Lefatšeng la liboto tsa potoloho tse hatisitsoeng (PCBs), khetho ea thepa le mekhoa ea tlhahiso e ka ama boleng le ts'ebetso ea lisebelisoa tsa elektroniki haholo. Phapang e 'ngoe e joalo ke PCB ea khauta e teteaneng, e fanang ka melemo e ikhethang ho feta li-PCB tse tloaelehileng.Mona re ikemiselitse ho fana ka kutloisiso e felletseng ea PCB ea khauta e teteaneng, ho hlalosa sebopeho sa eona, melemo le liphapang ho tsoa ho li-PCB tsa setso.

1.Utloisisa Thick Gold PCB

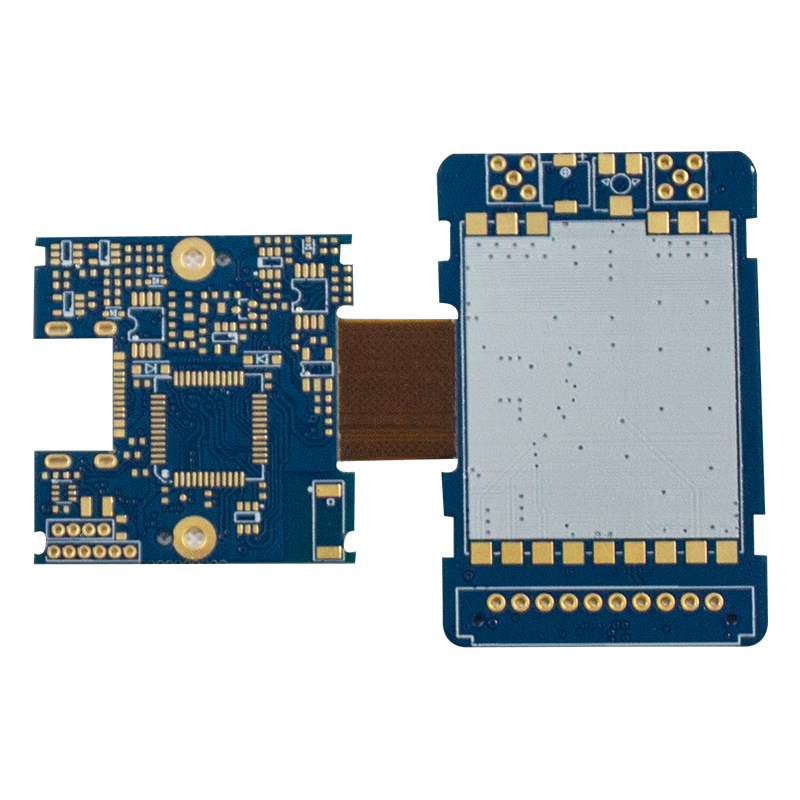

PCB ea khauta e teteaneng ke mofuta o ikhethileng oa boto ea potoloho e hatisitsoeng e nang le lera le letenya la khauta holim'a eona.Li entsoe ka likarolo tse ngata tsa lisebelisoa tsa koporo le dielectric tse nang le lesela la khauta le kentsoeng ka holimo. Li-PCB tsena li etsoa ka mokhoa oa electroplating o tiisang hore lera la khauta le lekana ebile le tlameletsoe ka thata.Ho fapana le li-PCB tse tloaelehileng, li-PCB tsa khauta tse teteaneng li na le lera le letenya haholo la khauta qetellong ea ho qetela. Botenya ba khauta ho PCB e tloaelehileng hangata bo ka ba lisenthimithara tse 1-2 kapa 0.025-0.05 microns. Ha ho bapisoa, li-PCB tsa khauta tse teteaneng hangata li na le botenya ba khauta ea 30-120 microns kapa 0.75-3 microns.

2.Melemo ea PCB ea khauta e teteaneng

Li-PCB tsa khauta tse teteaneng li fana ka melemo e mengata ho feta likhetho tse tloaelehileng, ho kenyelletsa le ho tšoarella ho matlafalitsoeng, ts'ebetso e ntlafetseng le ts'ebetso e phahameng.

Nako e telele:

E 'ngoe ea melemo ea mantlha ea li-PCB tsa khauta tse teteaneng ke ho tšoarella ha tsona ho ikhethang. Liboto tsena li etselitsoe ho mamella maemo a thata, e leng se etsang hore e be tse loketseng lits'ebetso tseo hangata li pepesetsoang mocheso o feteletseng kapa maemo a thata. Botenya ba plating ea khauta bo fana ka tšireletso khahlanong le kutu, oxidation le mefuta e meng ea tšenyo, ho netefatsa bophelo bo bolelele ba PCB.

