Tsebisa

ha ho tluoa tabeng ea tlhokomelo le ho hloekisa, basebelisi ba bangata ba PCB ha ba na bonnete ba hore na mapolanka a thata-thata a ka hlatsuoa kapa a hloekisoa ntle le ho baka tšenyo leha e le efe. Ka poso ena ea blog, re tla ikakhela ka setotsoana sehloohong sena ho u fa lintlha tsa bohlokoa le tataiso. Kahoo a re qaleng!

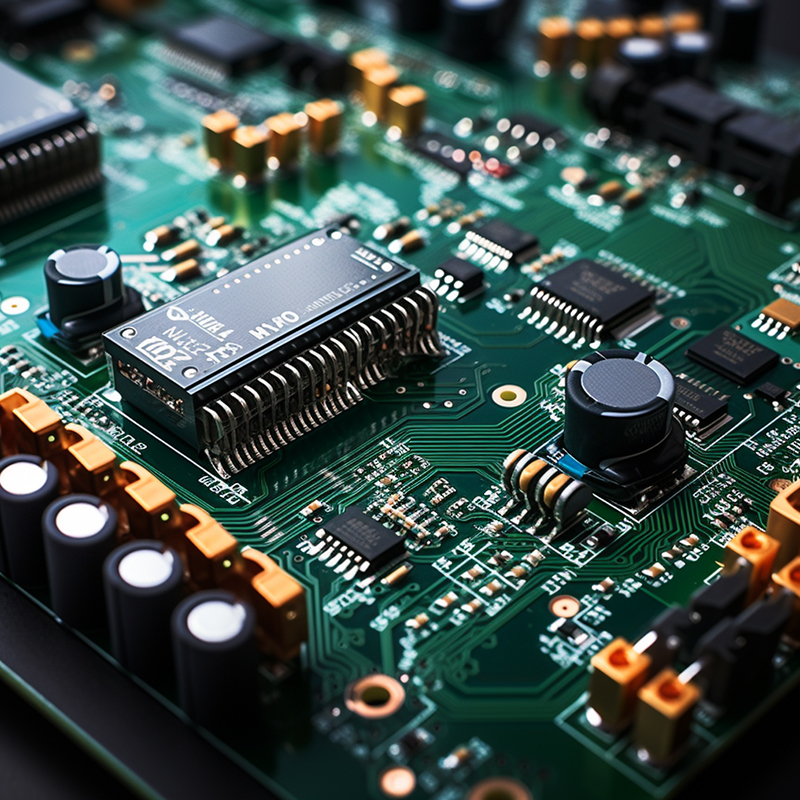

Liboto tsa potoloho tse hatisitsoeng (PCBs) ke karolo ea bohlokoa ea lisebelisoa tsa sejoale-joale tsa elektroniki. Ba fana ka likhokahano tsa motlakase le tšehetso bakeng sa likarolo tse fapaneng. Ha theknoloji e ntse e hatela pele, ho hlahile meralo e rarahaneng le e sebetsang ea PCB, ho kenyeletsoa le li-PCB tse sa fetoheng. Liboto tsena li kopanya likarolo tse thata le tse tenyetsehang ho fana ka ts'ebetso e ntlafalitsoeng le ts'ebeliso.

Ithute ka liboto tsa rigid-flex

Pele re bua ka ts'ebetso ea ho hloekisa liboto tse thata-flex, hoa hlokahala ho utloisisa sebopeho le sebopeho sa tsona. Li-PCB tse thata-thata li entsoe ka likarolo tse ngata tsa lisebelisoa tse thata le tse tenyetsehang, tse kang FR-4 le polyimide. Likarolo tsena li hokahane ka ho sebelisoa ka har'a likoti le lihokelo tsa flex. Li fana ka melemo e kang ho boloka sebaka, ho tšoarella ho eketsehileng le ho tšepahala ho ntlafetseng.

Ke hobane'ng ha u hloekisa liboto tse thata-thata?

Joalo ka PCB efe kapa efe, liboto tse thata-thata li ka bokella lerōle, litšila le litšila tse ling nakong ea ts'ebetso ea tlhahiso kapa nakong ea ts'ebeliso. Litšilafalo tsena li ka ama ts'ebetso ea PCB le bophelo bo bolelele. Ka hona, ho hloekisa khafetsa hoa hlokahala ho boloka ts'ebetso e nepahetseng le ho thibela mathata a ka bang teng.

