Tsebisa:

Prototyping e potlakileng ea PCB, haholo-holo ho kopanngoa ha likarolo tsa molumo o motle, ho hloka botsebi le ho nepahala. Ha theknoloji e ntse e tsoela pele, tlhahiso ea boto ea potoloho e ntse e rarahana le ho ba thata. Ka lilemo tse fetang 15 tsa boiphihlelo tšimong, Capel ke k'hamphani e etelletseng pele e kopanyang boiphihlelo ba tekheniki le boqapi bo sa feleng ho fana ka tharollo e ke keng ea bapisoa.Ka poso ena ea blog, re tla kenella ka har'a mekhoa, liphephetso, le mekhoa e metle bakeng sa prototyping e potlakileng ea PCB e nang le likarolo tse hlakileng, ha re ntse re hlahloba bokhoni ba Capel ba ho etsa lintho bo ke keng ba bapisoa.

Ithute ka likarolo tsa molumo o motle:

Likarolo tsa molumo o hlakileng li bapala karolo ea bohlokoa lisebelisoeng tsa sejoale-joale tsa elektroniki kaha li thusa ho tsamaisa ka lebelo le phahameng, ho etsa hore ho be bonolo, le ho ntlafatsa ts'ebetso. Sebaka sa phini ea likarolo tsena se ka tlase ho 0.8 mm, e leng se etsang hore ho beoa ha bona hantle ho PCB ho be thata le ho feta. Ka hona, ho bohlokoa ho sebelisa mekhoa le mekhoa e ikhethileng ho netefatsa prototyping e atlehileng.

Lisebelisoa tse tsoetseng pele tsa moralo oa PCB bakeng sa prototyping e potlakileng:

E le hore u sebelise ka mokhoa o nepahetseng likarolo tsa molumo o motle bakeng sa prototyping e potlakileng ea PCB, lisebelisoa tse tsoetseng pele tsa moralo oa PCB li tlameha ho sebelisoa. Lisebelisoa tse kang Altium Designer, Eagle kapa KiCad li fana ka likarolo tse kang ho beha likarolo hantle, tlhahlobo ea botšepehi ba matšoao le mesebetsi ea ho iketsetsa litsela, e thusang haholo ho ntlafatsa sebopeho. Sehlopha sa litsebi tsa Capel se na le tsebo ea ho sebelisa lisebelisoa tsena ho netefatsa boemo bo phahameng ka ho fetisisa ba ho nepahala nakong ea prototyping.

Lintho tseo u lokelang ho li ela hloko ha u theha likarolo tse nepahetseng tsa molumo:

Ha o rala sebopeho sa PCB se nang le likarolo tsa molumo o hlakileng, ho bohlokoa ho nahana ka lintlha tse itseng ho netefatsa ts'ebetso e nepahetseng le ho etsoa. Lintlha tse ling tsa bohlokoa ke tsena:

1. Moqapi oa liphahlo: Boholo ba liphahlo le sebōpeho ke lintlha tsa bohlokoa bakeng sa soldering e nepahetseng le puisano e ntle ea motlakase le karolo.Baenjiniere ba nang le phihlelo ba Capel ba qapa ka hloko li-pads ho latela litlhoko tse khethehileng tsa likarolo tse ntle, tse fanang ka solderability e babatsehang le ho tšepahala.

2. Mesaletsa le tsela: Matshwao a lebelo le phahameng a fetang dikarolong tse bopehileng hantle a hloka tsela e hlokolosi ho fokotsa lerata, ho fokotsa matshwao le ho se tsamaisane.E nepahetseng ka ho beha le mekhoa ea ho latela mohlala joalo ka ho bapisa bolelele le mefuta e fapaneng ea litsela li thusa ho boloka botsitso ba matšoao.

3. Tsamaiso ea mocheso: Likarolo tse ntle tsa molumo li hlahisa mocheso o mongata nakong ea ts'ebetso.Tlhokomelo e lekaneng ea mocheso ka ho sebelisa litšepe tsa mocheso, likhahla tsa mocheso, kapa ho beha liphahlo tsa mocheso ka tlas'a likarolo ke tsa bohlokoa ho thibela ho futhumala le ho netefatsa ho tšepahala ha nako e telele.

4. Design for Manufacturing (DFM): Sebetsa le sehlopha se nang le boiphihlelo sa Capel nakong ea mokhahlelo oa moralo oa PCB ho netefatsa hore likhetho tsa moralo li lumellana le bokhoni ba bona ba tlhahiso.Ho ntlafatsa meralo bakeng sa tlhahiso ho thusa ho fokotsa liphoso tsa prototyping le ho ntlafatsa ts'ebetso e akaretsang ea ts'ebetso.

Liphephetso le tharollo ea prototyping:

Prototyping e potlakileng ea PCB e nang le likarolo tse hlakileng e hlahisa mathata a khethehileng. Leha ho le joalo, ka boiphihlelo bo pharaletseng ba Capel le boitseanape bo sebetsang, mathata ana a ka fokotsoa habonolo.

