Tsebisa:

Ha tlhokahalo ea lisebelisoa tsa elektronike tse sebetsang ka bohlale e ntse e eketseha, bahlahisi ba ntse ba tsoela pele ho qapa mekhoa e mecha ho khotsofatsa litlhoko tsena. Liboto tsa potoloho tse hatisitsoeng ka thata-flex (PCBs) li ipakile e le papali-papali, e nolofalletsang meralo e feto-fetohang le e sebetsang hantle ho lisebelisoa tsa elektroniki tsa sejoale-joale. Leha ho le joalo, ho na le maikutlo a fosahetseng a tloaelehileng a hore ho etsa li-PCB tse thata-flex ho hloka lisebelisoa tse khethehileng tsa tlhahiso. Ka blog ena, re tla hlalosa tšōmo ena mme re buisane ka hore na ke hobane'ng ha thepa ena e khethehileng e sa hlokahale.

1. Utloisisa boto e thata-flex:

Rigid-flex PCB e kopanya melemo ea liboto tsa potoloho tse thata le tse tenyetsehang ho eketsa maemo a moralo, ho ntlafatsa ho tšepahala le ho fokotsa litšenyehelo tsa kopano. Liboto tsena li na le motsoako oa li-substrates tse thata le tse tenyetsehang, tse hokahaneng ka ho sebelisoa ka masoba, sekhomaretsi se tsamaisang, kapa lihokelo tse ntšoang. Sebopeho sa eona se ikhethang se e lumella ho kobeha, ho mena kapa ho sotha hore e kene libakeng tse thata le ho amohela meralo e rarahaneng.

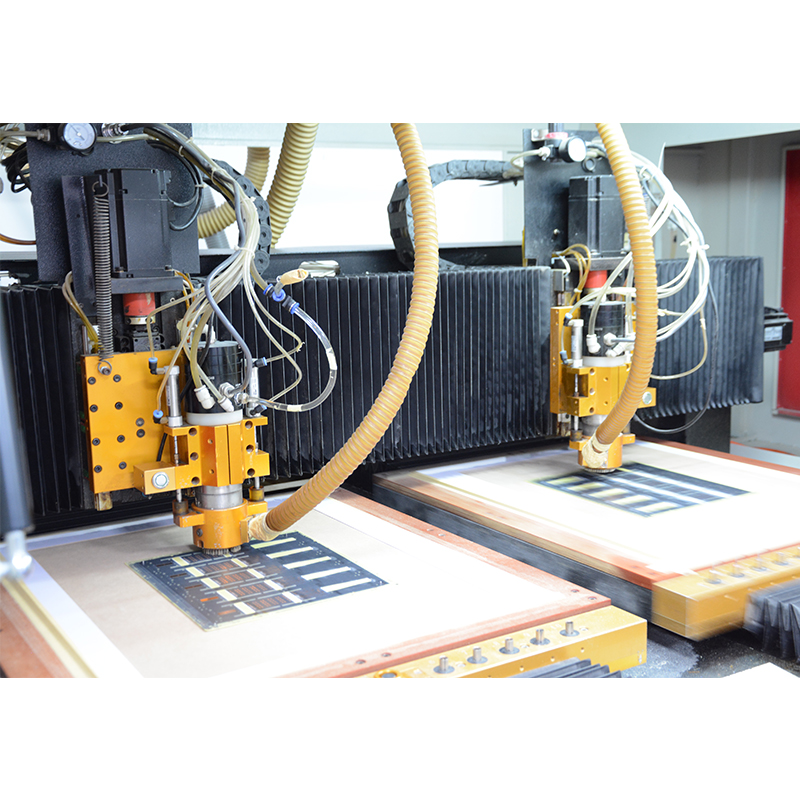

2. E hloka lisebelisoa tse khethehileng tsa tlhahiso:

Ho fapana le seo batho ba se lumelang, ho tsetela ho lisebelisoa tse khethehileng tse thata-thata ha ho hlokahale kamehla. Le ha liboto tsena li hloka lintlha tse eketsehileng ka lebaka la kaho ea tsona, mekhoa e mengata e teng ea tlhahiso le lisebelisoa li ntse li ka sebelisoa. Mehaho ea morao-rao ea tlhahiso e na le mechine e tsoetseng pele ho hlahisa liphanele tse thata-thata ntle le tlhokahalo ea lisebelisoa tse khethehileng.

