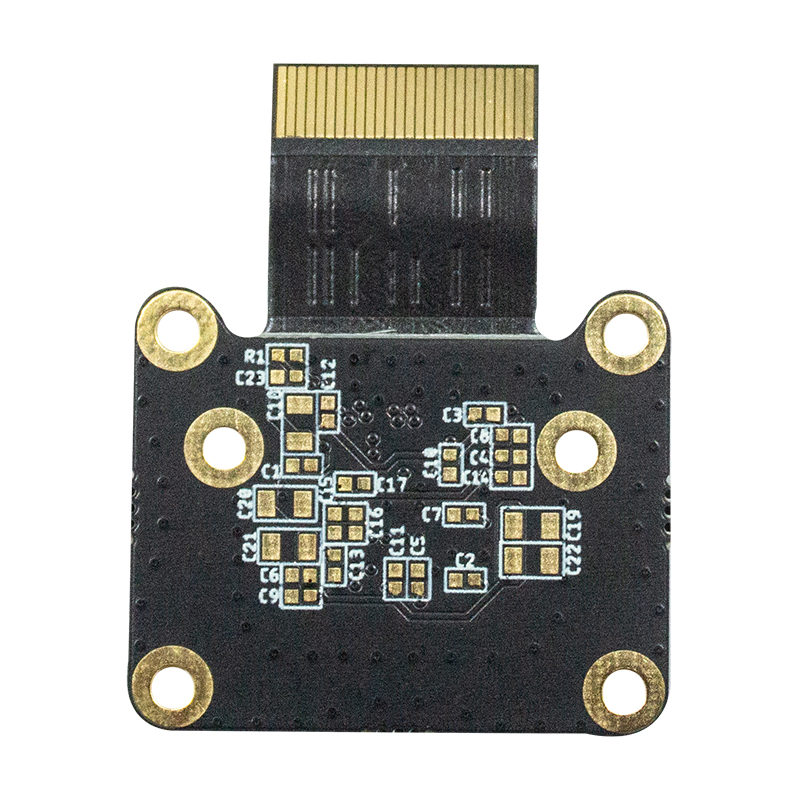

PCB (Printed Circuit Board) ke karolo ea bohlokoa lihlahisoa tsa sejoale-joale tsa elektroniki, tse nolofalletsang likhokahano le mesebetsi ea likarolo tse fapaneng tsa elektroniki. Ts'ebetso ea tlhahiso ea PCB e kenyelletsa mehato e 'maloa ea bohlokoa, e' ngoe ea eona ke ho kenya koporo holim'a substrate. Sengoliloeng sena re tla sheba mekhoa ea ho kenya koporo ho li-substrates tsa PCB nakong ea ts'ebetso ea tlhahiso, 'me re hlahlobe mekhoa e fapaneng e sebelisoang, joalo ka ho roala ka koporo ka electroless le electroplating.

1.Electroless koporo plating: tlhaloso, ts'ebetso ea lik'hemik'hale, melemo, melemo le libaka tsa kopo.

Ho utloisisa hore na plating ea koporo e se nang electroless ke eng, ho bohlokoa ho utloisisa hore na e sebetsa joang. Ho fapana le electrodeposition, e itšetlehileng ka motlakase oa motlakase bakeng sa ho kenngoa ha tšepe, ho roala ka koporo e se nang motlakase ke mokhoa oa autophoretic. E kenyelletsa phokotso ea lik'hemik'hale tse laoloang tsa li-ion tsa koporo holim'a substrate, e leng se etsang hore ho be le lera la koporo le ts'oanang haholo le le lumellanang.

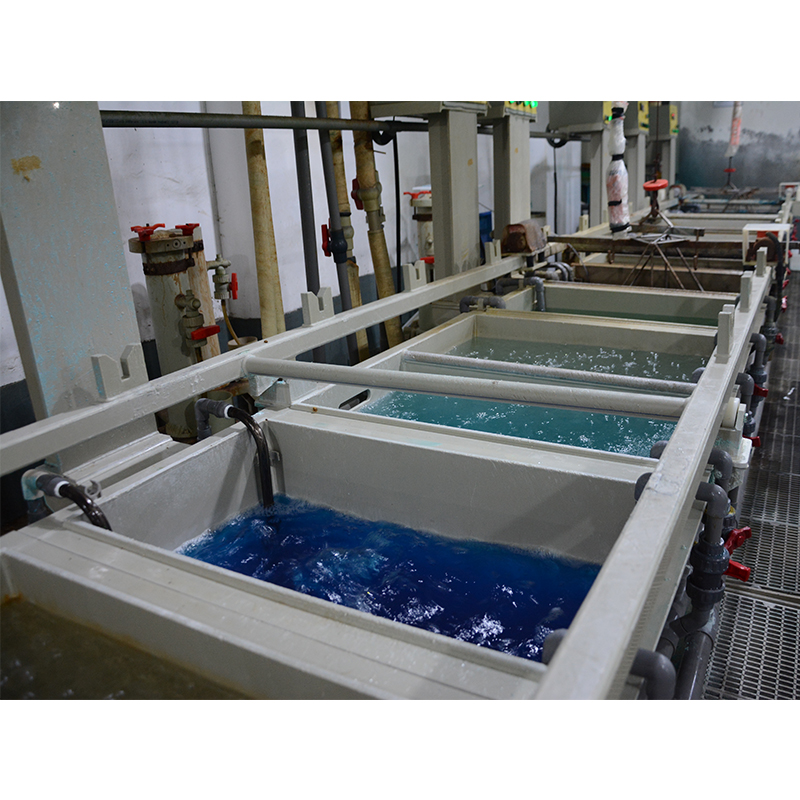

Hloekisa substrate:Hloekisa bokaholimo ba substrate ka botlalo ho tlosa litšila kapa li-oxide tse ka thibelang ho khomarela. Ts'ebetso: Tharollo ea ts'ebetso e nang le tšepe ea bohlokoa ea tšepe e kang palladium kapa platinum e sebelisoa ho qala ts'ebetso ea electroplating. Tharollo ena e thusa ho kenya koporo holim'a substrate.

Ikakhele ka setotsoana ka har'a tharollo ea plating:Kenya substrate e kentsoeng ka har'a tharollo ea koporo e senang electroless. Tharollo ea plating e na le li-ion tsa koporo, li-agent tse fokotsang le li-additives tse fapaneng tse laolang mokhoa oa ho beha.

Ts'ebetso ea Electroplating:Moemeli o fokotsang tharollo ea electroplating ka lik'hemik'hale o fokotsa li-ion tsa koporo hore e be liathomo tsa koporo tsa tšepe. Joale liathomo tsena li tlamahane sebakeng se kentsoeng tšebetsong, li etsa lera le sa khaotseng le le tšoanang la koporo.

