Posong ena ea blog, re tla hlahloba melemo, liqholotso, le monyetla oa ho sebelisa liboto tsa potoloho tse thata molemong oa moralo le tlhahiso ea likoloi.

Tikolohong ea kajeno ea mahlale a potlakileng, baetsi ba likoloi ba lula ba loanela ho lula ba le ka pele ho lebelo le ho holisa ts'ebetso ea koloi, ts'epahalo le ts'ebetso. Nts'etsopele e 'ngoe e kholo e fetotseng indasteri ke ho kopanya liboto tsa potoloho tse thata-flex. Liboto tsena tse ikhethang tsa potoloho li fana ka melemo e mengata e etsang hore e be e loketseng bakeng sa lits'ebetso tsa likoloi.

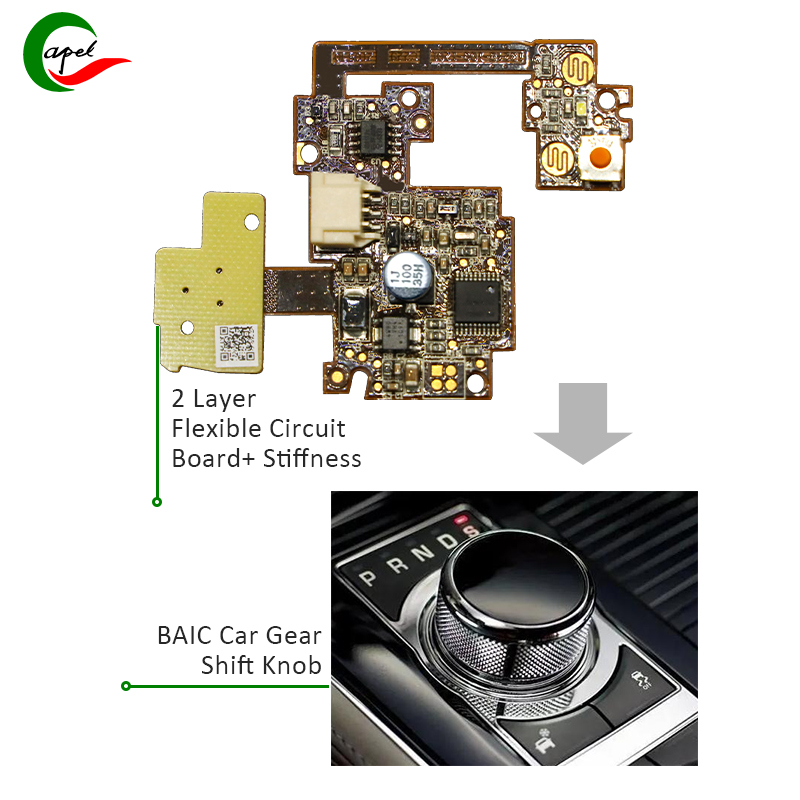

Ho utloisisa karolo ea liboto tsa potoloho tse thata-flex lefatšeng la likoloi, re lokela ho qala ka ho hlalosa hore na ke eng.Li-circuits tsa rigid-flex li kopanya tse ntle ka ho fetisisa tsa lefatše ka bobeli ka ho kopanya likarolo tse thata le tse tenyetsehang botong e le 'ngoe. Sebopeho sena sa lebasetere se fana ka melemo e mengata ho feta liboto tsa potoloho tse thata kapa tse tenyetsehang, e leng se etsang hore e be se loketseng lisebelisoa tsa likoloi.

E 'ngoe ea melemo ea mantlha ea ho sebelisa liboto tsa potoloho tse thata-thata indastering ea likoloi ke bokhoni ba tsona ba ho mamella maemo a thata.Lisebelisoa tsa likoloi li pepesa likarolo tsa elektronike mochesong o feteletseng, ho thothomela le khatello ea mochine. Li-circuits tsa rigid-flex li fana ka khanyetso e babatsehang ho lintlha tsena tsa tikoloho, ho netefatsa botšepehi le botšepehi ba lisebelisoa tsa elektronike tsa koloi. Ntle le moo, moralo oa eona o kopaneng, o bobebe o nolofalletsa tšebeliso e ntle ea sebaka ka har'a meeli e lekanyelitsoeng ea kahare ea koloi.

Molemo o mong oa liboto tsa potoloho tse thata-flex ke ho ts'epaha ha tsona ho ntlafalitsoeng.Motsoako oa thepa e thata le e tenyetsehang e felisa tlhoko ea lihokelo le manonyeletso a solder, ho fokotsa kotsi ea ho hloleha ka lebaka la likhokahano tse hlephileng kapa mokhathala oa solder. Sena se eketsa nako e telele ea ho tšoarella le nako e telele ea boto ea potoloho, ho etsa hore koloi e be matla le ho se khone ho senya motlakase.