Ntlafatsa conductivity ea motlakase:

Li-PCB tsa khauta tse teteaneng li na le conductivity e ntle ea motlakase, e leng se etsang hore e be khetho ea pele bakeng sa lits'ebetso tse hlokang phetisetso e nepahetseng ea mats'oao. Botenya bo ntseng bo eketseha ba ho roala khauta bo fokotsa khanyetso le ho ntlafatsa ts'ebetso ea motlakase, ho netefatsa phetisetso ea mats'oao a seamless ho pholletsa le boto. Sena ke sa bohlokoa ka ho khetheha bakeng sa liindasteri tse kang tsa mehala ea puisano, sefofane le lisebelisoa tsa bongaka, moo phetiso ea data e nepahetseng le e tšepahalang e leng bohlokoa.

Ntlafatsa ho solderability:

Molemo o mong oa li-PCB tsa khauta tse teteaneng ke ho ntlafatsoa ha tsona. Keketseho ea botenya ba khauta bo lumella ho phalla hantle ha solder le ho kolobisa, ho fokotsa monyetla oa ho ba le litaba tsa solder reflow nakong ea tlhahiso. Sena se tiisa manonyeletso a matla le a ka tšeptjoang a solder, ho felisa mefokolo e ka bang teng le ho ntlafatsa boleng ba sehlahisoa ka kakaretso.

Bophelo ba puisano:

Likhokahano tsa motlakase ho li-PCB tse teteaneng tsa khauta li tšoarella nako e telele ka lebaka la botenya bo ntseng bo eketseha ba khauta. Sena se matlafatsa ts'epahalo ea mabitso le ho fokotsa kotsi ea ho senyeha ha lets'oao kapa khokahanyo ea nakoana ha nako e ntse e ea. Ka hona, li-PCB tsena li sebelisoa haholo lits'ebetsong tse nang le lipotoloho tse phahameng tsa ho kenya / ho ntša, tse kang lihokelo tsa likarete kapa li-module tsa memori, tse hlokang ts'ebetso ea nako e telele ea ho ikopanya.

Ntlafatsa khanyetso ea ho apara:

Li-PCB tsa khauta tse teteaneng li sebetsa hantle lits'ebetsong tse hlokang ho taboha khafetsa. Botenya bo ntseng bo eketseha ba khauta ea khauta bo fana ka thibelo e sireletsang e thusang ho mamella ho senya le ho senya liphello tsa tšebeliso e pheta-phetoang. Sena se etsa hore e be tse loketseng bakeng sa lihokelo, li-touchpad, likonopo le likarolo tse ling tse tloaetseng ho kopana khafetsa, ho netefatsa hore li phela nako e telele le ts'ebetso e tsitsitseng.

Fokotsa tahlehelo ea lets'oao:

Ho lahleheloa ke mats'oao ke bothata bo atileng lits'ebetsong tse phahameng tsa maqhubu. Leha ho le joalo, li-PCB tsa khauta tse teteaneng li fana ka tharollo e sebetsang e ka fokotsang tahlehelo ea lets'oao ka lebaka la ts'ebetso ea tsona e ntlafalitsoeng. Li-PCB tsena li na le khanyetso e tlase ho netefatsa botšepehi bo nepahetseng ba matšoao, ho fokotsa tahlehelo ea phetisetso ea data le ho eketsa ts'ebetso ea sistimi. Ka hona, li sebelisoa haholo liindastering tse kang likhokahano tsa mehala, lisebelisoa tse se nang mohala, le lisebelisoa tsa maqhubu a holimo.

3.Bohlokoa ba ho eketsa botenya ba khauta bakeng sa li-PCB tsa khauta tse teteaneng:

Botenya bo eketsehileng ba ho roala khauta ka har'a li-PCB tsa khauta e teteaneng bo sebeletsa merero e mengata ea bohlokoa.Ntlha ea pele, e fana ka tšireletso e eketsehileng khahlanong le oxidation le corrosion, ho netefatsa ho tšepahala ha nako e telele le botsitso esita le libakeng tse thata. Sekhahla sa khauta se teteaneng se sebetsa e le tšitiso, se thibelang liphetoho leha e le life tsa lik'hemik'hale pakeng tsa mesaletsa ea koporo e ka tlas'a lefatše le sepakapaka se ka ntle, haholo-holo haeba se pepesehile mongobo, mongobo kapa litšila tsa indasteri.