Hlatsoa 'me u omise:Hang ha botenya ba koporo bo lakatsehang bo finyelloa, substrate e ntšoa ka tanka ea ho pata ebe e hlatsuoa ka botlalo ho tlosa lik'hemik'hale tse setseng. Omisa substrate e petelitsoeng pele o tsoela pele ho sebetsa. Ts'ebetso ea khemikhale ea koporo ea koporo Ts'ebetso ea lik'hemik'hale ea ho roala ka koporo e se nang electroless e kenyelletsa karabelo ea redox lipakeng tsa li-ion tsa koporo le lisebelisoa tse fokotsang. Mehato ea bohlokoa ts'ebetsong e kenyelletsa: Ts'ebetso: Ts'ebeliso ea li-catalyst tsa tšepe tse ntle joalo ka palladium kapa platinum ho kenya tšebetsong bokaholimo ba karolo. The catalyst e fana ka libaka tse hlokahalang bakeng sa ho kopanya lik'hemik'hale tsa li-ion tsa koporo.

Moemeli oa ho fokotsa:Moemeli oa ho fokotsa ka har'a tharollo ea plating (hangata formaldehyde kapa sodium hypophosphite) e qala karabelo ea ho fokotsa. Li-reagents tsena li fana ka lielektrone ho li-ion tsa koporo, li li fetola liathomo tsa koporo tsa tšepe.

Maikutlo a Autocatalytic:Liathomo tsa koporo tse hlahisoang ke karabelo ea phokotso li arabela ka lebaka la "catalyst" holim'a substrate ho etsa lera le ts'oanang la koporo. Karabelo e tsoela pele ntle le tlhoko ea hona joale e sebelisoang kantle, e e etsa "plating e se nang motlakase."

Taolo ea sekhahla sa deposition:Sebopeho le mahloriso a tharollo ea plating, hammoho le litekanyetso tsa ts'ebetso tse kang mocheso le pH, li laoloa ka hloko ho etsa bonnete ba hore tekanyo ea ho behoa e laoloa ebile e tšoana.

Melemo ea Uniformity ea koporo e se nang electroless:Plating ea koporo e se nang motlakase e na le ho ts'oana hantle, ho netefatsa botenya bo ts'oanang ka libopeho tse rarahaneng le libaka tse khutlisitsoeng morao. Conformal Coating: Ts'ebetso ena e fana ka lesela le lumellanang hantle le khomarelang likaroloana tse sa tloaelehang tsa geometrically joalo ka li-PCB. Ho khomarela hantle: Ho roala ka koporo e se nang motlakase ho na le sekhomaretsi se matla ho mefuta e fapaneng ea lisebelisoa tsa substrate, ho kenyeletsoa polasetiki, lirafshoa le tšepe. Selection Plating: Ho roala ka koporo e se nang motlakase ho ka beha koporo libakeng tse itseng tsa substrate ho sebelisa mekhoa ea ho pata. Litšenyehelo tse tlase: Ha ho bapisoa le mekhoa e meng, ho roala koporo ka electroless ke khetho e theko e tlaase ea ho kenya koporo holim'a substrate.

Mathata a ho roala ka koporo e se nang motlakase Sekhahla se fokolang sa ho beha:Ha ho bapisoa le mekhoa ea electroplating, plating ea koporo e se nang motlakase hangata e na le sekhahla se liehang sa deposition, se ka lelefatsang nako ea ts'ebetso ea electroplating ka kakaretso. Botenya bo lekantsoeng: Ho roala ka koporo e se nang motlakase hangata ho loketse bakeng sa ho beha likarolo tse tšesaane tsa koporo, ka hona ha ho loketse lits'ebetso tse hlokang ho beoa ho hoholo. Ho rarahana: Ts'ebetso e hloka taolo e hlokolosi ea liparamente tse fapaneng, ho kenyeletsoa mocheso, pH le likhahla tsa lik'hemik'hale, ho etsa hore ho be thata ho kenya ts'ebetsong ho feta mekhoa e meng ea electroplating. Taolo ea Litšila: Ho lahla litharollo tsa litšila tse nang le litšepe tse boima tse chefo ho ka baka mathata a tikoloho 'me ho hloka ho tšoaroa ka hloko.

Libaka tsa ts'ebeliso ea Tlhahiso ea PCB ea koporo e se nang electroless:Lisebelisoa tsa koporo tse se nang motlakase li sebelisoa haholo ha ho etsoa liboto tsa potoloho tse hatisitsoeng (PCBs) ho theha mesaletsa e tsamaisang le ho penta ka masoba. Indasteri ea semiconductor: E bapala karolo ea bohlokoa tlhahisong ea lisebelisoa tsa semiconductor joalo ka li-chip carriers le liforeimi tse etellang pele. Liindasteri tsa likoloi le tsa lifofane: Ho sebelisoa koporo e se nang motlakase ho etsa lihokelo tsa motlakase, li-switches le likarolo tsa elektronike tse sebetsang hantle haholo. Liaparo tse khabisitsoeng le tse sebetsang: Ho roala ka koporo e se nang motlakase ho ka sebelisoa ho etsa likhabiso tse khabisitsoeng holim'a li-substrates tse fapa-fapaneng, hammoho le tšireletso ea kutu le ho ntlafatsa motlakase oa motlakase.

2.Copper plating ka PCB substrate

Ho roala ka koporo ho li-substrates tsa PCB ke mohato oa bohlokoa tšebetsong ea tlhahiso ea boto ea potoloho e hatisitsoeng (PCB). Koporo e atisa ho sebelisoa e le lisebelisoa tsa electroplating ka lebaka la motlakase oa eona o motle haholo le ho khomarela hantle ho substrate. Ts'ebetso ea ho roala koporo e kenyelletsa ho beha karolo e tšesaane ea koporo holim'a PCB ho theha litsela tse tsamaisang mats'oao a motlakase.

Ts'ebetso ea ho roala koporo ho li-substrates tsa PCB hangata e kenyelletsa mehato e latelang: Tokiso ea Sefahleho:

Hloekisa substrate ea PCB ka botlalo ho tlosa litšila, li-oxide kapa litšila tse ka sitisang ho khomarela le ho ama boleng ba plating.

Ho lokisoa ha electrolyte:

Lokisetsa tharollo ea electrolyte e nang le sulfate ea koporo e le mohloli oa li-ion tsa koporo. Electrolyte e boetse e na le li-additives tse laolang ts'ebetso ea plating, joalo ka li-level, li-brighteners, le li-adjusters tsa pH.