Ntle le moo, ho tenyetseha ha mapolanka a rigid-flex ho lumella baqapi ho ntlafatsa sebopeho le ho fokotsa palo ea likhokahano, ka tsela eo ba ntlafatsa botšepehi ba matšoao le ho fokotsa tšitiso ea motlakase (EMI).Ha litsamaiso tsa elektronike tsa likoloi li ntse li tsoela pele ho eketseha ka mokhoa o rarahaneng, ho boloka botšepehi ba matšoao ho bohlokoa ho netefatsa puisano e sebetsang hantle, e se nang liphoso pakeng tsa likarolo tse fapaneng. Li-circuits tsa rigid-flex li fana ka tharollo e sebetsang phephetsong ena, ho thusa ho kopanya ka mokhoa o se nang moeli oa li-module tse fapaneng tsa elektroniki le ho ntlafatsa ts'ebetso ea sistimi ka kakaretso.

Ho kopanngoa ha liboto tsa potoloho tse thata-flex ho boetse ho boloka litšenyehelo tse kholo bakeng sa indasteri ea likoloi.Ka ho felisa tlhokahalo ea likhokahanyo tse eketsehileng le ho fokotsa palo ea likhokahano, bahlahisi ba ka tsamaisa mekhoa ea tlhahiso le ho fokotsa nako ea kopano, qetellong ba fokotsa litšenyehelo tsa tlhahiso. Ho feta moo, ts'epo e ntseng e eketseha ea liboto tsena e fokotsa tlhokahalo ea litokiso tse bitsang chelete e ngata le ho nchafatsoa, ka hona ho lelefatsa nako ea bophelo le ho fokotsa litšenyehelo tsa tlhokomelo.

Leha ho le joalo, ho sa tsotellehe melemo ea eona e mengata, ho na le mathata a itseng a amanang le ho kenya ts'ebetsong liboto tsa potoloho tse thata-flex ho lisebelisoa tsa likoloi.Kaho e ikhethang ea mapolanka ana e hloka mekhoa e khethehileng ea tlhahiso le tsebo, e ka eketsang litšenyehelo tsa pele tsa tlhahiso. Leha ho le joalo, ha tlhokahalo ea liboto tsa potoloho e thata e ntse e tsoela pele ho hola indastering ea likoloi, moruo oa sekhahla o ka fokotsa litšenyehelo tsa tlhahiso, oa ba etsa khetho e sebetsang haholoanyane moruong ha nako e ntse e ea.

Ntle le moo, maemo a thata a indasteri ea likoloi le maemo a polokeho a hloka tlhahlobo e phethahetseng le netefatso ea likarolo tsohle, ho kenyeletsoa liboto tsa potoloho.Liphanele tsa rigid-flex li tlameha ho etsa tlhahlobo e matla ea ho ts'epahala ho netefatsa hore li ka mamella maemo a thata ao likoloi li tobaneng le 'ona. Ts'ebetso ea ho etsa liteko e ka nka nako mme e ka hlahisa mathata a nako ho ea 'marakeng bakeng sa baetsi ba likoloi. Leha ho le joalo, melemo ea ts'episo e eketsehileng le ts'ebetso e feta nako e ka bang teng, ho etsa hore mapolanka a thata-thata e be tharollo ea bohlokoa ho moralo le tlhahiso ea likoloi.

Ka kakaretso, ho kopanngoa ha liboto tsa potoloho tse thata-flex ho bula menyetla e mecha bakeng sa indasteri ea likoloi, ho ntlafatsa ts'ebetso ea likoloi, ho tšepahala le ho sebetsa.Liboto tsena li sebetsa hantle maemong a thata, li fana ka ts'epo e phahameng, botšepehi bo ntlafalitsoeng ba matšoao le ho boloka litšenyehelo. Leha ho na le liqholotso tse joalo ka mekhoa e ikhethang ea tlhahiso le litlhoko tse thata tsa tlhahlobo, melemo e mengata ea liboto tsa potoloho tse thata li li etsa khetho e ntle bakeng sa lits'ebetso tsa likoloi. Ha theknoloji e ntse e tsoela pele, re lebelletse hore liboto tsena tse ncha tsa potoloho li tla bapala karolo ea bohlokoa indastering ea likoloi.

Nako ea poso: Sep-19-2023

Morao