hantle-ntle mapolanka a rigid-flex ke eng, 'me na a hlile a ka sebelisoa lits'ebetsong tsa matla a phahameng? Tataisong ena e felletseng, re tla hlahloba lipotso tsena le ho fana ka leseli mabapi le sehlooho.

Tikolohong ea kajeno ea mahlale a potlakileng, baenjiniere le baqapi ba lula ba batla litharollo tse ncha ho fihlela tlhokahalo e ntseng e hola ea lisebelisoa tsa elektroniki tse matla le tse kopaneng. Sebaka se seng moo sena se leng bohlokoa haholo ke lits'ebetsong tsa matla a holimo. Ho sebetsana le liphephetso tse hlahisoang ke litsamaiso tsena tse boima, litsebi tse ngata li retelehela ho liboto tsa potoloho tse hatisitsoeng tse thata-flex (PCBs).

I. Ho Utloisisa Rigid Flex PCBs:

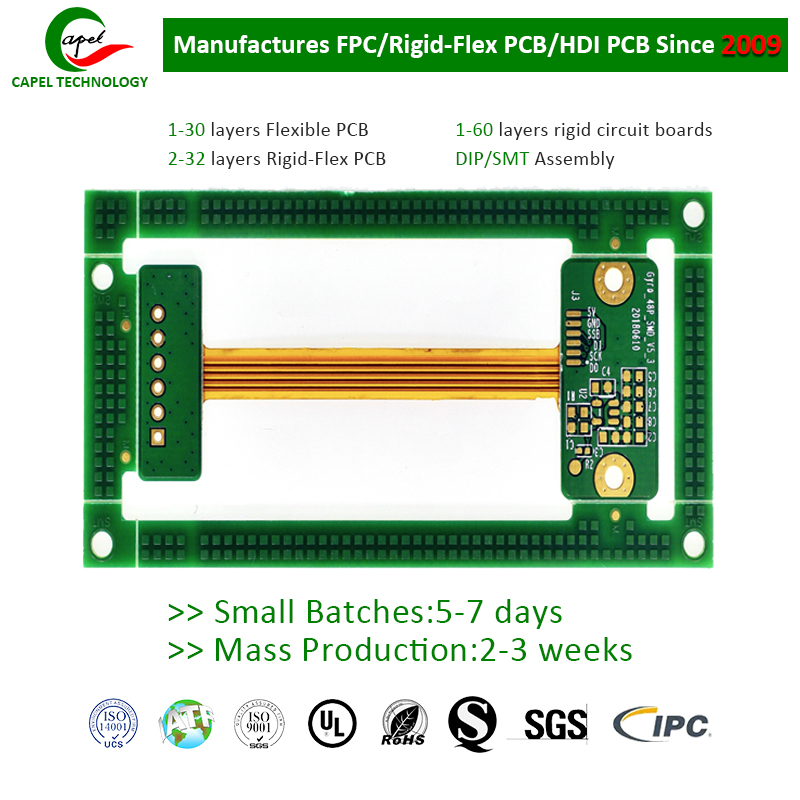

A. Tlhaloso ea li-PCB tse thata tse feto-fetohang

Rigid-flex PCB ke lebasetere la PCB e thata ea setso le PCB e tenyetsehang. Li na le mekhahlelo e mengata ea li-substrates tse thata le tse tenyetsehang tse hokahantsoeng ke lisebelisoa tse feto-fetohang tsa conductive. Moralo ona o lumella PCB ho inama le ho kobeha ntle le ho sekisetsa botšepehi ba likhokahano tsa elektroniki, ho fana ka tokoloho e ncha ea moralo le ho feto-fetoha ha maemo.

