Tikolohong ea kajeno ea theknoloji e ntseng e tsoela pele ka potlako, tlhoko ea matla a ka nchafatsoang ha e so ka e phahama. Mebuso le likhoebo lefatšeng ka bophara li amohela mekhoa ea matla a ka nchafatsoang e le tharollo ea moshoelella ho loants'a phetoho ea maemo a leholimo le ho fokotsa ho itšetleha ka libeso tsa khale.Ho fihlela katleho e kholo le ho ts'epahala lits'ebetsong tsena ho hloka ts'ebeliso ea mahlale a morao-rao, e 'ngoe ea eona ke liboto tse thata tsa potoloho.

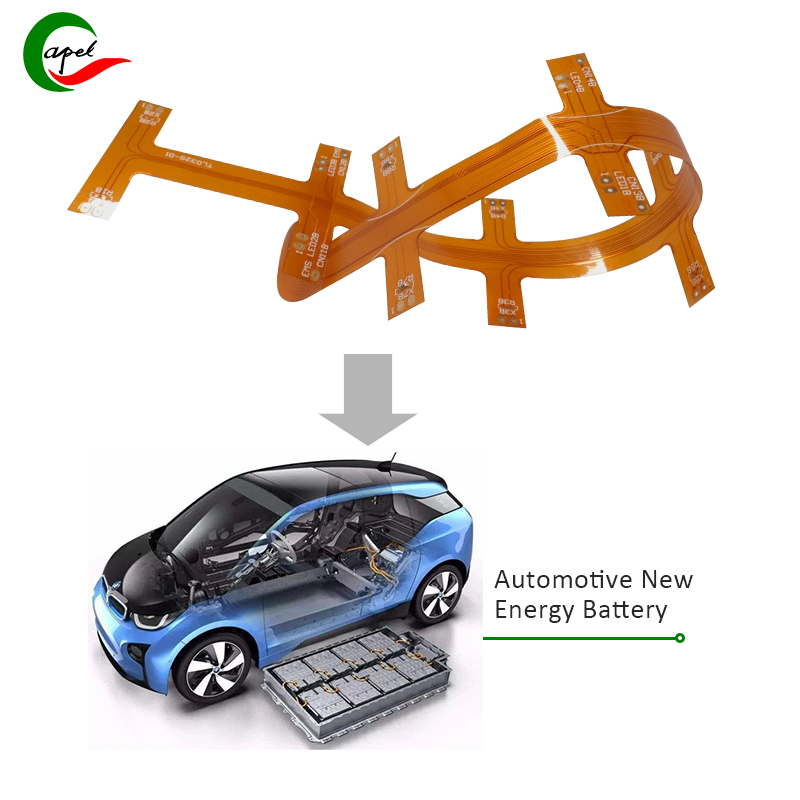

Li-circuits tsa rigid-flex, tse tsejoang hape e le li-circuits tsa flex, ke motsoako oa liboto tsa potoloho tse hatisitsoeng tse thata le tse tenyetsehang.Liboto tsena tse ikhethang tsa potoloho li fana ka ho tiea ha liboto tsa potoloho tse thata tsa setso le ho feto-fetoha ha li-circuits tse feto-fetohang, tse hlahisang lefatše le letle ka ho fetisisa. Li bōpiloe ka laminating mekhahlelo e mengata ea lipotoloho tse tenyetsehang tse nang le lisebelisoa tse thata, tse fanang ka tharollo e matla le e feto-fetohang bakeng sa mefuta e sa tšoaneng ea likopo.

Litsamaiso tsa matla a ka nchafatsoang hangata li hloka likarolo tse rarahaneng tsa elektroniki hore li sebetse hantle. Ebang ke ho hapa matla a letsatsi, ho fetola matla a moea kapa ho sebelisa matla a mocheso oa mobu, litsamaiso tsena li itšetlehile ka lisebelisoa tsa elektroniki tse tsoetseng pele bakeng sa phetolo ea matla le tsamaiso e nepahetseng. Li-circuits tsa rigid-flex li ipakile li loketse lits'ebetso tse joalo tse boima. Ha re hlahlobeng hore na ke hobane'ng ha liboto tsena li nepahetse bakeng sa litsamaiso tsa matla a ka nchafatsoang:

1. Ho ntlafatsa sebaka: E 'ngoe ea melemo ea bohlokoa ea liboto tsa potoloho tse thata-flex ke bokhoni ba tsona ba ho fokotsa litlhoko tsa sebaka.Lisebelisoa tsa matla a tsosolositsoeng hangata li kenyelletsa palo e kholo ea likarolo tsa elektronike le li-sensor tse hlokang ho hokahanngoa. Li-circuits tsa rigid-flex li etsa hore ho be le meralo e nang le mahlakore a mararo, ho sebelisa sebaka se fumanehang hantle le ho nolofatsa mathata a ho kenya.