Electrodeposition:

Kenya substrate e lokiselitsoeng ea PCB ka har'a tharollo ea electrolyte 'me u sebelise motlakase o tobileng. PCB e sebetsa e le khokahanyo ea cathode, ha anode ea koporo e boetse e le teng ka tharollo. Hona joale e etsa hore li-ion tsa koporo tse electrolyte li fokotsehe ebe li kenngoa holim'a PCB.

Taolo ea liparamente tsa plating:

Mekhahlelo e fapaneng e laoloa ka hloko nakong ea ts'ebetso ea plating, ho kenyeletsoa letsoalo la hajoale, mocheso, pH, nako ea ho hlohlelletsa le ea ho penta. Mekhahlelo ena e thusa ho netefatsa ho beoa ho tšoanang, ho khomarela, le botenya bo lakatsehang ba lera la koporo.

Phekolo ea kamora ho pola:

Hang ha botenya ba koporo bo lakatsehang bo fihletsoe, PCB e ntšoa ka bateng ea plating ebe e hlatsuoa ho tlosa tharollo efe kapa efe e setseng ea electrolyte. Liphekolo tse ling tsa ka mor'a ho roala, tse kang ho hloekisa holim'a metsi le passivation, li ka etsoa ho ntlafatsa boleng le botsitso ba lera la koporo.

Lintlha tse amang boleng ba electroplating:

Tokiso ea Sebaka:

Ho hloekisa hantle le ho lokisoa ha sefahleho sa PCB ho bohlokoa ho tlosa litšila kapa likarolo tsa oxide le ho netefatsa hore ho khomarela hantle ha koporo ea koporo. Sebopeho sa tharollo ea Plating:

Sebopeho sa tharollo ea electrolyte, ho kenyelletsa le khatello ea sulfate ea koporo le li-additives, e tla ama boleng ba plating. The plating bath sebopeho lokela ho ka hloko ho laoloa ho finyella a lakatsa litšobotsi plating.

Li-Parameters tsa Plating:

Ho laola likarolo tsa plating tse joalo ka bongata ba hona joale, mocheso, pH, nako e tsosang takatso le ea ho penta hoa hlokahala ho etsa bonnete ba hore ho behiloe ka mokhoa o ts'oanang, ho khomarela le botenya ba lera la koporo.

Sesebediswa sa Substrate:

Mofuta le boleng ba thepa ea substrate ea PCB e tla ama sekhomaretsi le boleng ba plating ea koporo. Lisebelisoa tse fapaneng tsa substrate li ka hloka liphetoho ts'ebetsong ea plating bakeng sa liphetho tse nepahetseng.

Bokhopo ba bokaholimo:

Bokhachane bo kaholimo ba substrate ea PCB bo tla ama ho khomarela le boleng ba lera la plating ea koporo. Tokiso e nepahetseng ea bokaholimo le taolo ea liparamente tsa plating li thusa ho fokotsa mathata a amanang le ho ba mahoashe

Melemo ea PCB substrate koporo plating:

Ts'ebetso e ntle ea motlakase:

Koporo e tsebahala ka matla a eona a phahameng a motlakase, e leng se etsang hore e be khetho e nepahetseng bakeng sa lisebelisoa tsa ho roala tsa PCB. Sena se tiisa hore ho tsamaisoa ka mokhoa o atlehileng le o ka tšeptjoang oa lipontšo tsa motlakase. Ho khomarela hantle:

Koporo e bonts'a ho khomarela ka mokhoa o babatsehang ho mefuta e sa tšoaneng ea li-substrates, ho tiisa maqhama a matla le a nako e telele pakeng tsa ho roala le substrate.

Corrosion Resistance:

Koporo e na le khanyetso e ntle ea kutu, e sireletsa likarolo tsa PCB le ho netefatsa ts'epo ea nako e telele. Solderability: Copper plating e fana ka sebaka se loketseng bakeng sa solder, ho etsa hore ho be bonolo ho hokahanya likarolo tsa elektronike nakong ea kopano.

Phallo e matlafalitsoeng ea mocheso:

Koporo ke sekontiri se setle sa mocheso, se nolofalletsang ho qhala mocheso o sebetsang hantle oa li-PCB. Sena ke sa bohlokoa haholo bakeng sa lisebelisoa tse phahameng tsa matla.

Meeli le mathata a koporo ea electroplating:

Taolo ea Botenya:

Ho fumana taolo e nepahetseng holim'a botenya ba koporo e ka ba phephetso, haholo-holo libakeng tse rarahaneng kapa libakeng tse thata ho PCB. Ho tšoana: Ho ka ba thata ho etsa bonnete ba hore koporo e kenngoa ka mokhoa o ts'oanang holim'a sebaka sohle sa PCB, ho kenyeletsoa libaka tse khutliselitsoeng morao le likarolo tse ntle.

Litšenyehelo:

Electroplating koporo e ka ba theko e boima ho feta ha e bapisoa le mekhoa e meng ea electroplating ka lebaka la litšenyehelo tsa lik'hemik'hale tsa tanka ea plating, lisebelisoa le tlhokomelo.

Tsamaiso ea litšila:

Ho lahla metsi a litšila a nang le li-ion tsa koporo le lik'hemik'hale tse ling ho hloka mekhoa e nepahetseng ea ho laola litšila ho fokotsa tšusumetso ea tikoloho.

Ts'ebetso e rarahaneng:

Electroplating koporo e kenyelletsa liparamente tse ngata tse hlokang taolo e hlokolosi, e hlokang tsebo e khethehileng le litlhophiso tse rarahaneng tsa ho pola.

3.Papiso pakeng tsa ho roala ka koporo ea electroless le electroplating

Phapang ea tšebetso le boleng:

Ho na le liphapang tse 'maloa tsa ts'ebetso le boleng lipakeng tsa plating ea koporo e se nang electroless le electroplating likarolong tse latelang:

Electroless copper plating ke ts'ebetso ea ho beha lik'hemik'hale e sa hlokeng mohloli oa matla a kantle, athe electroplating e kenyelletsa ho sebelisa hona joale ka kotloloho ho kenya lera la koporo. Phapang ena ea mekhoa ea deposition e ka lebisa ho phapano ea boleng ba ho roala.

Lisebelisoa tsa koporo tse se nang motlakase hangata li fana ka sebaka se ts'oanang ho feta holim'a karolo eohle ea substrate, ho kenyeletsoa libaka tse phomotsoeng le likarolo tse ntle. Sena se bakoa ke hore plating e etsahala ka ho lekana libakeng tsohle ho sa tsotelehe hore na li sekametse hokae. Electroplating, ka lehlakoreng le leng, e ka ba le bothata ba ho fihlela deposition e tšoanang libakeng tse rarahaneng kapa tseo ho leng thata ho fihla ho tsona.

