: Likoloing, li-PCB li angoa ke maemo a phahameng a mocheso ka lebaka la mocheso oa enjene le tikoloho e potolohileng.Ka hona, ho qhala mocheso le taolo ea mocheso ke lintlha tsa bohlokoa moralong oa likoloi oa PCB. Likarolo tse fehlang mocheso joalo ka motlakase oa motlakase, li-microcontroller, le li-sensor li tlameha ho beoa ka mokhoa o hlophisehileng ho PCB ho fokotsa khatello ea mocheso. Lichelete tsa mocheso le li-vents li teng bakeng sa ho felisa mocheso ka katleho. Ho feta moo, mekhoa e nepahetseng ea ho phalla ha moea le ea ho pholisa e lokela ho kenyelletsoa meralong ea likoloi ho thibela mocheso o feteletseng le ho netefatsa ho ts'epahala le ho phela nako e telele ha PCB.

4.2 Ho thothomela le ho hanyetsa ho tsukutleha: Likoloi li sebetsa tlas'a maemo a fapaneng a litsela 'me li ka ba le ho thothomela le ho thothomela ho bakoang ke maqhutsu, likoti le libaka tse makukuno.Litšisinyeho tsena le litšisinyeho li ka ama ho tšoarella ha PCB le ho ts'epahala. Ho etsa bonnete ba ho hanyetsa ho thothomela le ho thothomela, li-PCB tse sebelisoang likoloing li lokela ho ba matla ka mochini le ho kenngoa ka mokhoa o sireletsehileng. Mekhoa ea ho qapa e kang ho sebelisa manonyeletso a eketsehileng a solder, ho matlafatsa PCB ka lisebelisoa tsa epoxy kapa tse matlafatsang, le ho khetha ka hloko likarolo le lihokelo tse thibelang ho sisinyeha ho ka thusa ho fokotsa liphello tse mpe tsa ho thothomela le ho makala.

4.3 Tšebelisano ea motlakase (EMC): Tšitiso ea motlakase (EMI) le tšitiso ea maqhubu a seea-le-moea (RFI) e ka ama ts'ebetso ea lisebelisoa tsa elektroniki tsa likoloi hampe.Khokahano e haufi ea likarolo tse fapaneng tsa koloi e tla hlahisa masimo a motlakase a sitisang. Ho netefatsa EMC, moralo oa PCB o tlameha ho kenyelletsa mekhoa e nepahetseng ea ho sireletsa, ho beha fatše le ho sefa ho fokotsa tlhahiso le ho ba le ts'oaetso ea mats'oao a motlakase. Likoti tse sireletsang, li-spacers tse tsamaisang, le mekhoa e nepahetseng ea ho hlophisa PCB (e kang ho arola li-analog le li-digital traces) li ka thusa ho fokotsa liphello tsa EMI le RFI le ho netefatsa ts'ebetso e nepahetseng ea lisebelisoa tsa motlakase tsa likoloi.

4.4 Maemo a polokeho le a ts'epahalo: Lisebelisoa tsa elektroniki tsa likoloi li tlameha ho latela melao e tiileng ea polokeho le ts'epahalo ho netefatsa polokeho ea bapalami le ts'ebetso ea koloi ka kakaretso.Litekanyetso tsena li kenyelletsa ISO 26262 bakeng sa polokeho ea ts'ebetso, e hlalosang litlhoko tsa polokeho ea likoloi tsa litsela, le litekanyetso tse fapaneng tsa naha le tsa machabeng bakeng sa polokeho ea motlakase le menahano ea tikoloho (joalo ka IEC 60068 bakeng sa tlhahlobo ea tikoloho). Baetsi ba PCB ba tlameha ho utloisisa le ho latela litekanyetso tsena ha ba rala le ho etsa li-PCB tsa makoloi. Ntle le moo, tlhahlobo ea ts'epo e joalo ka ho palama baesekele, tlhahlobo ea vibrate, le botsofali bo potlakileng bo lokela ho etsoa ho netefatsa hore PCB e kopana le maemo a ts'eptjoang a ts'ebetso ea likoloi.

Ka lebaka la maemo a phahameng a mocheso oa tikoloho ea likoloi, ho senya mocheso le tsamaiso ea mocheso ke habohlokoa. Ho thothomela le ho tsieleha hoa bohlokoa ho netefatsa hore PCB e khona ho mamella maemo a thata a litsela. Khokahano ea motlakase e bohlokoa ho fokotsa tšitiso lipakeng tsa lisebelisoa tse fapaneng tsa elektroniki tsa likoloi. Ho feta moo, ho latela melao ea polokeho le ts'epo ho bohlokoa ho netefatsa polokeho le ts'ebetso e nepahetseng ea koloi ea hau. Ka ho rarolla mathata ana, baetsi ba PCB ba ka hlahisa li-PCB tsa boleng bo holimo tse fihlelang litlhoko tse ikhethang tsa indasteri ea likoloi.

