Kopano ea PCB e thata-flex ke theknoloji e ncha le e feto-fetohang e kopanyang melemo ea liboto tsa potoloho tse hatisitsoeng tse thata le tse tenyetsehang (PCBs). Sengoliloeng sena se ikemiselitse ho fana ka tataiso e felletseng ea kopano ea PCB e thata, e totobatsang ts'ebetso ea eona ea tlhahiso, lintlha tsa moralo, lits'ebetso le melemo.

Tafole ea likateng:

Regid-flex board assembly ke eng?

Mokhoa oa ho etsa tlhahiso ea boto ea rigid-flex

Lintlha tsa Moqapi oa Bohlokoa bakeng sa Li-PCB tsa Rigid-Flex

Melemo ea rigid-flex board

Likopo tse Tloaelehileng tsa Kopano ea Rigid-Flex PCB

Litlhahiso bakeng sa Kopano e Atlehileng ea PCB ea Rigid-Flex

Liphephetso le Mefokolo ea Kopano ea Rigid-Flex PCB

Ha re phethela

Regid-flex board assembly ke eng?

Kopano ea PCB e sa fetoheng e kenyelletsa ho kopanya li-PCB tse thata le tse tenyetsehang ho yuniti e le 'ngoe. E thusa ho theha lipotoloho tse rarahaneng tsa mahlakore a mararo (3D) ka mokhoa o kopaneng le o sebetsang hantle. Karolo e thata e fana ka botsitso le tšehetso, ha karolo e tenyetsehang e lumella ho kobeha le ho sotha.

Ts'ebetso ea tlhahiso ea kopano ea boto ea Rigid-Flex:

Ts'ebetso ea tlhahiso ea kopano ea PCB e thata-flex hangata e kenyelletsa mehato e mengata. Tsena li kenyelletsa moralo oa PCB, khetho ea thepa, tlhahiso ea potoloho, kopano ea likarolo, tlhahlobo le tlhahlobo ea ho qetela. Sebelisa lisebelisoa le mekhoa e khethehileng ho netefatsa maqhama a tšepahalang pakeng tsa likarolo tse thata le tse tenyetsehang.

Mohato oa pele ke ho rala sebopeho sa PCB.Sena se kenyelletsa ho khetholla ho beoa ha likarolo le mesaletsa likarolong tse thata le tse tenyetsehang tsa boto.

Khetho ea Lintho:Ho khetha thepa e nepahetseng ho bohlokoa bakeng sa ho tšepahala le ho fetoha ha maemo. Sena se kenyelletsa khetho ea li-substrates tse thata tse kang FR4 le lisebelisoa tse tenyetsehang joalo ka polyimide kapa polyester.

Thepa ea Potoloho:Ts'ebetso ea ho etsa PCB e kenyelletsa mehato e mengata e kenyelletsang ho hloekisa, ho sebelisa likarolo tsa koporo, etching ho theha mesaletsa ea potoloho, ho eketsa maske a solder le silkscreening bakeng sa ho tsebahatsa likarolo. Ts'ebetso e etsoa ka thoko bakeng sa likarolo tse thata le tse tenyetsehang tsa boto.

Kopano ea Karolo:Joale likarolo li kenngoa likarolong tse thata le tse tenyetsehang tsa boto ho sebelisoa Surface Mount Technology (SMT) kapa Ka Hole Technology (THT). Tlhokomelo e khethehileng e nkoa ho etsa bonnete ba hore likarolo li behiloe ka mokhoa o nepahetseng le ka mokhoa o sireletsehileng likarolong tse peli tse thata le tse tenyetsehang.

Bonding:Mokhoa oa ho kopanya o bohlokoa ho netefatsa hore ho na le kamano e ka tšeptjoang pakeng tsa likarolo tse thata le tse tenyetsehang tsa boto. Sebelisa likhomaretsi, mocheso le khatello ho kopanya likotoana ka thata. Bakeng sa morero ona, ho sebelisoa lisebelisoa le mekhoa e khethehileng, joalo ka tšebeliso ea li-laminator kapa ho futhumatsa ho laoloang.

