HDI (High Density Interconnect) li-PCB tse thata-thata li emela tlhōrō ea theknoloji e tsoetseng pele ea boto ea potoloho e hatisitsoeng, e kopanyang melemo ea bokhoni ba lithapo tse phahameng le ho fetoha ha mapolanka a thata-thata.Sengoliloeng sena se ikemiselitse ho hlakisa ts'ebetso ea tlhahiso ea HDI rigid-flex PCB le ho fana ka lintlha tsa bohlokoa mabapi le sebopeho sa eona, lisebelisoa le mehato ea bohlokoa ea tlhahiso.Ka ho utloisisa mathata a amehang, baenjiniere le baqapi ba ka ntlafatsa meralo ea bona le ho sebelisana hantle le bahlahisi ho fetola mehopolo ea bona e ncha hore e be 'nete.

1.UtloisisaHDI e thata e tenyetsehang PCB:

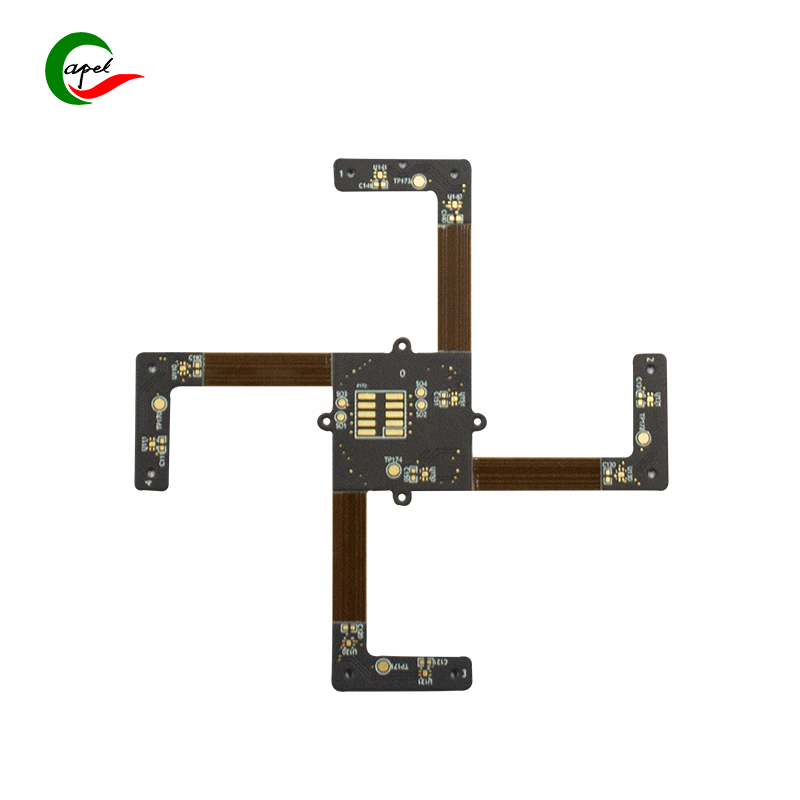

HDI (High Density Interconnect) rigid-flex PCB ke mofuta o tsoetseng pele oa boto ea potoloho e hatisitsoeng e kopanyang melemo ea ho hokahana ho phahameng le ho feto-fetoha ha maemo.Motsoako ona o ikhethang o etsa hore li tšoanelehe hantle ho fihlela litlhoko tsa lisebelisoa tsa sejoale-joale tsa elektroniki.

Khokahano e phahameng haholo e bolela bokhoni ba ho fihlella likarolo tse phahameng haholo le ho tsamaisa lipontšo ka har'a sebaka se lekanyelitsoeng sa boto.Ha tlhoko ea lisebelisoa tse nyane, tse nang le komporo e ntse e hola, theknoloji ea HDI e thusa ho rala le ho hlahisa lipotoloho tse rarahaneng ka lintlha tse nyane. Khokahano e eketsehang ea likhokahano e lumella ts'ebetso e eketsehileng ho kopanngoa lisebelisoa tse nyane, ho etsa hore li sebetse hantle le ho ba matla.