5.Automotive electronic PCB kopano le kopanyo:

Kopano le kopanyo ea PCB ea likoloi tsa elektroniki e kenyelletsa mekhahlelo e fapaneng e kenyelletsang theko ea likarolo, kopano ea thekenoloji ea holim'a metsi, mekhoa ea ho kopanya e ikemetseng le ea matsoho, le taolo ea boleng le tlhahlobo. Mohato o mong le o mong o thusa ho hlahisa li-PCB tsa boleng bo holimo, tse tšepahalang tse fihlelang litlhoko tse thata tsa lits'ebetso tsa likoloi. Baetsi ba tlameha ho latela mekhoa e thata le litekanyetso tsa boleng ho netefatsa ts'ebetso le nako e telele ea likarolo tsena tsa elektronike likoloing.

5.1 Theko ea likarolo: Ho reka likarolo ke mohato oa bohlokoa ts'ebetsong ea kopano ea PCB ea likoloi tsa elektroniki.Sehlopha sa thepa se sebetsa haufi-ufi le bafani ba thepa ho fumana le ho reka likarolo tse hlokahalang. Likarolo tse khethiloeng li tlameha ho fihlela litlhoko tse boletsoeng bakeng sa ts'ebetso, ho ts'epahala, le ho lumellana le lits'ebetso tsa likoloi. Ts'ebetso ea ho reka e kenyeletsa ho tsebahatsa bafepedi ba thepa ba tshepahalang, ho bapisa ditheko le dinako tsa thomelo, le ho netefatsa hore dikarolo ke tsa nnete mme di fihlella maemo a bohlokwa a boleng. Lihlopha tsa ho reka thepa li boetse li nahana ka lintlha tse kang taolo ea ho felloa ke nako ho netefatsa ho ba teng ha likarolo nakong eohle ea bophelo ba sehlahisoa.

5.2 Surface Mount Technology (SMT): Theknoloji ea Surface Mount Technology (SMT) ke mokhoa o ratoang oa ho kopanya li-PCB tsa likoloi tsa motlakase ka lebaka la ts'ebetso ea eona, ho nepahala, le ho lumellana le likaroloana tse nyenyane. SMT e kenyelletsa ho beha likarolo ka kotloloho holim'a PCB, ho tlosa tlhoko ea lithapo kapa likhoele.Likarolo tsa SMT li kenyelletsa lisebelisoa tse nyane, tse bobebe tse kang li-resistor, li-capacitor, li-circuits tse kopaneng, le li-microcontrollers. Likarolo tsena li behiloe ho PCB ho sebelisoa mochini o ikemetseng oa ho beha. Mochini o beha likarolo hantle holim'a solder peista ho PCB, ho netefatsa tlhophiso e nepahetseng le ho fokotsa menyetla ea liphoso. Ts'ebetso ea SMT e fana ka melemo e mengata, ho kenyelletsa ho eketseha ha sekhahla sa likarolo, ho ntlafatsa ts'ebetso ea tlhahiso, le ts'ebetso e ntlafalitsoeng ea motlakase. Ho feta moo, SMT e thusa ho itlhahloba le ho etsa liteko ka boiketsetso, ho nolofalletsa tlhahiso e potlakileng le e tšepahalang.

5.3 Kopano e ikemetseng le ea matsoho: Kopano ea li-PCB tsa elektroniki tsa likoloi li ka finyelloa ka mekhoa e ikemetseng le ea matsoho, ho latela ho rarahana ha boto le litlhoko tse ikhethileng tsa kopo.Kopano e ikemetseng e kenyelletsa tšebeliso ea mechini e tsoetseng pele ho kopanya li-PCB kapele le ka nepo. Mechini e iketsetsang, joalo ka li-chip mounters, liprinta tsa solder paste, le lionto tsa reflow, li sebelisoa bakeng sa ho beha likarolo, ts'ebeliso ea solder paste, le reflow soldering. Kopano e ikemetseng e sebetsa hantle haholo, e fokotsa nako ea tlhahiso le ho fokotsa liphoso. Ho kopanya ka letsoho, ka lehlakoreng le leng, hangata ho sebelisoa bakeng sa tlhahiso ea molumo o tlaase kapa ha likarolo tse itseng li sa tšoanelehe bakeng sa kopano e ikemetseng. Litsebi tse hloahloa li sebelisa lisebelisoa le lisebelisoa tse khethehileng ho beha likarolo ka hloko ho PCB. Kopano ea matsoho e lumella ho feto-fetoha ha maemo le ho itloaetsa ho feta kopano e ikemetseng, empa e lieha ebile e na le tšekamelo ea liphoso tsa batho.

