Tsebisa:

Tsoelo-pele ea theknoloji lits'ebetsong tsa ho tjhaja betri e ntlafalitse haholo bokhoni ba rona ba ho matlafatsa lisebelisoa tse fapaneng hantle. Leha ho le joalo, ts'ebetso ea ho theha litsamaiso tsena e hloka moralo o hlokolosi, tlhahlobo le prototyping.Blog ena e ikemiselitse ho u fa tataiso e felletseng mabapi le mokhoa oa ho tšoaea boto ea potoloho e hatisitsoeng (PCB) ka kotloloho bakeng sa tšebeliso ea sistimi ea ho tjhaja betri.Ka ho kopanya tsebo ea theory le mehato e sebetsang, o tla hlomelloa ho nts'etsapele li-prototypes tse atlehileng le ho khanna boqapi lebaleng lena le khahlisang.

1. Utloisisa moralo oa mohlala oa PCB oa sistimi ea ho tjhaja betri:

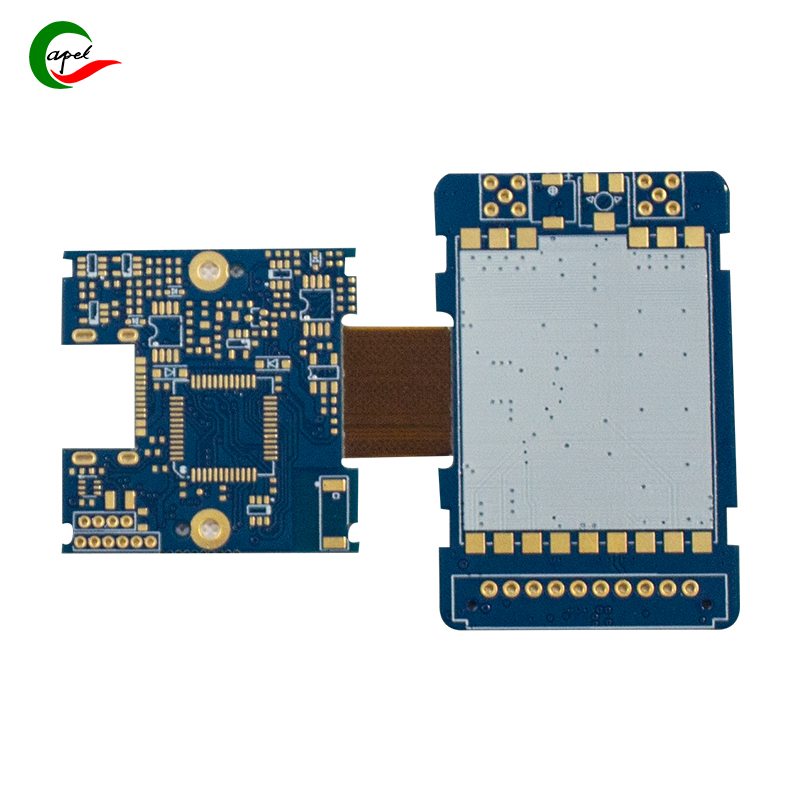

Pele o kenella ts'ebetsong ea prototyping, ho bohlokoa ho tseba metheo ea moralo oa PCB le lits'ebetso tsa ho tjhaja betri. Li-PCB ke motheo oa sesebelisoa leha e le sefe sa elektroniki, ho kenyeletsoa lishaja tsa betri, hobane li fana ka likhokahano tse hlokahalang tsa motlakase lipakeng tsa likarolo. Ho tloaelana le mefuta e fapaneng ea li-PCB tse kang lehlakore le le leng, mahlakoreng a mabeli le li-multi-layer kaha khetho e itšetlehile ka ho rarahana ha tsamaiso.

2. Moralo le moralo oa sistimi ea ho tjhaja betri:

Moralo o atlehileng le moralo o bohlokoa katlehong ea prototyping ea PCB. Qala ka ho hlalosa lipheo tsa sistimi ea ho tjhaja betri le ho khetha hore na e tšehetsa mefuta ea betri. Nahana ka mekhoa ea ho tjhaja (voltage e sa feleng, motlakase o sa feleng, joalo-joalo), nako ea ho tjhaja, bokhoni, likarolo tsa polokeho le lintlha tse ling. Sebelisa software ea ketsiso ho etsa mohlala le ho sekaseka boits'oaro ba sistimi pele u kena karolong ea 'mele ea prototyping.