B. Melemo le go tlhoka mesola ya rigid flex PCBs

Melemo ea rigid-flex board:

Ntlafatso ea Sebaka: Li-PCB tse thata-fetohang li thusa baqapi ho sebelisa sebaka se nang le mahlakore a mararo ka nepo hobane li ka kobeha, tsa menwa kapa tsa sotheha hore li lekane sebaka se fumanehang. Ho tšepahala ho matlafalitsoeng: Ha ho lihokelo le likhoele tse hokelang tse hlokahalang, ho fokotsa monyetla oa ho hloleha ha mochini le tahlehelo ea matšoao. Li-PCB tsa Rigid-flex li boetse li hanana le ho thothomela, ho tšoha, le ho fetoha ha mocheso. Ntlafatsa botšepehi ba matšoao: Ka ho fokotsa likhokahano le ho khutsufatsa litsela tsa phetisetso, li-PCB tse thata-flex li fokotsa ho sotha ha matšoao, ho netefatsa ts'ebetso e ntle le ts'epahalo ea sistimi. Kopano e Nolofalitsoeng: Li-PCB tse thata-thata li felisa tlhokahalo ea mekhoa e rarahaneng ea ho kopanya ka ho felisa tlhokahalo ea li-connectors le li-solder, ho fokotsa kotsi ea phoso ea motho le ho boloka nako nakong ea ts'ebetso ea tlhahiso. Tšebeliso ea Litšenyehelo: Le hoja e le theko e boima ho feta li-PCB tsa setso, li-PCB tse thata-flexible li ka boloka litšenyehelo ka ho fokotsa palo ea likarolo le ho felisa tlhoko ea lithapo le likhokahanyo tse eketsehileng.

Mathata a rigid-flex board:

Meralo e rarahaneng: Ho rala li-PCB tse sa fetoheng ho hloka tsebo e khethehileng le boitseanape ka lebaka la ho kopanya thepa e thata le e tenyetsehang. Ho rarahana hona ho ka fella ka ho eketseha ha nako ea ntlafatso le litšenyehelo tse phahameng tsa moralo. Litšenyehelo tsa pele: Litsenyehelo tsa pele tsa ho theha PCB e thata-thata e ka 'na ea e-ba holimo ho feta PCB e tloaelehileng, e leng se etsang hore e se ke ea tšoaneleha bakeng sa tlhahiso ea boleng bo tlaase kapa merero e nang le lichelete tse fokolang. Reworkability e lekanyelitsoeng: Hang ha PCB e thata-thata e bokelloa, ho thata ho e fetola kapa ho e lokisa hobane likarolo tse tenyetsehang li fokola haholo ebile li utloa liphetoho.

C. Lisebelisoa tsa li-PCB tse tsitsitseng tse thata

Mapolanka a Rigid-flex a sebelisoa haholo liindastering tse sa tšoaneng, ho akarelletsa: Aerospace le Tšireletso: Li-PCB tse thata-thata li loketse lisebelisoa tsa sefofane le tšireletso ka lebaka la bokhoni ba tsona ba ho mamella maemo a feteletseng le ho tšepahala ho phahameng. Li sebelisoa lits'ebetsong tsa avionics, radars, satellites le lisebelisoa tsa sesole. Lisebelisoa tsa Bongaka: Li-PCB tse Rigid-flex li ntse li sebelisoa ka ho eketsehileng lisebelisoa tsa bongaka ka lebaka la ho fetoha ha tsona le compact form factor. Li sebelisoa ho li-pacemaker, li-implants, litsamaiso tsa litšoantšo tsa bongaka le lisebelisoa tse aparoang tsa ho lekola bophelo bo botle. Consumer Electronics: Mmaraka oa lisebelisoa tsa elektroniki oa bareki o rua molemo ho tsoa ho li-PCB tse sa fetoheng ka har'a lisebelisoa tse kang li-smartphones, matlapa, li-consoles tsa lipapali le tse ka roaloang. Li-PCB tsena li nolofalletsa meralo e nyane le ts'ebetso e ntlafalitsoeng. Indasteri ea likoloi: Rigid-flex PCB e loketse lisebelisoa tsa elektroniki tsa likoloi, ho kenyeletsoa le lits'ebetso tse tsoetseng pele tsa lithuso tsa bakhanni (ADAS), lits'ebetso tsa infotainment, li-powertrains le litsamaiso tsa mabone. Li fana ka ts'epo le ntlafatso ea sebaka libakeng tse thata tsa likoloi.