Teko:Ka mor'a kopano, mapolanka a lekoa ka ho feletseng ho netefatsa ts'ebetso le ho tšepahala. Sena se kenyelletsa tlhahlobo ea motlakase, tlhahlobo ea ts'ebetso, 'me mohlomong tlhahlobo ea tikoloho ho netefatsa ts'ebetso ea boto e thata-thata tlas'a maemo a fapaneng.

Tlhahlobo ea ho Qetela:Tlhahlobo ea ho qetela e etsoa ho hlahloba boleng ba kopano le ho netefatsa hore ha ho na liphoso kapa mathata sehlahisoa se felileng. Mohato ona o kenyelletsa tlhahlobo ea pono, litekanyo tsa boholo, le liteko life kapa life tse hlokahalang bakeng sa ts'ebeliso.

Lintlha tsa bohlokoa tsa moralo bakeng sa li-PCB tse thata-flex:

Ho rala PCB e thata-fetohang ho hloka hore ho nahanoe ka hloko lintlha tse fapaneng tse kang bend radius, layer stackup, flex area placement, le ho beha likarolo. Mekhoa e nepahetseng ea moralo e netefatsa ts'ebetso e nepahetseng le ho ts'epahala ha sehlahisoa sa ho qetela.

Radius ea ho Kobela:Mapolanka a thata-thata a lumelloa ho kobeha le ho phutha, empa a na le radius e fokolang e sa lokelang ho fetisoa. The bend radius ke radius e nyane ka ho fetisisa eo boto e ka e kobehang ntle le ho senya potoloho kapa ho baka khatello ea maikutlo. Ha ho etsoa moralo oa likarolo le mesaletsa, ke habohlokoa ho nahana ka radius ea bend ea libaka tsa flex ho netefatsa botšepehi ba bona nakong ea ho khumama.

Layer Stack:Layer stack e bolela tlhophiso ea likarolo tse fapaneng tsa PCB. Ho PCB e thata-fetohang, hangata ho na le likarolo tse thata le tse tenyetsehang. Stackup e tlameha ho reroa ka hloko ho netefatsa kamano e nepahetseng lipakeng tsa likarolo tse thata le tse tenyetsehang le ho fana ka ts'ebetso e lekaneng ea motlakase ha o ntse o kopana le litlhoko tsa ho phutha le ho mena.

Flex Area Layout:Sebaka se tenyetsehang sa PCB e thata-thata ke sebaka seo ho kobeha kapa ho kobeha ho tla etsahala. Libaka tsena li lokela ho behoa ka mokhoa o hlophisitsoeng ho qoba ho kena-kenana le likarolo, li-connectors le mekhoa ea mechine. Ke habohlokoa ho nahana ka mokhoa le sebaka sa libaka tse feto-fetohang ho fokotsa khatello ea kelello likarolong tsa bohlokoa nakong ea ts'ebetso.

Ho beoa ha karolo:Ho behoa ha likarolo ho PCB e thata-thata ho lokela ho reriloe ka hloko ho qoba ho kena-kenana le sebaka sa flex le ho ikarabella bakeng sa motsamao ofe kapa ofe nakong ea ho kobeha. Likarolo tsa bohlokoa li lokela ho behoa likarolong tse thata, ha likaroloana tse fokolang haholo li ka kenngoa likarolong tse tenyetsehang. Ho behoa ha likarolo ho boetse ho lokela ho nahana ka ts'ebetso ea mocheso oa boto le bokhoni bo ka khonehang ba ho senya mocheso.

Letšoao la Botšepehi:Li-PCB tse thata-thata hangata li hloka ho shebisisa botšepehi ba matšoao. Ho kobeha le ho kobeha ha PCB ho ka baka ho se tsamaisane ha impedance, lipontšo tsa matšoao le litaba tsa crosstalk. Ho bohlokoa ho nahana ka trace routing le taolo ea impedance ho boloka botsitso ba matšoao ho pholletsa le boto.