3. Ho sebetsana le lintho tse bonolo:

E 'ngoe ea lintlha tsa bohlokoa tsa ho etsa li-PCB tse thata-flex ke ho sebetsana le ho sebetsa ha thepa e tenyetsehang. Lisebelisoa tsena li ka ba tse fokolang 'me li hloka tlhokomelo e khethehileng nakong ea tlhahiso. Leha ho le joalo, ka koetliso e nepahetseng le mekhoa e ntlafalitsoeng ea tlhahiso, lisebelisoa tse teng li ka sebetsana le lisebelisoa tsena ka katleho. Litokiso ho mekhoa ea ho koala, litlhophiso tsa li-conveyor le mekhoa ea ho sebetsana le eona li ka etsa bonnete ba ho sebetsana ka nepo ha li-substrates tse tenyetsehang.

4. Ho Cheka le ho Pola ka Mekoti:

Liboto tse thata-thata hangata li hloka ho cheka ka masoba ho hokahanya likarolo le likarolo. Ba bang ba ka 'na ba lumela hore mochine o khethehileng oa ho phunya o hlokahala ka lebaka la liphetoho tsa thepa ea substrate. Le hoja maemo a mang a ka hloka li-drill tse thata kapa li-spindles tse lebelo le phahameng, lisebelisoa tse teng li ka finyella litlhoko tsena. Ka mokhoa o ts'oanang, ho koala masoba ka lisebelisoa tsa conductive ho ka etsoa ka lisebelisoa tse tloaelehileng le mekhoa e netefalitsoeng ke indasteri.

5. Copper foil lamination le etching:

Copper foil lamination le mekhoa e latelang ea etching ke mehato ea bohlokoa tlhahisong ea boto e thata-flex. Nakong ea lits'ebetso tsena, likarolo tsa koporo li tlamelloa ho substrate ebe li tlosoa ka mokhoa o ikhethileng ho theha potoloho e lakatsehang. Le hoja lisebelisoa tse khethehileng li ka ba molemo bakeng sa tlhahiso ea boleng bo phahameng, mechine e tloaelehileng ea lamination le etching e ka finyella liphello tse babatsehang tlhahisong e nyenyane.

6. Ho kopanya likarolo le ho tjheseletsa:

Mekhoa ea ho kopanya le ea ho kopanya le eona ha e hloke lisebelisoa tse khethehileng bakeng sa li-PCB tse thata-flex. Proven surface Mount Technology (SMT) le mekhoa ea ho kopanya ka mekoti e ka sebelisoa ho liboto tsena. Ntho ea bohlokoa ke moralo o nepahetseng bakeng sa manufacturability (DFM), ho netefatsa hore likarolo li behiloe ka mokhoa o hlophisehileng ka libaka tse feto-fetohang le lintlha tse ka bang teng tsa khatello kelellong.

ha re phethela:

Ka kakaretso, ke maikutlo a fosahetseng a hore li-PCB tse thata-thata li hloka lisebelisoa tse khethehileng tsa tlhahiso. Ka ho ntlafatsa lits'ebetso tsa tlhahiso, ho sebetsana ka hloko le lisebelisoa tse tenyetsehang, le ho latela tataiso ea moralo, lisebelisoa tse teng li ka hlahisa liboto tsena tsa potoloho tse sebetsang ka katleho. Ka hona, bahlahisi le baqapi ba tlameha ho sebetsa le balekane ba nang le boiphihlelo ba tlhahiso ba ka fanang ka boiphihlelo le tataiso e hlokahalang nakong eohle ea tlhahiso. Ho notlolla bokhoni ba li-PCB tse thata-thata ntle le moroalo oa lisebelisoa tse khethehileng ho fa liindasteri monyetla oa ho sebelisa melemo ea tsona le ho theha lisebelisoa tse ncha tsa elektroniki.

Nako ea poso: Sep-19-2023

Morao