Ha tlhoko ea litharollo tsa elektronike tse feto-fetohang le tse sebetsang li ntse li eketseha, li-PCB tse sa fetoheng li fetohile khetho e tsebahalang molemong oa moralo le tlhahiso ea PCB. Liboto tsena li kopanya melemo ea li-PCB tse thata le tse tenyetsehang ho fana ka maemo a ntlafalitsoeng ntle le ho tela nako le ts'ebetso. Ho rala li-PCB tse tšepahalang le tse ntlafalitsoeng tse thata, kutloisiso e phethahetseng ea tlhophiso ea li-stack-up e bohlokoa. Sebopeho sa stack-up se etsa qeto ea tlhophiso le sebopeho sa lera sa PCB, se amang ts'ebetso ea eona le tlhahiso ea eona ka kotloloho.Tataiso ena e felletseng e tla shebana le ho rarahana ha li-stackups tsa PCB tse thata-flex, ho fana ka lintlha tsa bohlokoa ho thusa baqapi ho etsa liqeto tse nepahetseng nakong ea moralo. E tla akaretsa likarolo tse fapaneng tse kenyelletsang khetho ea thepa, ho beoa ha lera, lintlha tsa botšepehi ba matšoao, taolo ea impedance le lithibelo tsa tlhahiso. Ka ho utloisisa ho rarahana ha li-stackups tsa PCB tse thata-flex, baqapi ba ka netefatsa bots'epehi le ts'epahalo ea meralo ea bona. Ba tla ntlafatsa botšepehi ba matšoao, ba fokotse ho kena-kenana le motlakase (EMI) le ho tsamaisa mekhoa e metle ea tlhahiso. Hore na o ncha ho moralo o thata oa PCB kapa o batla ho ntlafatsa tsebo ea hau, tataiso ena e tla ba sesebelisoa sa bohlokoa, se o nolofalletsang ho shebana le maemo a thata a ho etsa litlhophiso le ho rala litharollo tsa PCB tsa boleng bo holimo, tse thata tse tenyetsehang bakeng sa lihlahisoa tse ngata.

1.Boto e thata-fetohang ke eng?