Ho roala ha koporo ho se nang motlakase ho ka fihlella karo-karolelano e phahameng (karolelano ea bophahamo ho isa bophara) ho feta electroplating. Sena se etsa hore e loketse lits'ebetso tse hlokang thepa e phahameng ea karo-karolelano, joalo ka masoba a PCB.

Lisebelisoa tsa koporo tse se nang motlakase hangata li hlahisa sebaka se boreleli, se bataletseng ho feta electroplating.

Electroplating ka linako tse ling e ka etsa hore ho be le li-deposit tse sa tsitsang, tse mahlahahlaha kapa tse se nang letho ka lebaka la liphetoho tse teng hona joale le maemo a ho hlapa. Boleng ba tlamahano pakeng tsa lera koporo plating le substrate ka 'na fapana pakeng tsa electroless koporo plating le electroplating.

Motlakase oa koporo o se nang motlakase ka kakaretso o fana ka momahano o betere ka lebaka la mochini o kopanyang lik'hemik'hale oa koporo e se nang motlakase ho substrate. Plating e ipapisitse le bonding ba mochini le electrochemical, e leng se ka bakang litlamo tse fokolang maemong a mang.

Papiso ea Litšenyehelo:

Chemical Deposition vs. Electroplating: Ha u bapisa litšenyehelo tsa ho roala ka koporo ka electroless le electroplating, lintlha tse 'maloa li lokela ho nkoa:

Litšenyehelo tsa lik'hemik'hale:

Lisebelisoa tsa koporo tse se nang motlakase hangata li hloka lik'hemik'hale tse theko e boima haholo ha li bapisoa le electroplating. Lik'hemik'hale tse sebelisoang ho polating ka motlakase, joalo ka li-reduction agents le stabilizers, hangata li ikhethile ebile li theko e boima.

Litšenyehelo tsa lisebelisoa:

Lisebelisoa tsa ho roala li hloka lisebelisoa tse rarahaneng le tse theko e boima, ho kenyelletsa le lisebelisoa tsa motlakase, li-rectifiers le anode. Lisebelisoa tsa koporo tse se nang motlakase li batla li le bonolo 'me li hloka likarolo tse fokolang.

Litšenyehelo tsa ho hlokomela:

Lisebelisoa tsa ho roala li ka hloka ho lokisoa nako le nako, ho lekanyetsoa, le ho nkeloa sebaka ha li-anode kapa likarolo tse ling. Lisebelisoa tsa ho roala ka koporo tse se nang motlakase hangata li hloka tlhokomelo e fokolang khafetsa 'me li na le litšenyehelo tse tlase tsa tlhokomelo.

Tšebeliso ea Lik'hemik'hale Tsa Plating:

Lisebelisoa tsa ho roala li sebelisa lik'hemik'hale tsa plating ka lebelo le holimo ka lebaka la tšebeliso ea motlakase. Tšebeliso ea lik'hemik'hale ea lisebelisoa tsa ho roala ka koporo tse se nang motlakase li tlase hobane karabelo ea electroplating e etsahala ka karabelo ea lik'hemik'hale.

Litšenyehelo tsa taolo ea litšila:

Electroplating e hlahisa litšila tse ling, ho kenyeletsoa libate tsa ho roala le ho hlatsoa metsi a silafalitsoeng ka li-ion tsa tšepe, tse hlokang phekolo e nepahetseng le ho lahloa. Sena se eketsa litšenyehelo tse akaretsang tsa plating. Motlakase oa koporo o se nang motlakase o hlahisa litšila tse fokolang hobane ha o itšetlehe ka phepelo e tsoelang pele ea li-ion tsa tšepe ka bateng ea plating.

Mathata le Liphephetso tsa Electroplating le Chemical Deposition:

Electroplating e hloka taolo e hlokolosi ea liparamente tse fapaneng joalo ka bongata ba hona joale, mocheso, pH, nako ea ho pola le ho sisinyeha. Ho fihlela sebopeho se ts'oanang le litšoaneleho tse lakatsehang tsa ho rala e ka ba phephetso, haholo-holo ho li-geometri tse rarahaneng kapa libakeng tse tlase tsa hajoale. Ntlafatso ea sebopeho sa bate le liparamente li ka hloka liteko tse ngata le boiphihlelo.

Ho roala ka koporo e se nang motlakase ho boetse ho hloka taolo ea liparamente tse kang ho fokotsa mahloriso a moemeli, mocheso, pH le nako ea plating. Leha ho le joalo, taolo ea litekanyo tsena ka kakaretso ha e bohlokoa haholo ho plating ea electroless ho feta ho electroplating. Ho fihlela thepa e lakatsehang ea ho pola, joalo ka sekhahla sa deposition, botenya, le ho khomarela, ho ntse ho ka hloka ts'ebetso le ho lekola ts'ebetso ea plating.

Ho plating ea koporo ea electroplating le electroless, ho khomarela lisebelisoa tse fapaneng tsa substrate e ka ba phephetso e tloaelehileng. Phekolo ea pele ea sebaka sa substrate ho tlosa litšila le ho khothalletsa ho khomarela ho bohlokoa bakeng sa mekhoa e 'meli.

Ho rarolla mathata le ho rarolla mathata ka electroplating kapa electroless copper plating ho hloka tsebo e khethehileng le phihlelo. Mathata a kang ho ba mahlahahlaha, ho behoa ka tsela e sa leka-lekaneng, bofokoli, ho phunya, kapa ho se mamelle hantle ho ka etsahala nakong ea mekhoa eo ka bobeli, 'me ho ka ba thata ho tseba sesosa le ho nka khato ea ho lokisa.

Sebaka sa tšebeliso ea theknoloji e 'ngoe le e' ngoe:

Electroplating e sebelisoa hangata liindastering tse fapaneng tse kenyelletsang lisebelisoa tsa elektroniki, tsa likoloi, tsa sefofane le mabenyane a hlokang taolo e nepahetseng ea botenya, boleng ba boleng bo holimo le thepa ea 'mele e lakatsehang. E sebelisoa haholo ha ho etsoa likhabiso, ho roala tšepe, tšireletso ea kutu le ho etsa likarolo tsa elektroniki.

Lisebelisoa tsa koporo tse se nang motlakase li sebelisoa haholo indastering ea lisebelisoa tsa elektronike, haholo-holo ha ho etsoa liboto tsa potoloho tse hatisitsoeng (PCBs). E sebelisoa ho theha litsela tsa conductive, bokaholimo bo rekisoang le liphetho tsa bokaholimo ho li-PCB. Electroless koporo plating e boetse e sebelisoa ho etsa tšepe ea polasetiki, ho hlahisa likhokahano tsa koporo ka har'a liphutheloana tsa semiconductor, le lits'ebetso tse ling tse hlokang ho beoa ha koporo e tšoanang le e lumellanang.