5.4 Taolo ea Boleng le Teko: Taolo ea boleng le tlhahlobo ke mehato ea bohlokoa ea kopano ea PCB ea lisebelisoa tsa elektroniki tsa likoloi. Mekhoa ena e thusa ho netefatsa hore sehlahisoa sa ho qetela se finyella litekanyetso le ts'ebetso ea boleng bo hlokahalang.Taolo ea boleng e qala ka ho hlahloba likarolo tse kenang ho netefatsa bonnete ba tsona le boleng ba tsona. Nakong ea ts'ebetso ea kopano, tlhahlobo e etsoa ka mekhahlelo e fapaneng ho fumana le ho lokisa liphoso kapa litaba. Tlhahlobo ea pono, automated optical inspection (AOI) le tlhahlobo ea X-ray hangata li sebelisoa ho bona mefokolo e ka bang teng joalo ka marokho a solder, ho se tsamaisane hantle ha likarolo kapa likhokahano tse bulehileng.

Kamora kopano, PCB e hloka ho lekoa ka mokhoa o sebetsang ho netefatsa ts'ebetso ea eona. TMekhoa ea ho hlahloba e ka kenyelletsa tlhahlobo ea matla, tlhahlobo ea ts'ebetso, tlhahlobo ea potoloho, le tlhahlobo ea tikoloho ho netefatsa ts'ebetso, litšobotsi tsa motlakase le ts'epahalo ea PCB.

Taolo ea boleng le tlhahlobo e boetse e kenyelletsa ho latelloa, moo PCB ka 'ngoe e tšoailoeng kapa e tšoailoeng ka sekhetho se ikhethileng ho latela nalane ea eona ea tlhahiso le ho netefatsa boikarabello.Sena se thusa bahlahisi ho tseba le ho lokisa mathata afe kapa afe le ho fana ka lintlha tsa bohlokoa bakeng sa ntlafatso e tsoelang pele.

6.Automotive electronics PCB Litloaelo le mathata a ka moso:Bokamoso ba li-PCB tsa elektroniki tsa likoloi bo tla susumetsoa ke

mekhoa e kang miniaturization, ho rarahana ho eketsehileng, kopanyo ea mahlale a tsoetseng pele, le tlhokahalo ea ntlafatso.

mekhoa ea tlhahiso.

6.1 Miniaturization le ho rarahana ho eketsehileng: E 'ngoe ea litloaelo tsa bohlokoa ho li-PCB tsa elektroniki tsa likoloi ke ts'ebetso e tsoelang pele bakeng sa miniaturization le ho rarahana.Ha likoloi li ntse li hatela pele le ho hlomelloa ka lisebelisoa tse fapaneng tsa elektroniki, tlhoko ea li-PCB tse nyane le tse teteaneng e ntse e eketseha. Miniaturization ena e baka liphephetso ho beheng likaroloana, ho tsamaisa litsela, ho felloa ke mocheso, le ho tšepahala. Baqapi le bahlahisi ba PCB ba tlameha ho fumana litharollo tse ncha tsa ho amohela lintlha tse ntseng li fokotseha ha ba ntse ba boloka ts'ebetso ea PCB le ho tšoarella.

6.2 Momahano ya dithekenoloji tse hatetseng pele: Indaseteri ya dikoloi e bona kgatelopele e potlakileng ya thekenoloji, ho kenyeletswa ho kopanngwa ha dithekenoloji tse hatetseng pele dikoloing.Li-PCB li bapala karolo ea bohlokoa ho nolofatseng mahlale ana, joalo ka litsamaiso tse tsoetseng pele tsa lithuso tsa bakhanni (ADAS), litsamaiso tsa likoloi tsa motlakase, litharollo tsa khokahano le likarolo tsa ho khanna tse ikemetseng. Theknoloji ena e tsoetseng pele e hloka li-PCB tse ka tšehetsang lebelo le phahameng, ho sebetsana le ts'ebetso e rarahaneng ea data, le ho netefatsa puisano e tšepahalang pakeng tsa likarolo tse fapaneng le litsamaiso. Ho rala le ho etsa li-PCB tse fihlelang litlhoko tsena ke phephetso e kholo bakeng sa indasteri.

6.3 Ts'ebetso ea tlhahiso e hloka ho matlafatsoa: Ha tlhoko ea li-PCB tsa elektroniki tsa likoloi e ntse e hola, bahlahisi ba tobane le phephetso ea ho ntlafatsa lits'ebetso tsa tlhahiso ho fihlela palo e phahameng ea tlhahiso ha ba ntse ba boloka maemo a boleng bo holimo.Ho fokotsa mekhoa ea tlhahiso, ho ntlafatsa ts'ebetso, ho khutsufatsa linako tsa potoloho le ho fokotsa liphoso ke libaka tseo bahlahisi ba lokelang ho tsepamisa maikutlo ho tsona. Tšebeliso ea mahlale a tsoetseng pele a tlhahiso, joalo ka kopano e ikemetseng, liroboto le lits'ebetso tse tsoetseng pele tsa tlhahlobo, li thusa ho ntlafatsa ts'ebetso le ho nepahala ha ts'ebetso ea tlhahiso. Ho amohela maikutlo a Indasteri ea 4.0 joalo ka Marang-rang a Lintho (IoT) le li-analytics tsa data li ka fana ka leseli la bohlokoa mabapi le ts'ebetso ea ts'ebetso le tlhokomelo e boletsoeng esale pele, ka hona, ho eketsa tlhahiso le tlhahiso.

