Indastering ea kajeno ea tlholisano ea elektronike, ho na le tlhokahalo e ntseng e hola ea liboto tsa potoloho tse hatisitsoeng tse nchafalitsoeng (PCBs). Ha indasteri e ntse e hola, ho joalo le ka tlhokahalo ea li-PCB tse ka mamellang maemo a fapaneng a tikoloho le ho fihlela litlhoko tsa lisebelisoa tse rarahaneng tsa elektroniki. Mona ke moo mohopolo oa flex rigid-flex PCB o kenang tšebetsong.

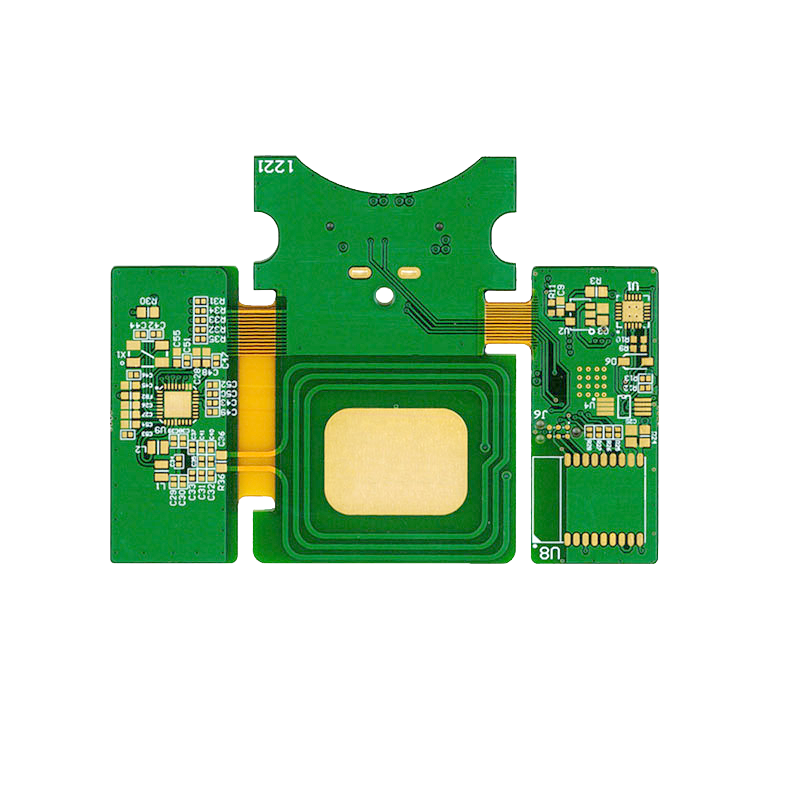

Li-Rigid-flex board li fana ka motsoako o ikhethang oa lisebelisoa tse thata le tse tenyetsehang, tse etsang hore e be tse loketseng bakeng sa lits'ebetso tse hlokang ho tšoarella le ho feto-fetoha ha maemo. Liboto tsena li fumaneha hangata lisebelisoa tsa bongaka, litsamaiso tsa sefofane, le lits'ebetso tse ling tse tšepahalang haholo.

Taolo ea impedance ke karolo ea bohlokoa e amang haholo ts'ebetso ea mapolanka a rigid-flex. Impedance ke khanyetso eo potoloho e fanang ka eona ho phallo ea alternating current (AC). Taolo e nepahetseng ea impedance e bohlokoa kaha e netefatsa phetisetso ea mats'oao e tšepahalang mme e fokotsa tahlehelo ea matla.

Ho blog ena, Capel e tla hlahloba lintlha tse hlano tse ka amang haholo taolo ea impedance ea mapolanka a thata-thata. Ho utloisisa lintlha tsena ho bohlokoa ho baqapi le bahlahisi ba PCB ho fana ka lihlahisoa tsa boleng bo holimo tse fihlelang litlhoko tsa lefatše la kajeno le tsamaisoang ke theknoloji.