2. Ho eketsa bokhoni ba li-PCB tse thata-thata lits'ebetsong tse matla a phahameng: Lintlha tsa bohlokoa:

2.1. Litlhoko le meeli ea matla:

A. Utloisisa litlhoko tsa matla: Pele u theha PCB e thata-flex bakeng sa lisebelisoa tsa matla a phahameng, litlhoko tsa matla li tlameha ho hlalosoa ka ho hlaka. Etsa qeto ea maemo a motlakase, a hona joale le a matla ao PCB e lokelang ho a sebetsa, ho nahanoa ka tlhoro le ts'ebetso e tsoelang pele.

B. Nahana ka mefokolo ea matla: Li-PCB tse thata-thata li na le litekanyetso tse khethehileng tsa matla tse lokelang ho nahanoa nakong ea moralo. PCB overloading ka lebisa ho overheating, ho theoha ha voltage, le tšenyo e ka bang teng ho likarolo. Netefatsa meeli ea matla e fanoeng ke moetsi 'me u netefatse hore moralo o kopana le lintlha tsena.

2.2. Litlhokomelo tsa ho felisa mocheso:

K. Lemoha likarolo tsa ho futhumatsa: Lits'ebetsong tse nang le matla a phahameng, likarolo tse itseng li ka hlahisa mocheso o mongata. Hlalosa likarolo tsena 'me u nahane ka sebaka sa tsona ho PCB e thata-flex. Li kopanye ho tsepamisa maikutlo boitekong ba ho pholisa le ho netefatsa leano le nepahetseng la ho pholisa.

B. Ho kenya ts'ebetsong mekhoa e sebetsang ea tsamaiso ea mocheso: Ho senya mocheso ke habohlokoa ho boloka ts'ebetso le ho tšepahala lits'ebetsong tse phahameng tsa matla. Kenyelletsa li-vias tsa mocheso, licheso tsa mocheso, le liphaephe tsa mocheso ka har'a moralo oa PCB ho ntlafatsa phetisetso ea mocheso. Ho feta moo, ha ho hlokahala, nahana ka ho sebelisa mekhoa e tsoetseng pele ea ho pholisa, joalo ka ho pholisa ka mafolofolo ka li-fan kapa ho futhumatsa metsi. tharo.

2.3.Khetho ea likarolo le ho beoa:

K. Khetha likarolo tse nepahetseng: Ho khetha likarolo tse nang le matla a ho sebetsana le matla a nepahetseng ke habohlokoa bakeng sa katleho ea lisebelisoa tsa matla a phahameng. Khetha likarolo tse etselitsoeng le ho fuoa lintlha bakeng sa tšebeliso ea matla a holimo. Nahana ka litekanyetso tsa mocheso oa bona, matla a hona joale a ho jara, le meeli ea motlakase ho netefatsa hore ba khona ho sebetsana le maemo a hlokahalang a matla.

B. Ntlafatsa tlhophiso ea likarolo: Ho hlophisoa ha likarolo ho PCB e thata-flexible ho ka ama haholo ts'ebetso ea eona le matla a ho qhala mocheso. Bokella likarolo tsa matla a phahameng hammoho ho netefatsa sebaka se lekaneng sa ho qhala mocheso. Ho feta moo, nahana ka ho ba haufi le karolo ho fokotsa tšitiso ea matšoao le ho ntlafatsa ts'ebetso ea motlakase.

2.4.Ho tšoarella ha mochini le ho ts'epahala:

K. Khetha Lisebelisoa tse Rugged: Lisebelisoa tse matla haholo hangata li kenyelletsa tikoloho e thata, ho thothomela le khatello ea mochini. Khetha lisebelisoa tse thata le tse tenyetsehang tse nang le thepa e nepahetseng ea mochini ho netefatsa ho tšoarella le ho ts'epahala ha PCB. Nahana ka botsitso ba thepa, ho feto-fetoha ha maemo le ho hanyetsa mongobo, lik'hemik'hale le ho fetoha ha mocheso.

B. Matlafatsa sebaka se feto-fetohang: Ho PCB e thata-flexible, karolo e tenyetsehang e ka hlaseloa ke khatello ea mechine le mokhathala. Matlafatsa libaka tsena ka likarolo tse ling tsa koporo kapa likoahelo tsa polyimide ho eketsa matla a bona a mochini le ho lelefatsa bophelo ba PCB.

