Joang ho sebetsana ka katleho le likhohlano lipakeng tsa lithapo tsa ka hare le likhokahano tsa marang-rang tsa kantle ho liboto tsa potoloho tse hatisitsoeng ka mekhahlelo e mengata?

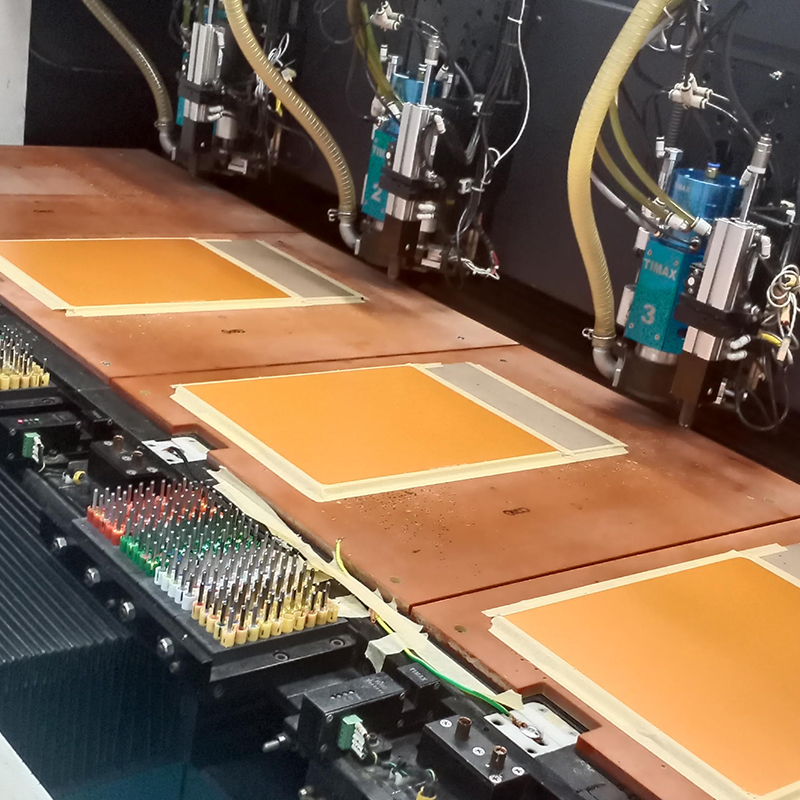

Lefats'eng la lisebelisoa tsa elektronike, liboto tsa potoloho tse hatisitsoeng (PCBs) ke mokhoa oa bophelo o hokahanyang likarolo tse fapaneng hammoho, ho lumella puisano le ts'ebetso e se nang moeli. Li-PCB tsa Multilayer, haholo-holo, li ntse li tsebahala haholo ka lebaka la ts'ebetso ea tsona e ntlafalitsoeng le bongata bo phahameng ba likarolo. Leha ho le joalo, ho rarahana ha bona ho baka phephetso ea ho laola likhohlano lipakeng tsa mela e ka hare le likhokahano tsa pad kantle.Ho blog ena, re tla hlahloba maano a sebetsang a ho sebetsana le likhohlano tsena le ho netefatsa ts'ebetso e nepahetseng le ts'epo.

1. Utloisisa khohlano:

Ho rarolla bothata leha e le bofe ka katleho, ke habohlokoa ho utloisisa sesosa sa bona. Likhohlano lipakeng tsa mela e ka hare le likhokahano tsa marang-rang tsa kantle li hlaha ka lebaka la litlhoko tsa bona tse fapaneng. Mesaletsa ea ka hare e hloka bophara bo fokolang le sebaka sa sebaka bakeng sa litsela tse ngata haholo, ha li-pads tse ka ntle li hloka boholo bo boholo bakeng sa ho kopanya likaroloana le likhokahano tsa 'mele. Likhohlano pakeng tsa litlhoko tsena li ka lebisa mathateng a sa tšoaneng, a kang ho lahleheloa ke botšepehi ba pontšo, ho hlahisa mocheso o feteletseng, esita le lifupi tsa motlakase. Ho elelloa le ho utloisisa khohlano ena ke mohato oa pele oa ho fumana tharollo.