Ho feto-fetoha ha maemo ke tšobotsi e 'ngoe ea bohlokoa ea HDI rigid-flex PCBs. Ho feto-fetoha ha maemo ho lumella boto hore e kobehe, e phuthoe kapa e sothehe ntle le ho ama ts'ebetso kapa ts'epahalo.Ho feto-fetoha ha maemo ho molemo haholo bakeng sa lisebelisoa tsa elektroniki tse hlokang meralo e rarahaneng ea 'mele kapa tse hlokang ho mamella ho thothomela, ho ts'oha, kapa tikoloho e feteletseng. E boetse e nolofalletsa ho kopanya ka mokhoa o se nang moeli oa likarolo tsa elektronike ho tloha likarolong tse fapaneng tsa boto ea potoloho, ho felisa tlhokahalo ea li-connectors kapa lithapo tse eketsehileng.

Ho sebelisa theknoloji ea HDI ho fana ka melemo e mengata.Taba ea pele, e ntlafatsa haholo botšepehi ba matšoao ka ho fokotsa sebaka se pakeng tsa likarolo le likhokahano, ho fokotsa tahlehelo ea lets'oao, tšitiso ea crosstalk le electromagnetic. Sena se matlafatsa ts'ebetso le ts'epahalo bakeng sa lits'ebetso tsa digital le RF tsa lebelo le holimo. Taba ea bobeli, HDI rigid-flex PCB e ka fokotsa haholo boholo le boima ba lisebelisoa tsa elektroniki. Theknoloji ea HDI e felisa tlhoko ea likhokahano tse eketsehileng, likhoele, le likhokahano tsa boto ho ea boto, e lumellang meralo e kopaneng, e bobebe. Sena ke sa bohlokoa haholo bakeng sa liindasteri tse kang sefofane le lisebelisoa tsa elektronike tse nkehang habonolo, moo ho boloka boima ba 'mele le sebaka ho leng bohlokoa. Ntle le moo, theknoloji ea HDI e boetse e ntlafatsa ts'epahalo ea lisebelisoa tsa elektroniki. Ka ho fokotsa palo ea likhokahano, HDI rigid-flex PCBs e fokotsa kotsi ea ho hloleha ka lebaka la likhokahano tse hlephileng kapa mokhathala o kopaneng oa solder. Sena se ntlafatsa boleng ba sehlahisoa mme se eketsa ts'epo ea nako e telele.

Lisebelisoa tsa HDI rigid-flex li fumaneha liindastering tse fapaneng, ho kenyeletsoa sefofane, lisebelisoa tsa bongaka, lithelefono le lisebelisoa tsa elektronike tsa bareki.Lefapheng la lifofane, li-PCB tsa HDI tse thata-thata li sebelisoa mekhoeng ea ho laola lifofane, li-avionics, le mekhoa ea puisano ka lebaka la boholo ba tsona bo kopanetsoeng, boima bo bobebe, le bokhoni ba ho mamella maemo a feteletseng. Lefapheng la bongaka, li sebelisoa lisebelisoa tse kang li- pacemaker, mechine ea litšoantšo ea bongaka le lisebelisoa tse kentsoeng. Likhokahano le lisebelisoa tsa elektronike tsa bareki li rua molemo ka boholo bo fokotsehileng le ts'ebetso e ntlafetseng ea HDI rigid-flex PCBs ho li-smartphone, matlapa, tse roaloang le lisebelisoa tse ling tse nkehang habonolo.

2.Ts'ebetso ea tlhahiso ea PCB e thata-thata ea HDI: mohato ka mohato

A. Rala lithibelo 'me u lokise lifaele tsa CAD:

Mohato oa pele ts'ebetsong ea tlhahiso ea HDI e thata-flexible PCB ke ho nahana ka litšitiso tsa moralo le ho lokisa lifaele tsa CAD. Litšitiso tsa moralo li bapala karolo ea bohlokoa ho khethollang ts'ebetso ea PCB, ts'epahalo, le ho etsoa. Tse ling tsa lithibelo tsa bohlokoa tsa moralo tse lokelang ho nahanoa ke:

Meeli ea Boholo:

Boholo ba PCB bo itšetlehile ka litlhoko tsa sesebelisoa seo e sebelisoang ho sona. Hoa hlokahala ho etsa bonnete ba hore PCB e lumellana le sebaka se khethiloeng ntle le ho ama ts'ebetso kapa ho tšepahala.

