Mehleng ea kajeno ea tsoelo-pele e potlakileng ea theknoloji, lisebelisoa tsa elektroniki li fetohile karolo ea bohlokoa ea bophelo ba rona ba letsatsi le letsatsi. Ho tloha ho li-smartphones ho ea ho lisebelisoa tsa bongaka, liboto tsa potoloho tse hatisitsoeng (PCBs) li phetha karolo ea bohlokoa ho matlafatsa lisebelisoa tsena ka katleho. Li-PCB tsa theknoloji tsa High Density Interconnect (HDI) li fetotse papali, li fana ka sekhahla se phahameng sa potoloho, ts'ebetso e ntlafalitsoeng le ts'epo e ntlafalitsoeng.Empa na u kile ua ipotsa hore na li-PCB tsa theknoloji tsa HDI li etsoa joang? Sehloohong sena, re tla ikakhela ka setotsoana litabeng tse rarahaneng tsa mokhoa oa ho etsa tlhahiso le ho hlakisa mehato e amehang.

1. Kenyelletso e khuts'oane ea theknoloji ea HDI PCB:

Li-PCB tsa theknoloji tsa HDI li tumme ka bokhoni ba tsona ba ho amohela palo e kholo ea likarolo ka moralo o kopaneng, ho fokotsa boholo ba lisebelisoa tsa elektroniki.Liboto tsena li na le mekhahlelo e mengata, li-vias tse nyane, le mela e mesesane bakeng sa sekhahla se seholo sa litsela. Ho feta moo, ba fana ka ts'ebetso e ntlafalitsoeng ea motlakase, taolo ea impedance, le sets'oants'o sa matšoao, e leng se etsang hore e be tse loketseng lits'ebetso tse lebelo le holimo le maqhubu a phahameng.

2. Moralo oa moralo:

Leeto la tlhahiso la HDI Technology PCB le qala ho tloha sethaleng sa moralo.Baenjiniere ba nang le litsebo le baqapi ba sebetsa 'moho ho ntlafatsa sebopeho sa potoloho ha ba ntse ba netefatsa hore melao ea moralo le lithibelo lia fihlelleha. Sebelisa lisebelisoa tse tsoetseng pele tsa software ho theha meralo e nepahetseng, ho hlalosa li-stackups, ho beha likarolo le ho tsamaisa litsela. Sebopeho se boetse se nahanela lintlha tse kang botšepehi ba matšoao, tsamaiso ea mocheso, le botsitso ba mochine.

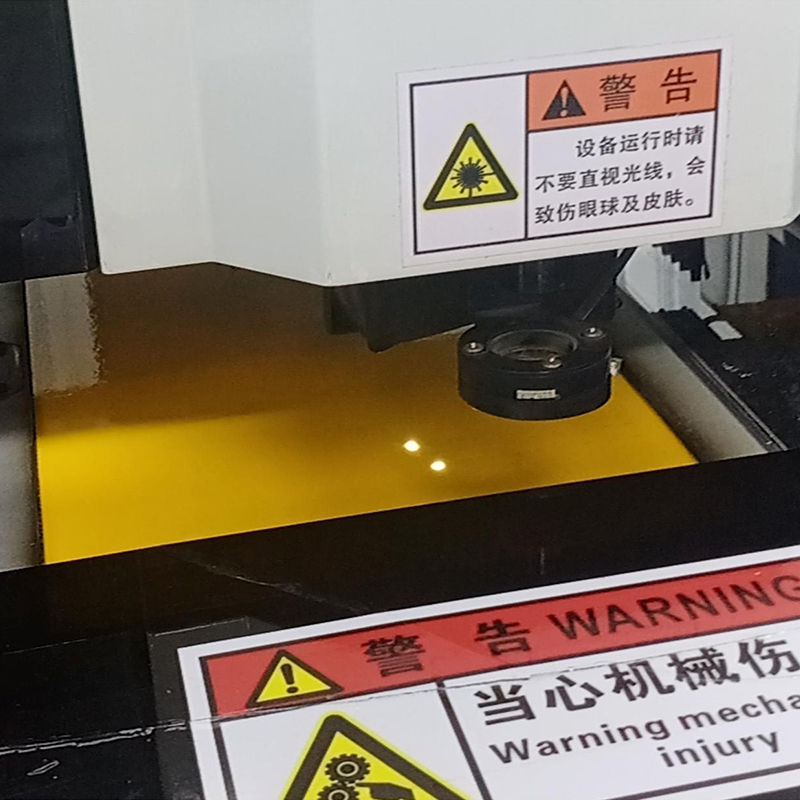

3. Ho cheka ka laser:

E 'ngoe ea mehato ea bohlokoa ea ho etsa theknoloji ea HDI PCB ke ho cheka ka laser.Theknoloji ea Laser e ka theha li-vias tse nyane, tse nepahetseng haholoanyane, tse bohlokoa ho fihlela maemo a phahameng a potoloho. Mechini ea ho cheka ka laser e sebelisa khanya e matla e matla ho tlosa thepa ho tloha substrate le ho etsa masoba a manyane. vias tsena ka nako eo metallized ho bopa dikgokelo motlakase pakeng tsa mekhahlelo e fapaneng.