Taba ea bobeli, lera le letenya la khauta le ntlafatsa bokhoni ba ho tsamaisa le ho fetisa mats'oao a PCB.Khauta ke conductor e ntle haholo ea motlakase, e betere ho feta koporo e atisang ho sebelisoa bakeng sa mesaletsa ea conductive ho li-PCB tse tloaelehileng. Ka ho eketsa dikahare tsa khauta ka holim'a metsi, li-PCB tsa khauta tse teteaneng li ka finyella ho hanyetsa ho tlaase, ho fokotsa tahlehelo ea matšoao le ho netefatsa ts'ebetso e ntlafetseng, haholo-holo lits'ebetsong tsa maqhubu a phahameng kapa tse kenyelletsang matšoao a tlaase.

Ho feta moo, likarolo tse teteaneng tsa khauta li fana ka solderability e ntle le karolo e matla ea ho hlopha holim'a metsi.Khauta e na le solderability e ntle haholo, e lumellang hore ho be le manonyeletso a tšepahalang nakong ea kopano. Taba ena ke ea bohlokoa hobane haeba manonyeletso a solder a fokola kapa a sa tloaeleha, a ka baka ho hloleha ha potoloho kapa ka ho felletseng. Keketseho ea botenya ba khauta e boetse e ntlafatsa ho tšoarella ha mochini, ho etsa hore li-PCB tsa khauta tse teteaneng li se ke tsa taboha ebile li hanana le khatello ea maikutlo le ho thothomela.

Ke habohlokoa ho hlokomela hore botenya bo eketsehileng ba lesela la khauta ho PCBs ea khauta e teteaneng le bona bo tlisa litšenyehelo tse phahameng ha li bapisoa le li-PCB tse tloaelehileng.Ts'ebetso e pharalletseng ea ho rala khauta e hloka nako e eketsehileng, lisebelisoa le botsebi, e leng se bakang litšenyehelo tse eketsehileng tsa tlhahiso. Leha ho le joalo, bakeng sa likopo tse hlokang boleng bo phahameng, botšepehi le bophelo bo bolelele, matsete a li-PCB tsa khauta tse teteaneng hangata a feta likotsi le litšenyehelo tse amanang le ho sebelisa li-PCB tse tloaelehileng.

4.Phapang pakeng tsa PCB e teteaneng ea khauta le PCB e tloaelehileng:

Li-PCB tse tloaelehileng hangata li entsoe ka thepa ea epoxy e nang le lera la koporo lehlakoreng le le leng kapa ka bobeli la boto. Likarolo tsena tsa koporo li behiloe nakong ea ts'ebetso ea tlhahiso ho theha potoloho e hlokahalang. Botenya ba lesela la koporo bo ka fapana ho latela ts'ebeliso, empa hangata bo maemong a 1-4 oz.

PCB ea khauta e teteaneng, joalo ka ha lebitso le fana ka maikutlo, e na le lesela le tenya la khauta ha le bapisoa le PCB e tloaelehileng. Li-PCB tse tloaelehileng hangata li na le botenya ba khauta ea 20-30 microns (0.5-0.75 microns), ha li-PCB tsa khauta tse teteaneng li na le botenya ba khauta ea 50-100 microns (1.25-2.5 microns).

Phapang e kholo lipakeng tsa li-PCB tsa khauta tse teteaneng le li-PCB tse tloaelehileng ke botenya ba lera la khauta, ho rarahana ha tlhahiso, litšenyehelo, libaka tsa ts'ebeliso, le ts'ebeliso e fokolang ea maemo a mocheso o phahameng.

Botenya ba lesela la khauta:

Phapang e kholo lipakeng tsa PCB ea khauta e teteaneng le PCB e tloaelehileng ke botenya ba lera la khauta. PCB ea khauta e teteaneng e na le lesela le tenya la khauta ho feta PCB e tloaelehileng. Botenya bona bo eketsehileng bo thusa ho ntlafatsa ho tšoarella ha PCB le ts'ebetso ea motlakase. Lera le letenya la khauta le fana ka tšireletso e matlafatsang khanyetso ea PCB ho corrosion, oxidation le ho apara. Sena se etsa hore PCB e be matla haholoanyane maemong a thata, ho netefatsa ts'ebetso e tšepahalang ea nako e telele. Ho roala khauta e teteaneng ho boetse ho lumella hore ho be le tsamaiso e ntle ea motlakase, e leng se lumellang phetisetso e nepahetseng ea matšoao. Sena se molemo haholo lits'ebetsong tse hlokang phetiso ea mats'oao a maqhubu a holimo kapa a lebelo le holimo, joalo ka likhokahano tsa mehala, lisebelisoa tsa bongaka, le litsamaiso tsa sefofane.