3.Melemo ea ho Sebelisa Li-PCB tse Rigid Flex bakeng sa Likopo tse Matla a Phahameng

A. Botšepehi bo ntlafetseng ba pontšo

Li-PCB tsa Rigid-flex li ntlafatsa haholo botšepehi ba matšoao, kahoo li ntlafatsa ts'ebetso ea lisebelisoa tse matla haholo. Ka ho laola impedance hantle, tahlehelo ea matšoao e ka fokotsoa, e fella ka phetisetso e tšepahalang, e sebetsang ea mats'oao. Tšebeliso ea likarolo tse thata li thusa ho fokotsa ho etsahala ha litšitiso tsa matšoao tse bakoang ke ho sisinyeha le khatello ea mochine, ho netefatsa ts'ebetso e tsitsitseng ea boleng bo phahameng.

B. Tsamaiso e matlafetseng ea mocheso

Thermal dissipation ke ntho e ka sehloohong eo ho nahanoang ka eona lits'ebetsong tsa matla a phahameng, kaha mocheso o feteletseng o ka baka ho senyeha ha ts'ebetso esita le ho baka tšenyo e ke keng ea etsolloa likarolong. Li-PCB tse thata-thata li na le matla a ho laola mocheso, li fana ka litsela tse sebetsang tsa ho qhala mocheso le ho fokotsa khatello ea mocheso. Ka ho sebelisa thepa e nang le conductivity e babatsehang ea mocheso le ho behoa ka hloko ka li-vias tsa mocheso le licheso tsa mocheso, li-PCB tsena li tiisa hore ho fela mocheso o nepahetseng, ho etsa bonnete ba hore tsamaiso e tšepahala le ho lelefatsa bophelo ba eona.

C. Bokhoni ba ho boloka sebaka

Ha tlhoko ea litsamaiso tse sebetsang hantle tsa elektroniki li ntse li hola, bokhoni ba ho boloka sebaka e fetohile karolo ea bohlokoa ea moralo oa PCB. Li-PCB tse thata-thata lia ipabola sebakeng sena, li tšehetsa meralo ea mahlakore a mararo le ho sebelisa sebaka se fumanehang hantle. Ho felisa li-connectors tse ngata le li-interconnects ho fokotsa boholo le boima ba 'mele, e leng ntho ea bohlokoa ka ho khetheha lits'ebetsong tse matla haholo moo sebaka se fokolang.

D. Matlafatso ea ho feto-fetoha ha mechine

Ho feto-fetoha ha maemo ho matlafalitsoeng: Monyetla o mong oa li-PCB tse sa fetoheng ke ho tenyetseha ha tsona hantle ha mochini. Motsoako oa likarolo tse thata le tse tenyetsehang li li lumella ho ikamahanya le libopeho tse sa tloaelehang, li-curve le li-curve, e leng se etsang hore e be tse loketseng bakeng sa lits'ebetso tse hlokang meralo e rarahaneng le e kopaneng. Ho feto-fetoha ha maemo ho boetse ho eketsa ho hanyetsa ha bona khatello ea kelello ea mochine, ho sisinyeha le ho thothomela, ho netefatsa ts'ebetso e ka tšeptjoang libakeng tse thata.

E. Keketseho ea menyetla ea moralo

Li-PCB tsa Rigid-flex li bula lefats'e la menyetla mabapi le ho feto-fetoha ha moralo. Baetsi ba na le bolokolohi ba ho kopanya likarolo tse fapaneng le ho ntlafatsa sebopeho sa bona ho ntlafatsa ts'ebetso ea motlakase. Bokhoni ba ho etsa sebopeho sa PCB ho ipapisitse le litlhoko tse ikhethileng tsa kopo bo eketsa katleho le ts'ebetso ea sistimi ka kakaretso. Ho feto-fetoha ha maemo ho fetoha bohlokoa haholo lits'ebetsong tsa matla a holimo, moo mathata a sebaka le ho rarahana ha moralo hangata ho bakang mathata a bohlokoa.

