Delamination ho PCB e ka lebisa mathateng a bohlokoa a ts'ebetso, haholo-holo meralong e thata-fetohang moo lisebelisoa tse thata le tse tenyetsehang li kopantsoeng. Ho utloisisa mokhoa oa ho thibela delamination ho bohlokoa bakeng sa ho netefatsa bophelo bo bolelele le ho ts'epahala ha likopano tsena tse rarahaneng. Sengoliloeng sena se tla hlahloba malebela a sebetsang bakeng sa ho thibela PCB delamination, ho shebana le PCB lamination, tshebeletsano thepa, le optimized machining parameters.

Ho utloisisa PCB Delamination

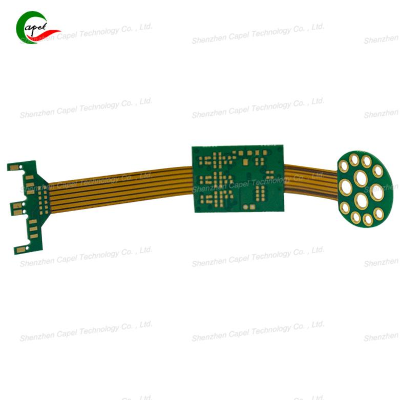

Delamination e etsahala ha likarolo tsa PCB li arohana ka lebaka la mabaka a fapaneng, ho kenyelletsa khatello ea mocheso, ho monya mongobo, le khatello ea mochini. Ho li-PCB tse sa fetoheng, phephetso ea eketseha ka lebaka la mefuta e fapaneng ea thepa e thata le e tenyetsehang. Ka hona, ho netefatsa tšebelisano lipakeng tsa lisebelisoa tsena ke mohato oa pele oa ho thibela delamination.

Etsa bonnete ba hore PCB e lumellana le thepa

Khetho ea thepa e bohlokoa ho thibela delamination. Ha o rala PCB e sa fetoheng, ho bohlokoa ho khetha lisebelisoa tse nang le li-coefficients tse tšoanang tsa katoloso ea mocheso. Tšebelisano ena e fokotsa khatello ea kelello nakong ea libaesekele tse futhumetseng, tse ka lebisang ho delamination. Ho phaella moo, nahana ka sekhomaretsi se sebelisoang ha ho etsoa lamination. Likhomaretsi tsa boleng bo holimo tse etselitsoeng ka ho khetheha lits'ebetso tse thata tsa flex li ka matlafatsa matla a maqhama lipakeng tsa masela.

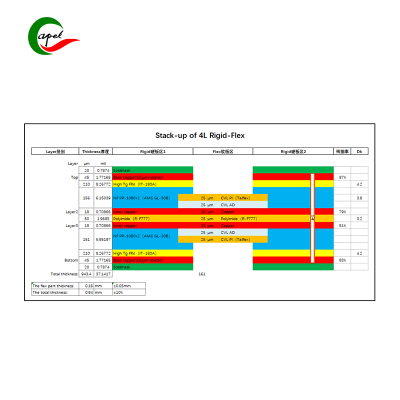

Mokhoa oa ho Lamination oa PCB

Ts'ebetso ea lamination ke mohato oa bohlokoahali tlhahisong ea PCB. Lamination e nepahetseng e tiisa hore lihlopha li khomarelana hantle, ho fokotsa kotsi ea delamination. Mona ke tse ling tsa malebela a sebetsang bakeng sa PCB lamination e sebetsang:

Taolo ea Mocheso le Khatello: Etsa bonnete ba hore ts'ebetso ea lamination e etsoa ka mocheso o nepahetseng le khatello. Mocheso o phahameng haholo o ka senya lisebelisoa, ha khatello e sa lekaneng e ka lebisa ho se khomarelang hantle.

Vacuum Lamination: Ho sebelisa vacuum nakong ea ts'ebetso ea lamination ho ka thusa ho felisa li-bubble tsa moea tse ka bakang matheba a fokolang tlamong. Mokhoa ona o tiisa khatello e ts'oanang ho feta likarolo tsa PCB.

Nako ea ho ikoetlisa: Lumella nako e lekaneng ea ho phekola hore sekhomaretsi se kopane hantle. Ho potlakisa ts'ebetso ena ho ka lebisa ho khomarela ho sa phethahalang, ho eketsa kotsi ea delamination.

Optimized Rigid-Flex PCB Machining Parameters

Mekhatlo ea mochini e bapala karolo ea bohlokoa ho ts'epahalang ea li-PCB tse thata-flex. Mona ke malebela a macha a ntlafalitsoeng a ho thibela delamination:

Mekhoa ea ho Epa: Sebelisa likotoana tse loketseng tsa ho cheka le lebelo ho fokotsa ho hlahisa mocheso nakong ea ho cheka. Mocheso o feteletseng o ka fokolisa sekhomaretsi sa sekhomaretsi 'me sa lebisa ho delamination.

Tsela le ho Seha: Ha u tsamaisa kapa u seha PCB, etsa bonnete ba hore lisebelisoa li bohale ebile li hlokometsoe hantle. Lisebelisoa tse lerootho li ka baka khatello e feteletseng le mocheso, tse senyang botšepehi ba lihlopha.

Phekolo ea Edge: Tšoara ka nepo mathōko a PCB ka mor'a machining. Sena se ka kenyelletsa ho bebofatsa kapa ho tiisa mathōko ho thibela ho kenella ha mongobo, e leng se ka tlatsetsang ho delamination ka nako.

Malebela a Sebetsang a ho Thibela PCB Delamination

Ho phaella maqheka ana a ka holimo, nahana ka malebela a latelang a sebetsang:

Taolo ea Tikoloho: Boloka li-PCB sebakeng se laoloang ho thibela ho kenngoa ha mongobo. Mongobo o ka fokolisa maqhama a sekhomaretsi mme oa lebisa ho delamination.

Teko ea Kamehla: Kenya ts'ebetsong liteko tsa kamehla tsa li-PCB bakeng sa matšoao a delamination nakong ea ts'ebetso ea tlhahiso. Ho lemoha kapele ho ka thusa ho fokotsa mathata pele a ka mpefala.

Koetliso le Tlhokomeliso: Netefatsa hore basebetsi bohle ba amehang ts'ebetsong ea tlhahiso ea PCB ba koetlisetsoa mekhoa e metle bakeng sa lamination le machining. Ho hlokomela lintlha tse tlatsetsang ho delamination ho ka lebisa ho etseng liqeto tse molemo.

Nako ea poso: Oct-31-2024

Morao