Mofuta o mong oa boto ea potoloho e ntseng e ata haholo indastering ea lisebelisoa tsa elektronike keboto e thata-thata.

Ha ho tluoa lisebelisoa tsa elektroniki joalo ka li-smartphones le lilaptop, ts'ebetso ea kahare e bohlokoa joalo ka bokantle ba setaele. Likarolo tse etsang hore lisebelisoa tsena li sebetse hangata li patiloe ka tlas'a likarolo tsa boto ea potoloho ho netefatsa hore li sebetsa le ho tšoarella. Empa ke lisebelisoa life tse sebelisoang libotong tsee tse ncha tsa potoloho?

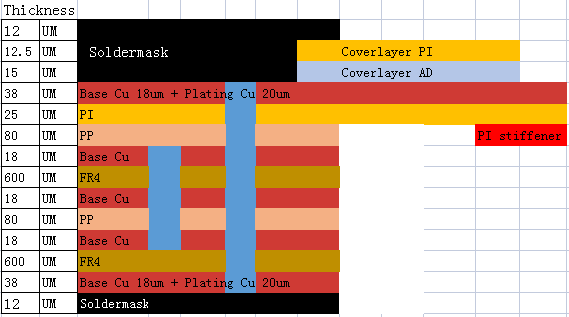

PCB e sa fetohenge kopanya melemo ea liboto tsa potoloho tse thata le tse feto-fetohang, ho fana ka tharollo e ikhethang bakeng sa lisebelisoa tse hlokang motsoako oa matla a mochine le ho feto-fetoha ha maemo. Liboto tsena li bohlokoa haholo lits'ebetsong tse kenyelletsang meralo e rarahaneng ea mahlakore a mararo kapa lisebelisoa tse hlokang ho mena kapa ho kobeha khafetsa.

Ha re shebisiseng lisebelisoa tse sebelisoang haholo kahong ea PCB e thata:

1. FR-4: FR-4 ke lelakabe le thibelang malakabe le matlafatsoang ke lisebelisoa tsa epoxy laminate tse sebelisoang haholo indastering ea lisebelisoa tsa elektronike. Ke ntho e sebelisoang ka ho fetesisa ea substrate ho li-PCB tse rigid-flex. FR-4 e na le thepa e ntle ea ho kenya motlakase le matla a matle a mochini, e etsa hore e be e loketseng likarolo tse thata tsa liboto tsa potoloho.

2. Polyimide: Polyimide ke polymer e phahameng e hanyetsanang le mocheso e atisang ho sebelisoa e le thepa ea substrate e feto-fetohang ka mapolanka a thata-thata. E na le botsitso bo botle ba mocheso, thepa ea ho kenya motlakase le ho feto-fetoha ha mochine, ho e lumella hore e mamelle ho phunya khafetsa le ho khumama ntle le ho senya botšepehi ba boto ea potoloho.

3. Koporo: Koporo ke thepa e ka sehloohong e tsamaisang liboto tse thata-thata. E sebelisetsoa ho etsa litsela tse tsamaisang le li-interconnections tse lumellang motlakase oa motlakase ho phalla pakeng tsa likarolo ho boto ea potoloho. Koporo e khethoa ka lebaka la conductivity ea eona e phahameng, solderability e ntle le katleho ea litšenyehelo.

4. Sekgomaretsi: Sekgomaretsi se sebelisetsoa ho kopanya likarolo tse thata le tse tenyetsehang tsa PCB hammoho. Ho bohlokoa ho khetha sekhomaretsi se ka mamellang likhatello tsa mocheso le tsa mochini tse kopaneng nakong ea ts'ebetso ea tlhahiso le bophelo ba lisebelisoa. Likhomaretsi tsa Thermoset, tse kang li-epoxy resin, li sebelisoa hangata ho li-PCB tse thata-flex ka lebaka la thepa ea tsona e ntle ea ho kopanya le ho hanyetsa mocheso o phahameng.

5. Coverlay: Coverlay ke lera le sireletsang le sebelisetsoang ho koahela karolo e tenyetsehang ea boto ea potoloho. Hangata e entsoe ka polyimide kapa ntho e tšoanang e tenyetsehang 'me e sebelisetsoa ho sireletsa mesaletsa le likaroloana tse tsoang ho maemo a tikoloho joalo ka mongobo le lerōle.

6. Mask a solder: Mask ea solder ke lesela le sireletsang le koahetsoeng karolong e thata ea PCB. E thusa ho thibela borokho ba solder le marikhoe a makhutšoanyane a motlakase ha e ntse e fana ka tšireletso le ts'ireletso ea kutu.

Tsena ke lisebelisoa tse ka sehloohong tse sebelisoang kahong ea PCB e thata-tenyetsehang.Leha ho le joalo, ke habohlokoa ho hlokomela hore lisebelisoa tse khethehileng le thepa ea tsona li ka fapana ho itšetlehile ka kopo ea boto le ts'ebetso e lakatsehang. Hangata bahlahisi ba etsa lisebelisoa tse sebelisoang ho li-PCB tse thata-flex ho fihlela litlhoko tse khethehileng tsa sesebelisoa seo ba se sebelisang.

Ka kakaretso,rigid-flex PCBs ke boqapi bo tsotehang indastering ea lisebelisoa tsa elektroniki, tse fanang ka motsoako o ikhethang oa matla a mochini le ho fetoha ha maemo. Thepa e sebelisoang joalo ka FR-4, polyimide, koporo, likhomaretsi, likoahelo, le limaske tsa solder kaofela li phetha karolo ea bohlokoa ts'ebetsong le ho tšoarella ha liboto tsena. Ka ho utloisisa lisebelisoa tse sebelisoang ho li-PCB tse sa fetoheng, bahlahisi le baqapi ba ka etsa lisebelisoa tsa elektronike tsa boleng bo holimo, tse tšepahalang tse fihlelang litlhoko tsa lefatše la kajeno le khannoang ke theknoloji.

Nako ea poso: Sep-16-2023

Morao