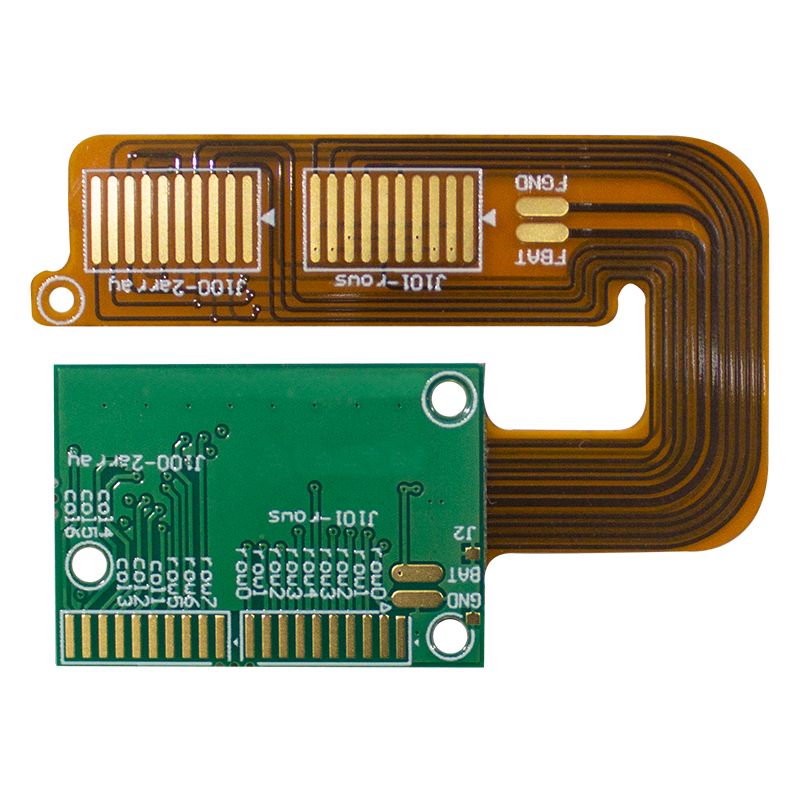

Rigid-flex board, eo hape e tsejoang e le rigid-flex printed circuit board (PCB), ke PCB e kopanyang li-substrates tse thata le tse tenyetsehang holim'a boto e le 'ngoe.E kopanya melemo ea li-PCB tse thata le tse tenyetsehang ho ntlafatsa maemo a moralo le ho tšoarella. Ka boto e thata-fetohang, karolo e thata e entsoe ka thepa ea setso e thata ea PCB (e kang FR4), ha karolo e tenyetsehang e entsoe ka thepa ea PCB e tenyetsehang (e kang polyimide). Likarolo tsena li hokahane ka ho petetsoa ka masoba kapa lihokelo tsa flex ho etsa boto e le 'ngoe e kopaneng. Likarolo tse thata li fana ka tšehetso le botsitso ho likarolo, lihokelo, le likarolo tse ling tsa mochini, tse ts'oanang le PCB e thata e tloaelehileng. Karolo e feto-fetohang, ka lehlakoreng le leng, e lumella boto ea potoloho hore e kobehe le ho kobeha, e lumella hore e kene ka har'a lisebelisoa tsa elektronike tse nang le sebaka se lekanyelitsoeng kapa libopeho tse sa tloaelehang. Li-Rigid-flex board li fana ka melemo e mengata ho feta li-PCB tsa setso tse thata kapa tse tenyetsehang. Ba fokotsa tlhoko ea likhokahano le likhoele, ho boloka sebaka, ho fokotsa nako ea kopano, le ho eketsa ts'epo ka ho felisa lintlha tse ka bang teng tsa ho hloleha. Ho feta moo, mapolanka a thata-thata a nolofatsa mokhoa oa ho qapa ka ho nolofatsa likamano pakeng tsa likarolo tse thata le tse tsitsitseng, ho fokotsa ho rarahana ha litsela le ho ntlafatsa botšepehi ba matšoao. Li-Rigid-flex boards li sebelisoa hangata lits'ebetsong moo sebaka se lekanyelitsoeng kapa boto e hlokang ho lumellana le sebopeho se itseng kapa profil. Hangata li fumaneha sebakeng sa sefofane, lisebelisoa tsa bongaka, lisebelisoa tsa elektronike tsa likoloi le lisebelisoa tsa elektronike tse nkehang habonolo moo boholo, boima le botšepehi e leng lintlha tsa bohlokoa. Ho rala le ho etsa mapolanka a thata-thata ho hloka tsebo e khethehileng le botsebi ka lebaka la motsoako oa thepa e thata le e tenyetsehang le likhokahano. Ka hona, ho bohlokoa ho sebetsa le moetsi oa PCB ea nang le boiphihlelo ea khonang ho sebetsana le mathata a ho etsa boto e thata-flex.

2.Ke hobane'ng ha e le thata flex pcb stacking phetolo bohlokoa?

Botšepehi ba Mechini:

Li-PCB tsa Rigid-flex li etselitsoe ho fana ka maemo le ho tšepahala. Sebopeho sa stacking se etsa qeto ea tlhophiso ea likarolo tse thata le tse tenyetsehang, ho netefatsa hore boto e ka mamella ho kobeha, ho sotha le likhatello tse ling tsa mochine ntle le ho senya botšepehi ba eona ba sebopeho. Ho tsamaisana hantle ha lera ho bohlokoa ho thibela mokhathala oa PCB, khatello ea maikutlo le ho hloleha ha nako e ntse e feta.

Ntlafatso ea sebaka:

Liboto tsa rigid-flex li sebelisoa haholo lisebelisoa tsa elektroniki tse kopaneng tse nang le sebaka se lekanyelitsoeng. Litlhophiso tse behiloeng li lumella baqapi ho sebelisa sebaka se teng ka nepo ka ho hlophisa likarolo le likarolo ka tsela e tla eketsa tšebeliso ea sebaka sa 3D. Sena se nolofalletsa li-PCB hore li kenngoe ka har'a meketjana e thata, lisebelisoa tse nyane le lintlha tse rarahaneng. Letšoao la Botšepehi:

Botšepehi ba lets'oao la PCB e thata ea flex ke ea bohlokoa ts'ebetsong ea eona e nepahetseng. Litlhophiso tsa stacking li phetha karolo ea bohlokoa ho ntlafatseng botšepehi ba lets'oao ka ho ela hloko lintlha tse joalo ka tšitiso e laoloang, mehala ea phetisetso, le ho fokotsa crosstalk. Sebopeho se nang le mabaka a utloahalang se ka netefatsa tsela e sebetsang ea mats'oao a lebelo le phahameng, ho fokotsa ho fokotsa matšoao, le ho netefatsa phetiso e nepahetseng ea data.

Taolo ea Thermal:

Lisebelisoa tsa elektronike li hlahisa mocheso, 'me tsamaiso e nepahetseng ea mocheso e bohlokoa ho thibela ho chesa le ho senya likarolo tse ka bang teng. Tlhophiso e bokelletsoeng ea li-PCB tse thata-fetohang li lumella ho beoa ka nepo ha li-vias tse futhumetseng, likarolo tsa koporo, le lisinki tsa mocheso bakeng sa ho qhala mocheso hantle. Ka ho nahana ka litaba tsa mocheso nakong ea moralo oa li-stack-up, baqapi ba ka netefatsa hore PCB e phela nako e telele le ho tšepahala.

