Quick-Turn PCB Prototyping 6 Layer High-Density Multi-Layer Flexible Boards Bakeng sa Likoloi.

Tlhaloso

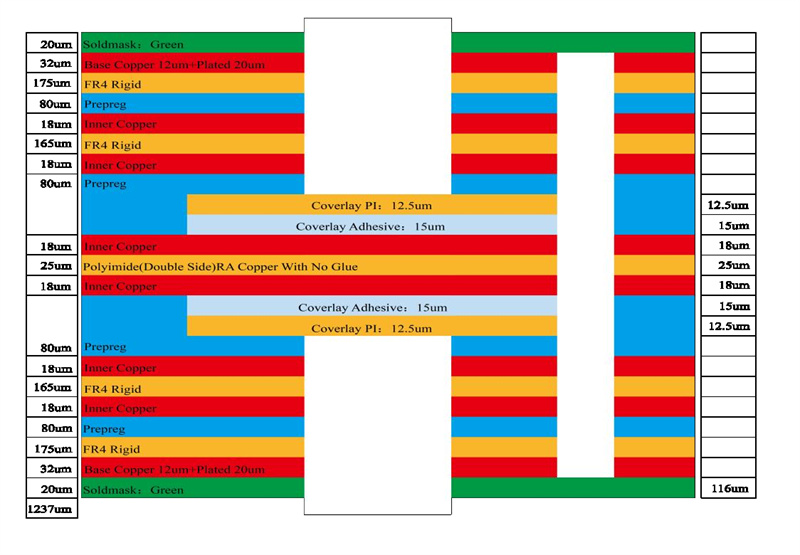

| Sehlopha | Bokhoni ba Ts'ebetso | Sehlopha | Bokhoni ba Ts'ebetso |

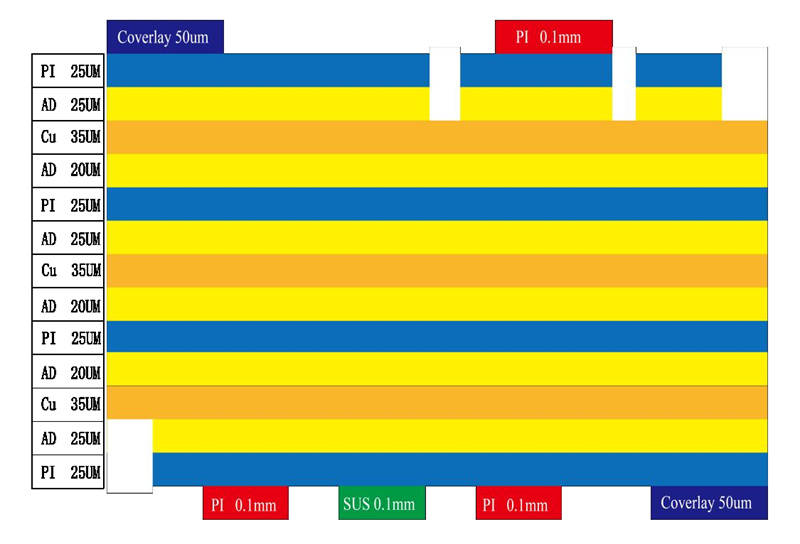

| Mofuta oa Tlhahiso | FPC e le 'ngoe / Mekhahlelo e habeli FPC Mefuta e mengata ea FPC / Aluminium PCBs Li-PCB tse thata-Flex | Layer Number | 1-16 mekhahlelo FPC 2-16 mekhahlelo e Rigid-FlexPCB HDI Printed Pota Boards |

| Max Manufacture size | FPC e le 'ngoe ea 4000mm Likarolo tsa Doulbe FPC 1200mm Mefuta e mengata ea FPC 750mm Regid-Flex PCB 750mm | Insulating Layer Botenya | 27.5um / 37.5/ 50um / 65/ 75um / 100um / 125um / 150um |

| Botenya ba Boto | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm | Mamello ea PTH Boholo | ± 0.075mm |

| Surface Finish | Ho qoelisoa ka Khauta/ Ho qoelisoa Silver/Gold Plating/Tin Plat ing/OSP | Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Ka tlase ho 0.4mm | Min Line Space/ bophara | 0.045mm/0.045mm |

| Botenya Mamello | ± 0.03 limilimithara | Tšitiso | 50Ω-120Ω |

| Botenya ba Koporo ea Foil | 9um/12um/18um/35um/70um/100um | Tšitiso Laolwa Mamello | ±10% |

| Mamello ea NPTH Boholo | ± 0.05 limilimithara | The Min Flush Width | 0.80 limilimithara |

| Min Via Hole | 0.1 limilimithara | Phethahatsa Standard | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Re etsa liboto tse ngata tse feto-fetohang tse nang le boiphihlelo ba lilemo tse 15 ka botsebi ba rona

