Tsebisa:

Rea u amohela posong e 'ngoe ea li-blog ho tsoa ho Capel, sebapali se hlahelletseng indastering ea boto ea potoloho bakeng sa lilemo tse 15 tse fetileng.Sehloohong sena, re tla tšohla monyetla le melemo ea ho sebelisa likarolo tse holim'a metsi ho merero ea prototyping ea boto ea PCB.Joalo ka moetsi ea ka sehloohong, re ikemiselitse ho fana ka tlhahiso e potlakileng ea prototyping ea PCB, lits'ebeletso tsa kopano ea boto ea potoloho le tharollo e felletseng ea ho emisa litlhoko tsohle tsa boto ea potoloho.

Karolo ea 1: Ho Utloisisa Metheo ea Likarolo tsa Surface Mount

Lisebelisoa tsa Surface Mount, tse tsejoang hape e le likarolo tsa SMD (surface mount device) li ntse li ata haholo indastering ea lisebelisoa tsa elektroniki ka lebaka la boholo ba tsona bo nyane, kopano e ikemetseng le litšenyehelo tse tlase. Ho fapana le likarolo tsa setso ka lesoba, likarolo tsa SMD li behiloe ka kotloloho holim'a PCB, li fokotsa litlhoko tsa sebaka le ho nolofalletsa lisebelisoa tsa elektroniki tse nyane.

Karolo ea 2: Melemo ea ho sebelisa likarolo tsa holim'a metsi ho prototyping ea boto ea PCB

2.1 Tšebeliso e nepahetseng ea sebaka: Boholo bo kopanetsoeng ba likarolo tsa SMD bo nolofalletsa likarolo tse phahameng, ho lumella baqapi ho etsa lipotoloho tse nyenyane, tse bobebe ntle le ho senya ts'ebetso.

2.2 Ts'ebetso e ntlafetseng ea motlakase: Theknoloji ea holim'a marulelo e fana ka litsela tse khutšoanyane tsa morao-rao, ho fokotsa inductance ea parasitic, ho hanyetsa le bokhoni. Ka lebaka leo, sena se ntlafatsa botšepehi ba matšoao, se fokotsa lerata, 'me se ntlafatsa ts'ebetso ea motlakase ka kakaretso.

2.3 Katleho ea Litšenyehelo: Likarolo tsa SMD li ka iketsetsa habonolo nakong ea kopano, kahoo li fokotsa nako ea tlhahiso le litšenyehelo. Ho phaella moo, boholo ba bona bo fokolang bo fokotsa litšenyehelo tsa ho romela le ho boloka.

2.4 Matla a matla a mochine: Hobane likarolo tsa holim'a holim'a metsi li khomaretsoe ka ho toba holim'a PCB, li fana ka botsitso bo matla ba mochine, ho etsa hore potoloho e be khahlanong le khatello ea tikoloho le ho sisinyeha.

Karolo ea 3: Maikutlo le Liphephetso tsa ho hlahisa likarolo tsa Surface Mount ho Prototyping ea Boto ea PCB

3.1 Litaelo tsa Moqapi: Ha ho kenyelletsa likarolo tsa SMD, baqapi ba tlameha ho khomarela litataiso tse tobileng ho netefatsa hore ho na le sebopeho se nepahetseng, ho lumellana ha likarolo, le botšepehi ba soldering nakong ea kopano.

Theknoloji ea 3.2 Soldering: Likarolo tsa holim'a marulelo hangata li sebelisa theknoloji ea reflow soldering, e hlokang lisebelisoa tse khethehileng le profil ea mocheso e laoloang. Tlhokomelo e eketsehileng e tlameha ho nkoa e le ho qoba ho chesa haholo kapa ho se phethe ho kopanya ha solder.

3.3 Boteng ba Karolo le Khetho: Le hoja likarolo tsa holim'a metsi li fumaneha hohle, ho bohlokoa ho nahana ka lintlha tse kang ho fumaneha, nako ea ho etella pele, le ho lumellana ha u khetha likarolo bakeng sa prototyping ea boto ea PCB.