Litšitiso tsa Mechini:Litšitiso tsa mochini tse joalo ka ho hanyetsa ho ts'oha, ho thothomela le ho atolosoa ha mocheso li hloka ho nahanoa nakong ea moralo. Likarolo tse thata le tse tenyetsehang tsa boto li lokela ho etsoa ho mamella likhatello tsena tsa mochine ntle le ho senya botšepehi ba potoloho.

Litšitiso tsa tlhahiso:Moralo oa ho etsa lintho o bohlokoa molemong oa katleho ea ho etsa li-PCB tse thata-flex. Lintlha tse joalo ka bophara ba bonyane ba trace, ka sebaka, letsoalo la koporo, le mamello ea tlhahiso li lokela ho nahanoa ho netefatsa hore moralo oa fihlelleha ka har'a bokhoni ba tlhahiso le lithibelo.

Melemo ea mapolanka a rigid-flex:

Li-PCB tse thata-fetohang li fana ka melemo e mengata ho feta li-PCB tsa setso tse thata kapa tse tenyetsehang. Tsena li kenyelletsa boholo bo fokotsehileng le boima ba 'mele, ho tšepahala ho ntlafetseng, botšepehi bo matlafalitsoeng ba lipontšo, ho eketseha ha maemo a moralo, le mekhoa e nolofalitsoeng ea kopano le liteko.

Boholo le boima bo fokotsehile:Li-PCB tse thata-thata li lumella ho kopanngoa ha likarolo tse thata le tse tenyetsehang ka har'a boto e le 'ngoe, ho felisa tlhokahalo ea lihokelo le likhoele tse hokelang. Likarolo tse fokolang le lithapo li etsa hore sehlahisoa ka kakaretso se be se senyane mme se be bobebe.

Botšepehi bo ntlafetseng:Li-PCB tse thata-thata li na le ts'epo e phahameng ha li bapisoa le li-PCB tsa setso. Ho felisoa ha likhokahano le likhoele tse hokelang ho fokotsa monyetla oa ho hloleha ka lebaka la likhokahano tse hlephileng kapa mehala e robehileng. Ho phaella moo, karolo e tenyetsehang ea boto e ka mamella ho khumama le ho tsitsa ntle le ho senya botšepehi ba potoloho.

Botšepehi bo Ntlafetseng ba Letšoao:Ho kopanya likarolo tse thata le tse tenyetsehang botong e le 'ngoe ho fokotsa tlhoko ea likhokahano tse eketsehileng le ho fokotsa tahlehelo ea matšoao le tšitiso. Litsela tse khuts'oane tsa lipontšo le ho fokotseha ho fokolang ho khaotsa ho thibela ho ntlafatsa boleng ba matšoao le botšepehi.

Keketseho ea ho feto-fetoha ha moralo:Li-PCB tsa Rigid-flex li fa baqapi monyetla oa ho feto-fetoha le maemo ho sebopeho sa sebopeho le ho beha likarolo. Bokhoni ba ho koba le ho mena liboto tsa potoloho bo thusa meralo e kopaneng le ea boqapi, e lumellang lienjiniere ho kopanya tšebetso e ngata sebakeng se senyenyane.

Mokhoa o nolofalitsoeng oa ho kopanya le ho etsa liteko:Li-PCB tse thata-thata li nolofatsa ts'ebetso ea kopano ka ho fokotsa palo ea likarolo le likhokahano tse hlokahalang. Sena se nolofalletsa kopano e potlakileng le e sebetsang haholoanyane. Ho feta moo, ho tlosa likhokahano ho fokotsa monyetla oa ho se lumellane kapa litaba tsa khokahano nakong ea kopano. Mokhoa o bonolo oa ho kopanya o bolela litšenyehelo tse tlase le nako e potlakileng ea ho rekisa.

Lisebelisoa tse tloaelehileng tsa kopano ea PCB e thata-flex:

Likopano tsa PCB tse Rigid-flex li sebelisoa liindastering tse fapaneng tse fapaneng, ho kenyeletsoa lisebelisoa tsa bongaka, sefofane, likoloi, lisebelisoa tsa elektroniki tsa bareki le tse ling. E loketse lits'ebetso tse hlokang lisebelisoa tsa elektroniki tse kopaneng le tse tšepahalang libakeng tse thata.

