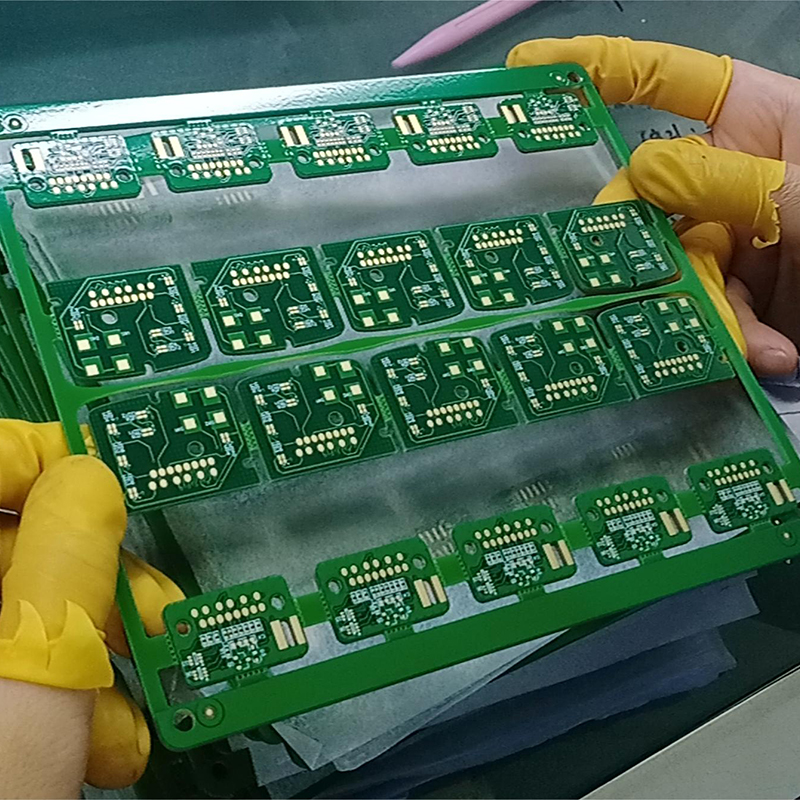

Tsoelo-pele e potlakileng ea indasteri ea lisebelisoa tsa elektronike e lebisitse ts'ebetsong e pharaletseng ea boto ea rigid-flex. Leha ho le joalo, ka lebaka la ho se tšoane ha matla, thekenoloji, phihlelo, ts'ebetso ea tlhahiso, bokhoni ba ts'ebetso le lisebelisoa tsa lisebelisoa tsa bahlahisi ba fapaneng, mathata a boleng ba mapolanka a thata-thata mosebetsing oa tlhahiso ea boima a boetse a fapane.Capel e latelang e tla hlalosa ka ho qaqileng mathata a mabeli a tloaelehileng le tharollo e tla etsahala tlhahisong e kholo ea liboto tse thata tse tenyetsehang.

Ts'ebetsong ea tlhahiso e boima ea liboto tse thata-thata, ho sesa hantle ke bothata bo tloaelehileng. Tining e fosahetseng e ka baka ho hloka botsitso

manonyeletso a solder le ho ama ho tšepahala ha sehlahisoa.

Mona ke mabaka a mang a ka bakang tšitiso e fosahetseng:

1. Bothata ba ho hloekisa:Haeba bokaholimo ba boto ea potoloho bo sa hloekisoa hantle pele ho tining, bo ka lebisa ho solder e mpe;

2. Thempereichara ea soldering ha e ea lokela:haeba mocheso oa soldering o phahame haholo kapa o le tlase haholo, o ka lebisa ho tinning e fokolang;

3. Mathata a boleng ba solder paste:paste ea boleng bo tlase ea solder e ka lebisa ho tinning e futsanehileng;

4. Mathata a boleng ba likarolo tsa SMD:Haeba boleng ba pad ea likarolo tsa SMD bo sa nepahale, bo tla lebisa ho tinning e mpe;

5. Ts'ebetso ea welding e sa nepahalang:Ts'ebetso e sa nepahalang ea li-welding le eona e ka lebisa ho se nang tinning hantle.

