Ho blog ena, re tla tšohla mekhoa e tloaelehileng ea solder e sebelisoang kopanong ea PCB e thata-flex le kamoo e ntlafatsang botšepehi le ts'ebetso ea lisebelisoa tsena tsa elektronike.

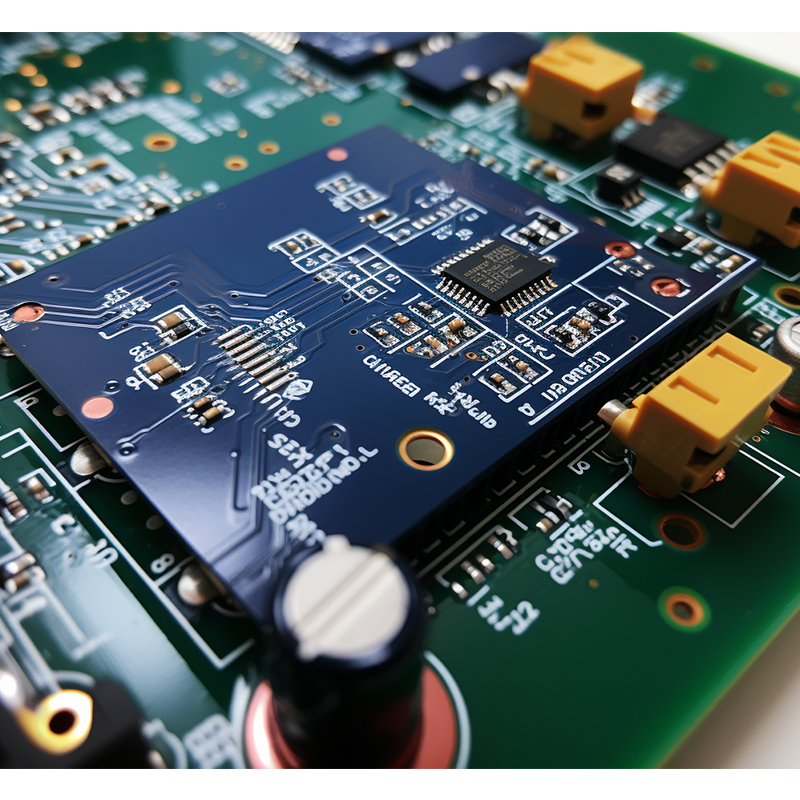

Theknoloji ea soldering e bapala karolo ea bohlokoa ts'ebetsong ea kopano ea PCB e thata-flex. Liboto tsena tse ikhethang li etselitsoe ho fana ka motsoako oa ho tiea le ho feto-fetoha ha maemo, ho etsa hore e be tse loketseng bakeng sa mefuta e fapaneng ea likopo moo sebaka se lekanyelitsoeng kapa likhokahano tse rarahaneng li hlokahalang.

1. Theknoloji ea Surface Mount (SMT) e entsoe ka PCB e thata ea flex:

Theknoloji ea Surface Mount (SMT) ke e 'ngoe ea litheknoloji tse sebelisoang ka ho fetesisa tsa ho rekisa ka har'a kopano e thata ea PCB. Mokhoa ona o kenyelletsa ho beha likarolo tsa holim'a holim'a boto le ho sebelisa solder paste ho li tšoara. Solder paste e na le likaroloana tse nyane tsa solder tse emisitsoeng ka har'a phallo e thusang ts'ebetsong ea solder.

SMT e nolofalletsa likarolo tse phahameng tsa density, e lumellang palo e kholo ea likarolo ho kenngoa ka mahlakoreng a mabeli a PCB. Theknoloji e boetse e fana ka ts'ebetso e ntlafetseng ea mocheso le motlakase ka lebaka la litsela tse khutšoanyane tsa conductive tse entsoeng pakeng tsa likarolo. Leha ho le joalo, e hloka taolo e nepahetseng ea ts'ebetso ea welding ho thibela marokho a solder kapa manonyeletso a sa lekaneng a solder.

