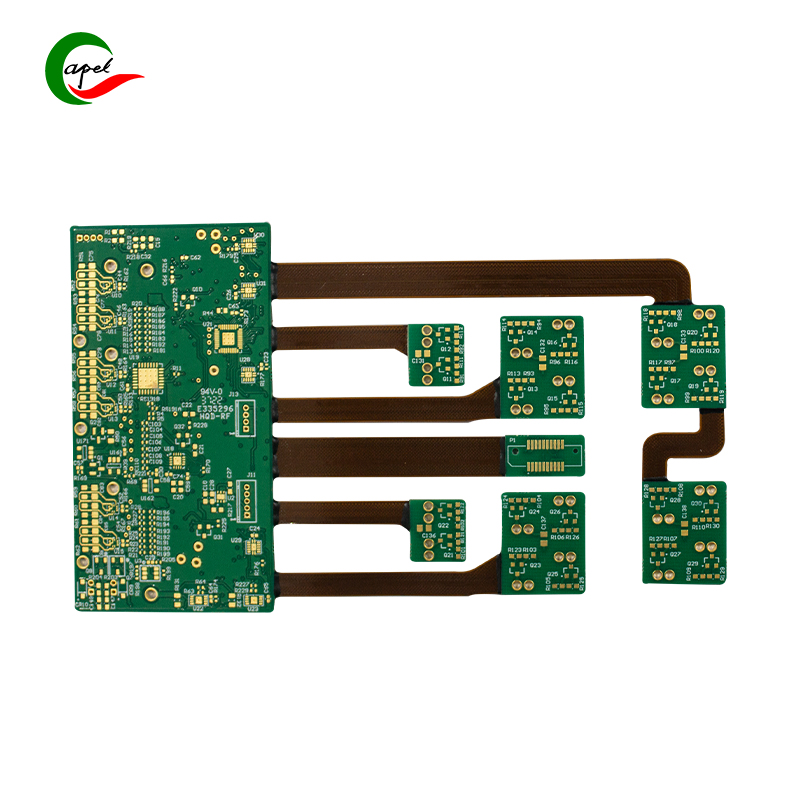

Ha thekenoloji e ntse e tsoela pele ka lebelo le sa lebelloang, tlhokahalo ea lisebelisoa tsa elektroniki tse kopaneng, tse bobebe le tse tenyetsehang haholoanyane e eketsehile. Ho fihlela tlhoko ena, nts'etsopele ea liboto tsa potoloho tse thata-flex e fetohile boqapi bo boholo indastering ea lisebelisoa tsa elektronike. Liboto tsena li kopanya ho feto-fetoha ha li-circuits tse feto-fetohang le ho tšoarella ha liboto tse thata, ho etsa hore e be tse loketseng bakeng sa lisebelisoa tse ngata tse kenyeletsang sefofane, lisebelisoa tsa bongaka le lisebelisoa tsa motlakase tsa bareki.

Karolo ea bohlokoa ea ho etsa liboto tsa potoloho tse thata-flex ke mokhoa oa ho kopanya. Ts'ebetso ena e phetha karolo ea bohlokoa ho netefatsa botsitso le ts'epahalo ea liboto tsena kaha e tiisa likarolo tse tenyetsehang le tse thata hammoho. Ka poso ena ea blog, Capel o tla shebisisa lintlha tsa ts'ebetso ea tlamahano, a buisane ka sephetho sa eona, mekhoa le maikutlo.

Utloisisa moelelo:

Mokhoa oa ho kopanya o bohlokoa ho boloka botšepehi ba sebopeho sa liboto tsa potoloho tse thata-flex. E kenyelletsa ho sebelisoa ha sekhomaretsi pakeng tsa potoloho e feto-fetohang le substrate e thata, ho theha maqhama a matla a ka mamellang maemo a tikoloho, khatello ea mechine le liphetoho tsa mocheso. Ha e le hantle, sekhomaretsi ha se tšoare feela lihlopha, empa se boetse se sireletsa potoloho ho tloha tšenyo e ka bang teng.

Khetha sekhomaretsi se nepahetseng:

Ho khetha sekhomaretsi se nepahetseng ho bohlokoa ho netefatsa ts'epo ea nako e telele le ts'ebetso ea liboto tsa potoloho tse thata-flex. Lintlha tse 'maloa li lokela ho nkoa ha ho khethoa sekhomaretsi, tse kang ho lumellana le lisebelisoa tse sebelisoang, ts'ebetso ea mocheso, ho feto-fetoha ha maemo, le litlhoko tse khethehileng tsa kopo.

Likhomaretsi tse thehiloeng ho polyimide li sebelisoa haholo ka lebaka la botsitso ba tsona bo botle ba mocheso, ho feto-fetoha ha maemo, le ho lumellana le lisebelisoa tse thata le tse tenyetsehang. Ho feta moo, li-adhesives tse thehiloeng ho epoxy li sebelisoa haholo ka lebaka la matla a tsona a phahameng, ho hanyetsa mongobo le lik'hemik'hale. Ke habohlokoa ho buisana le moetsi oa sekhomaretsi le moetsi oa boto ea potoloho e thata-flex ho fumana lisebelisoa tse loketseng ka ho fetisisa bakeng sa kopo e itseng.