3. Khetha likarolo tse nepahetseng:

Khetho ea likarolo e ka ama ts'ebetso ea PCB haholo le ho ts'epahala. Khetha likarolo tse tsamaellanang le motlakase le litlhoko tsa hajoale tsa sistimi ea hau ea ho tjhaja. Nahana ka ho sebelisa seketsoana sa boleng bo holimo se kopaneng (IC) se etselitsoeng ka kotloloho lits'ebetso tsa ho tjhaja betri. Ntle le moo, khetha lihokelo tse tšepahalang, li-resistors, li-capacitor le likarolo tse ling tse hlokahalang ho netefatsa ts'ebetso e nepahetseng.

4. Moralo oa moralo le sebopeho sa PCB:

Hang ha khetho ea karolo e felile, ke nako ea ho theha moralo le ho rala sebopeho sa PCB. Sebelisa lisebelisoa tsa software tse kang Altium Designer, Eagle kapa KiCad ho theha meralo e felletseng e bonts'ang likhokahano tsohle lipakeng tsa likarolo. Etsa bonnete ba ho ngola le ho hlaka hore ho be bonolo ho utloisisa.

Kamora hore moralo o phetheloe, rala moralo oa PCB. Etsa bonnete ba hore likarolo li behiloe ka nepo, ho nahanoa ka lintlha tse kang ho qhalana ha mocheso, bolelele ba ho bala, le botšepehi ba matšoao. Ela hloko ka ho khethehileng lintlha tsa khokahanyo ea betri ho etsa bonnete ba hore li tiile 'me li khona ho sebetsana le maemo a hlokahalang a hona joale le a voltage.

5. Hlahisa lifaele tsa Gerber:

Kamora hore moralo oa PCB o phetheloe, faele ea Gerber e hlahisoa. Lifaele tsena li na le tlhahisoleseding eohle eo moetsi a e hlokang ho hlahisa PCB ho ea ka litlhaloso tsa hau. Hlahloba moralo ka botlalo ho netefatsa ho nepahala le ho lumellana le litataiso tsa moetsi.

6. Prototyping le liteko:

Hang ha o fumana PCB e entsoeng, o ka kopanya le ho leka mohlala. Qala ka ho tlatsa boto ka likarolo tse khethiloeng, ho netefatsa polarity e nepahetseng le ho lumellana. Hlahloba solder ka hloko 'me u ele hloko ka hloko likarolo tsa bohlokoa tse kang potoloho ea matla le ho tjhaja IC.

Kamora kopano, mohlala o lekoa ho sebelisoa software e nepahetseng le lisebelisoa tsa tlhahlobo. Lekola ts'ebetso ea ho tjhaja ho netefatsa hore e latela maemo a boletsoeng esale pele. Lekola ho phahama ha mocheso, botsitso ba hona joale, le ts'ebetso ka kakaretso. Etsa liphetoho tse hlokahalang le lintlafatso tse pheta-phetoang ha ho hlokahala.

7. Pheta le ho ntlafatsa:

Prototyping ke ts'ebetso e pheta-phetoang. Sekaseka liphetho tsa liteko ho bona mefokolo kapa libaka tseo u ka li ntlafatsang le ho ntlafatsa moralo oa hau oa PCB ka nepo. Sena se ka kenyelletsa ho fetola tlhophiso ea likarolo, ho lata litsela, kapa ho khetha likarolo tse fapaneng. Mokhahlelo oa teko o phetoa ho fihlela ts'ebetso e lakatsehang le ho tšepahala ho finyelloa.

Ha re phethela:

Sistimi ea ho tjhaja betri Ho etsa prototyping ea PCB ho hloka moralo o hlokolosi, moralo le netefatso. Ka ho utloisisa metheo ea PCB, khetho ea leano la likarolo, moralo o hlokolosi oa moralo le moralo oa PCB, o lateloa ke tlhahlobo e phethahetseng le ho pheta-pheta, o ka theha sistimi e sebetsang hantle le e tšepahalang ea ho tjhaja betri. Hopola, ho tsoela pele ho ithuta le ho lula u le ka holim'a theknoloji ea morao-rao ho tla u thusa ho sutumelletsa meeli ea boqapi sebakeng sena se matla. Thabela prototyping!

Nako ea poso: Oct-29-2023

Morao