Fumana hore na theknoloji e tsoetseng pele ea tlhahiso ea FPC-Flex PCB ea Capel e kopana joang le phephetso ea ho hlahisa2-layer Flex PCBs bakeng sa koloi e ncha ea matlaliboto tsa potoloho ea tšireletso ea betri. Ikakhetse ka setotsoana matleng a botekgeniki le phello ea indasteri ea thuto ena e atlehileng.

Tsebisa

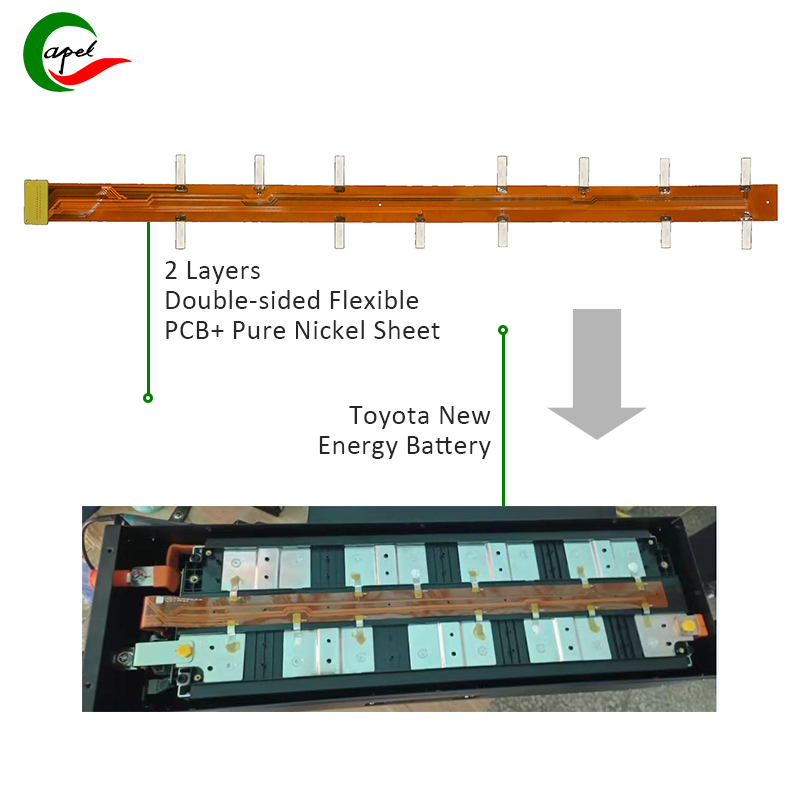

Likoloi tse ncha tsa motlakase tse kang likoloi tsa motlakase le likoloi tsa lebasetere li ka pele ho lipalangoang tse se nang tikoloho. Ka tsoelo-pele ea theknoloji, likoloi tse ncha tsa motlakase li na le litlhoko tse ntseng li eketseha tsa lisebelisoa tsa elektroniki tse sebetsang hantle, tse tšepahalang le tse sebetsang hantle. Li-PCB tse feto-fetohang (li-circuits tse hatisitsoeng tse feto-fetohang) li bapala karolo ea bohlokoa likoloing tsena, haholo lits'ebetsong tse joalo ka liboto tsa potoloho ea ts'ireletso ea betri. Sengoliloeng sena, re tla shebisisa ka botebo kamoo theknoloji ea tšebetso ea Capel e netefalitsoeng ea FPC le litharollo tse ncha li rarollang liqholotso tse ikhethileng indastering tseo bareki ba tobaneng le tsona likoloing.ho etsa koloi e ncha ea matla a 2-layer flexible PCB.

Mathata a bareki

Moreki, moetsi ea ka sehloohong indastering ea likoloi tse ncha tsa matla, o ile a tobana le mathata a maholo ha a hlahisa li-PCB tse feto-fetohang tse 2 bakeng sa liboto tsa potoloho ea betri. Litlhoko tse khethehileng tsa PCB tse feto-fetohang li kenyelletsa:

Lisebelisoa: Li-PCB tse feto-fetohang li hloka ho hahoa ka polyimide (PI) e le karoloana le mesaletsa ea koporo le sekhomaretsi e le lera la ho kopanya.