Bakeng sa ho qoba kapa ho rarolla mathata ana a fokolang a solder, ka kopo ela hloko lintlha tse latelang:

1. Etsa bonnete ba hore bokaholimo ba boto bo hloekisitsoe hantle ho tlosa oli, lerōle le litšila tse ling pele ho tining;

2. Laola mocheso le nako ea ho tining: Ha ho etsoa tinning, ho bohlokoa haholo ho laola mocheso le nako ea ho tining. Etsa bonnete ba hore u sebelisa mocheso o nepahetseng oa solder 'me u etse liphetoho tse nepahetseng ho latela lisebelisoa le litlhoko tsa solder. Mocheso o feteletseng le nako e telele haholo Nako e ka 'na ea etsa hore manonyeletso a solder a chese haholo kapa a qhibilihe,' me a ba a baka tšenyo ho boto e thata-flex. Ho fapana le hoo, mocheso o tlase haholo le nako e ka etsa hore thepa ea solder e se ke ea khona ho koloba ka ho feletseng le ho hasana ho motsoako oa solder, kahoo e etsa motsoako o fokolang oa solder;

3. Khetha thepa e loketseng ea solder: khetha mofani oa thepa ea solder e ka tšeptjoang, etsa bonnete ba hore e lumellana le thepa ea boto e thata-thata, 'me u netefatse hore maemo a ho boloka le ho sebelisa solder paste a lokile.

Khetha lisebelisoa tsa boleng ba boleng bo phahameng ho etsa bonnete ba hore lisebelisoa tsa solder li na le mongobo o motle le sebaka se nepahetseng sa ho qhibiliha, e le hore li ka aroloa ka ho lekana 'me li thehe manonyeletso a tsitsitseng a solder nakong ea ts'ebetso ea tinning;

4. Etsa bonnete ba hore u sebelisa lisebelisoa tsa patch tsa boleng bo botle, 'me u hlahlobe ho bata le ho roala ha patch;

5. Koetliso le ho ntlafatsa tsebo ea ts'ebetso ea welding ho netefatsa mokhoa o nepahetseng oa solder le nako;

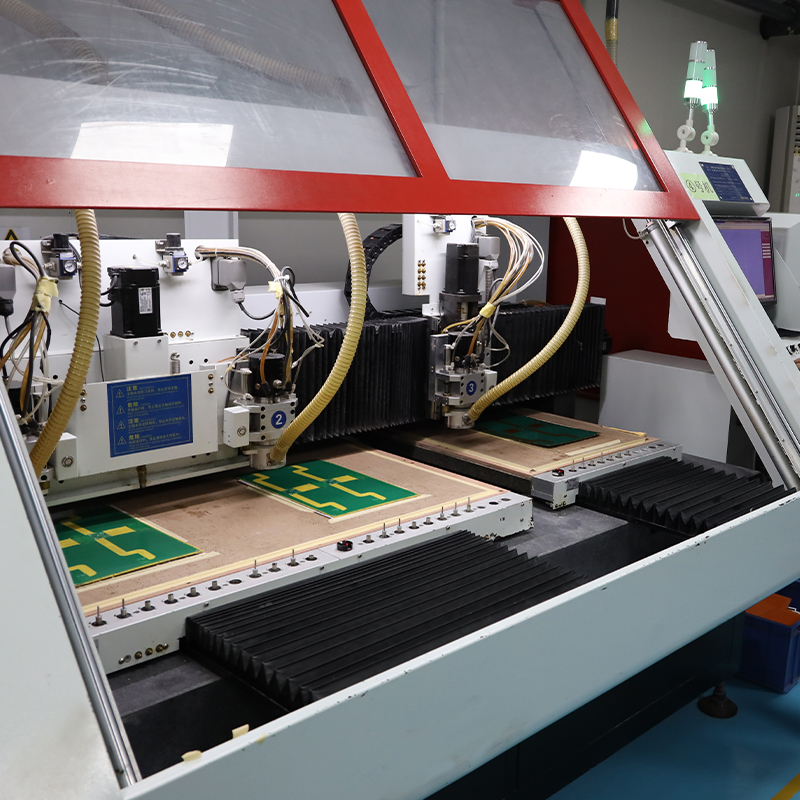

6. Laola botenya le ho tšoana ha thini: etsa bonnete ba hore thini e arotsoe ka mokhoa o lekanang sebakeng sa soldering ho qoba ho tsepamisa mohopolo le ho se lekane ha sebaka. Lisebelisoa le mekhoa e nepahetseng, joalo ka metjhini e tining kapa lisebelisoa tse itšebetsang tsa othomathike, li ka sebelisoa ho etsa bonnete ba kabo le botenya bo nepahetseng ba thepa e kolobisang;

7. Ho hlahlojoa le ho hlahlojoa khafetsa: Ho hlahlojoa le ho hlahlojoa khafetsa ho etsoa ho netefatsa boleng ba lihlopha tsa solder tsa boto e thata-thata. Boleng le ts'epahalo ea manonyeletso a solder a ka hlahlojoa ho sebelisoa tlhahlobo ea pono, tlhahlobo ea ho hula, joalo-joalo Fumana le ho rarolla bothata ba ho sesa hantle ka nako ho qoba mathata a boleng le ho hloleha ha tlhahiso e latelang.