4.Copper deposition mekhoa ea mefuta e fapaneng PCB

PCB ea lehlakore le le leng:

Ho li-PCB tse nang le lehlakore le le leng, ho beoa ha koporo hangata ho etsoa ho sebelisoa mokhoa oa ho tlosa. Hangata substrate e entsoe ka thepa e sa tsitsang e kang FR-4 kapa phenolic resin, e koahetsoeng ka lesela le lesesaane la koporo ka lehlakoreng le leng. Lera la koporo le sebetsa e le tsela ea conductive bakeng sa potoloho. Mokhoa ona o qala ka ho hloekisa le ho lokisa sebaka sa substrate ho etsa bonnete ba ho khomarela hantle. E latelang ke ts'ebeliso ea lesela le tšesaane la lisebelisoa tsa photoresist, tse pepesetsoang leseli la UV ka photomask ho hlalosa mokhoa oa potoloho. Libaka tse pepeneneng tsa ho hanyetsa li qhibiliha 'me ka mor'a moo li hlatsuoa, li pepesa lera le ka tlas'a koporo. Libaka tsa koporo tse pepesitsoeng li behoa ho sebelisoa etchant e kang ferric chloride kapa ammonium persulfate. Etchant e khetha ho tlosa koporo e pepeneneng, e siea mokhoa o lakatsehang oa potoloho. Joale ho hanyetsoa ho setseng ho tlosoa, ho siea mesaletsa ea koporo. Ka mor'a ts'ebetso ea etching, PCB e ka 'na ea e-ba le mehato e meng ea ho lokisa holim'a metsi e kang mask a solder, khatiso ea skrine, le ts'ebeliso ea likarolo tse sireletsang ho netefatsa ho tšoarella le ho sireletsa linthong tsa tikoloho.

PCB ea mahlakoreng a mabeli:

PCB e mahlakoreng a mabeli e na le likarolo tsa koporo mahlakoreng ka bobeli a substrate. Mokhoa oa ho kenya koporo mahlakoreng ka bobeli o kenyelletsa mehato e eketsehileng ha e bapisoa le li-PCB tse nang le lehlakore le le leng. Ts'ebetso e ts'oana le PCB e nang le lehlakore le le leng, ho qala ka ho hloekisa le ho lokisa sebaka sa substrate. Ka mor'a moo, karolo ea koporo e kenngoa ka mahlakoreng ka bobeli a substrate ho sebelisoa lisebelisoa tsa koporo tse se nang electroless kapa electroplating. Electroplating e atisa ho sebelisoa bakeng sa mohato ona hobane e lumella taolo e molemo holim'a botenya le boleng ba lera la koporo. Ka mor'a hore lera la koporo le behoe, mahlakoreng ka bobeli a koahetsoe ke photoresist 'me mokhoa oa potoloho o hlalosoa ka mehato ea ho pepeseha le ea tsoelo-pele e tšoanang le ea li-PCB tse lehlakoreng le le leng. Likarolo tsa koporo tse pepesitsoeng li behoa ho etsa litsela tse hlokahalang tsa potoloho. Kamora ho ts'oaroa, mohanyetsi oa tlosoa mme PCB e tsoela pele ka mehato e meng ea ts'ebetso joalo ka ts'ebeliso ea mask ea solder le kalafo ea bokaholimo ho phethela ho etsoa ha PCB e mahlakore a mabeli.

Multilayer PCB:

Li-PCB tsa Multilayer li entsoe ka likarolo tse ngata tsa koporo le lisebelisoa tse sireletsang tse koaletsoeng holim'a tse ling. Ho beha koporo ho li-PCB tsa multilayer ho kenyelletsa mehato e mengata ea ho theha litsela tse tsamaisang lipakeng tsa mekhahlelo. Ts'ebetso e qala ka ho theha likarolo tsa PCB ka bomong, tse ts'oanang le li-PCB tse nang le lehlakore le le leng kapa tse mahlakore a mabeli. Lera le leng le le leng le lokiselitsoe 'me ho sebelisoa photoresist ho hlalosa mokhoa oa potoloho, o lateloa ke koporo ea koporo ka electroplating kapa electroless copper plating. Ka mor'a ho behoa, karolo e 'ngoe le e' ngoe e koahetsoe ka thepa e sireletsang (hangata epoxy-based prepreg kapa resin) ebe e kenngoa hammoho. Likarolo li tsamaellana ho sebelisoa ho cheka ka nepo le mekhoa ea ho ngolisoa ka mochini ho netefatsa khokahano e nepahetseng lipakeng tsa mekhahlelo. Ka lekhetlo le leng le dikarolo ba lolamisiwa, vias ba bōpiloe ke cheka masoba ka le dikarolo ka lintlha tse itseng moo ho hokahaneng ho hlokahala. The vias ebe plated ka koporo sebelisa electroplating kapa electroless koporo plating ho bopa dikgokelo motlakase pakeng tsa le dikarolo. Ts'ebetso e ntse e tsoela pele ka ho pheta mehato ea ho bokella, ho cheka, le mehato ea koporo ho fihlela likarolo tsohle tse hlokahalang le likhokahano li thehoa. Mohato oa ho qetela o kenyelletsa kalafo ea holim'a metsi, ts'ebeliso ea mask ea solder le lits'ebetso tse ling tsa ho phethela ho phethela tlhahiso ea PCB ea mekhahlelo e mengata.

High Density Interconnect (HDI) PCB:

HDI PCB ke PCB e nang le mekhahlelo e mengata e etselitsoeng ho amohela lipotoloho tse phahameng le tse nyane. Ho beha koporo ho li-PCB tsa HDI ho kenyelletsa mekhoa e tsoetseng pele ea ho thusa likarolo tse ntle le meralo e tiileng ea molumo. Ts'ebetso e qala ka ho theha li-layers tse ngata tse tšesaane, tseo hangata li bitsoang core material. Li-cores tsena li na le foil e tšesaane ea koporo ka lehlakoreng le leng le le leng 'me li entsoe ka lisebelisoa tse phahameng tsa resin tse kang BT (Bismaleimide Triazine) kapa PTFE (Polytetrafluoroethylene). Lisebelisoa tsa mantlha li phuthetsoe 'me li entsoe ka laminated hammoho ho theha mohaho oa li-multi-layer. Ka mor'a moo, ho cheka ka laser ho sebelisoa ho etsa li-microvia, e leng masoba a manyenyane a kopanyang likarolo. Li-microvias hangata li tlatsitsoe ka lisebelisoa tse tsamaisang joalo ka koporo kapa conductive epoxy. Ka mor'a hore li-microvias li thehoe, likarolo tse eketsehileng li kenngoa le ho kenngoa ka laminated. Ts'ebetso ea tatellano ea lamination le laser drilling e phetoa ho theha mekhahlelo e mengata e nang le likhokahano tsa microvia. Qetellong, koporo e kenngoa holim'a HDI PCB e sebelisa mekhoa e kang electroplating kapa electroless copper plating. Ka lebaka la likarolo tse ntle le potoloho e phahameng ea li-PCB tsa HDI, deposition e laoloa ka hloko ho fihlela botenya le boleng bo hlokahalang ba koporo. Tshebetso e qetella ka phekolo e eketsehileng ea holim'a holim'a metsi le mekhoa ea ho qeta ho phethela tlhahiso ea HDI PCB, e ka kenyelletsang kopo ea mask ea solder, kopo ea ho qeta holimo le tlhahlobo.