1. Li-substrates tse fapaneng li tla ama boleng ba impedance:

Bakeng sa Flex Rigid-Flex PCB, phapang ea thepa ea motheo e na le tšusumetso ho boleng ba impedance. Libotong tse thata-thata, substrate e tenyetsehang le substrate e thata hangata e na le li-conductivity tse fapaneng tsa dielectric le conductivity, e leng se tla baka mathata a ho se lumellane ha impedance ho sehokelo lipakeng tsa li-substrates tse peli.

Haholo-holo, li-substrates tse tenyetsehang li na le matla a phahameng a dielectric khafetsa le a tlase a motlakase, athe li-substrate tse thata li na le dielectric tse tlase le conductivity e phahameng ea motlakase. Ha pontso propagates ka thata-tenyetsehang oa potoloho boto, ho tla ba le ponahatso le phetiso ka segokanyimmediamentsi sa sebolokigolo thata-tenyetsehang pcb substrate. Liketsahalo tsena tsa ho bonahatsa le phetisetso li etsa hore ho feto-fetoha ha lets'oao ho fetoha, ke hore, ho se lumellane ha impedance.

Bakeng sa ho laola hantle ts'oaetso ea flex-rigid pcb, mekhoa e latelang e ka amoheloa:

Khetho ea substrate:khetha motsoako oa li-substrates tse thata tsa potoloho e le hore li-dielectric kamehla le conductivity li be haufi ka hohle kamoo ho ka khonehang ho fokotsa bothata ba ho se lumellane ha impedance;

Phekolo ea sefahleho:phekolo e khethehileng bakeng sa segokanyimmediamentsi sa sebolokigolo pakeng tsa pcb rigid flex substrates, tse kang ho sebelisa segokanyimmediamentsi sa sebolokigolo lera kapa laminated filimi, ho ntlafatsa impedance tšoanang ho isa tekanyong e itseng;

Taolo ea ho tobetsa:Ts'ebetsong ea tlhahiso ea pcb e thata e feto-fetohang, litekanyetso tse kang mocheso, khatello le nako li laoloa ka thata ho tiisa hore ho tlamahanngoa hantle ha likaroloana tse thata tsa boto ea flex le ho fokotsa liphetoho tsa impedance;

Ketsiso le debugging:Ka papiso le tlhahlobo ea phatlalatso ea lets'oao ho pcb e thata e tenyetsehang, fumana bothata ba ho se lumellane ha impedance, 'me u etse liphetoho tse tsamaellanang le lintlafatso.

2. Sebaka sa bophara ba mela ke ntlha ea bohlokoa e amang taolo ea impedance:

Ka har'a boto e thata-thata, sebaka sa bophara ba mela ke e 'ngoe ea lintlha tsa bohlokoa tse amang taolo ea impedance. Bophara ba mohala (ke hore, bophara ba terata) le sebaka sa mela (ke hore, sebaka se pakeng tsa mehala e haufi) se tsebahatsa geometry ea tsela ea hajoale, e amang litšobotsi tsa phetisetso le boleng ba ho sitisa lets'oao.

Se latelang ke tšusumetso ea sebaka sa bophara ba mela ho taolo ea impedance ea rigid-flex board:

Impedance ea mantlha:Phapang ea mela e bohlokoa bakeng sa ho laola tšitiso ea mantlha (ke hore, sebopeho sa mehala ea microstrip, likhoele tsa coaxial, jj.). Ho latela theory ea transmission line, lintlha tse joalo ka bophara ba mela, sebaka sa melapo, le botenya ba karoloana e ka tlas'a lefatše ka kopanelo li laola mokhoa oa ho sitisa mohala oa phetiso. Ha sebaka sa bophara ba mohala se fetoha, se tla lebisa phetohong ea sebopeho sa sebopeho, ka hona se ama phello ea phetisetso ea lets'oao.