Lintlha tsa Tlhahiso:

Ho hlophisoa ha stacking ho ama ts'ebetso ea tlhahiso ea PCB e thata-flex. E etsa qeto ea tatellano eo lihlopha li kopantsoeng ka eona, ho lumellana le ho ngolisoa ha lihlopha tse feto-fetohang le tse thata, le ho behoa ha likarolo. Ka ho khetha ka hloko litlhophiso tsa li-stack-up, baqapi ba ka nolofatsa ts'ebetso ea tlhahiso, ba fokotsa litšenyehelo tsa tlhahiso, le ho fokotsa kotsi ea liphoso tsa tlhahiso.

3.Likarolo tse ka sehloohong tsa li-stackup tsa PCB tse thata-flex

Ha u rala stackup ea PCB e thata-flex, ho na le likarolo tse 'maloa tsa bohlokoa tse lokelang ho nahanoa. Likarolo tsena li bapala karolo ea bohlokoa ho faneng ka tšehetso e hlokahalang ea meralo, khokahanyo ea motlakase, le ho feto-fetoha ha maemo bakeng sa moralo o akaretsang oa PCB. Lintlha tse latelang ke likarolo tsa bohlokoa tsa "PCB" e thata e feto-fetohang:

Lera le thata:

Lera le thata hangata le entsoe ka thepa e thata e kang FR-4 kapa lintho tse tšoanang. Lera lena le fana ka matla a mochini le botsitso ho PCB. E boetse e na le lisebelisoa 'me e lumella ho kenngoa ha lisebelisoa tsa holim'a metsi (SMD) le likarolo tsa ho pota-pota. Lera le tiileng le fana ka motheo o tiileng bakeng sa lera le tenyetsehang 'me le tiisa hore ho lokisoa hantle le ho tiea ha PCB kaofela.

Flexible layer:

Lera le tenyetsehang le na le lisebelisoa tsa motheo tse tenyetsehang joalo ka polyimide kapa lintho tse tšoanang. Lera lena le lumella PCB ho kobeha, ho mena le ho kobeha. The flex layer ke moo boholo ba likhokahano tsa potoloho le motlakase li leng teng. E fana ka phetoho e hlokahalang bakeng sa lits'ebetso tse hlokang hore PCB e kobehe kapa e lumellane le libopeho kapa libaka tse fapaneng. Ho feto-fetoha ha lera lena ho hloka ho nahanoa ka hloko ho netefatsa hore e finyella litlhoko tsa kopo.

Sekhomaretsi:

Lera la sekhomaretsi ke lesela le tšesaane la sekhomaretsi le sebelisoang pakeng tsa lera le thata le lera le tenyetsehang. Sepheo sa eona se seholo ke ho kopanya lihlopha tse thata le tse tenyetsehang hammoho, ho fana ka botšepehi ba sebopeho ho laminate. E etsa bonnete ba hore lihlopha li lula li hokahane ka thata ho tse ling esita le nakong ea ho khumama kapa ho phunya. Sekhomaretsi sa sekhomaretsi se boetse se sebetsa e le lisebelisoa tsa dielectric, tse fanang ka insulation pakeng tsa lihlopha. Khetho ea thepa ea sekhomaretsi e bohlokoa kaha e hloka ho ba le thepa e ntle ea tlamahano, matla a phahameng a dielectric, le ho lumellana le lisebelisoa tsa motheo.

Ho matlafatsa le ho koahela:

Li-reinforcements le likoahelo ke likarolo tse ling tse atisang ho eketsoa ho PCB stackup ho matlafatsa matla a eona a mochine, tšireletso le botšepehi. Li-reinforcements li ka kenyelletsa lisebelisoa tse kang FR-4 kapa lipampiri tse se nang sekhomaretsi tse thehiloeng ho polyimide tse nang le laminated libakeng tse itseng tsa lihlopha tse thata kapa tse tenyetsehang ho fana ka ho tiea le ho tšehetsa ho eketsehileng. Likarolo tsa PCB li koahetsoe ka likoahelo tse kang limaske tsa solder le lira tse sireletsang ho li sireletsa linthong tsa tikoloho joalo ka mongobo, lerōle le khatello ea maikutlo.

Likarolo tsena tsa bohlokoa li sebetsa 'moho ho theha sephutheloana sa PCB se hlophisitsoeng ka hloko se khahlano le litlhoko tsa ts'ebeliso. Botšepehi ba sebopeho le ho feto-fetoha ha maemo ho fanoang ke likarolo tse thata le tse feto-fetohang, hammoho le likarolo tse khomarelang, li netefatsa hore PCB e khona ho mamella metsamao ea ho kobeha kapa ho tsitsa ntle le ho senya botšepehi ba potoloho. Ho feta moo, ts'ebeliso ea li-reinforcements le likoahelo li matlafatsa ts'epo le ts'ireletso ka kakaretso ea PCB. Ka ho khetha le ho rala likarolo tsena ka hloko, lienjineri li ka theha li-stackups tsa PCB tse tiileng le tse tšepahalang.