2. Theknoloji ea ho sebelisa likoti (THT) ka mokhoa o thata oa ho kopanya PCB:

Le ha likarolo tse holim'a metsi li sebelisoa hangata ho li-PCB tse thata-thata, likarolo tsa lesoba le tsona lia hlokahala maemong a mang. Theknoloji ea ka-hole (THT) e kenyelletsa ho kenya likarolo tse lebisang ka sekoting ho PCB le ho li rekisa ka lehlakoreng le leng.

THT e fana ka matla a mochini ho PCB mme e eketsa ho hanyetsa khatello ea maikutlo le ho thothomela. E lumella ho kenngoa ka mokhoa o sireletsehileng oa likarolo tse kholoanyane, tse boima tse ka 'nang tsa se ke tsa tšoanela SMT. Leha ho le joalo, THT e fella ka litsela tse telele tsa ho khanna 'me e ka fokotsa ho fetoha ha PCB. Ka hona, ho bohlokoa ho ba le botsitso lipakeng tsa likarolo tsa SMT le THT ka meralo e thata ea PCB.

3. Boemo ba moea o chesang (HAL) ha ho etsoa PCB e thata:

Hot air leveling (HAL) ke mokhoa oa solder o sebelisetsoang ho sebelisa lesela le lekanang la solder ho mesaletsa ea koporo e pepeneneng ho li-PCB tse thata tse feto-fetohang. Mokhoa ona o kenyelletsa ho fetisa PCB ka bateng ea solder e entsoeng ka ho qhibilihisoa ebe o e pepesetsa moeeng o chesang, o thusang ho tlosa solder e feteletseng le ho etsa sebaka se bataletseng.

HAL e atisa ho sebelisoa ho etsa bonnete ba hore solderability e nepahetseng ea mesaletsa ea koporo e pepesitsoeng le ho fana ka tšireletso e sireletsang khahlanong le oxidation. E fana ka tšireletso e ntle ka kakaretso ea solder mme e ntlafatsa ts'epahalo e kopaneng ea solder. Leha ho le joalo, HAL e kanna ea se tšoanelehe bakeng sa meralo eohle ea PCB e thata, haholo e nang le potoloho e nepahetseng kapa e rarahaneng.

4. Khetho ea ho tjheseletsa ka har'a PCB e tsitsitseng e tsitsitseng e hlahisang:

Selectional soldering ke mokhoa o sebelisoang ho khetha likarolo tse ikhethileng ho li-PCB tse thata-flex. Mokhoa ona o kenyelletsa ho sebelisa wave soldering kapa tšepe ea solder ho sebelisa solder hantle libakeng tse itseng kapa likarolo tsa PCB.

Soldering e khethehileng e molemo ka ho khetheha ha ho e-na le likaroloana tse thibelang mocheso, li-connectors, kapa libaka tse nang le matla a mangata a ke keng a mamella mocheso o phahameng oa reflow soldering. E lumella taolo e betere ea ts'ebetso ea welding le ho fokotsa kotsi ea ho senya likarolo tse hlokolosi. Leha ho le joalo, ho khetha solder ho hloka ho hlophisoa ho eketsehileng le mananeo ha ho bapisoa le mekhoa e meng.

Ho akaretsa, mahlale a tloaelehileng a sebelisoang ho tjheseletsa bakeng sa ho kopanya boto e thata-flexible e kenyelletsa thekenoloji ya surface mount (SMT), thekenoloji ya through-hole (THT), hot air leveling (HAL) le selective welding.Theknoloji e 'ngoe le e' ngoe e na le melemo le maikutlo a eona, 'me khetho e itšetlehile ka litlhoko tse khethehileng tsa moralo oa PCB. Ka ho utloisisa litheknoloji tsena le litlamorao tsa tsona, bahlahisi ba ka netefatsa ts'epo le ts'ebetso ea li-PCB tse sa fetoheng ka mokhoa o fapaneng lits'ebetsong tse fapaneng.

Nako ea poso: Sep-20-2023

Morao