Litšenyehelo:

Ha ho bapisoa le PCB e tloaelehileng, theko ea tlhahiso ea PCB ea khauta e teteaneng hangata e phahame. Litšenyehelo tsena tse phahameng li hlahisoa ke mokhoa oa ho rala o hlokang lisebelisoa tse eketsehileng tsa khauta ho fihlela botenya bo hlokahalang. Leha ho le joalo, ho tšepahala ho hoholo le ts'ebetso ea li-PCB tsa khauta e teteaneng li lokafatsa litšenyehelo tse eketsehileng, haholo-holo lits'ebetsong moo litlhoko tse boima li tlamehang ho finyelloa.

Libaka tsa kopo:

Li-PCB tse tloaelehileng li sebelisoa haholo liindastering tse fapaneng, ho kenyeletsoa lisebelisoa tsa elektroniki tsa bareki, litsamaiso tsa likoloi le lisebelisoa tsa indasteri. Li loketse likopo moo ho tšepahala ho phahameng e seng ntho ea bohlokoa ka ho fetisisa. Li-PCB tsa khauta tse teteaneng, ka lehlakoreng le leng, li sebelisoa haholo-holo mafapheng a litsebi tse hlokang ho tšepahala le ts'ebetso e phahameng. Mehlala ea libaka tsena tsa kopo e kenyelletsa indasteri ea sepakapaka, lisebelisoa tsa bongaka, lisebelisoa tsa sesole, le litsamaiso tsa likhokahano. Libakeng tsena, mesebetsi ea bohlokoa e itšetlehile ka likarolo tsa elektronike tse tšepahalang le tsa boleng bo phahameng, kahoo li-PCB tsa khauta tse teteaneng ke khetho ea pele.

Mathata a Tlhahiso:

Ha ho bapisoa le li-PCB tse tloaelehileng, mokhoa oa ho etsa li-PCB tsa khauta tse teteaneng o rarahane ebile o nka nako. Ts'ebetso ea electroplating e tlameha ho laoloa ka hloko ho fihlela botenya bo lakatsehang ba khauta. Sena se eketsa ho rarahana le nako e hlokahalang ts'ebetsong ea tlhahiso. Taolo e nepahetseng ea ts'ebetso ea ho rala e bohlokoa hobane phapang ea botenya ba khauta e ka ama ts'ebetso ea PCB le ts'epahalo. Ts'ebetso ena e hlokolosi ea tlhahiso e kenya letsoho ho boleng bo holimo le tšebetsong ea li-PCB tsa khauta tse teteaneng.

Ho lekane ho fokolang tikolohong ea mocheso o phahameng:

Le hoja li-PCB tsa khauta tse teteaneng li sebetsa hantle libakeng tse ngata, li ka 'na tsa se ke tsa e-ba khetho e nepahetseng ka ho fetisisa bakeng sa likopo tse phahameng tsa mocheso. Tlas'a maemo a phahameng a mocheso a phahameng haholo, likhahla tse teteaneng tsa khauta li ka theola kapa tsa senya, tsa ama ts'ebetso eohle ea PCB.

Tabeng ena, mekhoa e meng ea phekolo e kang tin (ISn) kapa silevera ea ho qoelisoa (IAg) e ka khethoa. Liphekolo tsena li fana ka tšireletso e lekaneng khahlanong le liphello tsa mocheso o phahameng ntle le ho ama ts'ebetso ea PCB.

Khetho ea lisebelisoa tsa PCB e ka ama haholo boleng le ts'ebetso ea lisebelisoa tsa elektroniki. Li-PCB tsa khauta tse teteaneng li fana ka melemo e ikhethang joalo ka ho tšoarella ho matlafalitsoeng, ho ntlafala ha solderability, conductivity e ntle ea motlakase, ts'epahalo e phahameng ea ho ikopanya le bophelo bo atolositsoeng.Melemo ea bona e lokafatsa litšenyehelo tse phahameng tsa tlhahiso le ho li etsa hore li tšoanelehe ka ho khetheha bakeng sa liindasteri tse khethehileng tse etelletsang pele ho ts'epahala, joalo ka sepakapaka, lisebelisoa tsa bongaka, lisebelisoa tsa sesole le lits'ebetso tsa mehala. Ho utloisisa sebopeho, melemo, le liphapang lipakeng tsa li-PCB tsa khauta tse teteaneng le li-PCB tse tloaelehileng ho bohlokoa ho baenjiniere, baqapi le bahlahisi ba batlang ho ntlafatsa ts'ebetso le nako e telele ea lisebelisoa tsa bona tsa elektroniki. Ka ho sebelisa litšoaneleho tse ikhethang tsa li-PCB tsa khauta tse teteaneng, ba ka netefatsa lihlahisoa tse tšepahalang le tsa boleng bo holimo bakeng sa bareki ba bona.

Nako ea poso: Sep-13-2023

Morao