Na u tobane le mathata a katoloso ea mocheso le khatello ea mocheso ka li-PCB tse mahlakore a mabeli? Se ke oa sheba hole, posong ena ea blog re tla u tataisa mabapi le mokhoa oa ho rarolla mathata ana ka katleho. Empa pele re kenella ka har'a litharollo, a re itlhahiseng.

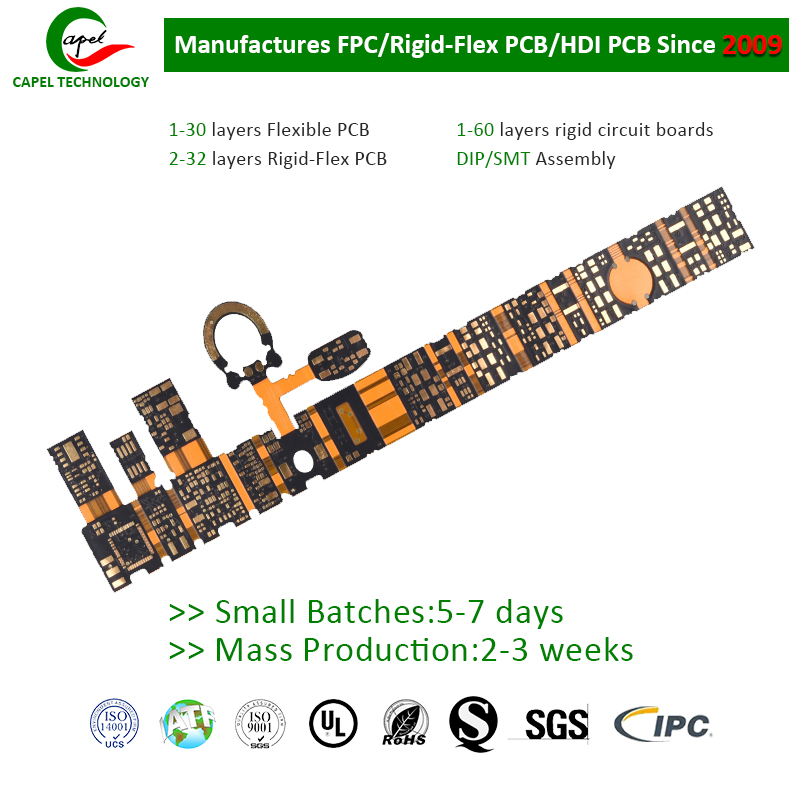

Capel ke moetsi ea nang le boiphihlelo indastering ea boto ea potoloho mme esale a sebeletsa bareki ka lilemo tse 15. E na le fektheri ea eona ea boto ea potoloho e feto-fetohang, fektheri ea boto ea potoloho e thata, fektheri ea kopano ea boto ea potoloho ea smt, 'me e thehile botumo bo botle tlhahisong ea liboto tsa potoloho tsa boleng bo holimo ho isa bohareng. Thepa ea rona e tsoetseng pele ea tlhahiso e ikemetseng e tsoang kantle le sehlopha se inehetseng sa R&D se bonts'a boitlamo ba rona ba ho sebetsa hantle. Joale, ha re khutleleng ho rarolleng bothata ba katoloso ea mocheso le khatello ea mocheso ho li-PCB tse mahlakore a mabeli.

Keketseho ea mocheso le khatello ea mocheso ke mathata a tloaelehileng indastering ea tlhahiso ea PCB. Mathata ana a hlaha ka lebaka la ho se tšoane ha coefficient of thermal expansion (CTE) ea thepa e sebelisoang ho PCB. Ha ho futhumatsoa, thepa e atoloha, 'me haeba litekanyetso tsa katoloso ea thepa e fapaneng li fapana haholo, khatello ea maikutlo e ka ba teng mme ea baka ho hloleha ha PCB. Ho rarolla mathata a joalo, ka kopo latela litataiso tsena:

1. Khetho ea lintho tse bonahalang:

Khetha lisebelisoa tse nang le boleng bo tšoanang ba CTE. Ka ho sebelisa lisebelisoa tse nang le litekanyetso tse tšoanang tsa ho atolosa, monyetla oa khatello ea mocheso le mathata a amanang le ho atolosa a ka fokotsoa. Ikopanye le litsebi tsa rona kapa u buisane le maemo a indasteri ho fumana lisebelisoa tse molemohali bakeng sa litlhoko tsa hau tse ikhethileng.