Mekhoa ea ho sebelisa Adhesive:

Tšebeliso e atlehileng ea li-adhesive e hloka tlhokomelo ho lintlha le ho khomarela mokhoa o nepahetseng. Mona re hlahloba tse ling tsa mekhoa ea mantlha e sebelisoang ts'ebetsong ea bonding ea rigid-flex board:

1. Ho hatisa skrineng:

Ho hatisa skrineng ke mokhoa o tummeng oa ho sebelisa li-adhesive ho liboto tsa potoloho. E kenyelletsa ho sebelisa stencil kapa skrine ea letlooeng ho fetisetsa sekhomaretsi libakeng tse itseng tsa boto. Mokhoa ona o lumella hore ho be le taolo e nepahetseng ea botenya ba sekhomaretsi le kabo, ho netefatsa tlamo e tsitsitseng le e ka tšeptjoang. Ho feta moo, khatiso ea skrine e ka iketsetsa, ea ntlafatsa katleho ea tlhahiso le ho fokotsa phoso ea batho.

2. Ho fana:

Ho fana ka likhomaretsi ho kenyelletsa ts'ebeliso e nepahetseng ea thepa e sebelisang lisebelisoa tse ikemetseng tsa ho tsamaisa. Theknoloji ena e lumella ho behoa ka nepo le ho tlatsoa ha sekhomaretsi, ho fokotsa kotsi ea li-voids le ho netefatsa matla a maholo a tlamo. Ho fana hangata ho sebelisoa bakeng sa meralo ea boto ea potoloho e rarahaneng kapa e mahlakore a mararo moo khatiso ea skrini e ka 'nang ea se khonehe.

3. Lamination:

Lamination ke mokhoa oa ho kopanya lera le tenyetsehang la potoloho lipakeng tsa likarolo tse peli tse thata tse nang le sekhomaretsi se kentsoeng lipakeng. Theknoloji ena e etsa bonnete ba hore sekhomaretsi se ajoa ka ho lekana ho pholletsa le boto, ho eketsa katleho ea ho kopanya. Lamination e loketse ka ho khetheha bakeng sa tlhahiso ea molumo o phahameng hobane e lumella mapolanka a mangata ho kopanngoa hammoho ka nako e le 'ngoe.

Lintlha tse mabapi le mokhoa oa ho kopanya:

Leha ho le bohlokoa ho utloisisa mekhoa e fapaneng ea ho sebelisa sekhomaretsi, ho na le lintlha tse ling tse tlatselletsang katlehong ea ts'ebetso ea sekhomaretsi ka kakaretso. Lintlha tsena li phetha karolo ea bohlokoa ho ntlafatsa ts'ebetso le ho tšepahala ha liboto tsa potoloho tse thata-flex. A re hlahlobeng tse ling tsa lintlha tsena:

1. Bohloeki:

Ke habohlokoa ho etsa bonnete ba hore libaka tsohle, haholo-holo li-circuit circuits, li hloekile ebile ha li na litšila pele u sebelisa sekhomaretsi. Esita le likaroloana tse nyenyane kapa masala a ka senya ho khomarela, ho lebisa ho fokotseng ho tšepahala kapa ho hlōleha. Mekhoa e nepahetseng ea ho hloekisa holim'a metsi e lokela ho kenngoa ts'ebetsong, ho kenyelletsa le tšebeliso ea joala ea isopropyl kapa tharollo e khethehileng ea ho hloekisa.

2. Maemo a ho folisa:

Maemo a tikoloho nakong ea ho phekola ka sekhomaretsi a bohlokoa ho fihlela matla a mangata a tlamo. Lintlha tse kang mocheso, mongobo le nako ea phekolo li tlameha ho laoloa ka hloko ho finyella litataiso tsa moetsi oa sekhomaretsi. Ho kheloha ho tloha maemong a khothaletsoang a pheko ho ka baka ts'ebetso e mpe ea bond kapa bond.

3. Maikutlo a khatello ea mochine:

Liboto tsa potoloho tsa rigid-flex hangata li ba tlas'a khatello e fapaneng ea mochini joalo ka ho kobeha, ho sotha le ho thothomela nakong ea bophelo ba bona ba ts'ebeletso. Ke habohlokoa ho nahana ka lintlha tsena nakong ea ho kopanya. Lisebelisoa tsa ho kopanya li lokela ho khethoa ka ho feto-fetoha ha maemo le ho hanyetsa mokhathala o motle ho etsa bonnete ba hore tlamo e ka mamella likhatello tsena tsa mechine ntle le ho hlōleha.

Ts'ebetso ea tlamahano ea tlhahiso ea boto ea potoloho e thata-flex e bohlokoa ho fihlela botsitso, ho tšoarella le ho ts'epahala. Khetho ea lisebelisoa tse nepahetseng tsa sekhomaretsi hammoho le mekhoa e nepahetseng ea ts'ebeliso le litemoso li ka netefatsa ts'ebetso ea nako e telele ea liboto tsena esita le lits'ebetsong tse thata ka ho fetisisa.

Ha theknoloji e ntse e tsoela pele ho fetoha, tlhokahalo ea lisebelisoa tsa elektronike tse tsoetseng pele le tse tenyetsehang li tla tsoela pele. Mokhoa oa ho kopanya o phetha karolo ea bohlokoa ho finyella tlhoko ena ka ho hlahisa liboto tsa potoloho tse tšeptjoang le tse tenyetsehang. Ka ho utloisisa bohlokoa ba ts'ebetso ea ho kopanya le ho e kenya ts'ebetsong ka nepo, bahlahisi ba ka etsa lisebelisoa tsa elektronike tse tsoetseng pele tse ka pele ho mekhoa e mecha ea theknoloji.

Nako ea poso: Aug-21-2023

Morao