Lefatšeng la kajeno le potlakileng la theknoloji, lisebelisoa tsa elektroniki li ntse li tsoela pele le ho sebetsa ka thata. Ho fihlela litlhoko tsa lisebelisoa tsena tsa sejoale-joale, liboto tsa potoloho tse hatisitsoeng (PCBs) li tsoela pele ho fetoha le ho kenyelletsa mekhoa e mecha ea meralo. E 'ngoe ea theknoloji e joalo ke stackup e thata ea flex pcb, e fanang ka melemo e mengata mabapi le ho feto-fetoha ha maemo le ho tšepahala.Tataiso ena e felletseng e tla hlahloba hore na "regid-flex board" stackup ke eng, melemo ea eona le kaho ea eona.

Pele re kenella ka har'a lintlha, ha re qaleng ka ho hlahloba lintlha tsa motheo tsa PCB stackup:

PCB stackup e bolela tlhophiso ea likarolo tse fapaneng tsa boto ea potoloho ka har'a PCB e le 'ngoe. E kenyelletsa ho kopanya lisebelisoa tse fapaneng ho theha liboto tsa multilayer tse fanang ka likhokahano tsa motlakase. Ka tloaelo, ka sephutheloana se thata sa PCB, ke lisebelisoa tse thata feela tse sebelisoang bakeng sa boto eohle. Leha ho le joalo, ka kenyelletso ea lisebelisoa tse tenyetsehang, ho ile ha hlaha khopolo e ncha-e thata-flexible PCB stackup.

Joale, hantle-ntle laminate e thata-thata ke eng?

A rigid-flex PCB stackup ke lebasetere potoloho boto e kopanyang thata le tenyetsehang PCB thepa. E na le likarolo tse feto-fetohang tse thata le tse tenyetsehang, tse lumellang boto hore e kobehe kapa e kobehe kamoo ho hlokahalang ha e ntse e boloka sebopeho sa eona sa sebopeho le ts'ebetso ea motlakase. Motsoako ona o ikhethang o etsa hore li-stackups tsa PCB tse thata-flex-flex e be tse loketseng bakeng sa lits'ebetso moo sebaka se leng bohlokoa le ho kobeha ho hlokahalang, joalo ka lintho tse aparoang, lisebelisoa tsa sefofane le lisebelisoa tsa bongaka.

Joale, ha re hlahlobeng melemo ea ho khetha sephutheloana se thata sa PCB bakeng sa lisebelisoa tsa hau tsa elektroniki.

Ntlha ea pele, ho feto-fetoha ha eona ho lumella boto hore e kene libakeng tse thata le ho lumellana le libopeho tse sa tloaelehang, ho eketsa sebaka se fumanehang. Ho feto-fetoha hona ho boetse ho fokotsa boholo ba kakaretso le boima ba sesebelisoa ka ho felisa tlhokahalo ea li-connectors le li-wiring tse eketsehileng. Ho feta moo, ho se be teng ha lihokelo ho fokotsa lintlha tse ka bang teng tsa ho hloleha, ho eketsa ts'epo. Ntle le moo, phokotso ea lithapo e ntlafatsa botšepehi ba matšoao le ho fokotsa mathata a tšitiso ea motlakase (EMI).

Kaho ea "PCB" stackup e thata e kenyelletsa lintlha tse 'maloa tsa bohlokoa:

Hangata e na le lihlopha tse ngata tse thata tse hokahaneng ka likarolo tse tenyetsehang. Palo ea lihlopha e itšetlehile ka ho rarahana ha moralo oa potoloho le ts'ebetso e lakatsehang. Likarolo tse thata ka tloaelo li na le li-laminate tse tloaelehileng tsa FR-4 kapa li-laminates tsa mocheso o phahameng, ha likarolo tse tenyetsehang e le polyimide kapa lisebelisoa tse tšoanang tse tenyetsehang. Ho etsa bonnete ba hore ho na le khokahanyo e nepahetseng ea motlakase pakeng tsa lihlopha tse thata le tse tenyetsehang, ho sebelisoa mofuta o ikhethang oa sekhomaretsi o bitsoang anisotropic conductive adhesive (ACA). Sekhomaretsi sena se fana ka likhokahano tsa motlakase le tsa mochini, ho netefatsa ts'ebetso e tšepahalang.