Lisebelisoa tsa Bongaka:Likopano tsa PCB tse Rigid-flex hangata li sebelisoa lisebelisoa tsa bongaka tse kang li-pacemaker, lipompo tsa insulin le lisebelisoa tsa bophelo bo botle tse aparoang. Lisebelisoa tsena li hloka boholo bo fokolang, ho tšoarella le ho feto-fetoha ha maemo ho mamella ho sisinyeha le ho kopana ha 'mele. Theknoloji ea Rigid-flex e nolofalletsa li-circuits tse kopanetsoeng le tse ka tšeptjoang ho lisebelisoa tsa bongaka.

Sepakapaka:Likopano tsa PCB tse thata-thata li loketse lisebelisoa tsa sefofane moo ho fokotsa boima ba 'mele, mathata a sebaka le ho tšepahala e le lintlha tsa bohlokoa. Li sebelisoa mekhoeng ea lifofane tsa lifofane, lisebelisoa tsa puisano, litsamaiso tsa ho tsamaea le liphanele tsa taolo. Theknoloji ea Rigid-flex e nolofalletsa lisebelisoa tsa elektroniki tse bobebe, tse sebetsang haholoanyane lits'ebetsong tsa sefofane.

Tsa makoloi:Lisebelisoa tsa likoloi li hloka lisebelisoa tsa elektroniki tse matsutla-tsutla tse ka mamellang ho thothomela, ho fetoha ha mocheso le khatello ea maikutlo. Likopano tsa PCB tse Rigid-flex li sebelisoa likarolong tsa taolo ea likoloi, litsamaiso tse tsoetseng pele tsa lithuso tsa bakhanni (ADAS), infotainment le litsamaiso tsa taolo ea enjene. Theknoloji ea rigid-flex e netefatsa moralo o bolokang sebaka le ho eketsa nako e telele.

Consumer Electronics:Likopano tsa PCB tse Rigid-flex li sebelisoa haholo lisebelisoa tse fapaneng tsa elektroniki tsa bareki joalo ka li-smartphone, matlapa, lisebelisoa tse aparoang le li-consoles tsa papali. Sebopeho se kopaneng le se tenyetsehang sa li-PCB tse thata-fetohang se nolofalletsa ts'ebetso e phahameng, bokhabane bo ntlafalitsoeng ba moralo, le boiphihlelo bo betere ba basebelisi. Li thusa bahlahisi ho etsa lisebelisoa tse mosesaane, tse bobebe le tse sebetsang haholoanyane.

Lisebelisoa tsa Indasteri:Lisebelisoa tsa indasteri moo ho ts'epahalang le ho tšoarella ho leng bohlokoa, likopano tsa PCB tse thata-flex li sebelisoa lits'ebetsong tsa taolo, liroboto, taolo ea matla, le ho fumana data. Ho kopana ha likarolo tse thata le tse tenyetsehang ho etsa hore sebaka se sebelisoe hantle, se fokotsa lithapo, 'me se eketsa ho hanyetsa maemo a thata a ho sebetsa.

Malebela a ho kopanya ka katleho PCB e thata-thata:

Ho etsa bonnete ba hore ho na le kopano e atlehileng ea PCB e tsitsitseng, mekhoa e metle e tlameha ho lateloa, joalo ka khetho ea moetsi ea nepahetseng, ho tšoara le ho boloka thepa e nepahetseng, tsamaiso e sebetsang ea mocheso, le mekhoa ea ho hlahloba le ho hlahloba ka botlalo.

Khetha moetsi ea tsebahalang:Ho khetha moetsi ea nepahetseng ho bohlokoa bakeng sa kopano e atlehileng ea PCB e thata. Batla moetsi ea nang le boiphihlelo ba ho hlahisa li-PCB tse sa fetoheng le rekoto ea ho fana ka lihlahisoa tsa boleng bo holimo. Nahana ka botsebi ba bona, bokhoni ba ho etsa tlhahiso, litifikeiti, le maikutlo a bareki.