Mofuta oa 4.Rigid-flex PCB stackup configuration

Ha ho etsoa li-stackups tsa PCB tse thata-flex, mefuta e fapaneng ea tlhophiso e ka sebelisoa ho latela litlhoko tse khethehileng tsa kopo. Sebopeho sa stack-up se etsa qeto ea palo ea lihlopha tse kenyellelitsoeng moralong le tlhophiso ea lihlopha tse thata le tse tenyetsehang. Tse latelang ke mefuta e meraro e tloaelehileng ea litlhophiso tsa li-stackup tsa PCB tse thata:

1 lera la lamination e thata le e bonolo:

Tlhophiso ena, PCB e na le karolo e le 'ngoe ea lintho tse thata le karolo e le' ngoe ea lisebelisoa tse tenyetsehang. Lera le thata le fana ka botsitso le ts'ehetso e hlokahalang, ha lera le tenyetsehang le lumella PCB hore e be bonolo le ho koba. Tlhophiso ena e loketse lits'ebetso tse hlokang ho feto-fetoha ha maemo le moralo o bonolo.

Likarolo tse 2 tsa superposition e thata le e bonolo:

Tlhophiso ena, PCB e na le likarolo tse peli - lera le thata le lera le tenyetsehang. Lera le thata le arotsoe pakeng tsa mekhahlelo e 'meli e feto-fetohang, ho etsa tokisetso ea "buka". Tlhophiso ena e fana ka phetoho e kholoanyane 'me e lumella meralo e rarahaneng ho sebelisa likarolo mahlakoreng ka bobeli a PCB. E fana ka maemo a betere a ho kobeha le ho kobeha ho feta tlhophiso ea lera le le leng.

Multi-layer e thata le e bonolo superposition:

Tlhophiso ena, PCB e na le likarolo tse ngata - motsoako oa lihlopha tse thata le tse tenyetsehang. Likarolo li phuthetsoe ka holim'a tse ling, li fapanyetsana lipakeng tse thata le tse tenyetsehang. Tlhophiso ena e fana ka boemo bo phahameng ka ho fetisisa ba ho feto-fetoha ha maemo 'me e lumella meralo e rarahaneng ka ho fetisisa e sebelisang likarolo tse ngata le lipotoloho. E loketse lits'ebetso tse hlokang ho feto-fetoha ha maemo ho phahameng le moralo o kopaneng.

Khetho ea tlhophiso ea stackup e thata-flex e itšetlehile ka lintlha tse kang boemo ba ho feto-fetoha ho hlokahalang, ho rarahana ha moralo oa potoloho, le mathata a sebaka. Baenjineri ba hloka ho lekola ka hloko litlhoko le meeli ea ts'ebeliso ho fumana hore na tlhophiso e nepahetseng ka ho fetisisa ea stacking.

Ntle le kaho ea laminate e thata-flex, lintlha tse ling tse kang khetho ea thepa, botenya ba lera le leng le le leng, le ka tsela le moralo oa khokahanyo le tsona li phetha karolo ea bohlokoa ho khethollang ts'ebetso ea kakaretso le ho tšepahala ha li-PCB tse thata-thata. Ho bohlokoa ho sebetsa haufi-ufi le moetsi oa PCB le litsebi tsa meralo ho netefatsa hore tlhophiso e khethiloeng ea li-stackup e fihlela litlhoko le litekanyetso tse ikhethileng tsa ts'ebeliso.

Ka ho khetha tlhophiso e nepahetseng ea li-stackup tse thata le ho ntlafatsa maemo a mang a meralo, baenjiniere ba ka kenya tšebetsong li-PCB tse tšepahalang, tse sebetsang hantle haholo tse fihlelang litlhoko tse ikhethang tsa lits'ebetso tsa bona.

5. Lintlha Tseo U Lokelang ho li Nahana Ha U Khetha Sebopeho sa Stacking PCB se Rigid-Flex

Ha u khetha tlhophiso e thata-fetohang ea PCB, ho na le lintlha tse 'maloa tse lokelang ho nahanoa ho netefatsa ts'ebetso e nepahetseng le ts'epo. Lintlha tse hlano tsa bohlokoa tseo u lokelang ho li hopola ke tsena:

Letšoao la Botšepehi:

Khetho ea tlhophiso ea stackup e ka ama haholo botšepehi ba matšoao a PCB. Mesaletsa ea mats'oao holim'a mekhahlelo e feto-fetohang e kanna ea ba le litšobotsi tse fapaneng tsa impedance ha li bapisoa le likarolo tse thata. Ho bohlokoa ho khetha tlhophiso ea stackup e fokotsang tahlehelo ea matšoao, crosstalk, le impedance mismatch. Mekhoa e nepahetseng ea taolo ea impedance e lokela ho sebelisoa ho boloka botšepehi ba matšoao ho pholletsa le PCB.

