Tsebisa:

Ho sebetsa hantle ha PCB ho bohlokoa bakeng sa kopano e atlehileng le ts'ebetso ea lipotoloho tsa elektroniki. Soldering e nepahetseng e tiisa khokahanyo e ka tšeptjoang ea motlakase, e amang ka ho toba tshebetso ea potoloho ka kakaretso.Tataiso ena e felletseng e tla hlahloba mekhoa, mefuta le mekhoa e fapaneng e amehang ho solder ea PCB. Ka ho utloisisa lintlha tsena, u ka etsa liqeto tse nang le tsebo ha u khetha mekhoa le lisebelisoa tse nepahetseng tsa welding.

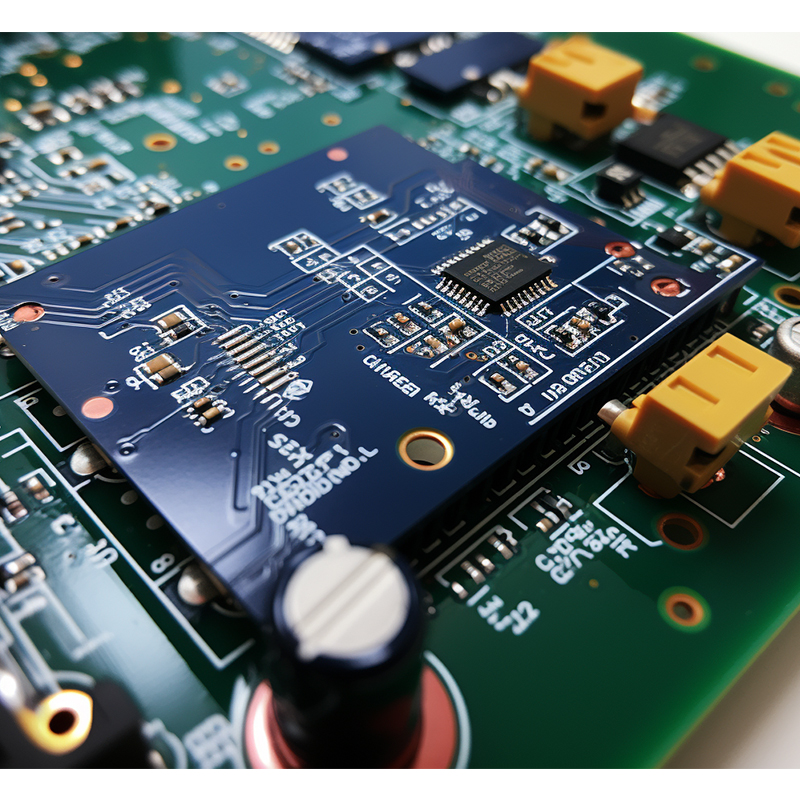

Tlhaloso: PCB soldering kakaretso:

PCB welding, eo hape e tsejoang e le soldering, e kenyelletsa ho etsa likhokahano tse tšepahalang tsa motlakase lipakeng tsa likarolo tsa elektroniki le liboto tsa potoloho. E phetha karolo ea bohlokoa ho netefatsa ts'ebetso e tloaelehileng ea potoloho eohle. Mekhoa e fapaneng ea ho kopanya e sebelisoa kopanong ea PCB, e 'ngoe le e' ngoe e na le melemo le mehopolo ea eona.

Ithute kaTheknoloji ea ho kopanya ea PCB:

A. PCB mokhoa oa ho tjheseletsa:

E le ho finyella weld e atlehileng, ke habohlokoa ho latela mokhoa o qaqileng. Karolo ena e tla hlalosa mohato ka mohato tshebetso ya PCB soldering. E tla boela e koahele boitokisetso ba likarolo tsa PCB bakeng sa soldering le ho hlalosa lisebelisoa le lisebelisoa tse hlokahalang.

B. Mekhoa e tloaelehileng ea ho kopanya PCB:

Ho solder ka lesoba:

Ka ho soasoa ka lesoba ke mokhoa o sebelisoang haholo o kenyelletsang likarolo tsa solder ka likoti tse entsoeng pele ho boto ea potoloho. Karolo ena e tla fana ka tlhaloso ea mokhoa oa "hole-hole soldering", ho buisana ka melemo le melemo ea eona, 'me e totobatsa mekhoa e metle le lisebelisoa.