Utloisisa litlhoko tsa moralo:Ho tloaelana le litlhoko tsa moralo oa mapolanka a rigid-flex. Sena se kenyelletsa ho utloisisa litšitiso tsa mochini le tsa motlakase tse joalo ka litlhoko tsa ho koba le ho mena, ho beoa ha likarolo le menahano ea botšepehi ba matšoao. Sebetsa haufi-ufi le moetsi oa hau oa PCB ho netefatsa hore meralo e ntlafalitsoe bakeng sa ho etsoa le ho kopanya.

Tšoaro e nepahetseng le polokelo ea thepa:Li-Rigid-flex board li ka senyeha habonolo ka ho se sebetse hantle le polokelo e sa lokelang. Etsa bonnete ba hore moetsi o latela mekhoa e nepahetseng ea ho sebetsana le thepa, ho kenyelletsa le ho sireletsa libaka tse tenyetsehang ho tloha ho kobeha ho feteletseng kapa khatello ea maikutlo. Hape, boloka mapolanka a thata-thata sebakeng se laoloang ho thibela ho kenngoa ha mongobo kapa ho pepesehela mocheso o phahameng.

Taolo e sebetsang hantle ea mocheso:Likopano tsa PCB tse Rigid-flex li ka ba le likarolo tse hlahisang mocheso. Tsamaiso e nepahetseng ea mocheso ke ea bohlokoa ho netefatsa ts'ebetso e ka tšeptjoang le ho thibela ho hlōleha ha motsoako oa solder. Nahana ka mekhoa e joalo ka li-vias tsa mocheso, li-spreaders tsa mocheso, kapa li-pads tsa mocheso ho laola ka katleho ho felloa ke mocheso. Sebetsa le moetsi ho ntlafatsa moralo bakeng sa taolo e nepahetseng ea mocheso.

Tlhahlobo le tlhahlobo e phethahetseng:Teko le tlhahlobo e matla lia hlokahala ho tseba mathata afe kapa afe nakong ea kopano le ho netefatsa ho ts'epahala ha sehlahisoa sa ho qetela. Kenya tšebetsong protocol e felletseng ea tlhahlobo e kenyelletsang tlhahlobo ea motlakase, tlhahlobo ea ts'ebetso le tlhahlobo ea ts'epo. Etsa tlhahlobo e phethahetseng ea pono ho bona mefokolo kapa liphoso tse teng kopanong.

Sebelisana le Baetsi:Boloka puisano e bulehileng 'me u sebetse haufi-ufi le bahlahisi nakong eohle ea ho kopanya. Buisanang ka lintlha tsa moralo, litlhoko tsa tlhahiso le litaba life kapa life tse ikhethileng. Nako le nako hlahloba le ho amohela li-prototype kapa lisampole ho netefatsa hore litebello tsa hau lia phethahala. Mokhoa ona oa tšebelisano o tla thusa ho rarolla mathata afe kapa afe a ka bang teng esale pele le ho netefatsa kopano e atlehileng ea PCB e sa fetoheng.

Mathata le mefokolo ea kopano ea PCB e thata-flex:

Le hoja kopano ea PCB e thata-thata e na le melemo e mengata, e boetse e hlahisa mathata le mefokolo. Tsena li kenyelletsa litšenyehelo tse phahameng tsa tlhahiso, ho eketseha ha moralo le ho rarahana ha tlhahiso, boteng bo fokolang ba lisebelisoa tse khethehileng tsa tlhahiso, le kotsi e kholo ea liphoso tsa tlhahiso.

Litšenyehelo tse holimo tsa tlhahiso:Likopano tsa PCB tse thata-flex li atisa ho bitsa chelete e ngata ho feta likopano tsa PCB tse thata ka lebaka la lisebelisoa tse eketsehileng tse hlokahalang, mekhoa e khethehileng ea tlhahiso, le ho rarahana ho holimo. Litsenyehelo tsa ho etsoa le ho bokana ha PCB tse thata-flex li lokela ho nahanoa ka hloko le ho lekanyetsoa morerong ona.