Botenya bo sa lekaneng ba lesoba le botenya bo sa lekaneng ba lesoba la koporo le tsona ke mathata a ka bang teng tlhahisong ea bongata.

mapolanka a thata-thata. Ho hlaha ha mathata ana ho ka ama boleng ba sehlahisoa. Se latelang se sekaseka mabaka le

tharollo e ka bakang bothata bona:

Lebaka:

1. Bothata ba ho alafa esale pele:Pele electroplating, pretreatment ea lerako lesoba ke ea bohlokoa haholo. Haeba ho na le mathata a kang corrosion, tšilafalo kapa ho se lekane leboteng la lesoba, ho tla ama ho ts'oana le ho khomarela mokhoa oa ho pata. Etsa bonnete ba hore mabota a lesoba a hloekisitsoe hantle ho tlosa litšila le likarolo tsa oxide.

2. Bothata ba ho etsa tharollo ea ho rala:Tlhahiso e fosahetseng ea tharollo ea plating e ka boela ea lebisa ho se leka-lekaneng. Sebopeho le mohopolo oa tharollo ea plating e lokela ho laoloa ka thata le ho lokisoa ho netefatsa ho ts'oana le botsitso nakong ea ts'ebetso ea plating.

3. Bothata ba liparamente tsa electroplating:electroplating parameters kenyeletsa segokanyipalo hona joale, electroplating nako le thempereichara, joalo-joalo Litlhophiso tsa paramethara e fosahetseng ka 'na lebisa mathateng a sa leka-lekaneng plating le botenya bo sa lekaneng. Netefatsa hore liparamente tse nepahetseng li behiloe ho latela litlhoko tsa sehlahisoa le ho etsa liphetoho tse hlokahalang le ho beha leihlo.

4. Litaba tsa ts'ebetso:Mehato ea ts'ebetso le ts'ebetso ea ts'ebetso ea electroplating e tla boela e ama ho tšoana le boleng ba electroplating. Etsa bonnete ba hore basebetsi ba latela mokhoa oa ts'ebetso ka tieo mme ba sebelisa lisebelisoa le lisebelisoa tse nepahetseng.

Tharollo:

1. Optimize tshebetso pretreatment ho etsa bonnete ba ho hloeka le ho batalla ha lerako lesoba.

2. Kamehla hlahloba le ho lokisa ho etsoa ha tharollo ea electroplating ho netefatsa botsitso le ho tšoana ha eona.

3. Beha liparamente tse nepahetseng ho latela litlhoko tsa sehlahisoa, 'me u behe leihlo le ho lokisa haufi-ufi.

4. Etsa koetliso ea basebetsi ho ntlafatsa tsebo ea ts'ebetso ea ts'ebetso le tlhokomeliso.

5. Hlahisa mokhoa oa tsamaiso ea boleng ho etsa bonnete ba hore sehokelo se seng le se seng se fetile taolong e tiileng ea boleng le tlhahlobo.

6. Matlafatsa tsamaiso ea data le ho rekota: theha tsamaiso e feletseng ea data le mokhoa oa ho rekota ho rekota liphetho tsa liteko tsa botenya ba sekoti sa sekoti le ho lumellana ha plating. Ka lipalo-palo le tlhahlobo ea lintlha, boemo bo sa tloaelehang ba botenya ba koporo ea lesoba le ho tšoana ha electroplating bo ka fumanoa ka nako, 'me mehato e lumellanang e lokela ho nkoa ho lokisa le ho ntlafatsa.

Lintlha tse ka holimo ke mathata a mabeli a maholo a ho sesa hantle, botenya ba sekoti sa koporo e sa lekaneng, le sekoti sa koporo se sa lekaneng se atisang ho hlaha ka botong e thata-thata.Ke tšepa hore tlhahlobo le mekhoa e fanoeng ke Capel e tla thusa bohle. Bakeng sa lipotso tse ling tse hatisitsoeng tsa boto ea potoloho, ka kopo ikopanye le sehlopha sa litsebi tsa Capel, lilemo tse 15 tsa boiphihlelo ba boto ea potoloho le boiphihlelo ba tekheniki li tla felehetsa morero oa hau.

Nako ea poso: Aug-21-2023

Morao