7.Moetsi ea tsebahalang oa boto ea potoloho ea likoloi:

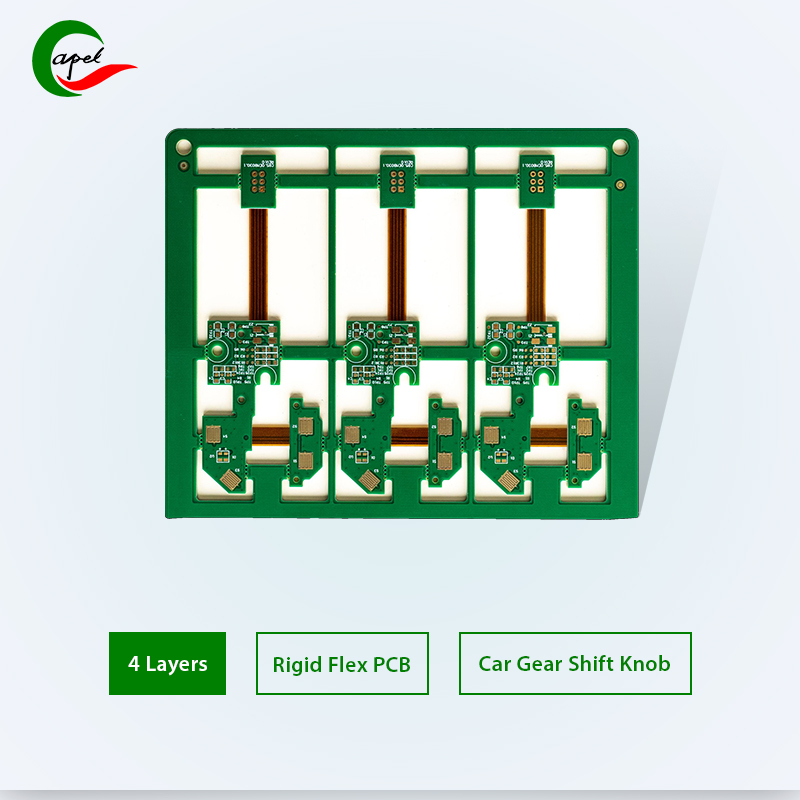

Shenzhen Capel Technology Co., Ltd. e thehile feme ea boto ea potoloho ka 2009 mme ea qala ho theha le ho etsa liboto tsa potoloho tse tenyetsehang, liboto tse nyalisitsoeng le liboto tse thata. Lilemong tse 15 tse fetileng, re atlehile ho qeta mashome a likete a merero ea boto ea potoloho ea likoloi bakeng sa bareki, re bokelletse boiphihlelo bo bongata indastering ea likoloi, mme ra fa bareki litharollo tse bolokehileng le tse tšepahalang. Boenjiniere ba Capel le lihlopha tsa R&D ke litsebi tseo u ka li tšepang!

Ka kakaretso,ts'ebetso ea tlhahiso ea lisebelisoa tsa elektroniki tsa PCB ke mosebetsi o rarahaneng le o hlokolosi o hlokang tšebelisano e haufi lipakeng tsa baenjiniere, baqapi le bahlahisi. Litlhoko tse thata tsa indasteri ea likoloi li hloka li-PCB tsa boleng bo holimo, tse tšepahalang le tse bolokehileng. Ha theknoloji e ntse e tsoela pele, li-PCB tsa elektroniki tsa likoloi li tla hloka ho fihlela tlhoko e ntseng e hola ea mesebetsi e rarahaneng le e rarahaneng. Ho lula ka pele ho sebaka sena se ntseng se fetoha ka potlako, baetsi ba PCB ba tlameha ho ikamahanya le mekhoa ea morao-rao. Ba hloka ho tsetela lits'ebetsong tse tsoetseng pele tsa tlhahiso le lisebelisoa ho netefatsa tlhahiso ea li-PCB tsa maemo a holimo. Ho sebelisa mekhoa ea boleng bo holimo ha ho ntlafatse boiphihlelo ba ho khanna feela, empa hape ho etelletsa pele polokeho le ho nepahala.

Nako ea poso: Sep-11-2023

Morao