Keketseho ea moralo le ho rarahana ha tlhahiso:Ka lebaka la ho kopana ha thepa e thata le e tenyetsehang, moralo oa li-PCB tse sa fetoheng o hloka boiphihlelo le boiphihlelo. Mokhoa oa moralo o rarahane haholo kaha o kenyelletsa ho kobeha, ho phutha le ho beha likarolo. Mekhoa ea tlhahiso e kang lamination, drilling le welding e boetse e fetoha e rarahaneng ka lebaka la ho kopana ha thepa le mehaho.

Boteng bo Lekanyelitsoeng ba Lisebelisoa tse Ikemetseng tsa Tlhahiso:Kopano ea PCB e thata-flex e ka hloka lisebelisoa tse khethehileng tsa tlhahiso tseo e seng baetsi bohle ba nang le tsona. Boteng ba lisebelisoa tse joalo bo ka fokotsoa, e leng se ka bakang nako e telele ea ho etella pele kapa tlhoko ea ho fana ka tlhahiso litsing tse khethehileng. Ho bohlokoa ho etsa bonnete ba hore moetsi ea khethiloeng o na le lisebelisoa le bokhoni bo hlokahalang bakeng sa kopano e sebetsang e thata-flex PCB.

Kotsi e Khōlō ea Litšitiso Tsa Tlhahiso:Ho rarahana ha likopano tsa PCB tse thata-fetohang ho baka kotsi e kholo ea bofokoli ba tlhahiso ha e bapisoa le likopano tse tloaelehileng tsa PCB tse thata. Libaka tse Flex le likhokahano tse bobebe li kotsing ea ho senyeha nakong ea tlhahiso le kopano. Tlhokomelo e eketsehileng e tlameha ho nkuoa nakong ea ho ts'oaroa, ho soasoa le ho etsa liteko ho fokotsa kotsi ea likoli.

Liphephetso tsa liteko le tlhahlobo:Likopano tsa PCB tse thata-thata li ka ba phephetso ho feta ho leka le ho hlahloba ka lebaka la ho kopana ha libaka tse thata le tse tenyetsehang. Mekhoa ea khale ea ho etsa liteko joalo ka mochini o fofang kapa tlhahlobo ea manala e kanna ea se tšoanelehe bakeng sa meralo e thata e thata-thata. Ho ka 'na ha hlokoa mekhoa ea ho etsa liteko le ho hlahloba ka tloaelo, e leng ho eketsang ho rarahana le litšenyehelo mosebetsing oa tlhahiso.

Ho sa tsotellehe mathata ana le mefokolo, likopano tsa PCB tse thata-flexible li fana ka melemo e ikhethang mabapi le ho boloka sebaka, ho tšepahala, le ho tšoarella, ho ba etsa khetho ea pele bakeng sa likopo tse nang le litlhoko tse khethehileng. Liphephetso tsena li ka rarolloa ka katleho ka ho sebetsa haufi-ufi le moetsi ea nang le phihlelo le ho nahanisisa ka hloko ka moralo le ho nahana ka tlhahiso, ho fella ka kopano e atlehileng ea PCB e thata-flex.