Flexible circuit board:

Li-PCB tse feto-fetohang, tse tsejoang hape e le li-circuits tse feto-fetohang, li etselitsoe ho tenyetseha le ho khona ho ikamahanya le libopeho tse fapaneng kapa ho kobeha nakong ea ts'ebetso. Ho beha koporo ho li-PCB tse tenyetsehang ho kenyelletsa mekhoa e ikhethileng e fihlelang litlhoko tsa ho feto-fetoha le maemo. Li-PCB tse feto-fetohang li ka ba le lehlakore le le leng, la mahlakore a mabeli, kapa li-multi-layered, 'me mekhoa ea ho beha koporo e fapana ho latela litlhoko tsa moralo. Ka kakaretso, li-PCB tse tenyetsehang li sebelisa foil e nyane ea koporo ha e bapisoa le li-PCB tse thata ho fihlela maemo a bonolo. Bakeng sa li-PCB tse tenyetsehang ka mahlakoreng a le mong, mokhoa ona o tšoana le li-PCB tse thata tse nang le lehlakore le le leng, ke hore, lesela le lesesaane la koporo le kenngoa holim'a substrate e feto-fetohang ho sebelisa electroless copper plating, electroplating, kapa motsoako oa bobeli. Bakeng sa li-PCB tse nang le mahlakoreng a mabeli kapa tse ngata, ts'ebetso e kenyelletsa ho kenya koporo mahlakoreng ka bobeli a substrate e feto-fetohang ho sebelisa electroless copper plating kapa electroplating. Ha ho nahanoa ka thepa e ikhethang ea mochini oa thepa e tenyetsehang, deposition e laoloa ka hloko ho netefatsa ho khomarela hantle le ho feto-fetoha ha maemo. Kamora ho beha koporo, PCB e feto-fetohang e feta lits'ebetsong tse ling tse kang ho cheka, mokhoa oa potoloho, le mehato ea kalafo ea holim'a metsi ho theha potoloho e hlokahalang le ho phethela tlhahiso ea PCB e tenyetsehang.

5.Advances and Innovations in Copper Deposition on PCBs

Lintlafatso tsa morao-rao tsa theknoloji: Ho theosa le lilemo, theknoloji ea ho beha koporo ho li-PCB e 'nile ea tsoela pele ho fetoha le ho ntlafala, e leng se bakang ts'ebetso e eketsehileng le ho tšepahala. Tse ling tsa lintlafatso tsa morao-rao tsa theknoloji ho PCB deposition ea koporo li kenyelletsa:

Theknoloji e tsoetseng pele ea plating:

Mahlale a macha a ho rala, joalo ka pulse plating le reverse pulse plating, a se a ntlafalitsoe ho fihlela ts'ebetso e ntle le e ts'oanang ea koporo. Theknoloji ena e thusa ho hlola liphephetso tse kang ho ba makukuno holimo, boholo ba lijo-thollo le kabo ea botenya ho ntlafatsa ts'ebetso ea motlakase.

Metallization e tobileng:

Tlhahiso ea setso ea PCB e kenyelletsa mehato e mengata ea ho theha litsela tse tsamaisang, ho kenyelletsa le ho beha lera la peo pele ho plating ea koporo. Tsoelo-pele ea mekhoa ea metallization e tobileng e felisa tlhokahalo ea lera le arohaneng la peo, kahoo e nolofatsa mokhoa oa ho etsa lihlahisoa, ho fokotsa litšenyehelo le ho ntlafatsa ho tšepahala.

Theknoloji ea Microvia:

Li-Microvias ke masoba a manyane a kopanyang likarolo tse fapaneng ho PCB ea multilayer. Tsoelo-pele ea theknoloji ea microvia joalo ka ho phunya laser le plasma etching e thusa ho theha li-microvias tse nyane, tse nepahetseng haholoanyane, tse nolofalletsang li-circuits tse phahameng le ho ntlafatsa boleng ba matšoao. Surface Finish Innovation: Qetello ea bokaholimo e bohlokoa ho sireletsa mesaletsa ea koporo ho oxidation le ho fana ka solderability. Lintlafatso tsa mahlale a kalafo ea holim'a metsi, joalo ka Immersion Silver (ImAg), Organic Solderability Preservative (OSP), le Electroless Nickel Immersion Gold (ENIG), li fana ka ts'ireletso e ntle ea kutu, e ntlafatsa ho solderability le ho eketsa ts'epo ka kakaretso.

Nanotechnology le Copper Deposition: Nanotechnology e bapala karolo ea bohlokoa ho nts'etsopele ea ho beha koporo ea PCB. Lisebelisoa tse ling tsa nanotechnology ho deposition ea koporo li kenyelletsa:

Nanoparticle-based plating:

Li-nanoparticles tsa koporo li ka kenngoa ka har'a tharollo ea plating ho ntlafatsa ts'ebetso ea deposition. Li-nanoparticles tsena li thusa ho ntlafatsa ho khomarela koporo, boholo ba lijo-thollo le kabo, ka hona ho fokotsa ho hanyetsa le ho ntlafatsa ts'ebetso ea motlakase.

Nanostructured Conductive Materials:

Lisebelisoa tsa nanostructured, joalo ka carbon nanotubes le graphene, li ka kopanngoa ho li-substrates tsa PCB kapa tsa sebetsa e le li-fillers tsa conductive nakong ea deposition. Lisebelisoa tsena li na le conductivity e phahameng ea motlakase, matla a mochine le thepa ea mocheso, kahoo e ntlafatsa ts'ebetso ea kakaretso ea PCB.

Nanocoating:

Nanocoating e ka sebelisoa holim'a PCB ho ntlafatsa boreleli bo holimo, ho solderability le ts'ireletso ea kutu. Hangata liaparo tsena li entsoe ka li-nanocomposites tse fanang ka tšireletso e ntle khahlanong le maemo a tikoloho le ho lelefatsa bophelo ba PCB.

