a re ke re hlahlobeng mokhoa oa ho etsa lipotoloho tse tenyetsehang 'me re utloisise hore na ke hobane'ng ha li sebelisoa haholo liindastering tse fapaneng.

Li-circuits tse feto-fetohang, tse tsejoang hape e le li-circuits tse hatisitsoeng tse bonolo kapa li-FPC, li tumme liindasteri tse fapaneng. Ho tloha ho lisebelisoa tsa elektroniki tsa bareki ho isa lisebelisoa tsa tlhokomelo ea bophelo bo botle, lipotoloho tse feto-fetohang li fetotse tsela eo likarolo tsa elektroniki li qapiloeng le ho etsoa. Ha tlhoko ea lisebelisoa tsa elektroniki tse kopaneng le tse bobebe e ntse e eketseha, ho bohlokoa ho utloisisa ts'ebetso ea tlhahiso ea lipotoloho tse feto-fetohang le hore na li fetohile karolo ea bohlokoa ea theknoloji ea sejoale-joale joang.

Li-circuits tsa Flex ha e le hantle ke motsoako oa likarolo tse ngata tsa thepa e feto-fetohang, joalo ka polyester kapa polyimide, eo ho eona ho kenngoeng mesaletsa, liphaephe le likarolo tsa eona. Li-circuits tsena lia tenyetseha 'me li ka menwa kapa tsa phuthoa, ho etsa hore e be tse loketseng lits'ebetso moo sebaka se lekanyelitsoeng.

1. Sebopeho sa moralo molemong oa tlhahiso ea potoloho ea flex:

Mohato oa pele oa ho etsa potoloho e feto-fetohang ke moralo le ts'ebetso ea moralo. Baenjiniere le baqapi ba sebetsa 'moho ho theha meralo e fihlelang litlhoko tse ikhethileng tsa kopo. Moralo o kenyelletsa ho beoa ha mesaletsa ea conductive, likarolo, le likarolo life kapa life tse ling tse ka hlokahalang.

2. Khetho ea thepa ho flex circuit fabrication:

Ka mor'a mohato oa moralo, mohato o latelang ke ho khetha lisebelisoa tse loketseng bakeng sa potoloho e feto-fetohang. Khetho ea thepa e itšetlehile ka lintlha tse kang ho feto-fetoha ho hlokahalang, mocheso oa ho sebetsa, le thepa e hlokahalang ea motlakase le ea mechine. Polyimide le polyester ke lisebelisoa tse sebelisoang hangata ka lebaka la ho tenyetseha ha tsona hantle le botsitso ba mocheso.

3. Ho hlahisa substrate ea motheo ka ho etsa potoloho ea flex:

Hang ha thepa e khethiloe, ho etsoa ha substrate ea motheo ho qala. Hangata substrate ke lera le tšesaane la polyimide kapa polyester filimi. Substrate e hloekisoa, e koahetsoe ka sekhomaretsi, 'me e laminate ka foil ea koporo e tsamaisang. Botenya ba foil ea koporo le substrate bo ka fapana ho latela litlhoko tse khethehileng tsa kopo.

4. Etching le laminating tlhahiso ea potoloho ea flex:

Ka mor'a hore ts'ebetso ea lamination e phethoe, ho sebelisoa etchant ea lik'hemik'hale ho tlosa foil e feteletseng ea koporo, e siea mekhoa e lakatsehang le liphahlo. Laola ts'ebetso ea etching ka ho sebelisa mask a hananang le etch kapa mekhoa ea photolithography. Hang ha etching e phethiloe, potoloho e feto-fetohang e hloekisoa le ho lokisetsoa mohato o latelang oa ts'ebetso ea tlhahiso.

