Lilemong tsa morao tjena, li-PCB tse thata-thata li fumane botumo ka lebaka la meralo ea tsona e ikhethang le bokhoni ba ho sebetsana le mathata a itseng a hlahisoang ke maemo a phahameng a vibration.Ka poso ena ea blog, re tla hlahloba melemo ea ho sebelisa li-PCB tse thata-thata libakeng tse joalo le ho buisana ka hore na li ka ntlafatsa ts'epo le ts'ebetso ea lisebelisoa tsa elektroniki joang.

Lefatšeng la kajeno, moo lisebelisoa tsa elektroniki li sebelisoang mefuteng e mengata ea lits'ebetso, ho netefatsa ho ts'epahala le ho tšoarella ha lisebelisoa tsena e se e le tsa bohlokoa. E 'ngoe ea lintlha tsa bohlokoa tse lokelang ho nahanoa ke ts'ebetso ea liboto tsa potoloho tse hatisitsoeng (PCBs) libakeng tse thothomelang haholo. Haholo-holo liindasteri tse kang sefofane, likoloi le bongaka, lisebelisoa li atisa ho tsamaisoa le ho sisinyeha, kahoo ho bohlokoa ho sebelisa li-PCB tse ka mamellang maemo a joalo.

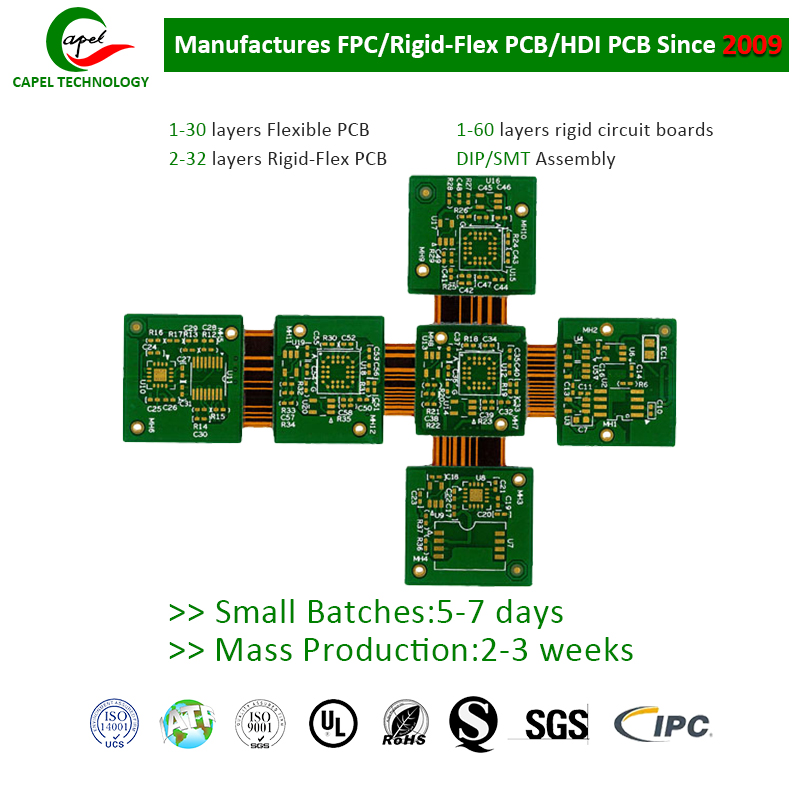

1. Selelekela ho rigid-flex board

Rigid-flex PCB ke lebasetere la PCB ea setso e thata le boto ea potoloho e tenyetsehang. Li na le likarolo tse thata le tse tenyetsehang tse hokahantsoeng ka likoti, tse nolofalletsang meralo ea mahlakore a mararo (3D). Mohaho ona o ikhethang o fana ka melemo e mengata, ho kenyelletsa le ts'ebeliso e ntlafalitsoeng ea sebaka, boima bo fokotsehileng, ho tšoarella ho matlafalitsoeng, le ho feto-fetoha ha maemo nakong ea ho kenya.