Bophara ba mela le sebaka sa mela: Bophara ba mela le sebaka sa mela e lokela ho nepahala ho isa ho 0.2mm/0.25mm ho netefatsa bots'epehi le ts'ebetso ea potoloho.

Botenya ba poleiti: Botenya ba poleiti bo hlalositsoe e le 0.25mm +/- 0.03mm, e hlokang ho lateloa ka thata le mamello ea boholo.

Minimum Hole: PCB e hloka bonyane ba lesoba la boholo ba 0.1 mm ho amohela likarolo tse hlokahalang.

Kalafo ea Bokaholimo: Phekolo ea bokaholimo ba Electroless Nickel Immersion Gold (ENIG) e laetsoe bakeng sa conductivity ea eona e ntle haholo le ho hanyetsa kutu.

Mamello: Bareki ba hloka mamello e tiileng ea ± 0.1mm ho fihlela litekanyo tse nepahetseng le tse nepahetseng tsa boto.

Litharollo tsa Capel le bokhoni ba tekheniki

Sehlopha se nang le boiphihlelo sa Capel sa baenjiniere ba FPC se sekaseka litlhoko tsa bareki ka hloko le ho rala litharollo tse ncha ho fihlela le ho feta litlhoko tsa projeke. Mona ke kamoo bokhoni ba Capel ba tekheniki le boqapi bo bonts'ang katleho ea bona ho sebetsana le mathata a bareki:

Khetho e Phahameng ea Lisebelisoa le Theko: Tsebo e tebileng ea Capel ea thepa le litšoaneleho tsa ts'ebetso ea polyimide, koporo le thepa e khomarelang e etsa hore ho khethoe ka hloko le ho reka thepa. Lisebelisoa tsa boleng bo holimo li khethiloe ho netefatsa ho ts'epahala, ho tenyetseha le botsitso ba mocheso oa li-PCB tse tenyetsehang, tse bohlokoa bakeng sa lits'ebetso tse ncha tsa motlakase.

Mekhoa ea Tlhahiso e nepahetseng: Mehaho e tsoetseng pele ea tlhahiso ea Capel le tsebo ea ho etsa litšoantšo le mekhoa ea tlhahiso ea FPC e thusa ho kenya ts'ebetsong ka mokhoa o nepahetseng oa bophara ba mela e boletsoeng, ho arohana ha mela, botenya ba boto le boholo ba masoba. Lisebelisoa tsa morao-rao le mehato e thata ea ho laola boleng li sebelisoa ho finyella ho nepahala le ho tsitsa ho hlokahalang bakeng sa PCB ka 'ngoe e tenyetsehang.

Phekolo e Phahameng ka ho Fetisisa: Ho sebelisoa ha Electroless Nickel Immersion Gold (ENIG) kalafo ea holim'a metsi e etsoa ka mokhoa o nepahetseng ka ho fetisisa le ho latela litekanyetso tsa indasteri. Ts'ebetso ea kalafo ea Capel e fana ka conductivity, solderability le durability e hlokahalang ho fihlela litlhoko tse thata tsa lisebelisoa tsa elektronike tsa morao-rao tsa likoloi.

Taolo ea Mamello le Tlhokomelo ea Boleng: Boitlamo ba Capel ba ho boloka mamello e tiileng ea ± 0.1mm e bontšoa ka mekhoa e hlokolosi ea netefatso ea boleng. Mohato o mong le o mong oa ts'ebetso ea tlhahiso o hlahlojoa ka thata ho netefatsa hore PCB e phethiloeng ea 2-layer e na le ho nepahala le ho ts'epahala, ho fihlela litekanyetso tse thata tsa indasteri e ncha ea likoloi.