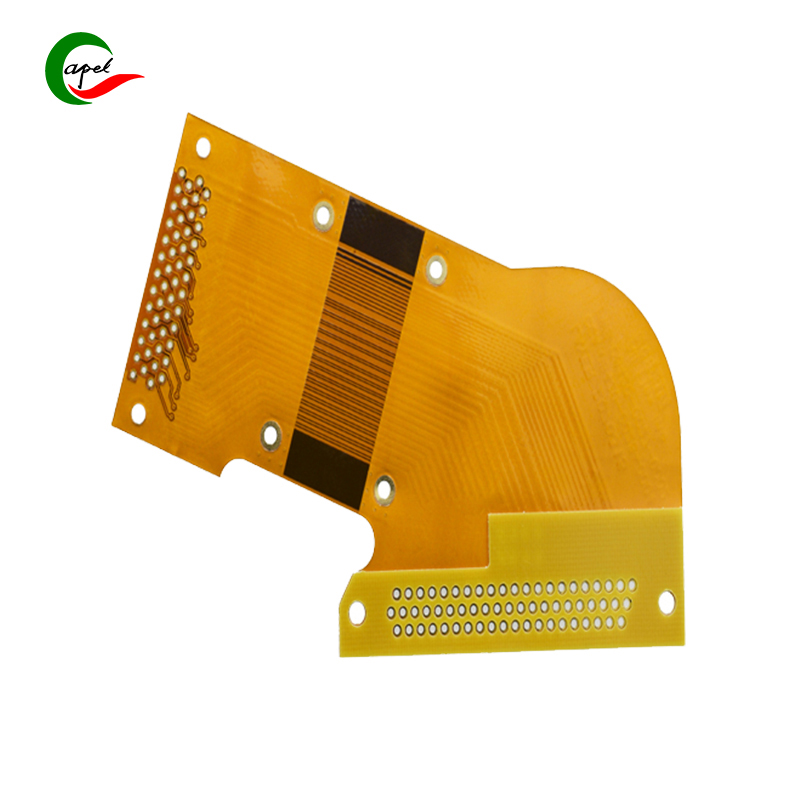

3 lera Flex PCBs

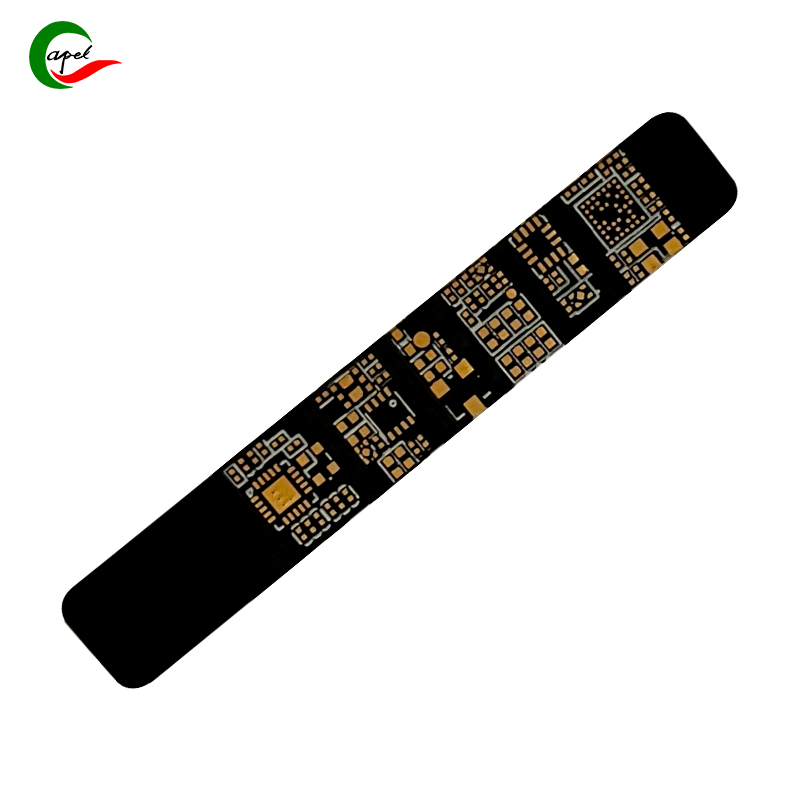

8 lera Rigid-Flex PCBs

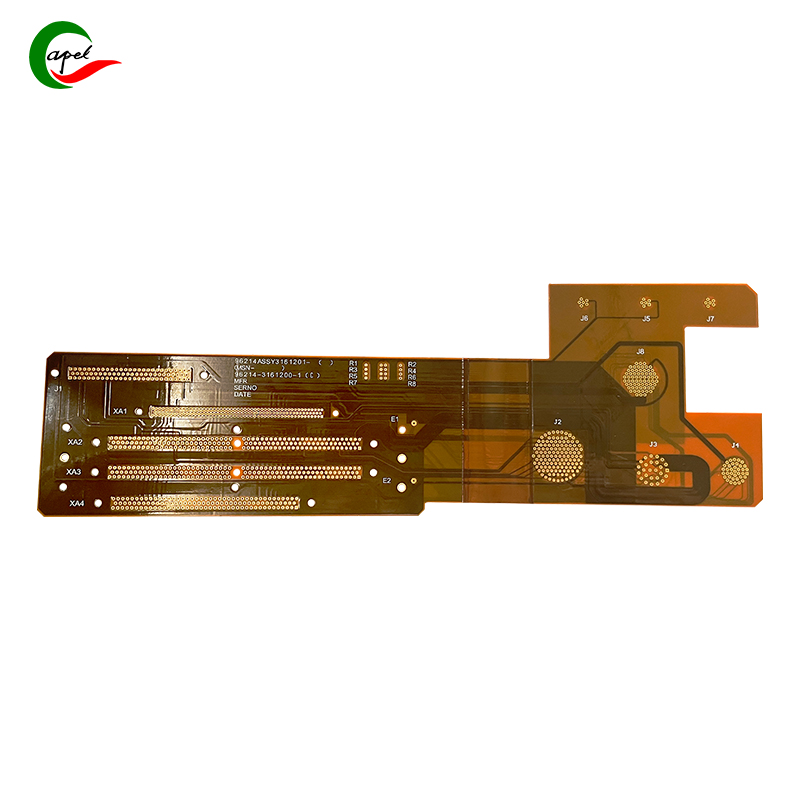

8 lera HDI Printed Circuit Boards

Lisebelisoa tsa Teko le Tlhahlobo

Teko ea microscope

Tlhahlobo ea AOI

Teko ea 2D

Teko ea Impedance

Teko ea RoHS

Flying Probe

Horizontal Tester

Ho Kobeha Teste

Tšebeletso ea rona ea liboto tse ngata tse feto-fetohang

. Fana ka tšehetso ea tekheniki Pele ho thekiso le ka mor'a thekiso;

. Tloaelo ho fihla ho mekhahlelo e 40, 1-2days Phetoho e potlakileng ea prototyping, Theko ea likarolo, Kopano ea SMT;

. E fana ka lisebelisoa tse peli tsa Bongaka, Taolo ea Liindasteri, Likoloi, Lifofane, Lisebelisoa tsa Bareki, IOT, UAV, Lipuisano joalo-joalo.

. Lihlopha tsa rona tsa baenjiniere le bafuputsi ba ikemiselitse ho phethahatsa litlhoko tsa hau ka ho nepahala le ka botsebi.

Litlhoko tsa tekheniki tsa li-PCB tsa likoloi bakeng sa liboto tse ngata tse tenyetsehang ke life?

1. Ho tšoarella nako e telele: Li-PCB tsa Likoloi li tlameha ho khona ho mamella maemo a thata a ho sebetsa a koloi, ho kenyelletsa le ho feto-fetoha ha mocheso, ho thothomela le mongobo. Ba tšepisa bophelo bo bolelele ba tšebeletso le botsitso bo babatsehang ba mechine.