Ho tšepahala:

Moqapi oa PCB o lokela ho tšepahala le ho khona ho mamella maemo a lebeletsoeng a ts'ebetso. Lintho tse kang mocheso, mongobo, ho thothomela le khatello ea mechine li hloka ho nkoa ka nako ea moralo.

Letšoao la Botšepehi:

Meralo e lokela ho nahana ka botšepehi ba mats'oao ho fokotsa kotsi ea ho fokotsa mats'oao, lerata kapa tšitiso. Matshwao a dijithale a lebelo le phahameng le a RF a hloka taolo e hlokolosi ya ho tsamaisa le ho thibela mathata.

Taolo ea Thermal:

Tsamaiso ea mocheso e bohlokoa ho thibela ho chesa le ho netefatsa ts'ebetso e nepahetseng ea likarolo tsa elektronike. Ho senya mocheso ho ka finyelloa ka ho behoa hantle ha li-vias tsa mocheso, litšepe tsa mocheso, le liphahlo tsa mocheso. Software ea CAD e sebelisoa ho etsa lifaele tsa sebopeho sa PCB. E lumella baqapi ho hlalosa stacking ea layer, ho beoa ha likarolo le litselana tsa koporo. Software ea CAD e fana ka lisebelisoa le bokhoni ba ho emela le ho bona meralo ka nepo, e nolofalletsa ho tseba le ho lokisa mathata afe kapa afe a ka bang teng pele ho tlhahiso.

B. Khetho ea Lintho le Moralo oa ho Rala:

Ka mor'a ho lokisa lifaele tsa CAD, mohato o latelang ke khetho ea thepa le moralo oa moralo. Ho khetha lisebelisoa tse nepahetseng ho bohlokoa ho etsa bonnete ba hore li-PCB tsa HDI tse sa fetoheng li fihlella ts'ebetso e hlokahalang ea motlakase, taolo ea mocheso le bots'epehi ba mochini. Lisebelisoa tse thata, tse kang FR-4 kapa li-laminates tse sebetsang hantle, li fana ka tšehetso ea mechine le botsitso. Lera le tenyetsehang hangata le entsoe ka filimi ea polyimide kapa polyester bakeng sa ho feto-fetoha ha maemo le ho tšoarella. Ts'ebetso ea moralo oa stackup e kenyelletsa ho khetholla tlhophiso ea likarolo tse fapaneng, ho kenyeletsoa likarolo tse thata le tse tenyetsehang, botenya ba koporo le lisebelisoa tsa dielectric. Moralo oa stackup o lokela ho nahana ka lintlha tse kang botšepehi ba matšoao, taolo ea impedance, le kabo ea matla. Tlhophiso e nepahetseng ea lera le khetho ea thepa e thusa ho netefatsa phetisetso e nepahetseng ea lets'oao, ho fokotsa ho fetella le ho fana ka phetoho e hlokahalang.

C. Ho cheka ka laser le ho theha microhole:

Ho cheka ka laser ke mohato oa bohlokoa oa ho theha li-microvia tse tsamaeang ka bongata ho HDI PCBs. Li-Microvias ke masoba a manyane a sebelisetsoang ho hokahanya likarolo tse fapaneng tsa PCB, tse lumellang likhokahano tse phahameng tsa sehloho. Ho cheka ka laser ho fana ka melemo e mengata ho feta mekhoa e tloaelehileng ea ho cheka ka mochini. E lumella li-apertures tse nyane, e lumellang hore ho be le sekhahla se phahameng sa litsela le meralo e kopaneng haholoanyane. Ho cheka ka laser ho boetse ho fana ka ho nepahala le ho laola haholoanyane, ho fokotsa kotsi ea ho se lumellane kapa ho senya thepa e potolohileng. Ts'ebetsong ea ho cheka ka laser, lebone la laser le tsepamisitsoeng le sebelisoa ho hlakola thepa, ho theha masoba a manyane. Joale likoti li entsoe ka metallized ho fana ka conductivity pakeng tsa lihlopha, ho lumella phetiso e nepahetseng ea matšoao.