4. Ho roala koporo ho se nang motlakase:

Ho etsa bonnete ba hore ho na le khokahanyo e nepahetseng ea motlakase pakeng tsa lihlopha, ho sebelisoa koporo e se nang electroless.Ts'ebetsong ena, marako a sekoti se phuntsoeng a koahetsoe ka lesela le tšesaane haholo la koporo e tsamaisang ka ho qoelisoa ka lik'hemik'hale. Lera lena la koporo le sebetsa e le peo bakeng sa ts'ebetso e latelang ea electroplating, ho ntlafatsa ho khomarela ka kakaretso le ho tsamaisa koporo.

5. Lamination le ho tobetsa:

HDI Technology PCB tlhahiso e kenyelletsa lipotoloho tse ngata tsa lamination le ho hatella moo likarolo tse fapaneng tsa boto ea potoloho li phuthetsoeng le ho hokahana hammoho.Khatello e phahameng le mocheso li sebelisoa ho netefatsa tlamahano e nepahetseng le ho felisa lipokotho leha e le life tsa moea kapa li-voids. Tshebetso ena e kenyelletsa tšebeliso ea lisebelisoa tse khethehileng tsa lamination ho finyella botenya bo lakatsehang le botsitso ba mechine.

6. Ho roala koporo:

Copper plating e bapala karolo ea bohlokoa ho li-PCB tsa HDI tsa theknoloji kaha li theha tsamaiso e hlokahalang ea motlakase.Mokhoa ona o kenyelletsa ho qoelisa boto kaofela ka har'a tharollo ea koporo le ho fetisa motlakase ho eona. Ka mokhoa oa electroplating, koporo e kenngoa holim'a boto ea potoloho, ho etsa lipotoloho, litsela le likarolo tsa holim'a metsi.

7. Phekolo ea sefahleho:

Phekolo ea holim'a metsi ke mohato oa bohlokoa ts'ebetsong ea tlhahiso ho sireletsa li-circuits le ho netefatsa ts'epo ea nako e telele.Litheknoloji tse tloaelehileng tsa kalafo ea holim'a metsi bakeng sa li-PCB tsa HDI li kenyelletsa silevera ea ho qoelisoa, khauta e qoelisoang, li-organic solderability preservatives (OSP), le nickel e se nang motlakase / khauta ea ho qoelisoa (ENIG). Litheknoloji tsena li fana ka lera le sireletsang le thibelang oxidation, le ntlafatsa ho solderability le ho nolofatsa kopano.

8. Teko le Taolo ea Boleng:

Teko e matla le mehato ea taolo ea boleng ea hlokahala pele li-PCB tsa theknoloji tsa HDI li bokelloa lisebelisoa tsa elektroniki.Automatically Optical Inspection (AOI) le tlhahlobo ea motlakase (E-test) hangata li etsoa ho bona le ho lokisa liphoso leha e le life kapa mathata a motlakase potolohong. Liteko tsena li netefatsa hore sehlahisoa sa ho qetela se kopana le litlhaloso tse hlokahalang mme se sebetsa ka ts'epo.

Ha re phethela:

HDI Technology PCBs e fetotse indasteri ea lisebelisoa tsa elektroniki, ea thusa ho nts'etsopele ea lisebelisoa tse nyane, tse bobebe, le tse matla haholoanyane.Ho utloisisa ts'ebetso e rarahaneng ea tlhahiso ka morao ho liboto tsena ho totobatsa boemo ba ho nepahala le botsebi bo hlokahalang ho hlahisa li-PCB tsa theknoloji tsa HDI tsa boleng bo holimo. Ho tloha moralong oa pele ka ho cheka, ho pola le ho lokisa bokaholimo, mohato o mong le o mong o bohlokoa ho netefatsa ts'ebetso e nepahetseng le ho ts'epahala. Ka ho sebelisa mekhoa e tsoetseng pele ea tlhahiso le ho latela litekanyetso tse thata tsa taolo ea boleng, bahlahisi ba ka fihlela litlhoko tse lulang li fetoha tsa 'maraka oa lisebelisoa tsa elektroniki le ho bula tsela bakeng sa lits'ebetso tse ncha.

Nako ea poso: Sep-02-2023

Morao