Litlhokahalo tsa ho Fetolana:

Boemo ba ho tenyetseha bo hlokahalang ho PCB ke taba ea bohlokoa. Lisebelisoa tse fapaneng li ka ba le litlhoko tse fapaneng tsa ho kobeha le ho kobeha. Sebopeho sa stackup se lokela ho khethoa ho lumellana le maemo a hlokahalang ha ho ntse ho etsoa bonnete ba hore PCB e finyella litlhoko tsohle tsa ts'ebetso ea mochine le motlakase. Palo le tlhophiso ea li-layers tse tenyetsehang li lokela ho khethoa ka hloko ho latela litlhoko tse khethehileng tsa kopo.

Litšitiso tsa Sebaka:

Sebaka se fumanehang ka har'a sehlahisoa kapa sesebelisoa se ka ama haholo khetho ea tlhophiso ea li-stack-up. Meralo e kopaneng e nang le sebaka se lekanyelitsoeng sa PCB e ka hloka litlhophiso tsa mekhahlelo e mengata e thata-thata ho eketsa tšebeliso ea sebaka. Ka lehlakoreng le leng, meralo e meholoanyane e lumella ho feto-fetoha ha maemo ha u khetha litlhophiso tsa stack-up. Ho ntlafatsa stacking ho lekana sebaka se fumanehang ntle le ho senya ts'ebetso kapa ho ts'epahala ho bohlokoa.

Taolo ea Thermal:

Tlhokomelo e nepahetseng ea mocheso ke ea bohlokoa ho thibela mocheso oa mocheso, o ka amang ts'ebetso le ho tšepahala ha lipotoloho le likaroloana. Khetho ea tlhophiso ea li-stackup e lokela ho nahanoa ka phallo ea mocheso. Ka mohlala, haeba PCB e hlahisa mocheso o mongata, e ka 'na ea hloka hore ho be le sethala se thusang ho senya mocheso, joalo ka ho kenyelletsa li-cores tsa tšepe kapa ho sebelisa li-vias tsa mocheso. Likarolo tse futhumatsang le tsona li lokela ho beoa ka har'a stack ho qhala mocheso hantle.

Litlhaloso tsa Boqapi le Likopano:

Sebopeho sa stack-up se khethiloeng se lokela ho ba bonolo ho se etsa le ho se kopanya. Lintlha tse kang boiketlo ba tlhahiso, ho lumellana le mekhoa ea tlhahiso le theknoloji ea ho kopanya, le boteng ba lisebelisoa tse loketseng li lokela ho nkoa. Mohlala, litlhophiso tse ling tsa li-stack-up li ka hloka mekhoa e ikhethileng ea tlhahiso kapa li ka ba le meeli ho lisebelisoa tse ka sebelisoang. Ho sebetsa le moetsi oa PCB pele ho ts'ebetso ea moralo ho bohlokoa ho netefatsa hore tlhophiso e khethiloeng e ka hlahisoa le ho bokelloa hantle.

Ka ho lekola lintlha tsena tse hlano ka hloko, baenjiniere ba ka etsa qeto e nang le tsebo mabapi le ho khetha tlhophiso e thata-thata ea PCB. Ho kgothaletswa haholo ho sebetsa le setsebi sa tlhahiso le kopano ho netefatsa hore tlhophiso e khethiloeng e finyella litlhoko tsohle tsa moralo mme e lumellana le mokhoa oa tlhahiso. Ho iketsetsa stackup ho sebetsana le botšepehi ba matšoao, ho feto-fetoha ha maemo, mathata a sebaka, tsamaiso ea mocheso le ho nahanisisa ka tlhahiso ho tla fella ka tharollo e tiileng le e tšepahalang ea PCB.

6.Design nahanela bakeng sa thata-tenyetsehang PCB stack-up

Ha ho etsoa stackup ea PCB e thata-flex, ho na le lintlha tse 'maloa tsa bohlokoa tse lokelang ho nahanoa ho netefatsa ts'ebetso e nepahetseng le ho tšepahala. Mona ke lintlha tse hlano tsa bohlokoa tsa moralo:

Kabo ea Lera le Symmetry:

Kabo ea lera ka har'a stackup ke ea bohlokoa bakeng sa ho fihlela teka-tekano le symmetry moralong. Sena se thusa ho thibela mathata a ho phunya kapa a buckling nakong ea ho kobeha. Ho kgothaletswa ho ba le palo e lekanang ea lihlopha ka lehlakoreng le leng le le leng la boto ea flex le ho beha sekhahla se bohareng ba stack. Sena se tiisa kabo e leka-lekaneng ea khatello ea maikutlo le ho fokotsa kotsi ea ho hloleha.