4. Tataiso ea ho Tseba Moralo oa High-Power Rigid-Flex PCB: Tsela e isang Katlehong hlahisa:

A. Bophara bo lekaneng ba mohlala le sebaka:

Taba ea bohlokoa ho rala li-PCB tsa matla a phahameng a rigid-flex ke ho netefatsa bophara bo lekaneng ba sebaka le sebaka. Mesaletsa e pharaletseng e thusa ho phalla hantle hona joale le ho fokotsa khanyetso, ho fokotsa kotsi ea ho futhumala le ho netefatsa ts'ebetso e nepahetseng. Phapang e nepahetseng lipakeng tsa mesaletsa e thusa ho thibela ho kopana ho ka bang teng le tšitiso le ho boloka botsitso ba matšoao. Ho latela maemo a indasteri bakeng sa ho batla bophara le sebaka ho bohlokoa ho netefatsa polokeho, ts'epahalo le botsitso ba lits'ebetso tsa matla a holimo.

B. Pokello e nepahetseng ea layer le khetho ea thepa:

Pokello ea lera le khetho ea thepa e ama haholo ts'ebetso le ho tšoarella ha li-PCB tsa matla a phahameng a rigid-flex. Ho bokella lera ho lekaneng ho thusa kabo e nepahetseng ea matla le phetiso ea matšoao ha ho ntse ho fokotsa tšitiso ea lerata. Khetho e hlokolosi ea lisebelisoa tse nepahetseng, tse kang li-laminates tsa boleng bo phahameng le foil ea koporo e nang le conductivity e ntle ea mocheso, e ka thusa ho matlafatsa mocheso oa mocheso le ho tšepahala ka kakaretso.

C. Mehato ea ho beoa le ho tsamaisa litsela:

Ho beha likarolo hantle le ho tsamaisa litsamaiso ho bohlokoa bakeng sa ts'ebetso e nepahetseng ea li-PCB tsa matla a phahameng a rigid-flex. Ho bea likarolo tsa maano ho fokotsa bolelele ba tsela ea matšoao, ho fokotsa ho theoha ha motlakase le ho ntlafatsa boleng ba matšoao. Ha o rala li-PCB bakeng sa lits'ebetso tsa matla a holimo, ho bohlokoa ho utloisisa litšobotsi tsa mocheso oa likarolo. Mekhoa e nepahetseng ea ho tsamaisa, joalo ka ho qoba ho kobeha ho hlabang le ho sebelisa lipara tse fapaneng ha ho hlokahala, e ka thusa ho laola lerata le ho netefatsa botšepehi ba matšoao.

D. Mekhoa ea ho laola mocheso:

Tsamaiso ea mocheso e bohlokoa ho thibela ho futhumala ho feteletseng le ho boloka botsitso ba li-PCB tse nang le matla a phahameng a rigid-flex. Ho kenyelletsa thekenoloji e kang li-vias tsa mocheso, licheso tsa mocheso le ho sebelisa libaka tsa maqiti tsa koporo ho thusa ho qhala mocheso le ho thibela likaroloana ho fihlela mocheso o boima. Ke habohlokoa ho nahana ka litšobotsi tsa mocheso oa thepa le likaroloana nakong ea moralo ho etsa bonnete ba hore ho na le moea o nepahetseng le ho senya mocheso o sebetsang hantle, kahoo ho lelefatsa bophelo ba PCB.

E. Ho latela maemo a polokeho:

Lits'ebetsong tsa matla a phahameng, polokeho ke ea bohlokoa 'me ho netefatsa hore ho latela litekanyetso tse nepahetseng tsa polokeho ho bohlokoa. Ho lumellana le litekanyetso tse kang UL, IEC, le IPC ho netefatsa hore meralo ea PCB e fihlela litlhoko tsa indasteri bakeng sa ho kenya motlakase, ho cha, le tšireletso khahlanong le likotsi tse ka bang teng. Ho ikamahanya le litekanyetso tsa polokeho ho netefatsa ho ts'epahala le ho ts'epahala ha li-PCB tsa matla a phahameng a rigid-flex, ho netefatsa ts'ebetso e bolokehileng bakeng sa basebelisi ba ho qetela.