Tlhahlobo ea Taba: Katleho ea Bareki le Tšusumetso ea Indasteri

Tšebelisano e atlehileng ea Capel le bareki e hlahisitse li-PCB tsa boleng bo holimo tsa 2-layer tse feto-fetohang tse fetang tebello ea indasteri. Ts'ebetso e matla le ho nepahala ha li-PCB tse feto-fetohang li entse tlatsetso e kholo ho liboto tse ncha tsa ts'ireletso ea betri ea koloi ea bareki, ho ntlafatsa polokeho le katleho ea litsamaiso tsa motlakase oa koloi.

Matla a tekheniki le popontshwa tse kenyeleditsweng ho thekenoloji ya tshebetso ya FPC e hodileng ya Capel di ne di le bohlokwa ho tsamaiseng projeke ena ho fihlela sephetho se setle. Bokhoni ba Capel ba ho fana ka litharollo tsa PCB tse feto-fetohang khafetsa ka har'a mamello e thata le litlhoko tse ikhethang tsa thepa li bonts'a matla a Capel sebakeng sena. Tšebeliso ea ts'ebelisano ena e fetela ka nģ'ane ho katleho e tobileng ea bareki 'me e totobatsa karolo e tsoetseng pele ea tlhahiso ea FPC ho ntšetseng pele nts'etsopele ea indasteri e ncha ea likoloi tsa eneji.

Boinehelo ba Capel ba ntlafatso e tsoelang pele le boqapi ba prototyping le tlhahiso ea FPC bo ipakile bo thusa ho fihlela litlhoko tse lulang li fetoha tsa lekala la matla a macha a likoloi. Boithuto bona bo bonts'a boitlamo ba Capel ba ho fana ka litharollo tse tšepahalang, tse sebetsang hantle le tse ikhethileng ho phahamisa boemo ba tlhahiso e feto-fetohang ea PCB 'marakeng oa likoloi tse ncha tse ntseng li hola ka potlako.

Mokhoa o Mocha oa Tlhahiso ea Koloi ea Matla a PCB

Ha re phethela

Sebakeng se matla sa mahlale a macha a matla a likoloi, karolo ea prototyping le tlhahiso ea FPC-Flex PCB e ke ke ea khelloa fatše. Lithuto tsa katleho tsa Capel li bonts'a bokhoni ba tekheniki le boqapi bo tšehetsang theknoloji ea ts'ebetso ea FPC. Ka ho rarolla phephetso e khethehileng ea ho hlahisa li-PCB tse feto-fetohang tsa 2-layer bakeng sa liboto tse ncha tsa tšireletso ea betri ea koloi ea matla, Capel ha e bontše feela bokhoni ba eona empa e boetse e kenya letsoho ntlafatsong ea lisebelisoa tsa motlakase tsa likoloi.

Ha indasteri e ntse e tsoela pele ho fetoha, tšebelisano e se nang moeli pakeng tsa Capel le bareki ba eona e bontša bokhoni ba ho rarolla mathata a FPC ho khanna mekhoa e mecha, e sebetsang hantle le e sireletsehileng likoloing tse ncha tsa matla. Tlhahlobo ea taba e totobatsa bohlokoa ba boitseanape ba botekgeniki, tlhahiso e nepahetseng le boitlamo bo sa thekeseleng ba boleng ba tikoloho e lulang e fetoha ea elektronike ea likoloi. Ka filosofi ea eona ea bareki le ho phehella bokhabane, Capel e ntse e tsoela pele ho beha litekanyetso tse ncha bakeng sa tlhahiso ea FPC-Flex PCB indastering e ncha ea likoloi tsa matla.

Sengoliloeng sena se fana ka lintlha tsa bohlokoa mabapi le kamano e teng lipakeng tsa theknoloji ea FPC-Flex PCB le bokamoso bo bocha ba matla a likoloi, ho beha Capel e le moetapele oa ho fana ka litharollo tse ncha tsa ho matlafatsa moloko o latelang oa lipalangoang tse se nang tikoloho.

Nako ea poso: Feb-27-2024

Morao