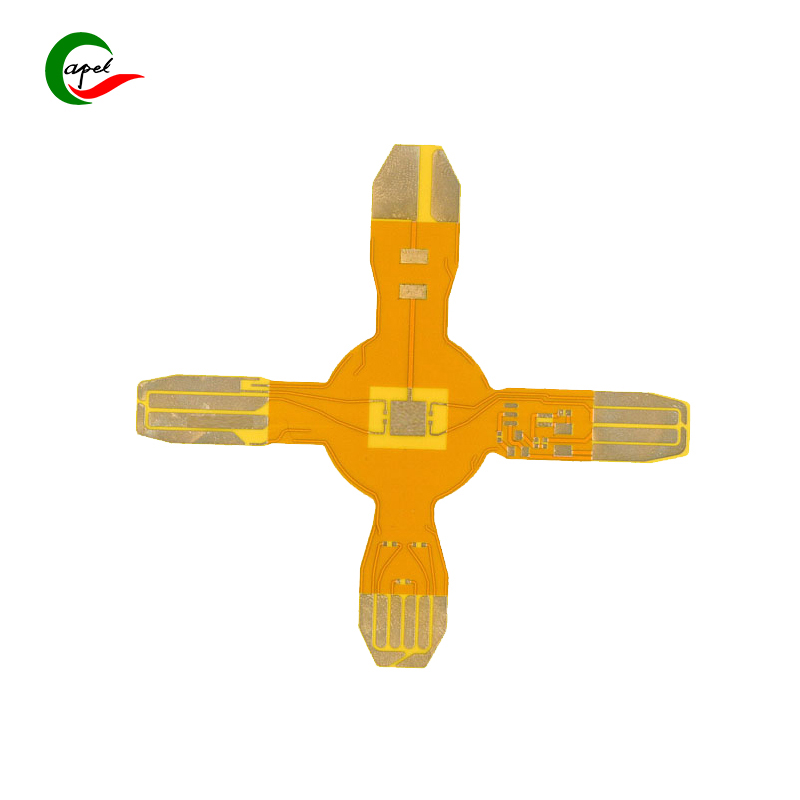

2. High Density: Multi-layer flexible PCB e lumella likhokahano tse ngata tsa motlakase le likaroloana ho kopanngoa sebakeng se kopanetsoeng. Moralo o nang le sets'oants'o se phahameng o thusa ho tsamaisa tsela e nepahetseng le ho fokotsa boholo ba PCB, ho boloka sebaka sa bohlokoa koloing.

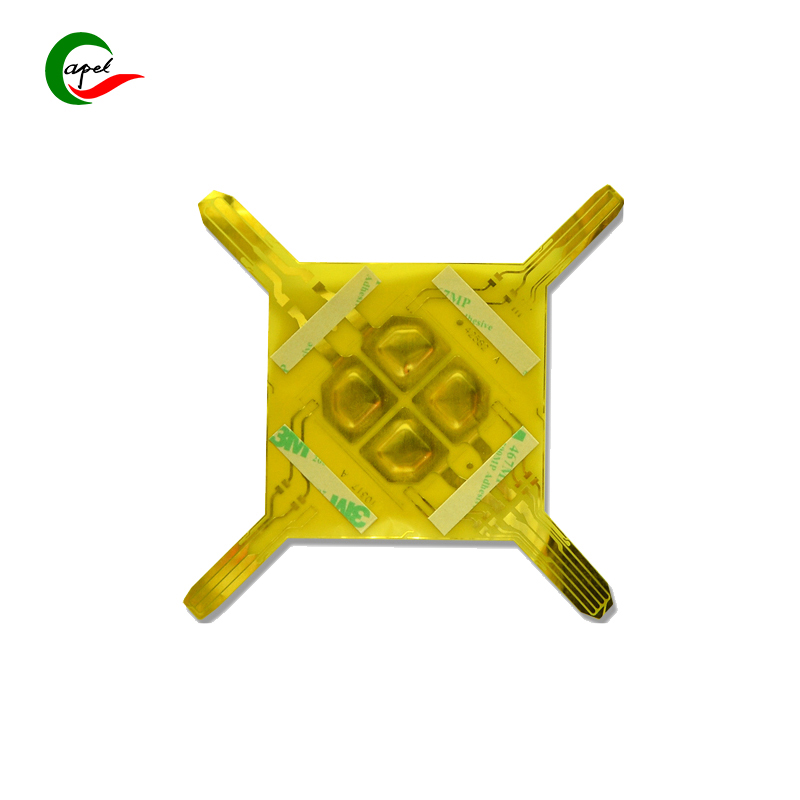

3. Ho tenyetseha le ho kobeha: Li-PCB tse tenyetsehang li ka menaha habonolo, tsa sotheha kapa tsa kobeha hore li lekane libaka tse thata kapa li lumellane le sebōpeho sa koloi. Ba lokela ho boloka botšepehi ba bona ba motlakase le mochini nakong ea ho kobeha khafetsa le ho kobeha.