D. Ho roala ka koporo ka lik'hemik'hale:

Ho roala ka koporo e se nang motlakase ke mohato oa bohlokoa ts'ebetsong ea tlhahiso ea liboto tsa HDI tse rigid-flex. Ts'ebetso ena e kenyelletsa ho beha karolo e tšesaane ea koporo ka har'a li-micropores le holim'a PCB. Bohlokoa ba ho roala ka koporo e se nang motlakase ke bokhoni ba eona ba ho netefatsa likhokahano tse tšepahalang tsa motlakase le phetiso e ntle ea matšoao. Lera la koporo le tlatsa li-microvias 'me le kopanya likarolo tse fapaneng tsa PCB, ho etsa tsela ea conductive bakeng sa lipontšo. E boetse e fana ka sebaka se solderable bakeng sa sehokelo sa karolo. Ts'ebetso ea ho roala ka koporo e se nang motlakase e kenyelletsa mehato e mengata, ho kenyelletsa le ho lokisa holim'a metsi, ts'ebetso le deposition. PCB e qala ho hloekisoa le ho kenngoa ts'ebetsong ho khothalletsa ho khomarela. Ka mor'a moo, ho sebelisoa lik'hemik'hale ho sebelisa tharollo e nang le li-ion tsa koporo sebakeng sa PCB, ho kenya lesela le lesesaane la koporo.

E. Phetisetso ea Litšoantšo le Lithography:

Phetiso ea litšoantšo le photolithography ke likarolo tsa mokhoa oa ho etsa HDI o thata-flex PCB. Mehato ena e kenyelletsa ho sebelisa sesebelisoa sa photoresist ho etsa mohlala oa potoloho holim'a PCB le ho e pepesetsa leseli la UV ka setšoantšo sa foto. Nakong ea ts'ebetso ea phetisetso ea litšoantšo, lisebelisoa tsa photoresist li sebelisoa sebakeng sa PCB. Lisebelisoa tsa Photoresist li na le maikutlo a mabone a UV 'me li ka pepeseha ka boikhethelo. Ka mor'a moo, PCB e tsamaisana le setšoantšo sa photomask 'me leseli la UV le fetisoa libakeng tse hlakileng tsa photomask ho hlahisa photoresist. Ka mor'a ho pepeseha, PCB e ntshetswa pele ho tlosa photoresist e sa pepesehang, e siea mokhoa o lakatsehang oa potoloho. Mekhoa ena e sebetsa e le likarolo tse sireletsang lits'ebetsong tse latelang. Ho theha marang-rang a potoloho, lik'hemik'hale tsa etching li sebelisoa ho tlosa koporo e sa batleheng. Libaka tse sa koahetsoeng ke photoresist li pepesehetse ho etchant, e khethang ho tlosa koporo, e siea mekhoa ea potoloho e lakatsehang.

F. Etching le electroplating process:

Morero oa ts'ebetso ea etching ke ho tlosa koporo e feteletseng le ho theha mesaletsa ea potoloho ho HDI rigid-flex PCB. Etching e kenyelletsa ho sebelisa etchant, hangata e leng acid kapa tharollo ea lik'hemik'hale, ho tlosa koporo e sa batleheng ka boikhethelo. Etching e laoloa ke lera le sireletsang photoresist le thibelang etchant ho hlasela litsela tse hlokahalang tsa potoloho. Laola ka hloko nako le ho tsepamisa mohopolo oa etchant ho fihlela bophara bo lakatsehang le botebo. Ka mor'a etching, photoresist e setseng e tlosoa ho pepesa mekhoa ea potoloho. Mokhoa oa ho hlobolisa o kenyelletsa ho sebelisa li-solvents ho qhaqha le ho tlosa photoresist, ho siea litsela tse hloekileng le tse hlalositsoeng hantle tsa potoloho. Ho matlafatsa mesaletsa ea potoloho le ho netefatsa conductivity e nepahetseng, ho hlokahala ts'ebetso ea plating. Sena se kenyelletsa ho beha karolo e 'ngoe ea koporo holim'a mesaletsa ea potoloho ka mokhoa oa electroplating kapa electroless plating. Botenya le ho ts'oana ha koporo ea koporo ke tsa bohlokoa bakeng sa ho fumana khokahanyo e tšepahalang ea motlakase.