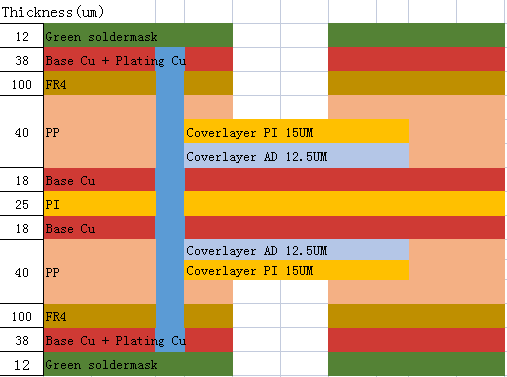

Ho utloisisa sebopeho sa "PCB" e thata-flexible stack up, mona ke karohano ea sebopeho sa boto ea 4-layer rigid-flex PCB:

Lera e ka holimo:

Mask ea solder e tala ke lesela le sireletsang le kentsoeng ho PCB (Printed Circuit Board)

Lera 1 (Lera la Letshwao):

Lera la Base Copper le mesaletsa ea Plated Copper.

Lera 2 (Lera le ka Hare / lera la dielectric):

FR4: Ena ke sesebelisoa se tloaelehileng sa insulating se sebelisoang ho li-PCB, se fanang ka tšehetso ea mochini le ho itšehla thajana ka motlakase.

Lera 3 (Flex Layer):

PP: Polypropylene (PP) sekhomaretsi se khomarelang se ka fana ka tšireletso ho boto ea potoloho

Lera 4 (Flex Layer):

Lera la sekoahelo PI: Polyimide (PI) ke thepa e feto-fetohang le e thibelang mocheso e sebelisoang e le lera le sireletsang ka holimo karolong e flexible ea PCB.

Sekoaelo sa AD: fana ka tšireletso ho thepa e ka tlase ho tšenyo ea tikoloho e kantle, lik'hemik'hale kapa mengoapo ea 'mele.

Lera 5 (Flex Layer):

Base Copper layer: Karolo e 'ngoe ea koporo, eo hangata e sebelisetsoang mesaletsa ea matšoao kapa kabo ea matla.

Lera 6 (Flex Layer):

PI: Polyimide (PI) ke thepa e feto-fetohang le e thibelang mocheso e sebelisoang e le setsi sa motheo karolong e flexible ea PCB.

Lera 7 (Flex Layer):

Base Copper layer: Leha ho le joalo karolo e 'ngoe ea koporo, eo hangata e sebelisetsoang mesaletsa ea matšoao kapa kabo ea matla.

Lera 8 (Flex Layer):

PP: Polypropylene (PP) ke thepa e feto-fetohang e sebelisoang karolong ea flex ea PCB.

Cowerlayer AD: fana ka tšireletso ho thepa e ka tlase ho tšenyo ea tikoloho e kantle, lik'hemik'hale kapa likhopo tsa 'mele.

Lera la sekoahelo PI: Polyimide (PI) ke thepa e feto-fetohang le e thibelang mocheso e sebelisoang e le lera le sireletsang ka holimo karolong e flexible ea PCB.

Lera 9 (Lera le ka Hare):

FR4: Lera le leng la FR4 le kenyelelitsoe bakeng sa tšehetso e eketsehileng ea mechine le ho itšehla thajana ha motlakase.

Lera 10 (Lera le ka Tlase):

Lera la Base Copper le mesaletsa ea Plated Copper.

Lera le tlase:

Mask e tala ea solder.

Ka kopo hlokomela hore bakeng sa tlhahlobo e nepahetseng haholoanyane le menahano e khethehileng ea moralo, ho khothaletsoa ho buisana le moetsi oa PCB kapa moetsi ea ka fanang ka tlhahlobo e felletseng le likhothaletso tse ipapisitseng le litlhoko le litšitiso tsa hau.

Ka kakaretso:

Rigid flex PCB stackup ke tharollo e ncha e kopanyang melemo ea thepa ea PCB e thata le e tenyetsehang. Ho feto-fetoha ha eona, ho kopana le ho tšepahala ho etsa hore e tšoanelehe bakeng sa lisebelisoa tse fapaneng tse hlokang ho ntlafatsa sebaka le ho kobeha ho matla. Ho utloisisa metheo ea li-stackups tse thata le kaho ea tsona ho ka u thusa ho etsa liqeto tse nang le tsebo ha u rala le ho etsa lisebelisoa tsa elektroniki. Ha thekenoloji e ntse e tsoela pele, tlhokahalo ea li-stackup tsa PCB tse thata ntle le pelaelo e tla eketseha, e tla tsamaisa tsoelo-pele e eketsehileng lebaleng lena.

Nako ea poso: Aug-24-2023

Morao