Sebopeho sa Cable and Trace:

Sebopeho sa lithapo le mesaletsa ho PCB e lokela ho nahanoa ka hloko. Tsamaiso ea likhoele le mesaletsa e lokela ho reroa ho fokotsa khatello ea maikutlo le ho thibela tšenyo nakong ea ho kobeha. Ho khothaletsoa ho tsamaisa likhoele tse tenyetsehang haholo le mesaletsa hole le libaka tse nang le khatello e matla ea ho kobeha, joalo ka libaka tse kobehang kapa tse menang. Ho feta moo, ho sebelisa likhutlo tse chitja sebakeng sa likhutlo tse bohale ho ka fokotsa khatello ea maikutlo le ho ntlafatsa maemo a PCB.

Lifofane tsa fatše le tsa Matla:

Kabo ea lifofane tse fatše le tsa matla li bohlokoa haholo ho boloka botsitso bo nepahetseng ba matšoao le kabo ea matla. E kgothaletswa ho aba ba inehetseng fatše le lifofane tsa matla a ho fana ka kabo e leka-lekaneng le e tsitsitseng ea matla ho pholletsa le PCB. Likarolo tsena li boetse li sebetsa joalo ka lithebe tsa electromagnetic interference (EMI). Maemo a nepahetseng a li-vias le li-vias tse rokiloeng ke tsa bohlokoa ho fokotsa ts'ireletso le ho ntlafatsa ts'ebetso ea EMI.

Tlhahlobo ea botšepehi ba matšoao:

Botšepehi ba pontšo bo bohlokoa ts'ebetsong e tloaelehileng ea PCB. Lits'oants'o tsa mats'oao li lokela ho raloa ka hloko ho fokotsa li-impedance discontinuities, crosstalk, le lipontšo tsa lipontšo. Baqapi ba PCB ba lokela ho sebelisa lisebelisoa tsa software ho etsa tlhahlobo ea bots'epehi ba mats'oao ho ntlafatsa bophara ba sebaka le sebaka, ho boloka ts'ebetso e laoloang, le ho netefatsa botšepehi ba matšoao ho PCB eohle e thata-thata.

Libaka tse Fetohang le tse Kobehang:

Likarolo tse tenyetsehang le tse thata tsa PCB li na le litlhoko tse fapaneng mabapi le ho feto-fetoha ha maemo le ho kobeha. Hoa hlokahala ho hlalosa le ho khetha libaka tse khethehileng bakeng sa likarolo tse tenyetsehang le tse thata. Sebaka sa flexible se lokela ho fetoha habonolo ho amohela radius e hlokahalang ntle le ho hatisa mesaletsa kapa likaroloana. Mekhoa ea ho matlafatsa e kang likhopo kapa liaparo tsa polymer li ka sebelisoa ho eketsa matla a mochine le ho tšepahala ha libaka tse tenyetsehang.

Ka ho nahana ka lintlha tsena tsa moralo, lienjineri li ka nts'etsapele li-stackups tsa PCB tse ntlafalitsoeng ka botlalo. Ho bohlokoa ho sebetsa le baetsi ba PCB ho utloisisa bokhoni ba bona, likhetho tsa thepa, le meeli ea tlhahiso. Ho feta moo, ho kenyelletsa sehlopha sa tlhahiso pele ho ts'ebetso ea moralo ho ka thusa ho rarolla mathata leha e le afe a tlhahiso le ho netefatsa phetoho e bonolo ho tloha ho moralo ho ea ho tlhahiso. Ka ho ela hloko kabo ea lera, ho tsamaisa le ho beha mohlala, lifofane tsa fatše le tsa matla, botšepehi ba lipontšo le libaka tse feto-fetohang, baqapi ba ka etsa li-PCB tse ka tšeptjoang le tse sebetsang ka botlalo tse thata-thata.

7.Layer moralo thekenoloji bakeng sa thata-thata tenyetsehang pcb

Ha ho etsoa mapolanka a rigid-flex, mekhoa ea moralo oa lera e bapala karolo ea bohlokoa ho netefatsa ts'ebetso e nepahetseng le ho ts'epahala. Mona ke mekhoa e mene ea bohlokoa ea moralo oa layer:

Lamination e latellanang:

Sequential lamination ke thekenoloji e sebelisoang hangata ha ho etsoa liboto tse thata-flex. Ka mokhoa ona, likarolo tse arohaneng tse thata le tse tenyetsehang li etsoa ka thoko ebe li entsoe ka laminated hammoho. Likarolo tse thata hangata li etsoa ho sebelisoa FR4 kapa lisebelisoa tse tšoanang, ha likarolo tse tenyetsehang li etsoa ho sebelisoa polyimide kapa li-substrates tse tšoanang tse tenyetsehang. Lamination ea tatellano e fana ka phetoho e kholo ho khetho ea lera le botenya, ho lumella taolo e kholo holim'a thepa ea motlakase le ea mechine ea PCB. Dual Access Lamination:

A habeli phihlello lamination, vias ba cheka ka le dikarolo thata le tenyetsehang ho lumella ho fihlella mahlakoreng a mabeli a PCB. Theknoloji ena e fana ka phetoho e kholo ea ho beha likarolo le ho latela litsela. E boetse e tšehetsa tšebeliso ea li-vias tse foufetseng le tse patoang, tse thusang ho fokotsa palo ea lera le ho ntlafatsa botšepehi ba pontšo. Lamination ea li-dual-channel e bohlokoa haholo ha ho etsoa li-PCB tse thata tse thata tse nang le likarolo tse ngata le mathata a sebaka.

