Tsebisa:

Tlhahisong ea lisebelisoa tsa elektroniki, solder e phetha karolo ea bohlokoa ho netefatsa ts'epo le ts'ebetso ea liboto tsa potoloho tse hatisitsoeng (PCBs). Capel o na le lilemo tse 15 tsa phihlelo ea indasteri 'me ke mofani ea ka sehloohong oa tharollo ea lisebelisoa tsa PCB tse tsoetseng pele.Tataisong ena e batsi, re tla hlahloba mekhoa le mekhoa e fapaneng ea ho solder e sebelisoang tlhahisong ea PCB, re totobatsa boitsebelo ba Capel le theknoloji e tsoetseng pele ea tšebetso.

1. Ho utloisisa PCB soldering: Overview

PCB soldering ke mokhoa oa ho kopanya likarolo tsa elektronike ho PCB ho sebelisa solder, motsoako oa tšepe o qhibilihisang mocheso o tlaase ho theha bond. Ts'ebetso ena e bohlokoa tlhahisong ea PCB kaha e netefatsa ts'ebetso ea motlakase, botsitso ba mochini le taolo ea mocheso. Ntle le soldering e nepahetseng, PCB e kanna ea se sebetse kapa ea sebetsa hampe.

Ho na le mefuta e mengata ea mekhoa ea soldering e sebelisoang ho etsa PCB, e 'ngoe le e' ngoe e na le lisebelisoa tsa eona tse thehiloeng ho litlhoko tse khethehileng tsa PCB. Theknoloji ena e kenyelletsa theknoloji ea holim'a metsi (SMT), ka theknoloji ea hole (THT) le theknoloji e nyalisitsoeng. SMT hangata e sebelisoa bakeng sa likaroloana tse nyane, athe THT e ratoa bakeng sa likarolo tse kholo le tse matla haholoanyane.

2. PCB thekenoloji tjheseletsa

A. Theknoloji ea tjheseletsa ea setso

Welding e le 'ngoe le mahlakore a mabeli

Ho solder ka lehlakore le le leng le mahlakore a mabeli ke mekhoa e sebelisoang haholo ha ho etsoa PCB. Ho soasoa ka mahlakoreng a le mong ho lumella likarolo hore li rekisoe ka lehlakoreng le le leng feela la PCB, ha soldering e nang le mahlakoreng a mabeli e lumella likarolo hore li rekisoe ka mahlakoreng ka bobeli.

Ts'ebetso ea solder e nang le lehlakore le le leng e kenyelletsa ho sebelisa solder paste ho PCB, ho beha likarolo tsa holim'a thaba, ebe o khutlisetsa solder ho theha maqhama a matla. Theknoloji ena e iketsetsa meralo e bonolo ea PCB 'me e fana ka melemo e kang ho boloka litšenyehelo le ho kopanya habonolo.

Soldering e mahlakoreng a mabeli,ka lehlakoreng le leng, ho kenyelletsa ho sebelisa likarolo tsa lesoba tse rekisoang mahlakoreng ka bobeli a PCB. Theknoloji ena e eketsa botsitso ba mechine 'me e lumella ho kopanngoa ha likarolo tse ngata.

Capel e sebetsa ka thata ho kenya ts'ebetsong mekhoa e tšepahalang ea ho tjheseletsa ka mahlakoreng a mabeli,ho netefatsa boleng bo phahameng ka ho fetisisa le ho nepahala ts'ebetsong ea welding.

Multilayer PCB soldering

Li-PCB tsa Multilayer li entsoe ka likarolo tse ngata tsa mesaletsa ea koporo le lisebelisoa tsa insulate, tse hlokang mekhoa e khethehileng ea ho solder. Capel e na le phihlelo e pharaletseng ea ho sebetsana le merero e rarahaneng ea li-welding tse ngata, ho netefatsa hore ho na le likamano tse ka tšeptjoang pakeng tsa lihlopha.

Multilayer PCB soldering process e kenyelletsa ho phunya masoba karolong e 'ngoe le e 'ngoe ea PCB ebe o koala masoba ka thepa e tsamaisang. Sena se lumella likarolo hore li rekisoe holim'a lihlopha tse ka ntle ha li ntse li boloka khokahanyo pakeng tsa lihlopha tse ka hare.

B. Theknoloji ea tjheseletsa e tsoetseng pele

HDI PCB soldering

Li-PCB tsa High-density interconnect (HDI) li ntse li ata ka ho eketsehileng ka lebaka la bokhoni ba tsona ba ho amohela likarolo tse ngata ka mekhoa e menyenyane. HDI PCB soldering thekenoloji nolofalletsa soldering e nepahetseng ea likaroloana tse nyenyane ka meralo e phahameng-sholo-holo.

Li-PCB tsa HDI li tobane le liphephetso tse ikhethang joalo ka sebaka se thata sa likarolo, likaroloana tse hlakileng, le tlhoko ea theknoloji ea microvia. Theknoloji ea ts'ebetso e tsoetseng pele ea Capel e nolofalletsa ho rekisoa ha HDI PCB, ho netefatsa boleng bo phahameng ka ho fetisisa le ho tšepahala bakeng sa meralo ena e rarahaneng ea PCB.