4. Botšepehi ba pontšo: Ho lokela ho ba le tahlehelo e fokolang ea pontšo kapa tšitiso ea lerata ho PCB ho netefatsa puisano e tšepahalang pakeng tsa likarolo tse fapaneng tsa elektronike. Sebelisa mekhoa e kang taolo ea impedance le motheo o nepahetseng ho boloka botšepehi ba matšoao.

5. Tsamaiso ea mocheso: Mapolanka a potoloho ea likoloi a lokela ho senya mocheso o hlahisoang nakong ea ts'ebetso. Mekhoa e sebetsang ea taolo ea mocheso, joalo ka ho sebelisa lifofane tse nepahetseng tsa koporo le li-vias tsa mocheso, lia hlokahala ho thibela ho chesa le ho netefatsa ts'ebetso e tsitsitseng.

6. Tšireletso ea EMI / RFI: Ho thibela ho kena-kenana le motlakase (EMI) le tšitiso ea maqhubu a seea-le-moea (RFI), li-PCB tsa likoloi li hloka mekhoa e nepahetseng ea ho sireletsa. Sena se kenyelletsa ho sebelisa lifofane tse sireletsang kapa tse fatše ho fokotsa litlamorao tsa mats'oao a kantle a motlakase.

7. Teko ea Marang-rang: Moralo oa PCB o lokela ho nolofatsa tlhahlobo le tlhahlobo ea PCB e kopaneng. Phihlello e nepahetseng ea lintlha tsa liteko le li-probe tsa liteko li tla fanoa ho netefatsa tlhahlobo e nepahetseng le e sebetsang nakong ea tlhahiso le tlhokomelo.

8. Ho lumellana le litekanyetso tsa likoloi: Moralo le tlhahiso ea li-PCB tsa likoloi li hloka ho latela litekanyetso tsa indasteri ea likoloi, tse kang AEC-Q100 le ISO/TS 16949. Ho lumellana le litekanyetso tsena ho netefatsa botšepehi, polokeho le boleng ba PCB.

Ke hobane'ng ha u hloka Quick-turn PCB Prototyping?

1. Lebelo: Prototyping e potlakileng ea PCB e potlakisa lipotoloho tsa ntlafatso ea sehlahisoa. E thusa ho fokotsa nako e hlokahalang ea ho pheta-pheta, ho leka, le ho ntlafatsa meralo ea PCB, ho nolofalletsa baenjiniere ho fihlela linako tse behiloeng tsa projeke kapa ho arabela ka potlako litlhoko tsa mmaraka.

2. Netefatso ea Moqapi: PCB Prototyping e lumella baenjiniere ho netefatsa ts'ebetso, ts'ebetso le ho etsoa ha meralo ea bona ea PCB pele ba ea tlhahisong ea bongata. E thusa ho tseba le ho rarolla liphoso leha e le life tsa moralo kapa menyetla ea ho ntlafatsa, ho boloka nako le chelete ha nako e ntse e ea.

3. Kotsi e fokotsehileng: Prototyping e potlakileng ea PCB e thusa ho fokotsa likotsi tse amanang le tlhahiso ea PCB e ngata. Ka ho lekola le ho netefatsa meralo ka lihlotšoana tse nyane, liphoso leha e le life tse ka bang teng kapa litaba li ka tšoaroa kapele, ho thibela liphoso tse theko e boima le ho sebetsa bocha nakong ea tlhahiso e felletseng.

4. Ho boloka litšenyehelo: Potlako e potlakileng ea PCB e ka sebelisa lisebelisoa le lisebelisoa ka nepo. Ka ho ts'oara litaba tsa moralo pele ho nako le ho etsa liphetoho tse hlokahalang, lienjineri li ka boloka thepa e senyehileng le ho etsa moralo o theko e boima.

5. Karabelo ea 'maraka: Khoebong e potlakileng, ho khona ho hlahisa le ho hlahisa lihlahisoa tse ncha ka potlako ho ka fa k'hamphani monyetla oa tlhōlisano. Prototyping e potlakileng ea PCB e nolofalletsa lik'hamphani ho arabela ka potlako litlhoko tsa 'maraka, ho fetola mekhoa kapa menyetla e mecha, ho netefatsa ho lokolloa ha lihlahisoa ka nako.

6. Boikemisetso le boqapi: Prototyping e thusa ho itloaetsa le ho nchafatsa. Baenjiniere ba ka hlahloba mehopolo e mecha ea meralo, ba leka likarolo tse fapaneng, 'me ba etsa liteko ka mahlale a tsoetseng pele. E ba nolofalletsa ho sutumetsa meeli le ho hlahisa lihlahisoa tsa maemo a holimo.