Z-axis conductive sekhomaretsi:

Z-axis conductive adhesive e sebelisetsoa ho theha likhokahano tsa motlakase pakeng tsa lera le thata le lera le tenyetsehang ka har'a boto e thata e feto-fetohang. E sebelisoa pakeng tsa lisebelisoa tsa conductive holim'a lera le feto-fetohang le liphahlo tse lumellanang le lera le thata. Sekhomaretsi se na le likaroloana tsa conductive tse etsang litsela tsa conductive ha li hatelloa pakeng tsa lihlopha nakong ea lamination. Z-axis conductive adhesive e fana ka khokahanyo e tšepahalang ea motlakase ha e ntse e boloka maemo a bonolo a PCB le bots'epehi ba mochini.

Sebopeho sa Hybrid stacking:

Ka tlhophiso e nyalisitsoeng ea stacking, motsoako oa likarolo tse thata le tse tenyetsehang li sebelisoa ho theha stack ea lera e ikhethileng. Sena se nolofalletsa baqapi ho ntlafatsa sebopeho sa PCB ho latela litlhoko tse ikhethang tsa moralo. Ka mohlala, likarolo tse thata li ka sebelisoa ho kenya likarolo le ho fana ka ho tiea ha mochine, ha likarolo tse feto-fetohang li ka sebelisoa ho tsamaisa lipontšo libakeng tseo ho tsona ho hlokahalang ho fetoha habonolo. Litlhophiso tsa "hybrid stacking" li fa baqapi boemo bo phahameng ba ho feto-fetoha le maemo bakeng sa meralo e thata ea PCB e thata.

Ka ho sebelisa mekhoa ena ea meralo ea lera, baqapi ba ka theha li-PCB tse thata tse sebetsang hantle. Leha ho le joalo, ho bohlokoa ho sebetsa haufi-ufi le moetsi oa PCB ho netefatsa hore theknoloji e khethiloeng e lumellana le bokhoni ba bona ba ho etsa. Puisano lipakeng tsa lihlopha tsa boqapi le ba boqapi e bohlokoa ho rarolla mathata afe kapa afe a ka bang teng le ho netefatsa phetoho e thellang ho tloha ho moralo ho ea ho tlhahiso. Ka mekhoa e nepahetseng ea moralo oa lera, baqapi ba ka fihlela ts'ebetso e hlokahalang ea motlakase, ho feto-fetoha ha mochini le ho ts'epahala ho li-PCB tse thata-flex.

8.Rigid-tenyetsehang PCB lamination tsoelo-pele ea theknoloji

Tsoelo-pele ea theknoloji e tsitsitseng ea PCB lamination e entse tsoelo-pele e kholo mafapheng a sa tšoaneng. Libaka tse 'ne tsa tsoelo-pele e hlokomelehang ke tsena:

Boiqapelo ba Lintho:

Tsoelo-pele ea mahlale a thepa e nolofalitse nts'etsopele ea lisebelisoa tse ncha tsa substrate tse etselitsoeng ka ho khetheha liboto tse thata-thata. Lisebelisoa tsena li fana ka ho feto-fetoha ha maemo, ho tšoarella, le ho hanyetsa mocheso le mongobo. Bakeng sa likarolo tse feto-fetohang, lisebelisoa tse kang polyimide le liquid crystal polymer (LCP) li fana ka phetoho e babatsehang ha li ntse li boloka thepa ea motlakase. Bakeng sa likarolo tse thata, lisebelisoa tse kang FR4 le li-laminates tse phahameng tsa mocheso li ka fana ka ho tiea le ho tšepahala ho hlokahalang. Lipotoloho tse hatisitsoeng tsa 3D:

Theknoloji ea khatiso ea 3D e fetotse liindasteri tse ngata, ho kenyeletsa le tlhahiso ea PCB. Bokhoni ba ho hatisa 3D traces conductive ka kotloloho holim'a li-flexible substrates bo lumella meralo e rarahaneng le e rarahaneng ea PCB. Theknoloji e thusa ho etsa li-prototyping ka potlako le ho itlhophisa, ho lumella baqapi ho etsa lintlha tse ikhethang tsa sebopeho le ho kopanya likarolo ka kotloloho ho mekhahlelo e fetohang. Tšebeliso ea li-circuits tse hatisitsoeng tsa 3D ho li-PCB tse thata-flex e eketsa ho fetoha ha moralo le ho khutsufatsa lipotoloho tsa nts'etsopele.