Tšebelisano ea impedance:Ho ts'oara li-impedance hangata hoa hlokahala ka mapolanka a thata-thata ho netefatsa phetiso e ntle ka ho fetisisa ea matšoao ho potoloha potoloho. Tšitiso ea tšitiso hangata e hloka ho lokisa sebaka sa bophara ba mela hore se fihlelle. Ka mohlala, moleng oa microstrip, ts'ebetso ea ts'oaetso ea mohala oa phetisetso e ka bapisa le ho thibela ho hlokeha ha tsamaiso ka ho fetola bophara ba li-conductor le sebaka se pakeng tsa li-conductor tse haufi.

Crosstalk le tahlehelo:Karohano ea mela e boetse e na le phello ea bohlokoa taolong ea crosstalk le tahlehelo. Ha sebaka sa bophara ba mela se le senyenyane, phello ea khokahanyo ea tšimo ea motlakase pakeng tsa lithapo tse haufi e ea ntlafatsoa, e leng se ka lebisang ho eketseha ha crosstalk. Ho feta moo, bophara ba terata e nyane le likheo tse kholoanyane tsa terata li etsa hore ho be le kabo e tsepamisitsoeng haholoanyane, ho eketsa ho hanyetsa le tahlehelo.

3. Botenya ba thepa hape ke ntlha ea bohlokoa e amang taolo ea impedance ea boto e thata-flex:

Ho fapana ha botenya ba lintho tse bonahalang ho ama ka ho toba sebopeho sa impedance ea mohala oa phetiso.

Se latelang ke phello ea botenya ba thepa taolong ea impedance ea liboto tse rigid-flex:

Impedans ea mokhoa oa phetisetso:Sebopeho sa ho sitisa mohala oa phetisetso se bolela kamano e leka-lekaneng lipakeng tsa motlakase oa hajoale le motlakase oa mohala oa phetisetso ka maqhubu a itseng. Ka boto e thata-flexible, botenya ba thepa bo tla ama boleng ba tšobotsi ea impedance ea mohala oa phetisetso. Ha re bua ka kakaretso, ha botenya ba thepa bo ntse bo fokola, ts'oaetso ea sebopeho e tla eketseha; 'me ha botenya ba thepa bo e-ba botenya, impedance ea tšobotsi e tla fokotseha. Ka hona, ha ho etsoa boto e thata-flexible, hoa hlokahala ho khetha botenya bo nepahetseng ba thepa ho fihlela sephetho se hlokahalang ho latela litlhoko tsa sistimi le litšobotsi tsa phetisetso ea matšoao.

Karolelano ea Mola ho ea Sebakeng:Ho fapana ha botenya ba thepa le hona ho tla ama karo-karolelano ea mela-to-spacing. Ho ea ka khopolo ea khoele ea phetisetso, phetiso ea tšobotsi e lekana le karo-karolelano ea bophara ba mohala ho ea sebakeng. Ha botenya ba thepa bo fetoha, e le ho boloka botsitso ba sebopeho sa impedance, hoa hlokahala ho fetola karo-karolelano ea bophara ba mela le sebaka sa mela ka tsela e nepahetseng. Ka mohlala, ha botenya ba thepa bo fokotsehile, e le ho boloka mokhoa oa ho thibela ts'ebetso o sa fetohe, bophara ba mohala bo lokela ho fokotsoa ka tsela e nepahetseng, 'me sebaka sa mola se lokela ho fokotsoa ka tsela e tšoanang ho boloka bophara ba mola ho ea sebakeng se sa fetohe.

4. Ho mamellana ha koporo ea electroplated hape ke ntho e amang taolo ea impedance ea boto e thata e tenyetsehang:

Electroplated koporo ke ka tloaelo ho sebelisoa lera conductive ka mapolanka rigid-flex, 'me liphetoho botenya ba eona le mamello tla ka ho toba ama tšobotsi impedance boto.