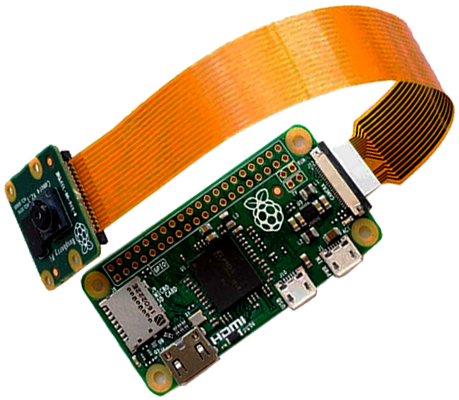

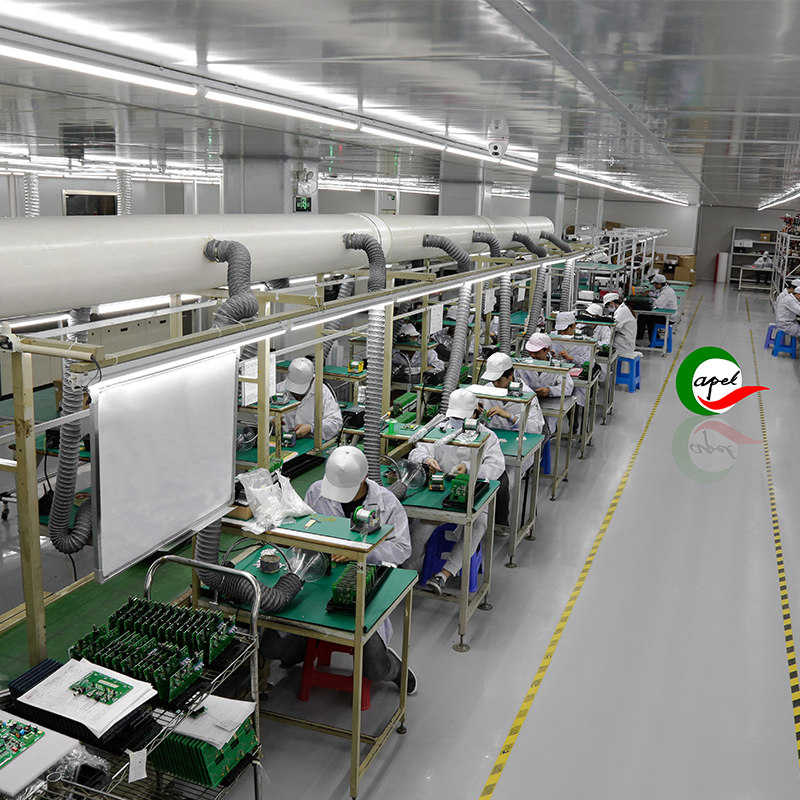

Kopano ea Rigid-flex PCB ke theknoloji e matla e ka sebelisoang ho theha lisebelisoa tsa elektroniki tse nchafalitsoeng.Likarolo tsa eona tse ikhethang le melemo li e etsa hore e tšoanelehe bakeng sa lits'ebetso tse fapaneng tse fapaneng ho pholletsa le liindasteri. Leha ho le joalo, ho nahanoa ka hloko mabapi le moralo, tlhahiso le ts'ebetso ea kopano ke ea bohlokoa ho netefatsa ts'ebetsong e atlehileng. Qetellong, ho utloisisa ts'ebetso ea tlhahiso, menahano ea moralo, lits'ebetso, melemo le mefokolo ea kopano ea PCB e thata-flex ke ea bohlokoa ho baenjiniere, baqapi le bahlahisi. Ka ho sebelisa matla a theknoloji ena e tsoetseng pele, lisebelisoa tsa elektroniki tse tsoetseng pele le tse tšepahalang li ka ntlafatsoa ho fihlela litlhoko tsa liindasteri tse ntseng li tsoela pele ka potlako.Shenzhen Capel Technology Co., Ltd.e thehile fektheri ea eona e thata ea flex pcb ka 2009 mme ke setsebi sa Flex Rigid Pcb Manufacturer. Ka lilemo tse 15 tsa boiphihlelo bo monate ba projeke, phallo e matla ea ts'ebetso, bokhoni bo botle ba tekheniki, lisebelisoa tse tsoetseng pele tsa othomathike, sistimi e felletseng ea taolo ea boleng, 'me Capel o na le sehlopha sa litsebi sa litsebi ho fa bareki ba lefats'e ka mokhoa o nepahetseng, oa boleng bo holimo oa 1-32 layer rigid flex. boto, hdi Rigid Flex Pcb, Rigid Flex Pcb Fabrication, rigid-flex pcb assembly,fast turn rigid flex pcb assembly,quick turn pcb assembly prototypes.Our responsive pre-sales and after-the-thekiso botekgeniki ditshebeletso le thomello ka nako thusa bareki ba rona ho potlaka. ho nka menyetla ea mebaraka bakeng sa merero ea bona.

Nako ea poso: Aug-29-2023

Morao