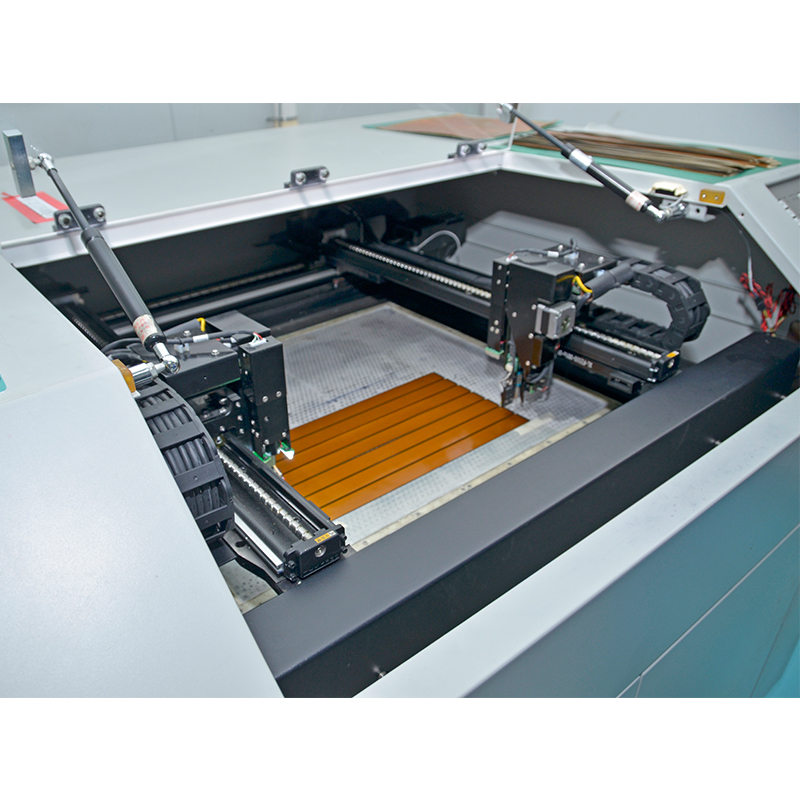

5. Kopano ea likarolo molemong oa tlhahiso ea potoloho ea flex:

Kamora hore ts'ebetso ea etching e phethe, potoloho e feto-fetohang e se e loketse kopano ea karolo. Theknoloji ea Surface Mount (SMT) e sebelisoa hangata bakeng sa ho beha likarolo kaha e nolofalletsa kopano e nepahetseng le e ikemetseng. Kenya pente ea solder ho li-conductive pads 'me u sebelise mochini oa ho khetha le ho beha likarolo. Joale potoloho ea flex e futhumatsoa, e etsa hore solder e khomarele liphahlo tsa conductive, e tšoere karolo sebakeng seo.

6. Ho etsa liteko le ho hlahloba tlhahiso ea potoloho ea flex:

Hang ha ts'ebetso ea kopano e phethiloe, potoloho ea flex e lekoa ka botlalo le ho hlahlojoa. Teko ea motlakase e netefatsa hore mesaletsa ea conductive le likarolo li sebetsa kamoo ho lebelletsoeng. Liteko tse ling, joalo ka ho palama baesekele e futhumatsang le tlhahlobo ea khatello ea mochini, le tsona li ka etsoa ho lekola ho tšoarella le ho ts'epahala ha li-circuits tse tenyetsehang. Liphoso life kapa life tse fumanoeng nakong ea tlhahlobo lia tsejoa le ho lokisoa.

7. Ts'ireletso e feto-fetohang le ts'ireletso molemong oa tlhahiso ea potoloho ea flex:

Ho sireletsa lipotoloho tse feto-fetohang ho tloha maemong a tikoloho le khatello ea mochini, ho sebelisoa likoahelo tse tenyetsehang kapa likarolo tse sireletsang. Lera lena e ka ba mask a solder, seaparo se lumellanang, kapa motsoako oa bobeli. Sekoahelo se eketsa nako e telele ea potoloho ea flex le ho lelefatsa bophelo ba eona ba tšebeletso.

8. Tlhahlobo ea ho qetela le ho paka tlhahisong ea potoloho ea flex:

Ka mor'a hore potoloho ea flex e fetile lits'ebetsong tsohle tse hlokahalang, e etsa tlhahlobo ea ho qetela ho netefatsa hore e kopana le litlhaloso tse hlokahalang. Li-circuits tse feto-fetohang li kenngoa ka hloko ho li sireletsa hore li se ke tsa senyeha nakong ea thomello le polokelo.

Ka kakaretso, ts'ebetso ea tlhahiso ea lipotoloho tse feto-fetohang e kenyelletsa mehato e mengata e rarahaneng, ho kenyelletsa moralo, khetho ea thepa, ho etsa masela, kopano, tlhahlobo le ts'ireletso.Tšebeliso ea theknoloji ea morao-rao le lisebelisoa tse tsoetseng pele li tiisa hore lipotoloho tse feto-fetohang li finyella litlhoko tse boima tsa liindasteri tse sa tšoaneng. Ka mokhoa oa bona oa ho fetoha le maemo, li-circuits tse feto-fetohang li fetohile karolo ea bohlokoa ea nts'etsopele ea lisebelisoa tsa elektronike tse ncha le tse tsoetseng pele. Ho tloha ho li-smartphone ho ea ho lisebelisoa tsa bongaka, lipotoloho tse feto-fetohang li fetola tsela eo likarolo tsa elektronike li kopantsoeng ka eona bophelong ba rona ba letsatsi le letsatsi.

Nako ea poso: Sep-21-2023

Morao