Tsebisa:

Tlhahiso e bonolo ea PCB e bapala karolo ea bohlokoa indastering ea tlhahiso ea lisebelisoa tsa elektroniki. Ha theknoloji e ntse e tsoela pele, tlhoko ea li-PCB tse tenyetsehang e eketsehile haholo. Tataisong ena ea mantlha, re tla hlahloba kaho ea PCB e feto-fetohang, sebopeho, le mefuta ea li-stackup. Ho bohlokoa ho utloisisa mantsoe a latelang a bohlokoa:Flexible PCB Manufacturing, Flexible PCB Structure, Flexible PCB Copper Thickness, Flexible PCB Solder Mask, Flexible PCB Layout, Flexible PCB Adhesive Sheet, le Flexible PCB Layup Mefuta kaha li bohlokoa bakeng sa ho ntlafatsa sehlahisoa sa hau.E bohlokoa.

1. Tsebo ea mantlha ea tlhahiso ea PCB e tenyetsehang:

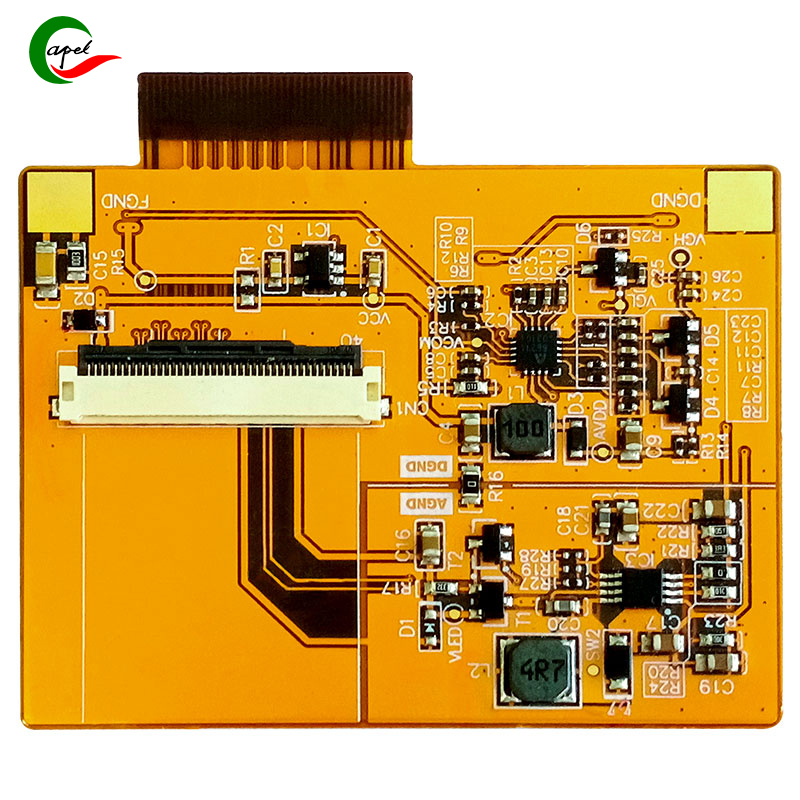

A. Tlhaloso le litšoaneleho tsa boto e tenyetsehang: PCB e tenyetsehang, e tsejoang hape e le potoloho e tenyetsehang, ke boto ea potoloho e hatisitsoeng e ka kobehang, ea phuthoa kapa ea sothoa ntle le ho robeha. Ba fana ka melemo e mengata ho feta li-PCB tse thata, ho kenyelletsa le ho feto-fetoha ha maemo, bobebe, le ho tšoarella. Lisebelisoa tsena li etsa hore li tšoanelehe bakeng sa lits'ebetso tse fapaneng, haholo tse hlokang lisebelisoa tsa elektroniki tse kopaneng le tse kobehang.

B. Sebopeho sa PCB se feto-fetohang: Ts'ebetso ea kaho ea PCB e tenyetsehang e kenyelletsa tšebeliso ea li-substrates tse tenyetsehang. Li-substrates tse sebelisoang ka ho fetisisa ke polyimide le polyester, tse fanang ka ho feto-fetoha le maemo a hlokahalang bakeng sa li-PCB tse tenyetsehang. Li-substrates tsena li etsa letoto la mehato ea ho etsa joalo ka etching, plating, le lamination ho theha mokhoa o lakatsehang oa potoloho.

C. Utloisisa botenya ba koporo ho PCB e tenyetsehang: Botenya ba koporo bo phetha karolo ea bohlokoa ts'ebetsong ea PCB e tenyetsehang. E lekanya matla a hona joale a ho jara, ho sitisa, le ho fetoha habonolo ha PCB. Likhetho tse fapaneng tsa botenya ba koporo li ka etsoa ho latela litlhoko tse khethehileng tsa moralo. Koporo e teteaneng e fana ka bokhoni bo phahameng ba ho jara hajoale empa hape e fokotsa ho tenyetseha ha PCB. Ho tlameha hore ho be le tekano e nepahetseng pakeng tsa lintlha tsena ho fihlela ts'ebetso e nepahetseng.

