U batla PCB ea boleng bo holimo e fielang? Capel e fana ka theknoloji e hahelletsoeng ka thata-flex printed circuit board ho fihlela litlhoko tsa hau.

Khaolo ea 1: Phetoho ea liroboto tse fielang

Tsebisa

Lefatšeng la liroboto tse ntseng li fetoha ka potlako, liroboto tse fielang li fetohile lisebelisoa tsa bohlokoa bakeng sa ho boloka bohloeki le taolo malapeng le libakeng tsa khoebo. Lisebelisoa tsena tse ikemetseng li itšetlehile ka theknoloji ea morao-rao ho tsamaea le ho hloekisa ka katleho. Boto ea potoloho e hatisitsoeng (PCB) ke e 'ngoe ea likarolo tsa bohlokoa tse ntlafatsang haholo ts'ebetso ea liroboto tse fielang. Sehloohong sena, re tla shebana le karolo ea PCB e sa fetoheng ho ntlafatsa ts'ebetso ea liroboto tse fielang, le ho sekaseka maemong a ikhethileng hore na tharollo ea PCB ea Capel e tlisitse phetoho ea mahlale joang indastering ea liroboto.

Khaolo ea 2: Karolo ea mantlha ea li-PCB ho li-vacuum cleaners tsa liroboto

Lisebelisoa tse hloekisang liroboto, tse tsejoang hape e le li-vacuum cleaners, li na le li-sensor, li-motor, le litsamaiso tsa taolo tse li lumellang ho tsamaea tikolohong e rarahaneng le ho etsa mesebetsi ea ho hloekisa ka nepo. Bohareng ba litsamaiso tsena tse rarahaneng ke PCB, e sebetsang e le tsamaiso ea methapo e bohareng ea roboto, e nolofatsang puisano lipakeng tsa likarolo tsa motho ka mong le ho netefatsa ts'ebetso e se nang moeli.

Khaolo ea 3: PCB e sa fetoheng: Phetoho ea liroboto tse fielang

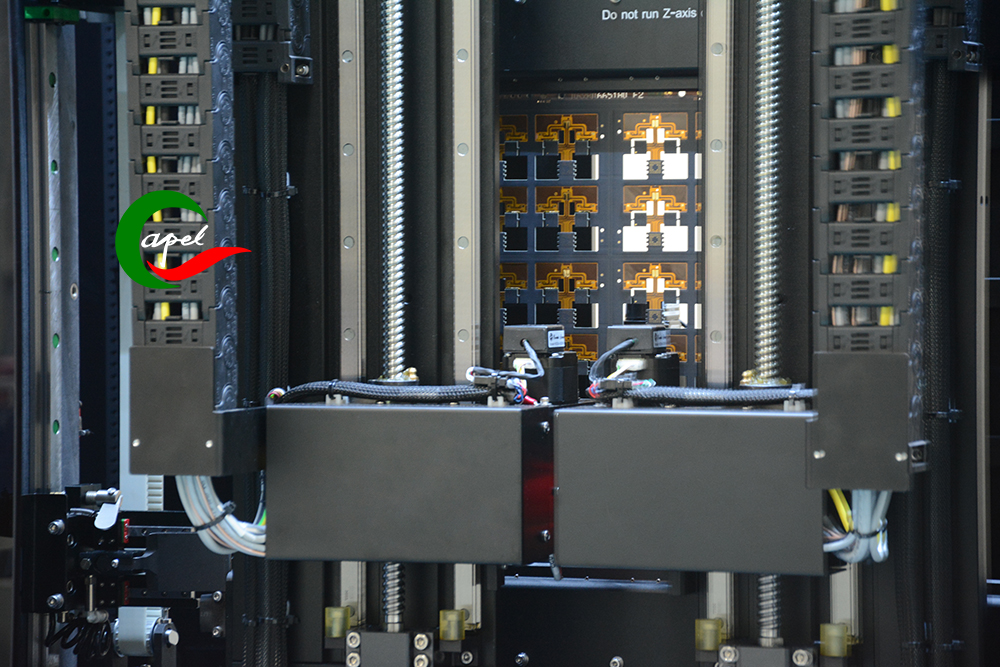

Li-PCB tsa setso tse thata li na le mefokolo ea ho ikamahanya le maemo a thata a jeometri le lithibelo tsa sebaka tsa meralo ea vacuum ea liroboto. Mona ke moo li-PCB tse thata-fetohang li kenang teng. Ka ho kopanya melemo ea li-PCB tse thata le tse tenyetsehang, li-PCB tse thata-flexible li fana ka phetoho e ke keng ea lekanngoa moralong le ho kopanya, ho etsa hore e be tse loketseng bakeng sa lisebelisoa tsa robotic vacuum.

Tsebo ea Capel ea litharollo tsa PCB tsa vacuum cleaner

Capel ke moetsi ea ka sehloohong oa li-PCB tse feto-fetohang le tse thata-thata 'me o ntse a le ka pele ho ho khanna mekhoa e mecha indastering ea vacuum ea liroboto. Ka lilemo tse fetang 16 tsa boiphihlelo ba ho nts'etsapele litharollo tsa PCB tsa tloaelo bakeng sa li-vacuum tsa liroboto, Capel e se e le molekane ea tšeptjoang bakeng sa baetsi ba liroboto ba batlang ho ntlafatsa ts'ebetso ea sehlahisoa le ho ts'epahala.

