Tsebisa:

Lefapheng la lisebelisoa tsa elektroniki, Li-Printed Circuit Boards (PCBs) li bapala karolo ea bohlokoa ho netefatsa hore lisebelisoa tse fapaneng li sebetsa ka mokhoa o se nang moeli. Ho netefatsa maemo a holimo ka ho fetisisa a boleng le ho ts'epahala, ho bohlokoa hore baetsi ba PCB ba kenye ts'ebetsong mehato e matla ea tlhahlobo nakong eohle ea tlhahiso.Ho blog ena, re tla hlahloba mehato ea tlhahlobo ea boleng e sebelisoang ts'ebetsong ea tlhahiso ea PCB ea k'hamphani ea rona, re shebane le litifikeiti tsa rona le litokelo tsa molao tse bonts'ang boitlamo ba rona ba ho sebetsa hantle.

Setifikeiti le Litumello:

Joalo ka moetsi oa PCB ea hlomphuoang, re na le litifikeiti tse ngata tse pakang hore re latela litekanyetso tse phahameng ka ho fetisisa tsa indasteri. Khampani ea rona e fetile ISO 14001:2015, ISO 9001:2015 le IATF16949: 2016 setifikeiti. Litifikeiti tsena li tiisa boinehelo ba rona taolong ea tikoloho, taolo ea boleng le litsamaiso tsa taolo ea boleng ba likoloi ka ho latellana.

Ho feta moo, re motlotlo hore ebe re fumane Matshwao a UL le ROHS, mme re boetse re totobatsa boitlamo ba rona ba ho latela maemo a polokeho le dithibelo ho dintho tse kotsi. Ho amohelwa ke mmuso e le "kgwebo e tiileng ya konteraka le e tshepahalang" le "kgwebo ya naha ya theknoloji e phahameng" ho bontsha boikarabelo ba rona le boqapi ba rona indastering.

Innovation Patent:

Khamphaning ea rona, re lumela ho ba ka pele ho tsoelo-pele ea theknoloji. Re fumane kakaretso ea lipatente tsa mefuta e 16 ea ts'ebeliso le litokelo tsa boqapi, tse bonts'ang matsapa a rona a tsoelang pele a ho ntlafatsa boleng le ts'ebetso ea li-PCB. Lipatente tsena ke bopaki ba boitseanape ba rona le boitelo ba rona ho boqapi, ho netefatsa hore lits'ebetso tsa rona tsa tlhahiso li ntlafatsoa bakeng sa ts'ebetso e nepahetseng.

Mehato ea tlhahlobo ea boleng pele ho tlhahiso:

Taolo ea boleng e qala qalong ea ts'ebetso ea tlhahiso ea PCB. Ho netefatsa litekanyetso tse phahameng ka ho fetisisa, re qala ka ho hlahloba ka botlalo lintlha le litlhoko tsa bareki ba rona. Sehlopha sa rona sa boenjiniere se nang le boiphihlelo se sekaseka litokomane tsa moralo ka hloko le ho buisana le bareki ho hlakisa lintho tse sa hlakang pele li fetela pele.

Hang ha moralo o amohetsoe, re hlahloba ka hloko le ho khetha lisebelisoa tse tala tsa boleng bo holimo, ho kenyeletsoa substrate, foil ea koporo le enke ea mask ea solder. Lisebelisoa tsa rona li etsa liteko tse matla tsa boleng ho netefatsa hore li latela maemo a indasteri joalo ka IPC-A-600 le IPC-4101.

Nakong ea mokhahlelo oa pele ho tlhahiso, re etsa tlhahlobo ea moralo bakeng sa tlhahiso ea tlhahiso (DFM) ho hlwaya mathata afe kapa afe a ka bang teng a tlhahiso le ho netefatsa chai e nepahetseng le ts'epo. Mohato ona o boetse o re lumella ho fana ka maikutlo a bohlokoa ho bareki ba rona, ho khothaletsa ntlafatso ea moralo le ho fokotsa litaba tse ka bang teng tsa boleng.

Mehato ea tlhahlobo ea boleng ba ts'ebetso:

Ho pholletsa le ts'ebetso eohle ea tlhahiso, re sebelisa mekhoa e fapaneng ea tlhahlobo ea boleng ho netefatsa boleng bo tsitsitseng le ho tšepahala. Mehato ena e kenyeletsa:

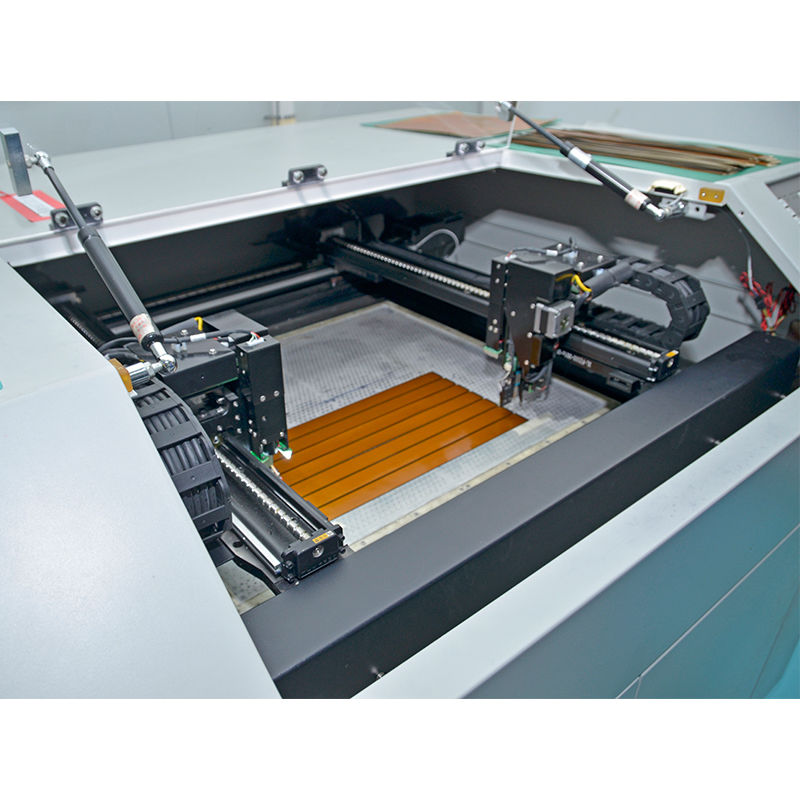

1. Automatic Optical Inspection (AOI): Re sebelisa lisebelisoa tse tsoetseng pele tsa AOI, re etsa tlhahlobo e nepahetseng ea li-PCB ka mekhahlelo ea bohlokoa, joalo ka ka mor'a kopo ea solder paste, ho kenya likarolo le ho solder. AOI e re lumella ho bona mefokolo e joalo ka litaba tsa ho cheselletsa litšepe, likarolo tse sieo le ho se tsamaisane hantle ka ho nepahala le ho sebetsa hantle haholo.

2. Tlhahlobo ea X-ray: Bakeng sa li-PCB tse nang le mehaho e rarahaneng le ho teteana haholo, tlhahlobo ea X-ray e sebelisetsoa ho fumana mefokolo e patehileng e ke keng ea fumanoa ka mahlo. Theknoloji ena ea tlhahlobo e sa senyeheng e re lumella ho hlahloba manonyeletso a solder, vias le likarolo tse ka hare bakeng sa likoli tse kang li-opens, shorts le voids.

3. Teko ea motlakase: Pele ho kopano ea ho qetela, re etsa tlhahlobo e felletseng ea motlakase ho netefatsa ts'ebetso le ts'epahalo ea PCB. Liteko tsena, ho kenyeletsoa Teko ea In-Circuit (ICT) le tlhahlobo ea ts'ebetso, li re thusa ho tseba mathata afe kapa afe a motlakase kapa a ts'ebetso e le hore a ka lokisoa kapele.

4. Teko ea tikoloho: Ho netefatsa ho tšoarella ha li-PCB tsa rona tlasa maemo a fapaneng a ts'ebetso, re li beha tekong e matla ea tikoloho. Sena se kenyelletsa ho palama libaesekele tse futhumatsang, tlhahlobo ea mongobo, tlhahlobo ea ho fafatsa letsoai, le tse ling. Ka liteko tsena, re lekola ts'ebetso ea PCB maemong a mocheso a feteletseng, mongobo le tikoloho e senyang.

Mehato ea tlhahlobo ea boleng ba Postpartum:

Hang ha ts'ebetso ea tlhahiso e felile, re tsoela pele ho nka mehato ea tlhahlobo ea boleng ho netefatsa hore ke li-PCB tsa boleng bo holimo feela tse fihlang ho bareki ba rona. Mehato ena e kenyeletsa:

1. Tlhahlobo ea Pono: Sehlopha sa rona sa taolo ea boleng bo nang le phihlelo se etsa tlhahlobo e hlokolosi ea pono ho fumana mefokolo leha e le efe ea litlolo tse kang mengoapo, matheba kapa liphoso tsa khatiso. Sena se tiisa hore sehlahisoa sa ho qetela se boetse se kopana le litekanyetso tsa botle.

2. Teko ea ts'ebetso: E le ho netefatsa ts'ebetso e felletseng ea PCB, re sebelisa lisebelisoa tse khethehileng tsa tlhahlobo le software ho etsa tlhahlobo e tiileng ea ts'ebetso. Sena se re lumella ho netefatsa ts'ebetso ea PCB tlas'a maemo a sebele a lefats'e le ho fihlela litlhoko tse khethehileng tsa bareki ba rona.

Ha re phethela:

Ho tloha mohatong oa pele oa moralo ho isa sehlahisoa sa ho qetela, k'hamphani ea rona e netefatsa mehato e ke keng ea lekanngoa ea taolo ea boleng ho pholletsa le ts'ebetso eohle ea tlhahiso ea PCB. Litifikeiti tsa rona, ho kenyeletsoa ISO 14001:2015, ISO 9001:2015 le IATF16949:2016, hammoho le matšoao a UL le ROHS, li totobatsa boitlamo ba rona ba ho boloka tikoloho, taolo ea boleng le ho latela melao ea polokeho.

Ho feta moo, re na le lipatente tse 16 tsa mohlala oa utility le lipatente tsa boiqapelo, tse bonts'ang ho phehella ha rona ho nchafatseng le ntlafatsong e tsoelang pele. Ka ho sebelisa mekhoa e tsoetseng pele ea tlhahlobo ea boleng joalo ka AOI, tlhahlobo ea X-ray, tlhahlobo ea motlakase, le tlhahlobo ea tikoloho, re netefatsa tlhahiso ea li-PCB tsa boleng bo holimo, tse tšepahalang.

Re khethe re le moetsi oa hau oa PCB eo u mo tšepang 'me u fumane tiisetso ea taolo ea boleng bo sa sekisetseng le tšebeletso e ikhethang ea bareki.

Nako ea poso: Oct-30-2023

Morao