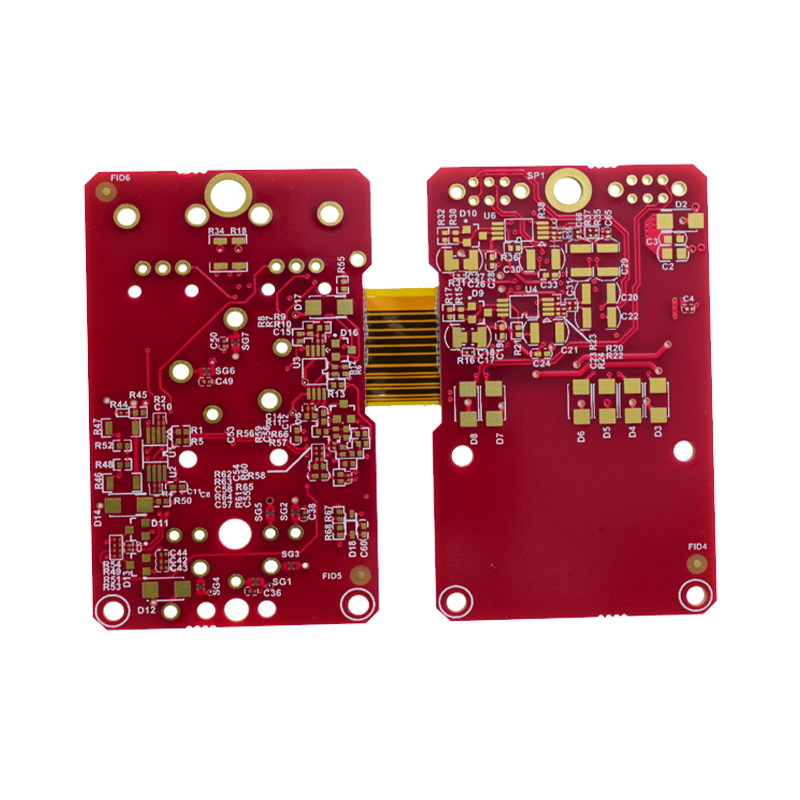

Flexible board le rigid-flex board welding

Liboto tsa potoloho tse hatisitsoeng tse feto-fetohang le tse thata-thata li fana ka maemo le ho feto-fetoha ha moralo, li etsa hore e be tse loketseng bakeng sa lits'ebetso tse hlokang ho kobeha kapa maemo a compact form. Ho rekisa mefuta ena ea liboto tsa potoloho ho hloka tsebo e khethehileng ho etsa bonnete ba ho tšoarella le ho tšepahala.

Tsebo ea Capel ea ho soldering flexible le rigid-flex PCBse netefatsa hore liboto tsena li khona ho mamella ho kobeha khafetsa le ho boloka ts'ebetso ea tsona. Ka theknoloji e tsoetseng pele ea ts'ebetso, Capel e finyella manonyeletso a ka tšeptjoang a solder esita le libakeng tse matla tse hlokang ho feto-fetoha ha maemo.

3. Theknoloji e tsoetseng pele ea ts'ebetso ea Capel

Capel e ikemiselitse ho lula ka pele ho indasteri ka ho tsetela lisebelisoa tsa morao-rao le mekhoa e mecha. Theknoloji ea bona e tsoetseng pele ea ts'ebetso e ba nolofalletsa ho fana ka litharollo tsa morao-rao bakeng sa litlhoko tse rarahaneng tsa welding.

Ka ho kopanya lisebelisoa tse tsoetseng pele tsa solder tse kang mechini e behang ka othomathiki le lionto tsa ho phalla hape tse nang le litsebi tsa mesebetsi ea matsoho le lienjineri, Capel e lula e fana ka liphetho tsa boleng bo holimo. Boitlamo ba bona ba ho nepahala le boqapi bo ba khetholla indastering.

Ka kakaretso

Tataiso ena e pharaletseng e fana ka kutloisiso e tebileng ea mekhoa le mekhoa ea ho kopanya PCB. Ho tloha ho solder e tloaelehileng ea lehlakore le le leng le mahlakore a mabeli ho ea ho theknoloji e tsoetseng pele e kang HDI PCB soldering le flexible PCB soldering, tsebo ea Capel e khanya ka ho fetisisa.

Ka lilemo tse 15 tsa boiphihlelo le boitlamo ba theknoloji e tsoetseng pele ea ts'ebetso, Capel ke molekane ea tšeptjoang bakeng sa litlhoko tsohle tsa thekiso ea PCB. Ikopanye le Capel kajeno bakeng sa tharollo e tšepahalang, ea boleng bo holimo ea PCB, e tšehelitsoeng ke boqapi ba bona le theknoloji e netefalitsoeng.

Nako ea poso: Nov-07-2023

Morao