Se latelang ke tšusumetso ea mamello ea koporo ea electroplating taolong ea impedance ea liboto tse thata tse tenyetsehang:

Mamello ea botenya ba koporo ea electroplated:Botenya ba koporo ea electroplated ke e 'ngoe ea lintlha tse ka sehloohong tse amang ho thibela boto e thata-flex. Haeba mamello ea botenya ea koporo ea electroplated e le kholo haholo, botenya ba lera la conductive holim'a poleiti bo tla fetoha, kahoo bo ama tšobotsi ea impedance ea poleiti. Ka hona, ha ho etsoa mapolanka a thata, ho hlokahala hore u laole ka thata ho mamellana ha botenya ba koporo ea electroplated ho netefatsa botsitso ba tšobotsi ea impedance.

Ho tšoana ha koporo ea electroplating:Ntle le mamello ea botenya, ho tšoana ha koporo ea electroplating ho boetse ho ama taolo ea impedance ea mapolanka a thata-thata. Haeba ho na le kabo e sa leka-lekaneng ea electroplated koporo lera ka boto, ho fella ka botenya fapaneng tsa koporo electroplated libakeng tse sa tšoaneng tsa boto, tšobotsi impedance tla boela fetola. Ka hona, hoa hlokahala ho etsa bonnete ba ho ts'oana ha koporo ea electroplated ho netefatsa ho ts'oana ha ts'ebetso ea ts'oaetso ha ho etsoa liboto tse bonolo le tse thata.

5. Etching tolerance e boetse ke ntlha ea bohlokoa e amang taolo ea impedance ea liboto tse rigid-flex:

Etching mamello e bolela ho kheloha ha botenya ba poleiti e ka laoloang ha etching e etsoa ka mokhoa oa ho etsa liboto tse thata tse tenyetsehang.

Tse latelang ke litlamorao tsa ho mamella mamello ho taolo ea impedance ea liboto tse rigid-flex:

Tšitiso ea ho ts'oara boto ea rigid-flex: Ts'ebetsong ea ho etsa boto e thata-thata, etching hangata e sebelisoa ho laola boleng ba impedance. Ka ho etching, bophara ba lera la conductive bo ka fetoloa ho fihlela boleng ba impedance bo hlokoang ke moralo. Leha ho le joalo, nakong ea tshebetso etching, kaha etching lebelo la etching tharollo poleiti ka 'na ba le mamello e itseng, ho ka' na ha e-ba le kheloha ka bophara ba lera conductive ka mor'a etching, e leng ama taolo e nepahetseng ea tšobotsi impedance.

Ho lumellana ha tšobotsi ho impedance:Etching tolerances le eona e ka lebisa ho phapano ea botenya ba lesela la conductive libakeng tse fapaneng, e leng se bakang ho se lumellane ha tšobotsi. Ho se lumellane ha ts'oaetso ea ts'ebetso ho ka 'na ha ama ts'ebetso ea phetisetso ea pontšo, e leng ea bohlokoa ka ho khetheha puisanong e potlakileng kapa lits'ebetsong tse phahameng.

Taolo ea impedance ke karolo ea bohlokoa ea moralo le boqapi ba Flex Rigid-Flex PCB.Ho fihlella litekanyetso tse nepahetseng le tse tsitsitseng tsa impedance ho bohlokoa ho phetiso ea matšoao e tšepahalang le ts'ebetso e akaretsang ea lisebelisoa tsa elektroniki.Kahoo ka ho ela hloko ka hloko khetho ea substrate, trace geometry, botenya ba dielectric bo laoloang, mamello ea tšepe ea koporo, le mamello ea etch, baqapi ba PCB le bahlahisi ba ka khona ho fana ka liboto tse tiileng tsa boleng bo holimo tse fihlelang litlhoko tse thata tsa indasteri. 15 lilemo ea ho arolelana phihlelo ea indasteri, ke tšepa hore Capel e ka u tlisetsa thuso e molemo. Bakeng sa lipotso tse ling tsa boto ea potoloho, ka kopo ikopanye le rona ka kotloloho, sehlopha sa litsebi tsa boto ea potoloho ea Capel se tla u araba inthaneteng.

Nako ea poso: Aug-22-2023

Morao