5.Li-PCB tse thata tse feto-fetohang li fetola lits'ebetso tse matla haholo:

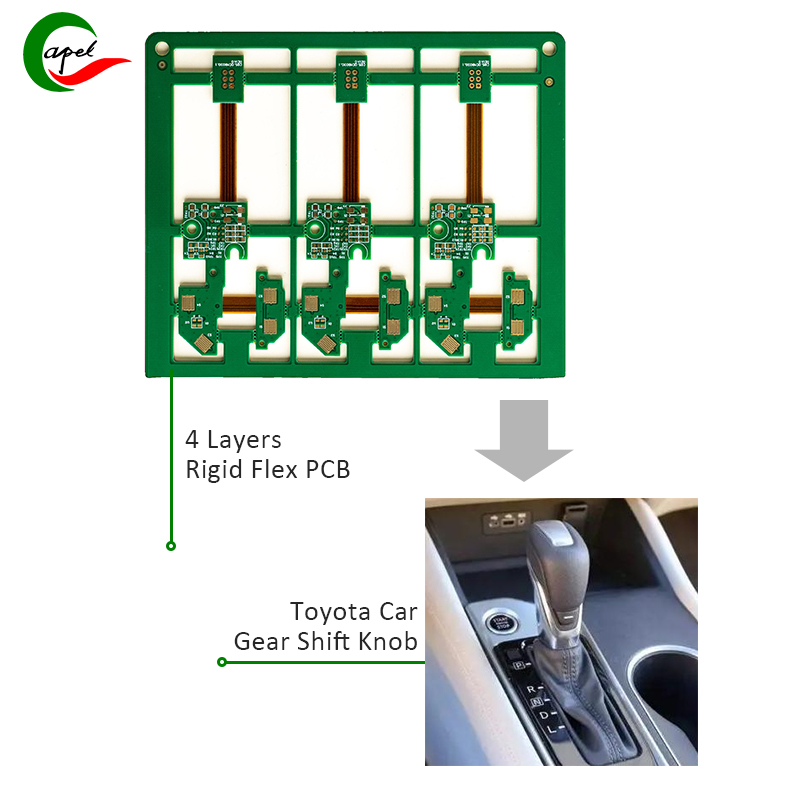

A. Mohlala 1: Indasteri ea likoloi:

Indasteri ea likoloi e ka pele ho boqapi, e lula e hatella meeli ho ntlafatsa ts'ebetso ea likoloi, polokeho le katleho. Li-PCB tsa Rigid-flex li bile le karolo ea bohlokoa phetohong ea sebaka sena, ho khothaletsa nts'etsopele ea litsamaiso tse tsoetseng pele tsa elektroniki. Lits'ebetsong tsa likoloi tse matla haholo joalo ka likoloi tsa motlakase (EVs), li-PCB tse thata-flex li bula tsela bakeng sa taolo e ntlafalitsoeng ea matla, meralo e kopaneng le ho ts'epahala ho ke keng ha bapisoa. Ho feto-fetoha ha tsona ho etsa hore ho be bonolo ho kopanya libaka tse fokolang, ho felisa tlhokahalo ea lithapo tse ngata tsa lithapo le ho fokotsa boima ba 'mele. Li-PCB tsa Rigid-flex li fetola litsamaiso tsa taolo ea betri, likarolo tsa taolo ea makoloi le likarolo tse ling tsa bohlokoa, ho netefatsa kabo e nepahetseng ea matla, e nolofalletsang libaka tse telele tsa ho khanna le ho ntlafatsa ts'ebetso ea koloi ka kakaretso - ho beha maemo a macha bakeng sa indasteri ea likoloi.