2. Ntlafatsa botsitso ba mechine

O mong oa melemo ea mantlha ea li-PCB tse thata-thata ke botsitso ba tsona bo ntlafalitsoeng ba mochini. Motsoako oa thepa e thata le e tenyetsehang e ba lumella ho mamella maemo a phahameng a ho thothomela le ho tsukutleha ntle le ho ama botšepehi ba bona ba sebopeho. Sena se bohlokoa haholo libakeng tse thothomelang haholo moo li-PCB tsa setso tse thata kapa liboto tsa potoloho tse tenyetsehang li ka hlolehang ka lebaka la mefokolo ea tsona.

3. Fokotsa ho hlōleha ha khokahano

Libakeng tse thothomelang haholo, ho hloleha ha likhokahano ke taba e kholo hobane ho ka lebisa mathateng a botsitso ba matšoao kapa ho hloleha ha sesebelisoa kaofela. Li-PCB tse thata-thata li rarolla bothata bona ka ho fana ka kamano e matla pakeng tsa likarolo tse thata le tse tenyetsehang. Tšebeliso ea plated ka likoti ha e ntlafatse feela ho tšepahala ha mochine, empa hape e tiisa khokahanyo e ka tšeptjoang ea motlakase le ho fokotsa kotsi ea ho hlōleha ha likhokahano.

4. Ntlafatsa ho tenyetseha ha moralo

Bokhoni ba meralo ea 3D ea li-PCB tse thata-fetohang li fana ka phetoho e ke keng ea lekanngoa ea moralo, e lumellang baenjiniere ho ntlafatsa sebopeho sa likarolo tsa elektroniki. Sena ke sa bohlokoa libakeng tse phahameng tsa vibration kaha se lumella likarolo hore li behoe libakeng tse itseng, ho ntlafatsa ts'ebetso ea kakaretso le ho tšepahala ha lisebelisoa. Ho feta moo, ho tlosa likhokahano tse kholo le likhoele ho nolofatsa moralo ka kakaretso, ho baka ho boloka litšenyehelo le tšebeliso e ntle ea sebaka.

5. Ho kopanya ho matla haholo

Ka miniaturization e tsoelang pele ea lisebelisoa tsa elektronike, e se e le ntho e ke keng ea qojoa ho finyella ho kopanya ho matla haholo. Li-PCB tse thata-thata li ipabola tabeng ena hobane li lumella likarolo hore li kopanngoe mahlakoreng a mabeli a boto, kahoo li eketsa tšebeliso ea sebaka. Bokhoni ba ho bokella likarolo tse ngata tsa lisebelisoa tse thata le tse tenyetsehang li eketsa bokhoni ba ho kopanya, ho etsa hore ho be bonolo ho amohela lipotoloho tse rarahaneng libakeng tse thothomelang haholo.

6. Khetho e phahameng ea lisebelisoa tsa vibration

Ha u sebelisa li-PCB tse thata-thata libakeng tse thothomelang haholo, ho khetha lisebelisoa tse nepahetseng ho ba bohlokoa. Khetho ea thepa e lokela ho nahana ka lintlha tse kang matla a mochine, botsitso ba mocheso le ho hanyetsa mokhathala oa vibrate. Ka mohlala, ho sebelisa lifilimi tsa polyimide tse nang le mocheso o phahameng oa ho fetola likhalase ho ka ntlafatsa ts'ebetso ea PCB le ts'ebetso tlas'a maemo a feteletseng.

Ka kakaretso

Ho sebelisa li-PCB tse thata-thata libakeng tse nang le li-vibration tse phahameng ho fana ka melemo e mengata mabapi le botsitso ba mechine, ho fokotsa ho hlōleha ha li-interconnect, ho eketseha ha maemo a moralo, le ho kopanya ho matla haholo. Melemo ena e li etsa tse loketseng liindasteri moo lisebelisoa li tsamaeang khafetsa le ho thothomela. Leha ho le joalo, ho bohlokoa ho khetha ka hloko lisebelisoa tse loketseng le menahano ea moralo ho netefatsa ts'ebetso e nepahetseng le ts'epo. Ka ho sebelisa bokhoni bo ikhethang ba li-PCB tse sa fetoheng, baenjiniere ba ka rala lisebelisoa tsa elektroniki tse ka mamellang mathata a tikoloho e sisinyehang haholo le ho fana ka ts'ebetso e phahameng.

Nako ea poso: Sep-18-2023

Morao