Flexible Embedded Components:

Khatelo-pele e 'ngoe e kholo ea thekenoloji ea lamination ke ho kopanngoa ka ho toba ha likarolo ho lera le tenyetsehang la PCB e thata-flex. Ka ho kenyelletsa likarolo tse kang li-resistors, li-capacitor esita le li-microcontrollers ho li-substrates tse tenyetsehang, baqapi ba ka fokotsa boholo ba PCB ka kakaretso le ho ntlafatsa botšepehi ba matšoao. Theknoloji ena e thusa meralo e kopaneng le e bobebe, e etsa hore e be e loketseng lits'ebetso tse nang le mathata a sebaka.

Wiring ya matshwao a lebelo le phahameng:

Ha tlhoko ea puisano e potlakileng e ntse e hola, tsoelo-pele ea theknoloji ea lamination e thusa ho etsa mohala o sebetsang oa lebelo le phahameng ho li-PCB tse thata tse tenyetsehang. Sebelisa mekhoa e tsoetseng pele joalo ka mokhoa o laoloang oa ho thibela mats'oao, ho tsamaisa lipara tse fapaneng, le meralo ea microstrip kapa stripline ho boloka botsitso ba matšoao le ho fokotsa tahlehelo ea matšoao. Mehopolo ea moralo e boetse e nahana ka litlamorao tsa coupling, crosstalk, le lipontšo tsa lipontšo. Tšebeliso ea lisebelisoa tse khethehileng le mekhoa ea tlhahiso e thusa ho finyella ts'ebetso e phahameng ea lebelo la li-PCB tse thata-flex.

Khatelo-pele e tsoelang pele ea theknoloji e thata-thata ea lamination e etsa hore ho be le nts'etsopele ea lisebelisoa tsa elektronike tse sebetsang ka thata, tse tenyetsehang le tse nang le likarolo tse feletseng. Tsoelo-pele ea boqapi ba thepa, lipotoloho tse hatisitsoeng tsa 3D, likarolo tse kentsoeng tse tenyetsehang le ho tsamaisa mats'oao a lebelo le holimo li fa baqapi monyetla oa ho fetoha le maemo le menyetla ea ho theha meralo e mecha le e tšepahalang ea PCB. Ha thekenoloji e ntse e tsoela pele ho fetoha, baqapi le bahlahisi ba tlameha ho lula ba nchafalitsoe le ho sebelisana haufi-ufi ho nka monyetla oa tsoelo-pele ea morao-rao le ho fihlela ts'ebetso e tsitsitseng ea PCB e tenyetsehang.

Ka kakaretso,ho rala le ho khetha tlhophiso e nepahetseng e thata-fetohang ea PCB ho bohlokoa ho fihlela ts'ebetso e nepahetseng, ts'epahalo, le bonolo. Ka ho nahana ka lintlha tse kang botšepehi ba matšoao, litlhoko tsa ho feto-fetoha le maemo le lithibelo tsa tlhahiso, baqapi ba ka hlophisa stackup ho finyella litlhoko tsa bona tse khethehileng tsa kopo. Tsoelo-pele e tsoelang pele ea theknoloji ea thepa e fana ka menyetla e pharaletseng ea moralo o ntlafalitsoeng oa elektroniki. Lisebelisoa tse ncha tsa substrate tse etselitsoeng li-PCB tse thata-flex li ntlafatsa ho tenyetseha, ho tšoarella, le mocheso le ho hanyetsa mongobo. Ho phaella moo, ho kopanya likarolo ka ho toba lesela la flex ho fokotsa boholo le boima ba PCB, ho etsa hore e tšoanelehe bakeng sa likopo tse nang le lithibelo tse thata tsa sebaka. Ho feta moo, tsoelo-pele ea theknoloji ea lamination e fana ka menyetla e thabisang. Tšebeliso ea theknoloji ea khatiso ea 3D e ka nolofalletsa meralo e rarahaneng le ho thusa ho etsa prototyping ka potlako le ho e etsa.

Ho feta moo, tsoelo-pele ea thekenoloji ea lebelo le phahameng ea ho tsamaisa melaetsa e nolofalletsa li-PCB tse thata-tenyetsehang ho finyella lipuisano tse sebetsang hantle le tse ka tšeptjoang.

Ha theknoloji e ntse e tsoela pele ho fetoha, baqapi ba tlameha ho lula ba tseba tsoelo-pele ea morao-rao le ho sebelisana haufi-ufi le bahlahisi. Ka ho ntlafatsa tsoelo-pele ea thepa le theknoloji ea tlhahiso, baqapi ba ka theha meralo e ncha le e tšepahalang ea PCB ho fihlela litlhoko tsa indasteri ea lisebelisoa tsa elektroniki tse lulang li fetoha. Ka ts'episo ea moralo o ntlafalitsoeng oa lisebelisoa tsa elektroniki, bokamoso ba li-stackups tse thata tsa PCB bo shebahala bo ts'episa.

Nako ea poso: Sep-12-2023

Morao