Lihokelo tsa Nanoscale:Lihokelo tsa Nanoscale, joalo ka li-nanowires le nanorods, li ntse li hlahlojoa ho thusa li-circuits tse phahameng ho li-PCB. Mehaho ena e thusa ho kopanngoa ha lipotoloho tse ngata sebakeng se senyenyane, ho lumella ho ntlafatsoa ha lisebelisoa tsa elektronike tse nyenyane, tse nang le lik'hamphani tse ngata.

Mathata le litataiso tsa nako e tlang: Leha ho na le tsoelo-pele e kholo, liphephetso le menyetla e mengata e ntse e le ea ho ntlafatsa ho beoa ha koporo ho li-PCB. Liphephetso tse ling tsa bohlokoa le litaelo tsa nako e tlang li kenyelletsa:

Koporo e Tlatsa ka Mehaho e Phahameng ea Karohano:

Mehaho e phahameng ea karo-karolelano joalo ka vias kapa microvias e hlahisa mathata a ho fihlela ts'ebetso e ts'oanang le e tšepahalang ea koporo. Ho hlokahala lipatlisiso tse ling ho nts'etsapele mekhoa e tsoetseng pele ea ho pola kapa mekhoa e meng ea ho tlatsa ho hlola liphephetso tsena le ho netefatsa ho beoa ka nepo ha koporo meahong ea likarolo tse phahameng.

Ho Fokotsa Bophara ba Copper Trace:

Ha lisebelisoa tsa elektronike li ntse li fokola 'me li kopana haholoanyane, tlhokahalo ea mesaletsa e menyenyane ea koporo e ntse e eketseha. Phephetso ke ho fumana kopo e ts'oanang le e ts'epahalang ea koporo ka har'a mesaletsa ena e moqotetsane, ho netefatsa ts'ebetso e ts'oanang ea motlakase le ts'epahalo.

Lisebelisoa tse ling tsa conductor:

Le hoja koporo e le thepa ea conductor e sebelisoang ka ho fetisisa, lisebelisoa tse ling tse kang silevera, aluminium, le carbon nanotubes li ntse li hlahlojoa bakeng sa thepa ea tsona e ikhethang le melemo ea ts'ebetso. Patlisiso ea nako e tlang e kanna ea shebana le ho nts'etsapele mekhoa ea ho beha lisebelisoa bakeng sa lisebelisoa tsena tse ling tsa conductor ho hlola liphephetso tse kang ho khomarela, ho hanyetsa, le ho tsamaellana le lits'ebetso tsa tlhahiso ea PCB. TikolohoMekhoa ea Setsoalle:

Indasteri ea PCB e lula e sebetsa molemong oa lits'ebetso tse se nang tikoloho. Lintlafatso tsa nako e tlang li kanna tsa shebana le ho fokotsa kapa ho felisa ts'ebeliso ea lik'hemik'hale tse kotsi nakong ea ho beoa ha koporo, ho ntlafatsa tšebeliso ea matla, le ho fokotsa tlhahiso ea litšila ho fokotsa tšusumetso ea tikoloho ea tlhahiso ea PCB.

Ketsiso e Tsoetseng Pele le Mohlala:

Mekhoa ea ho etsisa le ea ho etsa mohlala e thusa ho ntlafatsa lits'ebetso tsa ho beha koporo, ho bolela esale pele boits'oaro ba liparamente tsa deposition, le ho ntlafatsa ho nepahala le katleho ea tlhahiso ea PCB. Lintlafatso tsa nako e tlang li ka kenyelletsa ho kopanya lisebelisoa tse tsoetseng pele tsa ketsiso le ho etsa mohlala molemong oa moralo le oa tlhahiso ho thusa taolo le ntlafatso e betere.

6.Boleng ba Tiiso le Taolo ea Koporo Deposition bakeng sa PCB Substrates

Bohlokoa ba netefatso ea boleng: Netefatso ea boleng e bohlokoa ts'ebetsong ea ho beha koporo ka mabaka a latelang:

Tšepahalang ea Sehlahisoa:

Ho beha koporo ho PCB ho theha motheo oa likhokahano tsa motlakase. Ho netefatsa boleng ba koporo ea koporo ho bohlokoa bakeng sa ts'ebetso e tšepahalang le e tšoarellang ea lisebelisoa tsa elektroniki. Ho beoa ha koporo ho fosahetseng ho ka lebisa ho liphoso tsa khokahano, ho fokotsa matšoao, le ho ts'epaha ha PCB ka kakaretso.

Ts'ebetso ea motlakase:

Boleng ba ho roala koporo bo ama ka kotloloho ts'ebetso ea motlakase ea PCB. Botenya le kabo e tšoanang ea koporo, pheletso e boreleli ea holim'a metsi, le ho khomarela ka nepo ho bohlokoa ho fihlela khanyetso e tlase, phetisetso e sebetsang ea mats'oao, le tahlehelo e nyane ea matšoao.

Fokotsa litšenyehelo:

Tiisetso ea boleng e thusa ho tseba le ho thibela mathata qalong ea ts'ebetso, ho fokotsa tlhoko ea ho sebetsa bocha kapa ho lahla li-PCB tse nang le bokooa. Sena se ka boloka litšenyehelo le ho ntlafatsa katleho ea tlhahiso ka kakaretso.

Khotsofalo ea Bareki:

Ho fana ka lihlahisoa tsa boleng bo holimo ke habohlokoa bakeng sa khotsofalo ea bareki le ho haha setumo se setle indastering. Bareki ba lebelletse lihlahisoa tse tšepahalang le tse tšoarellang, 'me netefatso ea boleng e netefatsa hore koporo e kopana kapa e feta litebello tseo.

Mekhoa ea liteko le tlhahlobo ea ho beha koporo: Ho sebelisoa mekhoa e fapaneng ea tlhahlobo le tlhahlobo ho netefatsa boleng ba koporo ho li-PCB. Mekhoa e meng e tloaelehileng e kenyelletsa:

Tlhahlobo ea Pono:

Tlhahlobo ea pono ke mokhoa oa motheo le oa bohlokoa oa ho bona mefokolo e totobetseng ea bokaholimo joalo ka mengoapo, makhopho kapa mahoashe. Tlhahlobo ena e ka etsoa ka letsoho kapa ka thuso ea mokhoa oa automated optical inspection (AOI).

Microscopy:

Microscopy e sebelisang mekhoa e joalo ka scanning electron microscopy (SEM) e ka fana ka tlhahlobo e qaqileng ea ho beoa ha koporo. E ka hlahloba ka hloko qetello ea holimo, ho khomarela le ho tšoana ha lera la koporo.

Tlhahlobo ea X-ray:

Mekhoa ea tlhahlobo ea X-ray, joalo ka X-ray fluorescence (XRF) le X-ray diffraction (XRD), e sebelisoa ho lekanya sebopeho, botenya le kabo ea li-deposit tsa koporo. Mekhoa ena e ka khetholla litšila, sebopeho sa mantlha, le ho bona ho se lumellane hofe kapa hofe ha ho beoa koporo.