Karolo ea 4: Kamoo Capel e ka u thusang ho kopanya likarolo tsa holim'a thaba

Ha re le Capel, re utloisisa bohlokoa ba ho lula re tseba tsoelo-pele ea morao-rao ea theknoloji. Ka boiphihlelo ba rona bo batsi ho PCB board prototyping le kopano, re fana ka ts'ehetso e felletseng le litharollo tsa moetlo ho kopanya likarolo tsa holim'a holim'a meralo ea hau.

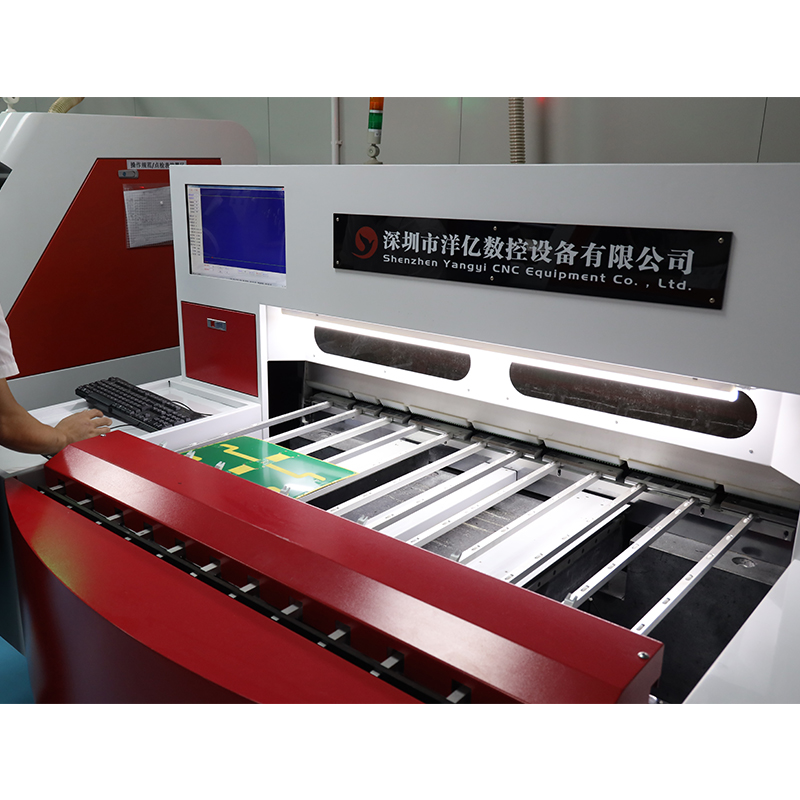

4.1 Setsi sa Tsoelo-pele sa Tlhahiso: Capel e na le setsi sa morao-rao sa tlhahiso ea thepa se nang le mechine e tsoetseng pele e re nolofalletsang ho sebetsana le mekhoa e rarahaneng ea ho kopanya holim'a holim'a metsi ka mokhoa o nepahetseng le ka katleho.

4.2 Theko ea Likarolo: Re thehile litšebelisano tsa maano le bafani ba thepa ba tšepahalang ho netefatsa hore re fana ka lisebelisoa tsa boleng bo holimo bakeng sa projeke ea hau ea boto ea PCB ea prototyping.

4.3 Sehlopha sa Tsebo: Capel e na le sehlopha sa litsebi le lienjineri tse nang le litsebo tse phahameng tse nang le boiphihlelo ba ho sebetsana le mathata a amanang le ho kopanya likarolo tsa holim'a marulelo. Kholiseha hore morero oa hau o tla sebetsoa ka hloko le ka botsebi bo boholo.

Ha re phethela:

Ho sebelisa likarolo tsa holim'a holim'a prototyping ea boto ea PCB ho ka tlisa melemo e mengata, joalo ka botsitso bo boholo ba mochini, ts'ebetso e ntlafetseng ea motlakase, ts'ebetso e eketsehileng le katleho ea litšenyehelo. Ka ho sebelisana 'moho le Capel, moetsi ea ka sehloohong indastering ea boto ea potoloho, o ka sebelisa boiphihlelo ba rona, lisebelisoa tse tsoetseng pele tsa tlhahiso le litharollo tse felletseng tsa ho nolofatsa leeto la hau la ho kopanya ka katleho holim'a thaba. Ikopanye le rona kajeno ho ithuta hore na re ka u thusa joang ka boiteko ba hau ba ho etsa prototyping ea boto ea PCB.

Nako ea poso: Oct-16-2023

Morao