B. Mohlala 2: Sefofane le indasteri ea ts'ireletso:

Lefapheng la lifofane le indasteri ea ts'ireletso, ho nepahala, ho tšoarella le ho ts'epahala li bohlokoa. Li-PCB tsa Rigid-flex li ipakile e le tse fetolang papali ho fihlela litlhoko tse thata tsa ts'ebeliso ea matla a phahameng lebaleng lena. Litsamaiso tsa sepakapaka, joalo ka litsamaiso tsa taolo ea sefofane, litsamaiso tsa sefofane le likhokahano, li hloka likarolo tsa elektronike tse matsutla-tsutla ho mamella maemo a feteletseng. Li-PCB tsa Rigid-flex li fana ka botsitso bo ke keng ba lekanngoa ba mochini ka lebaka la ho kopanya likarolo tse thata le tse tenyetsehang, tse li lumellang ho mamella ho thothomela, ho ts'oha le ho fetoha ha mocheso ntle le ho senya ts'ebetso. Ntle le moo, sebopeho sa eona se kopaneng le boima ba 'mele bo fokotsehileng se kenya letsoho ho ntlafatseng ts'ebetso ea mafura le ho eketsa bokhoni ba ho lefa. Ka ho amohela li-PCB tse sa fetoheng, indasteri ea sefofane le ts'ireletso e entse tsoelo-pele e kholo lits'ebetsong tse bohlokoa haholo, ho ntlafatsa ts'ebetso le ho netefatsa ts'epo e sa thekeseleng.

C. Mohlala 3: Lekala la Matla a Tsosolositsoeng:

Indasteri ea matla a ka nchafatsoang e tobane le phephetso ea ho sebelisa le ho aba motlakase ka bokhabane ho tsoa mehloling e ka nchafatsoang joalo ka letsatsi le moea. Li-PCB tsa Rigid-flex li fetohile karolo ea bohlokoa ea indasteri, ho khanna boqapi le ho nolofalletsa ho kopanya ka mokhoa o se nang moeli oa lisebelisoa tse rarahaneng tsa elektronike. Li-inverters tsa letsatsi, lisebelisoa tse bohlale tsa marang-rang le li-turbine tsa moea kaofela li itšetlehile ka matla a phahameng a matla le ho tšoarella ha li-PCB tse thata-thata. Bokhoni ba bona ba ho mamella maemo a thata a tikoloho, hammoho le thepa e ntle ea taolo ea mocheso, bo netefatsa ts'ebetso e tšepahalang le bophelo bo bolelele ba ts'ebeletso. Li-PCB tse tenyetsehang tse thata li thusa ho ntlafatsa ts'ebetso e felletseng ea litsamaiso tsa matla a ka nchafatsoang, tse nolofalletsang phetoho e nepahetseng ea matla, ho beha leihlo ka bohlale le tšebeliso e nepahetseng ea matla a ts'ebetso.

6.Ho hlola mathata le ho fokotsa likotsi lits'ebetsong tsa matla a holimo ka li-PCB tse thata-flex:

A. Litšenyehelo:

Litšenyehelo ke ntlha ea bohlokoa eo baetsi ba liqeto ba lokelang ho e lekanya ha ba nahana ka li-PCB tse sa fetoheng bakeng sa lits'ebetso tsa matla a holimo. Ha ho bapisoa le li-PCB tsa setso tse thata, li-PCB tse sa fetoheng li atisa ho bitsa chelete e ngata haholo ka lebaka la moralo o eketsehileng, lisebelisoa le lintho tse rarahaneng tsa tlhahiso tse amehang. Ho kopanya likarolo tse thata le tse tenyetsehang ho hloka boenjiniere bo nepahetseng le mehaho e rarahaneng, e leng se hlahisang litšenyehelo tse phahameng tsa tlhahiso. Leha ho le joalo, e tlameha ho talingoa e le letsete ho fapana le moeli. Litsenyehelo tsa ho sebelisa li-PCB tse thata-thata li ka lokafatsoa ke melemo e mengata eo e e tlisang, joalo ka ts'epo e matlafalitsoeng, boima bo fokotsehileng, ho boloka sebaka, le ho tšoarella ho ntlafetseng. Ka ho utloisisa melemo ea nako e telele le ho etsa tlhahlobo e phethahetseng ea melemo ea litšenyehelo, lik'hamphani li ka etsa liqeto tse nang le tsebo 'me tsa eketsa phaello ea matsete ha li kopanya li-PCB tse thata-thata ho likopo tsa matla a phahameng.

