Tsebisa:

Lefatšeng la kajeno le khannoang ke thekenoloji, tlhokahalo ea liboto tsa potoloho tse hatisitsoeng tse rarahaneng le tse tenyetsehang (PCBs) e ntse e hola ka potlako. Ho tloha ho litsamaiso tsa khomphutha tse sebetsang hantle haholo ho isa ho tse roaloang le lisebelisoa tsa bongaka, li-PCB tsena tse tsoetseng pele li fetohile karolo ea bohlokoa ea lisebelisoa tsa elektroniki tsa sejoale-joale. Leha ho le joalo, ha litlhoko tsa ho rarahana le ho feto-fetoha ha maemo li ntse li eketseha, ho joalo le ka tlhokahalo ea theknoloji e tsoetseng pele ea tlhahiso e ka finyellang litlhoko tsena tse ikhethang.Ho blog ena, re tla hlahloba sebopeho se ntseng se tsoela pele sa tlhahiso ea PCB le ho buisana ka hore na e khona ho fihlela litlhoko tsa li-PCB tse rarahaneng le tse tenyetsehang.

Ithute ka li-PCB tse rarahaneng le tse tenyetsehang:

Li-PCB tse rarahaneng li khetholloa ka meralo e rarahaneng e kopanyang mesebetsi e mengata sebakeng se lekanyelitsoeng. Tsena li kenyelletsa li-PCB tse ngata, liboto tsa li-high-density interconnect (HDI), le li-PCB tse nang le li-vias tse foufetseng le tse patiloeng. Ka lehlakoreng le leng, li-PCB tse feto-fetohang li etselitsoe ho kobeha kapa ho sotheha ntle le ho senya potoloho, ho li etsa hore e be tse loketseng lits'ebetso moo ho feto-fetoha ha maemo le ho ntlafatsa sebaka ho leng bohlokoa. Li-PCB tsena hangata li sebelisa li-substrates tse tenyetsehang joalo ka polyimide kapa polyester.

Ho eketseha ha theknoloji e tsoetseng pele ea tlhahiso:

Mekhoa e tloaelehileng ea tlhahiso ea PCB, e kang etching, lamination, joalo-joalo, ha e lekane ho finyella litlhoko tsa PCB tse rarahaneng, tse tenyetsehang. Sena se lebisitse ho nts'etsopele ea mefuta e fapaneng ea theknoloji e tsoetseng pele ea tlhahiso e fanang ka ho nepahala ho hoholo, ho feto-fetoha ha maemo le katleho.

1. Laser Direct Imaging (LDI):Theknoloji ea LDI e sebelisa li-laser ho pepesa likaroloana tsa PCB ka kotloloho, ho felisa tlhoko ea li-photomasks tse jang nako le liphoso. Theknoloji e etsa hore ho be le lipotoloho tse ntle haholo, litsela tse fokolang le li-vias tse nyenyane, tse bohlokoa bakeng sa li-PCB tse rarahaneng.

2. Keketseho ea Tlhahiso:Ho etsa tlatsetso kapa khatiso ea 3D e fetotse tlhahiso ea li-PCB tse rarahaneng le tse tenyetsehang. E etsa hore ho be bonolo ho etsa meralo e rarahaneng, haholo-holo bakeng sa li-prototypes le tlhahiso e tlase ea molumo. Ho etsa lintho tse ekelitsoeng ho thusa ho pheta-pheta le ho itlhophisa ka potlako, ho thusa baqapi le bahlahisi ho fihlela litlhoko tse ikhethang tsa li-PCB tse rarahaneng le tse tenyetsehang.