1. Ho fumana likaroloana: Likarolo tsa molumo o hlakileng hangata li na le nako e telele ea ho etella pele kapa ho fumaneha ho fokolang, ho etsa hore ho be le phephetso ho feta.Marang-rang a mangata a mofani oa thepa ea Capel le likamano tse matla li tiisa ho fihlella ka nako ea likarolo tsa boleng bo phahameng, ho netefatsa tlhahiso e sa sitisoeng.

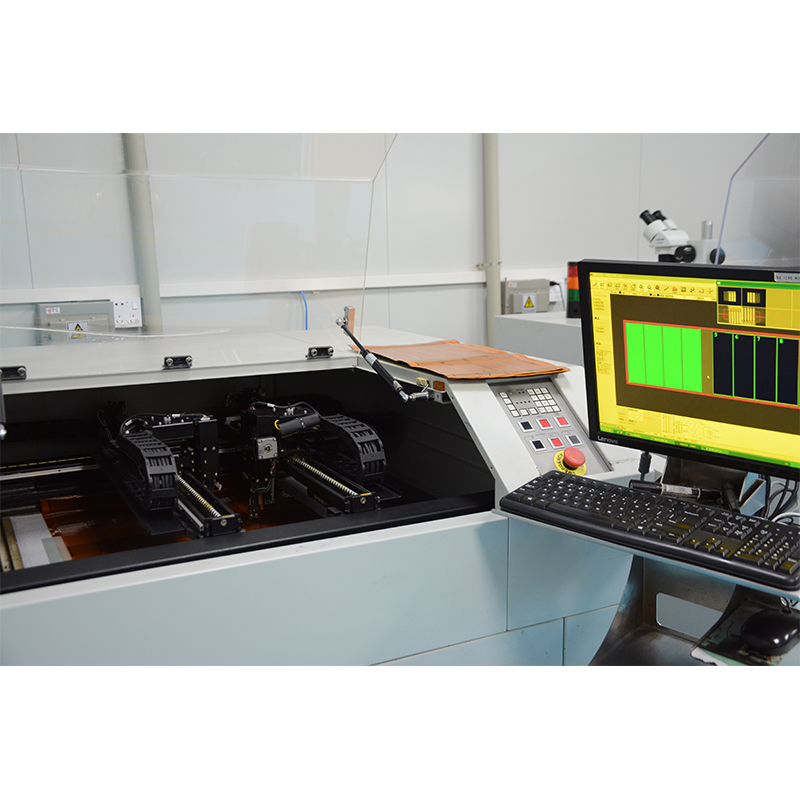

2. Welding: Ho tjheseletsa likarolo tsa sekontiri se setle ho hloka ho nepahala ho phahameng.Capel e sebelisa mahlale a tsoetseng pele a kopano joalo ka lionto tsa reflow tse nang le li-profiles tsa mocheso o laoloang, mechini e ikemetseng ea ho beha le tlhahlobo ea solder paste ho netefatsa hore ho na le li-solder tse phethahetseng.

3. Teko le Tlhahlobo: Nakong ea mohato oa prototyping, tlhahlobo e phethahetseng le tlhahlobo e bohlokoa ho tseba mefokolo e ka bang teng joalo ka marokho a solder, opens, kapa tombstones.Capel e etsa tlhahlobo e matla ea boleng ka ho sebelisa automated optical inspection (AOI), tlhahlobo ea X-ray le tlhahlobo ea moeli oa moeli ho netefatsa hore li-prototype ha li na sekoli.

Bokhoni ba ho hlahisa ba Capel bo ke keng ba lekanngoa:

Boitlamo ba Capel ho boleng bo holimo le tsoelo-pele e tsoelang pele ea theknoloji bo entse hore e be molekane ea tšeptjoang indastering ea tlhahiso ea PCB.Boitseanape bo boholo ba k'hamphani, bo tlatsitsoeng ke lisebelisoa tsa morao-rao tsa tlhahiso le ho latela litekanyetso tsa boleng ba machaba, bo e nolofalletsa ho fana ka bokhoni bo ke keng ba lekanngoa ba tlhahiso.

Ha re phethela:

Ho etsa prototyping ka potlako ea li-PCB ho sebelisa likarolo tsa molumo o hlakileng ho hloka tsebo e khethehileng le tsebo. Ka lilemo tse 15 tsa boiphihlelo, boiphihlelo le boikitlaetso ba boqapi bo tsoelang pele, Capel e maemong a ikhethang ho tobana le liphephetso tsena le ho feta tebello.Ho sebetsa le Capel ho netefatsa li-prototypes tse se nang sekoli, mekhoa e metle ea tlhahiso le tšehetso e ke keng ea lekanngoa sethaleng se seng le se seng sa morero. Tšepa litsebi tsa Capel ho etsa hore mohlala oa hau oa PCB o phele ha o ntse o fihlela litlhoko tse boima ka ho fetisisa tsa indasteri ea sejoale-joale ea elektroniki.

Nako ea poso: Oct-18-2023

Morao