Teko ea Motlakase:

Etsa mekhoa ea tlhahlobo ea motlakase, ho kenyelletsa le litekanyo tsa ho hanyetsa le tlhahlobo e tsoelang pele, ho lekola ts'ebetso ea motlakase ea li-deposit tsa koporo. Liteko tsena li thusa ho netefatsa hore lera la koporo le na le conductivity e hlokahalang le hore ha ho na li-opens kapa li-shorts ka har'a PCB.

Teko ea Matla a Peel:

Teko ea matla a peel e lekanya matla a maqhama pakeng tsa lera la koporo le substrate ea PCB. E etsa qeto ea hore na depositi ea koporo e na le matla a lekaneng a bond ho mamella ts'ebetso e tloaelehileng ea ts'ebetso le mekhoa ea tlhahiso ea PCB.

Maemo le melaoana ea indasteri: Indasteri ea PCB e latela maemo le melaoana e fapaneng ea indasteri ho netefatsa boleng ba ho beoa ha koporo. Melao le melaoana e meng ea bohlokoa e kenyelletsa:

IPC-4552:

Tekanyetso ena e totobatsa litlhoko tsa kalafo e se nang electroless nickel/immersion gold (ENIG) e sebelisoang hangata ho li-PCB. E hlalosa bonyane botenya ba khauta, botenya ba nickel le boleng ba bokaholimo bakeng sa kalafo e ka tšeptjoang le e tšoarellang ea ENIG.

IPC-A-600:

Tekanyetso ea IPC-A-600 e fana ka litataiso tsa kamohelo ea PCB, ho kenyeletsoa maemo a likarolo tsa koporo ea plating, bofokoli ba bokaholimo le maemo a mang a boleng. E sebetsa e le sesupo sa tlhahlobo ea pono le litekanyetso tsa ho amoheloa ha koporo ho li-PCB. Tataiso ea RoHS:

Taelo ea Thibelo ea Lintho Tse Kotsi (RoHS) e thibela tšebeliso ea lintho tse ling tse kotsi lihlahisoa tsa elektroniki, ho kenyeletsoa lead, mercury le cadmium. Ho latela taelo ea RoHS ho etsa bonnete ba hore li-depositi tsa koporo ho li-PCB ha li na lintho tse kotsi, ho li etsa hore li bolokehe le ho boloka tikoloho.

ISO 9001:

ISO 9001 ke tekanyetso ea machaba ea litsamaiso tsa tsamaiso ea boleng. Ho theha le ho kenya tšebetsong sistimi ea taolo ea boleng e thehiloeng ho ISO 9001 ho netefatsa hore lits'ebetso le litsamaiso tse nepahetseng li teng ho fana ka lihlahisoa tse fihlelang litlhoko tsa bareki, ho kenyeletsoa le boleng ba koporo ho li-PCB.

Ho fokotsa mathata a tloaelehileng le bofokoli: Mathata a mang a tloaelehileng le mefokolo e ka hlahang nakong ea koporo e kenyelletsa:

Ho se khomarele ka ho lekaneng:

Ho khomarela ho fokolang ha lera la koporo ho substrate ho ka lebisa ho delamination kapa peeling. Ho hloekisoa ka mokhoa o nepahetseng holim'a metsi, ho hloekisoa ha mechine, le liphekolo tse khothalletsang ho khomarela li ka thusa ho fokotsa bothata bona.

Botenya ba Koporo bo sa Lekaneng:

Botenya bo sa lekaneng ba koporo bo ka baka conductivity e sa tsitsang le ho sitisa phetiso ea matšoao. Ho ntlafatsa liparamente tsa plating, ho sebelisa pulse kapa reverse pulse plating le ho etsa bonnete ba ho tsitsinyeha ho nepahetseng ho ka thusa ho fihlela botenya ba koporo bo tšoanang.

Voids le Pinholes:

Likheo le likoti tse lera la koporo li ka senya likhokahano tsa motlakase le ho eketsa kotsi ea ho bola. Taolo e nepahetseng ea liparamente tsa plating le ts'ebeliso ea li-additives tse nepahetseng li ka fokotsa ho hlaha ha li-void le li-pinholes.

Bokhopo ba bokaholimo:

Bokhopo bo feteletseng ba holim'a metsi bo ka ama ts'ebetso ea PCB hampe, ba ama ho solderability le botsitso ba motlakase. Taolo e nepahetseng ea li-parameter tsa koporo ea koporo, ts'ebetso ea pele ho kalafo le ts'ebetso ea kamora kalafo e thusa ho fihlela pheletso e boreleli.

Ho fokotsa litaba le mefokolo ena, ho tlameha ho kengoa tšebetsong litsamaiso tse nepahetseng, tlhahlobo le liteko tsa khafetsa li tlameha ho etsoa, 'me ho tlameha ho lateloe litekanyetso le melaoana ea indasteri. Sena se tiisa hore ho behiloe koporo e tsitsitseng, e ka tšeptjoang le ea boleng bo holimo ho PCB. Ho feta moo, ntlafatso ea ts'ebetso e tsoelang pele, koetliso ea basebetsi, le mekhoa ea ho fana ka maikutlo li thusa ho tseba libaka tsa ntlafatso le ho rarolla mathata a ka bang teng pele e e-ba boima le ho feta.

Ho beha koporo ho substrate ea PCB ke mohato oa bohlokoa ts'ebetsong ea tlhahiso ea PCB. Electroless koporo deposition le electroplating ke mekhoa e ka sehloohong e sebelisoang, e 'ngoe le e' ngoe e na le melemo le mefokolo ea eona. Tsoelo-pele ea theknoloji e ntse e tsoela pele ho tsamaisa mekhoa e mecha ea ho kenya koporo, kahoo e ntlafatsa ts'ebetso ea PCB le ho tšepahala.Netefatso ea boleng le taolo li phetha karolo ea bohlokoa ho netefatsa tlhahiso ea li-PCB tsa boleng bo holimo. Ha tlhoko ea lisebelisoa tsa elektroniki tse nyane, tse potlakileng, le tse tšepahalang li ntse li eketseha, ho joalo le ka tlhoko ea ho nepahala le bokhabane ho theknoloji ea ho beha koporo ho li-substrates tsa PCB. Tlhokomeliso: Palo ea mantsoe a sengoloa e ka ba mantsoe a 3,500, empa ka kopo hlokomela hore palo ea mantsoe e ka fapana hanyane nakong ea ho hlophisoa le ho bala liphoso.

Nako ea poso: Sep-13-2023

Morao