2. Botšepehi bo ntlafetseng: Lisebelisoa tsa matla a tsosolositsoeng hangata li kenngoa libakeng tse thata, ho kenyeletsa le mocheso o feteletseng, ho thothomela le mongobo.Li-circuits tsa rigid-flex li fana ka ts'epo e ikhethang le bokhoni ba ho mamella maemo ana a thata. Motsoako oa thepa e thata le e tenyetsehang e tiisa hore mapolanka ana a ka mamella khatello ea mochine, ho fokotsa kotsi ea ho hlōleha le ho ntlafatsa tshebetso ea tsamaiso ka kakaretso.

3. Tsamaiso e Ntlafetseng ea Thermal: Tsamaiso e nepahetseng ea mocheso ke ea bohlokoa bakeng sa mekhoa ea matla a tsosolositsoeng kaha e thusa ho thibela ho chesa le ho lelefatsa bophelo ba likarolo tsa elektronike.Liboto tsa li-circuit tsa rigid-flex li ka etsoa ho kenyelletsa lisinki tsa mocheso, li-vias tsa mocheso, le mahlale a mang a ho pholisa ho khothaletsa phallo e sebetsang ea mocheso. Bokhoni bona ba ho laola mocheso ke ba bohlokoa ka ho khetheha bakeng sa litsamaiso tse kang liphanele tsa letsatsi tse hlahisang mocheso o mongata nakong ea ts'ebetso ea ho fetola matla.

4. Tšebeliso ea Litšenyehelo: Le hoja mapolanka a potoloho a thata-thata a ka 'na a e-ba le litšenyehelo tse phahameng ka pele ho feta mapolanka a tloaelehileng a thata kapa li-circuits tse feto-fetohang, hangata li fella ka ho boloka litšenyehelo tsa nako e telele.Ka lebaka la moralo oa bona o kopanetsoeng le ho tšepahala ho eketsehileng, mapolanka ana a fokotsa tlhokahalo ea likarolo tse eketsehileng le lithapo tse rarahaneng. Mokhoa ona o nolofalitsoeng o fokotsa litšenyehelo tsa tlhahiso, nako ea ho kenya le litlhoko tsa tlhokomelo ea lisebelisoa tsa matla a tsosolositsoeng.

5. Ho iketsetsa moralo: Sistimi e 'ngoe le e' ngoe ea matla a tsosolositsoeng e ikhethile 'me e na le litlhoko le meeli e itseng.Li-circuits tsa rigid-flex li fana ka phetoho e ke keng ea lekanngoa ea moralo, e lumellang baenjiniere ho fetola sebopeho sa bona ho finyella litlhoko tse khethehileng tsa tsamaiso. Tlhahiso ena e ntlafatsa ts'ebetso mme e ntlafatsa kopanyo ea likarolo tse fapaneng, ka hona e eketsa katleho ea sistimi ka kakaretso.

6. Ho tšoarella le ho feto-fetoha ha maemo: Lisebelisoa tsa matla a tsosolositsoeng hangata li kenyelletsa likarolo tse tsamaeang kapa tse potolohang, tse kang li-turbine tsa moea kapa lisebelisoa tsa ho latela letsatsi.Li-circuits tsa rigid-flex li na le bokhoni bo ikhethang ba ho mamella ho khumama khafetsa ntle le ho ama ts'ebetso ea bona. Ho tšoarella hona ho netefatsa phallo ea motlakase e sa sitisoeng, leha e le maemong a matla, e tiisang phepelo ea motlakase e tsoelang pele.

Ha mehloli ea matla a tsosolositsoeng e ntse e eketseha, tlhoko ea lisebelisoa tsa elektroniki tse tsoetseng pele litsamaisong tsena e tla eketseha feela.Li-circuits tsa rigid-flex li fana ka tharollo ea thekenoloji e ka sebetsanang ka katleho le liphephetso tse thulaneng le mekhoa ea matla a tsosolositsoeng. Ho feto-fetoha ha tsona, ho ts'epahala le bokhoni ba ho ntlafatsa sebaka le taolo ea mocheso li etsa hore e be tse loketseng lits'ebetso tsena tse boima.

Ka kakaretso,ho na le melemo e mengata ea ho sebelisa liboto tsa potoloho tse thata-flex mekhoeng ea matla a tsosolositsoeng. Liboto tsena li ipabola ka ho ntlafatsa sepakapaka, li matlafatsa ts'epahalo, li ntlafatsa taolo ea mocheso, li bonts'a katleho ea litšenyehelo, li lumella ho etsa moralo, 'me li bonts'a ho tšoarella le ho tenyetseha. Ka ho sebelisa bokhoni ba liboto tsa potoloho tse thata-flex, lisebelisoa tsa matla a tsosolositsoeng li ka finyella katleho e kholoanyane, bophelo bo bolelele ba tšebeletso, le ho boloka tikoloho.

Nako ea poso: Oct-08-2023

Morao