B. Lintho tse rarahaneng tsa tlhahiso:

Ho hlahisa li-PCB tse thata-flexbakeng sa lisebelisoa tsa matla a phahameng li hlahisa liphephetso tse ikhethang ka lebaka la meralo ea tsona e rarahaneng le litlhaloso tse hlokahalang. Ho kopanngoa ha likarolo tse thata le tse tenyetsehang ho hloka mekhoa e rarahaneng ea tlhahiso le lisebelisoa tse khethehileng. Ho tsamaisana hantle ha likarolo, ho netefatsa likhokahano tse tšepahalang tsa motlakase, le ho boloka matla a mochini bophelo bohle ba boto ea potoloho kaofela li hloka tlhokomelo e hlokolosi ho lintlha. Baetsi ba lokela ho tsetela mochining o tsoetseng pele, ho hira litsebi tse nang le boiphihlelo le ho kenya tšebetsong mehato e tiileng ea taolo ea boleng ho fokotsa likotsi ts'ebetsong ea tlhahiso. Ho sebetsa le moetsi oa PCB ea nang le boiphihlelo le ea nang le botumo bo botle ho bohlokoa ho netefatsa ts'ebetso e atlehileng ea lits'ebetso tsa matla a holimo. Ka ho sebelisa boiphihlelo ba bahlahisi bana, lik'hamphani li ka fokotsa ho rarahana ha tlhahiso le ho netefatsa ho tlisoa ha lihlahisoa tse tšepahalang le tsa boleng bo holimo.

C. Ho fumaneha ho fokolang ha barekisi ba khethehileng:

Phephetso e 'ngoe ha u sebelisa li-PCB tse thata-thata bakeng sa lisebelisoa tse matla haholo ke palo e lekanyelitsoeng ea bafani ba thepa e khethehileng. Meaho e rarahaneng le lits'ebetso tse rarahaneng tsa tlhahiso li thibetse bahlahisi ba bangata ba PCB ho kena 'marakeng ona oa niche. Ka hona, ho fumana barekisi ba tšepahalang le ba nang le tsebo ho ka ba thata. Ho sebetsa le mofani oa thepa ea nang le tsebo ea tekhenoloji ea PCB e sa fetoheng ho bohlokoa bakeng sa phihlello ea thepa ea boleng, boitseanape bo ikhethileng indastering le tšehetso ea tekheniki. Ho sebetsa haufi-ufi le barekisi bana ba khethehileng ho thusa ho fokotsa likotsi tse ka bang teng, ho netefatsa hore likarolo tse nepahetseng le thepa li fumaneha, le ho tsamaisa tšebetso eohle ea tlhahiso. Ho aha likamano tsa nako e telele le bafani ba thepa ba tšeptjoang ke leano le babatsehang le sa fokotseng feela liphephetso tse fokolang tsa ho fumaneha, empa hape le khothalletsa tšebelisano le mekhoa e mecha ka har'a indasteri ea matla a phahameng.

Ka kakaretso:

Li-PCB tse Rigid-flex ke khetho e ntle haholo bakeng sa lits'ebetso tse matla a holimo. Bokhoni ba bona ba ho sebetsana le khatello ea mocheso, boholo ba compact le botšepehi bo matlafalitsoeng ba pontšo bo etsa hore e be tharollo e tšepahalang, e sebetsang hantle.Leha ho le joalo, menahano e nepahetseng ea moralo le khetho ea thepa e bohlokoa ho fihlela sephetho se nepahetseng. Ho buisana le litsebi tse nang le phihlelo ea PCB ke karolo ea bohlokoa ea ts'ebetso.

Haeba u batla tharollo litlhoko tsa hau tsa kopo ea matla a holimo, nahana ka ho hlahloba melemo ea theknoloji ea PCB e thata-flex. Ka moralo le ts'ebetso ea tsona e ikhethang, liboto tsena li ka u thusa ho fihlela litlhoko tsa lefats'e la lisebelisoa tsa elektroniki tse lulang li fetoha.-Capel e nang le boiphihlelo ba lilemo tse 15 indastering ea Rigid Flexible PCB.

Nako ea poso: Sep-16-2023

Morao