2. Ntlafatsa moralo:

Senotlolo sa ho laola likhohlano ke ho ntlafatsa moralo oa li-PCB tse nang le mekhahlelo e mengata. Sena se ka finyelloa ka maano a latelang:

- Thero e hlokolosi ea li-stackup:Stackup e nahannoeng hantle e bohlokoa ho leka-lekanya litlhoko tsa mesaletsa ea ka hare le liphahlo tsa kantle. Ho beha likarolo tsa matšoao a ka hare haufi le sefofane se bohareng sa PCB stackup ho lumella ho thibela ho laoloa le ho boloka botšepehi ba matšoao. Ka lehlakoreng le leng, ho beha liphahlo tse ka ntle holim'a lera le ka ntle ho fana ka monyetla o motle oa ho fumana karolo.

- Mekhoa e metle ea li-wiring:Sebelisa mekhoa ea likhoele tse kang li-microvias le li-vias tse foufetseng ho hokahanya mela e ka hare ho li-pads tse ka ntle. Bophahamo bo bonyenyane ba microvia bo fana ka sekhahla se phahameng sa ho tsamaisa ntle le ho senya boleng ba matšoao. Li-vias tse foufetseng li kopanya lihlopha tse 'maloa feela tse bapileng, ho fana ka litsela tse ka hare ho tsela e tobileng ea liphahlo tsa ka ntle ntle le hore u haole le PCB eohle.

- Litlhaloso tse amanang le Impedans:Ho se lumellane pakeng tsa mela e ka hare le liphaephe tsa kantle ho ka baka ponts'o ea matšoao le ho senyeha ha ts'ebetso. Sebelisa mekhoa e ts'oanang ea ho ts'oara li-impedance joalo ka dielectric tse laoloang, bophara bo ntlafalitsoeng ba trace, le pheliso e nepahetseng ho netefatsa matšoao a ts'oanang ho PCB eohle.

- Taolo ea Thermal:Pholiso e lekaneng e bohlokoa bakeng sa ts'ebetso e tšepahalang ea PCB. Moralo PCBs le vias mogote ho ka tsela e atlehileng fetisetsa mocheso hlahisoang ke likarolo teng haufi le mapheo kantle ho le dikarolo ka hare.

3. Tšebelisano le puisano:

Ho laola likhohlano moralong oa PCB hangata ho hloka tšebelisano lipakeng tsa bankakarolo ba fapaneng, joalo ka baenjiniere ba meralo, bahlahisi ba PCB, le litsebi tsa kopano. Ho boloka mecha ea puisano e sebetsang ho bohlokoa ho netefatsa hore motho e mong le e mong o utloisisa litšitiso le litlhoko tsa moralo. Likopano tsa kamehla le lipuisano li ka thusa ho hokahanya litebello le ho rarolla likhohlano ka ho arolelana mathata.

4. Ketsiso le tlhahlobo:

Sebelisa ketsiso le lisebelisoa tsa tlhahlobo ho netefatsa ts'ebetso ea motlakase ea moralo oa hau, botšepehi ba matšoao le litšobotsi tsa mocheso. Lisebelisoa tsena li fana ka kutloisiso e felletseng ea boitšoaro ba PCB, ho thusa ho tseba likhohlano tse ka bang teng le meralo e ntle pele e etsoa. Simulation e boetse e thusa ho ntlafatsa mats'oao a mats'oao le ho etsa bonnete ba hore ho bapaloa ho senyehe lipakeng tsa mela e kahare le lipampiri tsa kantle.

5. Prototyping letekolo:

Prototyping le liteko ke mehato ea bohlokoa ho netefatsa ts'ebetso ea moralo le ho rarolla likhohlano tse setseng. Ka ho beha leihlo PCB ka hloko nakong ea liteko, baenjiniere ba ka tseba libaka tseo likhohlano li ntseng li tsoela pele le ho ntlafatsa moralo le ho feta. Prototyping e boetse e fana ka monyetla oa ho netefatsa mekhoa ea tsamaiso ea mocheso le ho netefatsa botšepehi ba PCB ka kakaretso.

Ka kakaretso

Ho laola likhohlano lipakeng tsa mesaletsa ea ka hare le likhokahano tsa marang-rang tsa kantle ho li-PCB tse ngata ho hloka mokhoa o akaretsang o kopanyang mekhoa e ntlafalitsoeng ea meralo, puisano e sebetsang, lisebelisoa tsa papiso le tlhahlobo, le tlhahlobo e phethahetseng. Ka ho utloisisa lisosa tsa likhohlano le ho kenya ts'ebetsong maqheka ao ho buisanoeng ka 'ona, u ka finyella moralo o leka-lekaneng o tiisang hore ts'ebetso eohle, botšepehi le ts'ebetso ea multilayer PCB ea hau.

Nako ea poso: Sep-26-2023

Morao