Mohlala oa thuto: Capel e kopanya liboto tse bonolo le tse thata ho ntlafatsa ts'ebetso ea liroboto tse fielang

Mohlala o mong oa konkreiti oa phello ea Capel ho thekenoloji ea vacuum ea liroboto ke ho kopanngoa ha PCB ea eona e thata-flexible ho mefuta e latelang ea liroboto tsa vacuum. Ka ho sebelisa li-PCB tsa Capel tse phahameng ka ho fetisisa, tse nang le matla a phahameng, li-vacuum tsa liroboto li khona ho finyella maemo a sa tloaelehang a ts'ebetso le ts'ebetso. Motsoako o thata oa Capel oa ho kopanya ka mokhoa o se nang seamless oa li-sensor, litsamaiso tsa taolo, le li-module tsa taolo ea matla ho PCB e theha roboto e fielang e ka tsamaisang tikoloho e rarahaneng ka ho nepahala le ho hloekisa bokhoni bo boholo.

Tlhahlobo ea Theknoloji: Melemo ea Capel Rigid-Flex Board

Capel's rigid-flex PCB e fana ka melemo e mengata ea bohlokoa e ntlafatsang ka kotloloho ts'ebetso ea vacuum ea hau ea liroboto. Tsena li kenyelletsa:

Ntlafatso ea sebaka: Moralo o ikhethileng oa PCB e thata-fetohang e ka sebelisa sebaka se ka hare ho roboto e fielang ho kopanya likarolo tse rarahaneng tsa elektroniki ntle le ho ama boholo kapa ts'ebetso ka kakaretso.

Ho tšoarella ho matlafalitsoeng: Roboto e fielang e tlas'a ho sisinyeha ho tsoelang pele le ho thothomela nakong ea ts'ebetso. Liboto tse thata tsa Capel li entsoe ho mamella likhatello tsena tsa tikoloho, ho netefatsa ts'epo ea nako e telele le ho tšoarella.

Bokhoni ba ho ikamahanya le maemo: Capel e ts'ehetsa litharollo tsa PCB tsa liroboto tse ikhethileng, tse fanang ka moralo le maemo a bonolo a kopano ho fihlela litlhoko tse ikhethileng tsa baetsi ba liroboto ba fielang.

Boleng le Litifikeiti: Mapolanka a Capel a rigid-flex a entsoe ho latela maemo a phahameng ka ho fetisisa a indasteri 'me a na le litifikeiti tse kang IPC 3, UL, ROHS, ISO 14001:2015, ISO 9001:2015, le IATF16949:2016. Boitlamo bona ba boleng bo netefatsa hore li-vacuum tsa liroboto tse nang le lisebelisoa tsa Capel PCB li fihlella litekanyetso tse thata ka ho fetisisa tsa ts'ebetso le polokeho.

Bokamoso ba theknoloji ea vacuum ea liroboto le Capel PCB Solutions

Ha thekenoloji ea vacuum ea liroboto e ntse e tsoela pele, karolo ea li-PCB molemong oa ho khanna boqapi le ts'ebetso e ke ke ea khelloa fatše. Ho phehella ho sa feleng ha Capel ho ipabola ho hlahiseng PCB e tenyetsehang le e thata, hammoho le kutloisiso e tebileng ea lits'ebetso tsa vacuum ea liroboto, e e etsa mokhanni oa bohlokoa oa tsoelo-pele ea theknoloji nakong e tlang indastering.

Khaolo ea 4: Tšusumetso ea Khokahano ea PCB e Rigid-Flexible

Ha re phethela

Ka bokhutšoanyane, ho kopanngoa ha PCB e thata-flexible ho ntlafatsa haholo ts'ebetso le ts'ebetso ea liroboto tse fielang, ho bula tsela ea ho ntlafatsa bokhoni ba ho hloekisa le ho sebetsa hantle. Tsebo ea Capel ea ho hlahisa litharollo tsa PCB tse tloaelehileng bakeng sa li-vacuum cleaners tsa liroboto li phethile karolo ea bohlokoa ho tsamaiseng mahlale a mahlale a theknoloji ena, ho beha palo e ncha ea indasteri. Ha bahlahisi ba liroboto ba ntse ba leka ho fana ka lihlahisoa tsa morao-rao tse khotsofatsang litlhoko tse lulang li fetoha tsa bareki, li-PCB tsa Capel tse thata-thata li hlahella e le lisebelisoa tsa bohlokoa tsa katleho 'marakeng ona o matla le oa tlhōlisano.

Ho akaretsa, tšebelisano ea Capel le baetsi ba liroboto tse fielang ha e ntlafatse ts'ebetso ea liroboto tse fielang feela empa hape e beha litekanyetso tse ncha tsa ntlafatso ea theknoloji indastering. Ka ho tsepamisitse maikutlo holim'a ho nepahala ho phahameng, ho tšoarella, le bokhoni ba ho itloaetsa, li-PCB tsa Capel tse thata-thata li ikemiselitse ho tsoela pele ho theha bokamoso ba theknoloji ea robotic vacuum, ho khanna tsoelo-pele ea theknoloji, le ho hlalosa bocha bokhoni le bokhoni ba lisebelisoa tsena tsa bohlokoa tsa ho hloekisa.

Nako ea poso: May-27-2024

Morao