Tšebeliso ea mask ea G. Solder le ho kopanya likaroloana:

Kopo ea mask ea solder le kopano ea likarolo ke mehato ea bohlokoa ts'ebetsong ea tlhahiso ea HDI e thata-flex PCB. Sebelisa mask a solder ho sireletsa mesaletsa ea koporo le ho fana ka insulation lipakeng tsa bona. Mask ea solder e etsa lera le sireletsang holim'a sebaka sohle sa PCB, ntle le libaka tse hlokang ho soasoa, joalo ka likarolo tsa likarolo le li-vias. Sena se thusa ho thibela borokho ba solder le marikhoe nakong ea kopano. Kopano ea likarolo e kenyelletsa ho beha likarolo tsa elektroniki ho PCB le ho li kopanya sebakeng sa tsona. Likarolo li behiloe ka hloko 'me li tsamaisana le sebaka sa ho lulisa ho netefatsa likhokahano tse nepahetseng tsa motlakase. Sebelisa mekhoa ea soldering e kang reflow kapa wave soldering ho itšetlehile ka mofuta oa motsoako le litlhoko tsa kopano. Ts'ebetso ea reflow soldering e kenyelletsa ho futhumatsa PCB ho mocheso o itseng o etsang hore solder e qhibilihe 'me e be le kamano e sa feleng pakeng tsa likarolo tse etellang pele le liphahlo tsa PCB. Wave soldering hangata e sebelisoa bakeng sa likarolo tsa lesoba, moo PCB e fetisoang ka leqhubu la solder e qhibilihisitsoeng ho theha khokahano.

H. Teko le Taolo ea Boleng:

Mohato oa ho qetela ts'ebetsong ea tlhahiso ea HDI e thata-flexible PCB ke teko le taolo ea boleng. Teko e matla e bohlokoa ho netefatsa ts'ebetso ea PCB, ts'epahalo le ts'ebetso. Etsa liteko tsa motlakase ho hlahloba borikhoe bo bokhutšoane, ho bula le ho tsoela pele. Sena se kenyelletsa ho sebelisa li-voltage le maqhubu a ikhethileng ho PCB le ho metha karabelo ka lisebelisoa tsa tlhahlobo tse ikemetseng. Litlhahlobo tse bonoang li boetse li etsoa ho netefatsa boleng ba kopanelo ea solder, ho beoa ha karolo, le bohloeki ka kakaretso ba PCB. E thusa ho tseba liphoso tse ka bang teng joalo ka likarolo tse sa lumellaneng, marokho a solder, kapa litšila. Ho feta moo, tlhahlobo ea khatello ea mocheso e ka etsoa ho hlahloba bokhoni ba PCB ba ho mamella ho palama baesekele kapa mocheso oa mocheso. Sena se bohlokoa haholo lits'ebetsong moo PCB e pepesehileng ho fetoha ha mocheso o feteletseng. Nakong le ka mor'a mohato o mong le o mong oa ts'ebetso ea tlhahiso, mehato ea taolo ea boleng e kenngoa ts'ebetsong ho netefatsa hore PCB e kopana le litlhaloso le litekanyetso tse hlokahalang. Sena se kenyeletsa maemo a ts'ebetso ea ho beha leihlo, ho tsamaisa taolo ea ts'ebetso ea lipalo-palo (SPC), le ho etsa lihlahlobo tsa nako le nako ho hlwaya le ho lokisa liphapang leha e le life kapa liphoso.

3.Mathata a tobaneng le ho etsa liboto tsa HDI tse thata-thata:

Ho etsa liboto tsa HDI rigid-flex ho hlahisa mathata le liphephetso tse lokelang ho laoloa ka hloko ho netefatsa sehlahisoa sa boleng bo holimo.Liphephetso tsena li pota-potile likarolo tse tharo tsa bohlokoa: ho lumellana hantle, bofokoli ba holim'a metsi, le liphetoho tsa impedance nakong ea lamination.