2. Likarolo tsa bohlokoa tsa tlhahiso ea PCB e tenyetsehang:

A. Flexible PCB solder mask: Mask ea solder ke lera le sireletsang le koahelang mesaletsa ea koporo e se nang letho ho PCB. E thusa ho thibela marokho a solder, corrosion, le lifupi tsa motlakase nakong ea ho cheselletsa. Flexible PCB e sebelisa lisebelisoa tse khethehileng tsa mask ho etsa bonnete ba hore e fetoha le maemo le ho tšoarella. Khetho e feto-fetohang ea PCB ea solder ea ho khetha le ts'ebetso ea kopo e hloka ho shebisisa moralo oa PCB le ts'ebeliso ea eona e reriloeng.

B. Flexible PCB Layout: Sebopeho sa PCB se entsoeng hantle, se tenyetsehang se bohlokoa bakeng sa ts'ebetso e nepahetseng le ho tšepahala. E kenyelletsa ho beoa ha likarolo, ho tsamaisa mesaletsa, le menahano ea botšepehi ba matšoao. Likarolo li tlameha ho behoa ka tsela e lumellang PCB hore e kobehe le ho koba ka nepo. Melato e lokela ho tsamaisoa ho fokotsa khatello ea maikutlo libakeng tsa flex le ho netefatsa phetisetso e nepahetseng ea matšoao. Mekhoa e metle ea ho rala sebopeho sa PCB se tenyetsehang se kenyelletsa ho sebelisa mesaletsa e kobehileng, ho qoba li-angles tse bohale, le ho netefatsa hore ho na le sebaka se lekaneng pakeng tsa mesaletsa.

C. Flexible PCB sekgomaretsi lakane: An lakane sekgomaretsi e sebelisoa ka tenyetsehang PCB tlhahiso ho tlamahane le dikarolo fapaneng hammoho. E fana ka matla a mochine, botsitso, le ho pata. Ho na le mefuta e fapaneng ea lipampiri tsa sekhomaretsi tse fumanehang, joalo ka lishiti tse thehiloeng ho acrylic, maqephe a thehiloeng ho epoxy le maqephe a thehiloeng ho rabara. Khetho ea lakane ea sekhomaretsi e itšetlehile ka lintlha tse kang ho hanyetsa mocheso, litlhoko tsa ho feto-fetoha ha maemo, le ho lumellana le lisebelisoa tse ling. Ho khetha leqephe le nepahetseng la sekhomaretsi ho bohlokoa haholo ho netefatsa ho ts'epahala le ho tšoarella ha PCB ea hau e tenyetsehang.

3. Mefuta e bonolo ea ho bokella PCB:

A. Selelekela ho PCB stackup: PCB stackup e bolela tlhophiso ea masela a fapaneng a PCB. Tlhahisong e feto-fetohang ea PCB, stack up e bapala karolo ea bohlokoa ho ts'epahalo ea matšoao, taolo ea impedance, le taolo ea mocheso. Ka ho khetha ka hloko le ho hlophisa likarolo, baqapi ba ka ntlafatsa ts'ebetso ea li-PCB tse tenyetsehang.

B. Mefuta e Tloaelehileng ea ho Rata PCB: Ho na le mefuta e fapaneng ea ho betla e sebelisoang ha ho etsoa tlhahiso ea PCB e feto-fetohang, ho kenyeletsoa lera le le leng, le nang le mekhahlelo e 'meli, le litlhophiso tsa mekhahlelo e mengata. Mofuta o mong le o mong oa stacking o na le melemo le mefokolo ea oona. Li-PCB tse tenyetsehang tsa lera le le leng ke khetho e bonolo ka ho fetisisa le e baballang chelete e ngata, empa li na le bokhoni bo fokolang ba ho tsamaisa. PCB e feto-fetohang ea mekhahlelo e 'meli e fana ka likhetho tse ngata tsa wiring' me e ka amohela meralo e rarahaneng. Li-PCB tse feto-fetohang tsa Multilayer li fana ka phetoho e kholo ea litsamaiso, le taolo e ntlafalitsoeng ea impedance, 'me li ka ts'ehetsa maemo a phahameng a potoloho. Leha ho le joalo, li rarahane haholoanyane ebile li bitsa chelete e ngata ho li etsa.

Ka kakaretso:

Tataisong ena e felletseng, re akaretsa likarolo tsohle tsa tlhahiso ea PCB e feto-fetohang, ho kenyeletsoa kaho, sebopeho, maske a solder, lishiti tsa sekhomaretsi, le mefuta ea li-stackup. Ho utloisisa lintlha tsena tsa bohlokoa ho tla thusa baqapi ho ntlafatsa ts'ebetso le ts'epahalo ea meralo ea bona e feto-fetohang ea PCB. Mekhoa le mekhoa ea thekenoloji ke ea bohlokoa bakeng sa tlhahiso ea li-PCB tse tenyetsehang, 'me ka ho latela mekhoa e metle, bahlahisi ba ka etsa bonnete ba ho fana ka lihlahisoa tsa boleng bo phahameng, tse ka tšeptjoang ho finyella litlhoko tsa indasteri ea lisebelisoa tsa elektronike.

Nako ea poso: Nov-10-2023

Morao