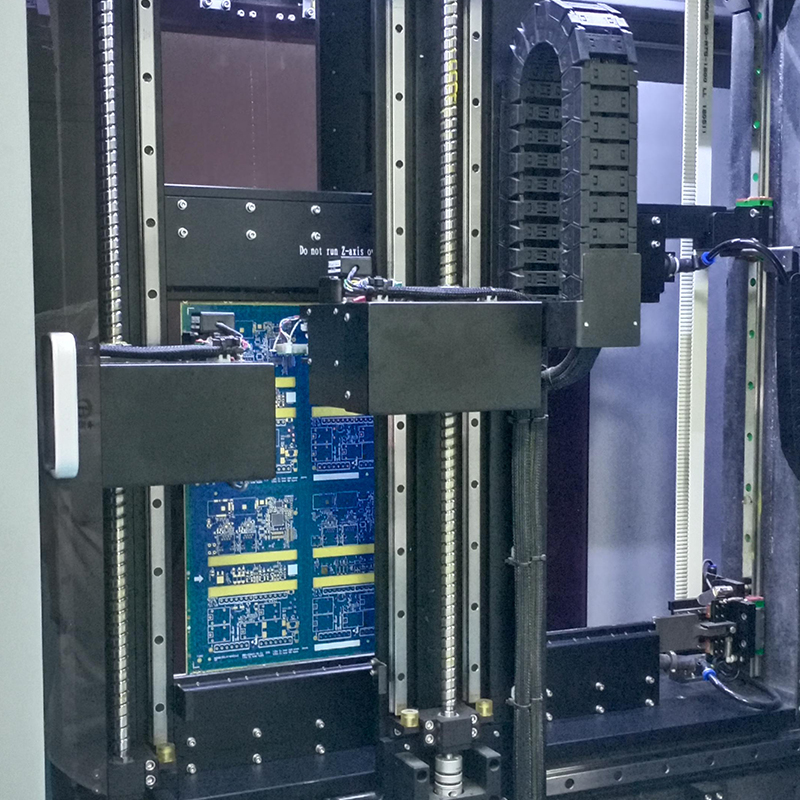

3. Ho sebetsana le substrate e bonolo:Ka tloaelo, li-PCB tse thata e ne e le ntho e tloaelehileng, e fokotsa menyetla ea moralo le ho fokotsa ho tenyetseha ha litsamaiso tsa elektroniki. Leha ho le joalo, tsoelo-pele ea thepa ea substrate le theknoloji ea ho sebetsa e butse litsela tse ncha bakeng sa tlhahiso ea liboto tsa potoloho tse hatisitsoeng. Hona joale bahlahisi ba na le mechini e khethehileng e netefatsang ho ts'oaroa le ho tsamaisana hantle ha li-substrates tse tenyetsehang, ho fokotsa kotsi ea tšenyo nakong ea tlhahiso.

Mathata le tharollo:

Leha theknoloji e tsoetseng pele ea tlhahiso e ntse e tsoela pele, liphephetso li ntse li hloka ho hlōloa ho fihlela litlhoko tsa tlhahiso ea li-PCB tse rarahaneng, tse tenyetsehang.

1. Litšenyehelo:Ho kenya ts'ebetsong mekhoa e tsoetseng pele ea tlhahiso hangata ho hloka litšenyehelo tse phahameng. Sena se ka amahanngoa le matsete a pele a hlokahalang lisebelisoa, koetliso le lisebelisoa tsa litsebi. Leha ho le joalo, ha mahlale ana a ntse a ata le tlhokahalo e ntse e eketseha, ho lebelletsoe hore moruo o tla fokotsa litšenyehelo.

2. Tsebo le koetliso:Ho amohela mekhoa e mecha ea tlhahiso ho hloka litsebi tse nang le tsebo ea ho sebetsa le ho boloka mechine e tsoetseng pele. Likhamphani li hloka ho tsetela mananeong a tsoelang pele a koetliso le ho hohela talenta ho netefatsa phetoho e thellang ho litheknoloji tsena tse ncha.

3. Maemo le taolo ea boleng:Ha theknoloji ea PCB e ntse e tsoela pele ho ntlafala, ho bile bohlokoa ho theha litekanyetso tsa indasteri le ho kenya tšebetsong mehato e tiileng ea taolo ea boleng. Baetsi, balaoli le mekhatlo ea indasteri ba hloka ho sebetsa 'moho ho netefatsa ho ts'epahala le polokeho ea li-PCB tse rarahaneng le tse tenyetsehang.

Ka kakaretso:

E susumetsoa ke litlhoko tse ntseng li eketseha tsa litsamaiso tsa morao-rao tsa elektronike, litlhoko tsa tlhahiso ea li-PCB tse rarahaneng le tse tenyetsehang li lula li fetoha.Le hoja mekhoa e tsoetseng pele ea tlhahiso e kang laser direct imaging le additive production e ntlafalitse haholo bokhoni ba ho etsa PCB, ho ntse ho e-na le liphephetso tse lokelang ho hlōloa mabapi le litšenyehelo, bokhoni le taolo ea boleng. Leha ho le joalo, ka boiteko bo tsoelang pele le matsapa a kopanetsoeng, sebaka sa tlhahiso se se se loketse ho kopana le ho feta litlhoko tsa li-PCB tse rarahaneng le tse tenyetsehang. Ha thekenoloji e ntse e tsoela pele, re ka lebella ntlafatso e tsoelang pele lits'ebetsong tsa tlhahiso ho netefatsa ho kopanngoa ha li-PCB ho lisebelisoa tsa elektroniki tse tsoetseng pele haholo.

Nako ea poso: Oct-30-2023

Morao