Surface mount soldering:

Surface mount soldering, eo hape e tsejoang e le surface mount technology (SMT) soldering, hangata e sebelisoa ho fokotsa likarolo tsa elektroniki. Karolo ena e tla fana ka kakaretso ea theknoloji ea thekiso ea SMT, melemo ea eona, mefokolo, le lintlha tsa bohlokoa bakeng sa ts'ebetsong e atlehileng.

Welding e ntle ea sekontiri:

Likarolo tsa soldering-pitch-pitch li ka hlahisa mathata a ikhethang ka lebaka la molumo o haufi oa lithakhisa. Karolo ena e hlahloba mathata a amanang le ho kopanya likaroloana tsa "solder" 'me e fana ka malebela le litemoso bakeng sa ho fumana manonyeletso a nepahetseng a solder. Ho feta moo, ho tla buisanoa ka lisebelisoa tse tsoetseng pele le lisebelisoa tse thusang ho etsa welding e nepahetseng hantle.

Welding ea rigid-flex board:

Rigid-flex welding e bua ka ts'ebetso ea likarolo tsa solder ho boto ea potoloho e tenyetsehang e kopantsoeng le karolo e thata. Karolo ena e tla hlahisa thekenoloji e ka morao ho rigid-flex soldering, ho buisana ka liphephetso tse amehang, le ho fana ka tharollo ea ho etsa bonnete ba hore li-solder tsa boleng bo phahameng likopanong tsa PCB tse thata-flex.

HDI PCB soldering:

Li-PCB tsa High-density interconnect (HDI) li na le meralo e rarahaneng le ho teteana ha likarolo tse phahameng. Soldering HDI PCB hloka tsebo e khethehileng. Karolo ena e hlahloba lintho tse rarahaneng tsa soldering HDI PCBs, e totobatsa boitseanape bo hlokahalang, 'me e tšohla melemo le ho nahanela HDI PCB soldering.

Malebela a ho sebetsa ka katleho PCB:

A. Boitokisetso le Moralo:

Katleho PCB soldering qala ka ho lokisetsa e nepahetseng le moralo. Karolo ena e bua ka bohlokoa ba sebopeho sa PCB le ho beoa ha karolo ho nolofatsa mokhoa oa ho kopanya. E tla boela e hatise tlhokahalo ea ho khetha mokhoa o nepahetseng oa solder o thehiloeng ho moralo oa PCB le bohlokoa ba tšebeliso e nepahetseng ea peista ea solder.

B. Ts'ebetso ea welding le khetho ea lisebelisoa:

Ho bohlokoa ho khetha lisebelisoa le lisebelisoa tse nepahetseng bakeng sa ho fumana liphetho tse atlehileng tsa welding. Karolo ena e tla u tataisa ha u khetha lisebelisoa le lisebelisoa tse nepahetseng bakeng sa mosebetsi o itseng. E tla boela e buisane ka lintlha tse lokelang ho nahanoa ha u khetha lisebelisoa tsa ho tjheseletsa le ho hatisa bohlokoa ba ho sebelisa li-profiles tse loketseng tsa mocheso oa welding.

C. Taolo ea Boleng le Tlhahlobo:

Ho kenya ts'ebetsong mehato ea ho laola boleng le ho etsa litlhahlobo nakong ea ts'ebetso ea welding ho bohlokoa ho netefatsa hore ho na le li-solder tse tšepahalang. Karolo ena e bua ka mekhoa ea tlhahlobo ea pono e kopaneng ea solder, hammoho le mekhoa e tsoetseng pele ea tlhahlobo le lisebelisoa tse ka sebelisoang ho lekola boleng ba weld.

Qetello:

Ka kakaretso, tataiso ena e pharaletseng e akaretsa bohlokoa ba ho sebetsa hantle ha PCB le phello eo soldering e nepahetseng e nang le eona mosebetsing oa potoloho. Ka ho khetha mokhoa o nepahetseng oa solder le mokhoa, o ka finyella li-joints tsa boleng bo phahameng. Tokisetso e nepahetseng, khetho e hlokolosi ea lisebelisoa, le taolo e phethahetseng ea boleng ke linotlolo tsa ho rekisa ka katleho PCB. Ho tsetela ka lisebelisoa tsa boleng bo holimo le ho latela mekhoa e metle ho tla fana ka litholoana tse ntle ho kopano ea PCB.

Nako ea poso: Nov-07-2023

Morao