Mokhoa oa ho hloekisa mapolanka a rigid-flex

Ha u hloekisa mapolanka a rigid-flex, ho bohlokoa ho sebelisa mekhoa le mehato e nepahetseng ho qoba ho senya boto. Mekhoa e meng e lumelletsoeng ea ho hloekisa liboto tsena ke ena:

1. Mokhoa oa joala oa Isopropyl (IPA):Mokhoa ona o kenyelletsa ho hlakola bokaholimo ba PCB ka lesela le se nang lesela kapa swab ea k'hothone e kentsoeng ka tharollo ea IPA. IPA ke mokelikeli o sebelisoang hangata o tlosang litšila ka katleho ntle le ho siea mesaletsa. Leha ho le joalo, ke habohlokoa ho sebelisa palo e fokolang ea IPA le ho qoba mongobo o feteletseng kaha o ka phunyeletsa libakeng tse flexible mme oa baka tšenyo.

2. Ho hloekisa ka mokhoa oa Ultrasonic:Ultrasonic Cleaning ke mokhoa o sebelisoang hangata ho hloekisa PCB. E kenyelletsa ho qoelisa PCB ka tharollo ea ho hloekisa ha u ntse u e phekola ka ultrasonically. Li-vibrations tse hlahisoang ke maqhubu li tlosa litšila 'me li hloekisa boto ea potoloho ka katleho. Leha ho le joalo, tlhokomeliso e feteletseng e lokela ho sebelisoa ha ho sebelisoa mokhoa ona kaha ho chesa haholo kapa khatello e feteletseng e ka senya likarolo tse tenyetsehang tsa PCB.

3. Ho hloekisa mohato oa mouoane:Ho hloekisa karolo ea mouoane ke mokhoa o mong o sebetsang oa ho hloekisa mapolanka a rigid-flex. Ts'ebetso ena e kenyelletsa ho pepesa PCB ho vaporized cleaner, e kopanyang holim'a boto ebe e qhala litšila. Theknoloji ena e tiisa ho hloekisa ka botebo ntle le ho khothalletsa ho kenella ha mongobo leha e le ofe. Leha ho le joalo, e hloka lisebelisoa tse khethehileng le botsebi, ho etsa hore e se fumanehe habonolo ho mosebelisi ea tloaelehileng.

Mehato e lokelang ho lateloa

Leha ho le bohlokoa ho hloekisa liboto tsa rigid-flex, ho bohlokoa hape ho latela mehato e itseng ho qoba tšenyo leha e le efe. Malebela ke ana ao u ka a hopolang:

1. Qoba ho sebelisa lintho tse chehang:Se ke oa sebelisa lintho tse hohlang joalo ka borashe kapa li-pads tsa ho hohla kaha li ka ngoapa kapa tsa senya bokaholimo ba PCB.

2. Se ke oa qoelisa PCB metsing:Se ke oa qoelisa PCB ka har'a tharollo efe kapa efe ea mokelikeli ntle le haeba u sebelisa mokhoa o lumelletsoeng joalo ka ho hloekisa ka ultrasonic. Mongobo o feteletseng o ka kenella libakeng tse flexible mme oa baka tšenyo.

3. Tšoara ka hloko:Kamehla tšoara li-PCB ka matsoho a hloekileng 'me u qobe ho koba kapa ho koba boto ho feta meeli ea eona kaha sena se ka baka mapetsong a khatello ea maikutlo kapa ho robeha.

Ha re phethela:

Ka kakaretso, e, u ka hlatsoa kapa ua hloekisa mapolanka a thata-thata, empa u tlameha ho latela mekhoa le litemoso tse nepahetseng ho thibela tšenyo leha e le efe. Ho hloekisa kamehla ho thusa ho boloka ts'ebetso le nako e telele ea li-PCB tsena tse tsoetseng pele. Ho sa tsotellehe hore na u khetha mokhoa oa IPA, ho hloekisa ka ultrasonic kapa ho hloekisa mouoane, e-ba hlokolosi 'me u qobe mongobo o feteletseng kapa khatello.

Haeba o sa tsebe hantle hore na o ka hloekisa boto e thata joang kapa ho sebetsana le mathata afe kapa afe a amanang le tlhokomelo, ho khothalletsoa ho batla thuso ea litsebi kapa ho buisana le moetsi oa PCB. Ho boloka PCB ea hau e hloekile ebile e hlokometsoe hantle ho tla netefatsa ts'ebetso e nepahetseng le ts'epahalo ea lisebelisoa tsa hau tsa elektroniki.

Nako ea poso: Sep-18-2023

Morao