2. Lintlha tsa moralo:

Nahana ka sebopeho le moralo oa PCB ho fokotsa khatello ea maikutlo. Ho kgothaletswa ho boloka likarolo tse senyang mocheso haholo hole le libaka tse nang le liphetoho tse kholo tsa mocheso. Likarolo tse pholileng hantle, ho sebelisa li-vias tsa mocheso, le ho kenyelletsa mekhoa ea mocheso ho ka boela ha thusa ho senya mocheso ka katleho le ho fokotsa khatello ea kelello.

3. Layer stacking:

Sekhahla sa PCB se nang le mahlakore a mabeli se ama boitšoaro ba eona ba mocheso. Layup e leka-lekaneng le e leka-lekaneng e thusa ho aba mocheso ka ho lekana, ho fokotsa monyetla oa khatello ea mocheso. Ikopanye le baenjiniere ba rona ho theha moralo oa ho rarolla mathata a hau a katoloso ea mocheso.

4. Botenya ba koporo le likhoele:

Botenya ba koporo le bophara ba trace li phetha karolo ea bohlokoa ho laola khatello ea mocheso. Mekhahlelo ea koporo e teteaneng e fana ka conductivity e ntle ea mocheso 'me e ka fokotsa liphello tsa ho atolosoa ha mocheso. Ka mokhoa o ts'oanang, mesaletsa e pharaletseng e fokotsa ho hanyetsa le ho thusa ho qhala mocheso o nepahetseng.

5. Khetho ea lisebelisoa tsa prepreg le tsa mantlha:

Khetha lisebelisoa tsa prepreg le tsa mantlha tse nang le CTE tse ts'oanang le seaparo sa koporo ho fokotsa kotsi ea delamination ka lebaka la khatello ea mocheso. Lisebelisuoa tsa prepreg le tsa mantlha tse phekotsoeng hantle le tse tlamahantsoeng li bohlokoa ho boloka botsitso ba sebopeho sa PCB.

6. Impedans e laoloang:

Ho boloka impedance e laoloang ho pholletsa le moralo oa PCB ho thusa ho laola khatello ea maikutlo. Ka ho boloka litsela tsa matšoao li le khuts'oane le ho qoba liphetoho tsa tšohanyetso ka bophara ba trace, o ka fokotsa liphetoho tsa impedance tse bakoang ke ho eketseha ha mocheso.

7. Theknoloji ea tsamaiso ea mocheso:

Ho sebelisa mekhoa ea tsamaiso ea mocheso e kang licheso tsa mocheso, li-pads tsa mocheso, le li-vias tsa mocheso ho ka thusa ho qhala mocheso ka katleho. Mahlale ana a ntlafatsa ts'ebetso e akaretsang ea mocheso oa PCB le ho fokotsa kotsi ea ho hloleha ho amanang le khatello ea maikutlo.

Ka ho kenya ts'ebetsong maqheka ana, o ka fokotsa haholo katoloso ea mocheso le mathata a khatello ea mocheso ho li-PCB tse nang le mahlakore a mabeli. Capel, re na le boitseanape le lisebelisoa ho u thusa ho hlola mathata ana. Sehlopha sa rona sa litsebi se ka fana ka tataiso le tšehetso ea bohlokoa mohatong o mong le o mong oa ts'ebetso ea hau ea tlhahiso ea PCB.

Se ke oa lumella katoloso ea mocheso le khatello ea mocheso ho ama ts'ebetso ea PCB ea hau e mahlakoreng a mabeli. Ikopanye le Capel kajeno 'me u utloe boleng le ts'epahalo e tlisoang ke lilemo tse 15 tsa boiphihlelo indastering ea boto ea potoloho. Ha re sebetseng 'moho ho aha PCB e kopanang le ho feta litebello tsa hau.

Nako ea poso: Oct-02-2023

Morao