Ho tsamaisana ka nepo ho bohlokoa bakeng sa liboto tsa HDI tse thata hobane li kenyelletsa likarolo tse ngata le lisebelisoa tse tlamehang ho beoa ka nepo. Ho finyella tolamiso e nepahetseng ho hloka ho tšoara ka hloko le ho beha maemo a mekhahlelo e fapaneng ho netefatsa hore vias le likarolo tse ling li tsamaisana hantle. Ho se tsamaisane hofe kapa hofe ho ka baka mathata a maholo joalo ka tahlehelo ea mats'oao, marikhoe a makhutšoane kapa likheo. Bahlahisi ba tlameha ho tsetela ho lisebelisoa tse tsoetseng pele le theknoloji ho netefatsa teka-tekano e nepahetseng nakong eohle ea ts'ebetso ea tlhahiso.

Ho qoba liphoso tse ka holimo ke bothata bo bong bo boholo. Nakong ea ts'ebetso ea tlhahiso, ho ka 'na ha e-ba le mefokolo e holim'a metsi e kang mengoapo, menoana, kapa litšila, tse amang ts'ebetso le ho ts'epahala ha liboto tsa HDI tse rigid-flex.Litšitiso tsena li ka kena-kenana le likhokahano tsa motlakase, tsa ama botsitso ba matšoao, kapa tsa etsa hore boto e hlolehe ka ho felletseng. Ho thibela bofokoli ba bokaholimo, mehato e tiileng ea taolo ea boleng e tlameha ho nkuoa, ho kenyeletsoa ho ts'oaroa ka hloko, tlhahlobo ea khafetsa, le ts'ebeliso ea tikoloho e hloekileng nakong ea tlhahiso.

Ho fokotsa liphetoho tsa impedance nakong ea lamination ho bohlokoa ho boloka ts'ebetso ea motlakase ea HDI rigid-flex board.Lamination e kenyelletsa ho sebelisa mocheso le khatello ho kopanya likarolo tse fapaneng hammoho. Leha ho le joalo, ts'ebetso ena e ka baka liphetoho ho bophara ba dielectric le bophara ba conductor, e leng se bakang liphetoho tse sa rateheng tsa impedance. Ho laola ts'ebetso ea lamination ho fokotsa liphetoho tsena ho hloka taolo e nepahetseng ea mocheso, khatello le nako, hammoho le ho khomarela ka thata ho litlhaloso tsa moralo. Ntle le moo, ho ka sebelisoa mekhoa e tsoetseng pele ea liteko le netefatso ho netefatsa hore ho bolokoa tšitiso e hlokahalang.

Ho hlōla mathata ana ha ho etsoa liboto tsa HDI flex ho hloka hore baqapi le bahlahisi ba sebetse haufi-ufi nakong eohle ea ts'ebetso.Baqapi ba hloka ho nahana ka hloko ka lithibelo tsa tlhahiso le ho li tsebisa bahlahisi ka katleho. Ka lehlakoreng le leng, bahlahisi ba tlameha ho utloisisa litlhoko le litšitiso tsa moralo e le hore ba ka kenya tšebetsong mokhoa o nepahetseng oa tlhahiso. Tšebelisano 'moho e thusa ho rarolla mathata a ka bang teng qalong ea moralo le ho netefatsa hore ts'ebetso ea tlhahiso e ntlafalitsoe bakeng sa liboto tsa boleng bo holimo tsa HDI rigid-flex.

Qetello:

Mokhoa oa tlhahiso ea HDI rigid-flex PCB ke letoto la mehato e rarahaneng empa e le ea bohlokoa e hlokang theknoloji e nang le tsebo, e nepahetseng le e ka tšeptjoang.Ho utloisisa mohato o mong le o mong oa ts'ebetso ho thusa Capel ho ntlafatsa bokhoni ba bona ba ho fana ka tlhahiso e hlahelletseng nakong ea linako tse behiloeng. Ka ho etelletsa pele boiteko ba meralo ea tšebelisano, boiketsetso le ntlafatso e tsoelang pele ea ts'ebetso, Capel e ka lula e le ka pele ho tlhahiso ea HDI e thata-flex PCB le ho fihlela tlhokahalo e ntseng e eketseha ea mapolanka a sebetsang ka bongata le a phahameng a sebetsang ho pholletsa le liindasteri.

Nako ea poso: Sep-15-2023

Morao