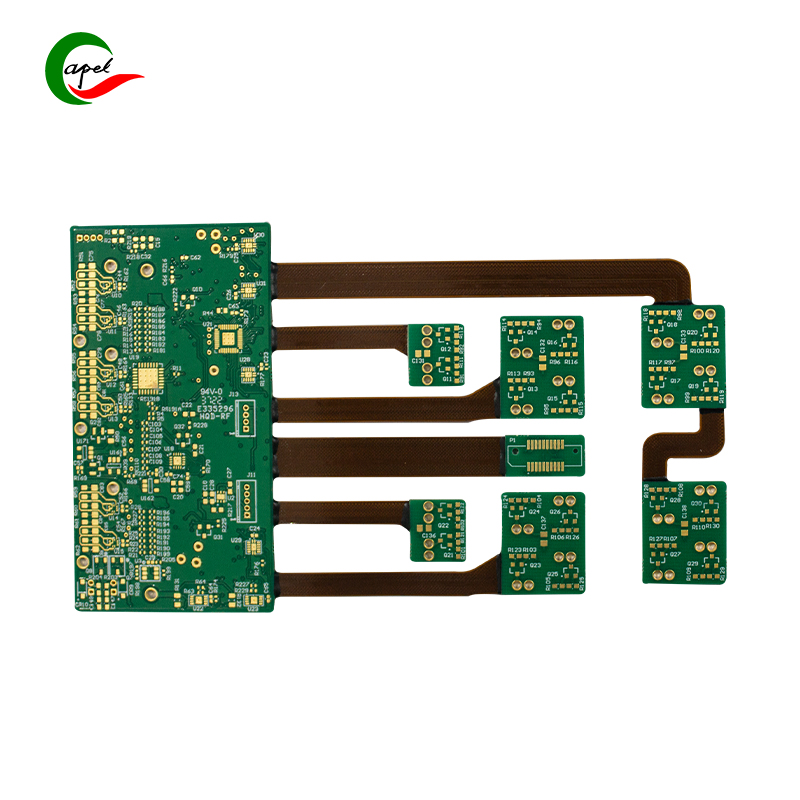

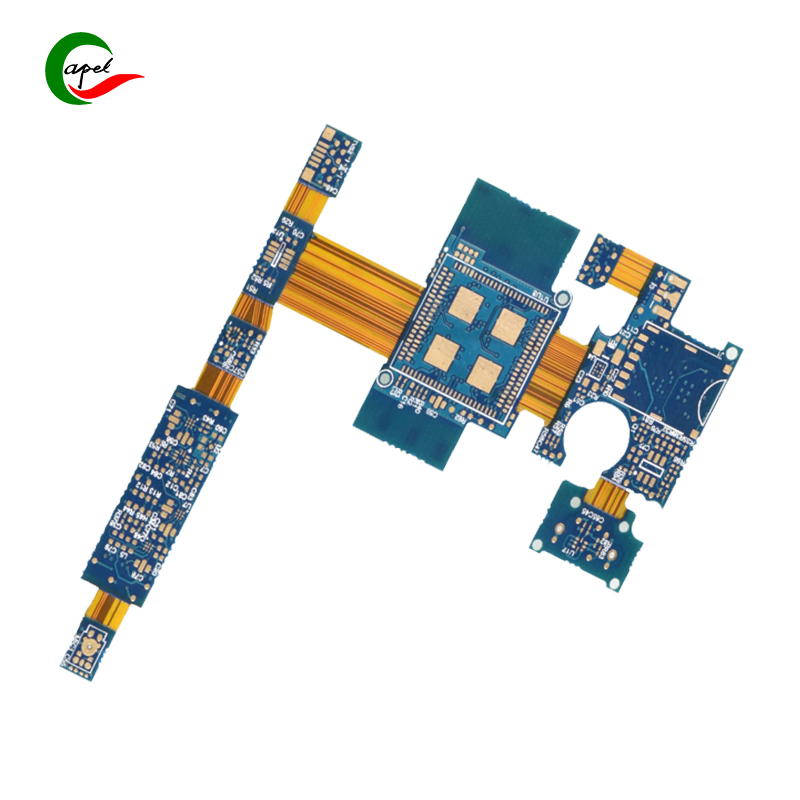

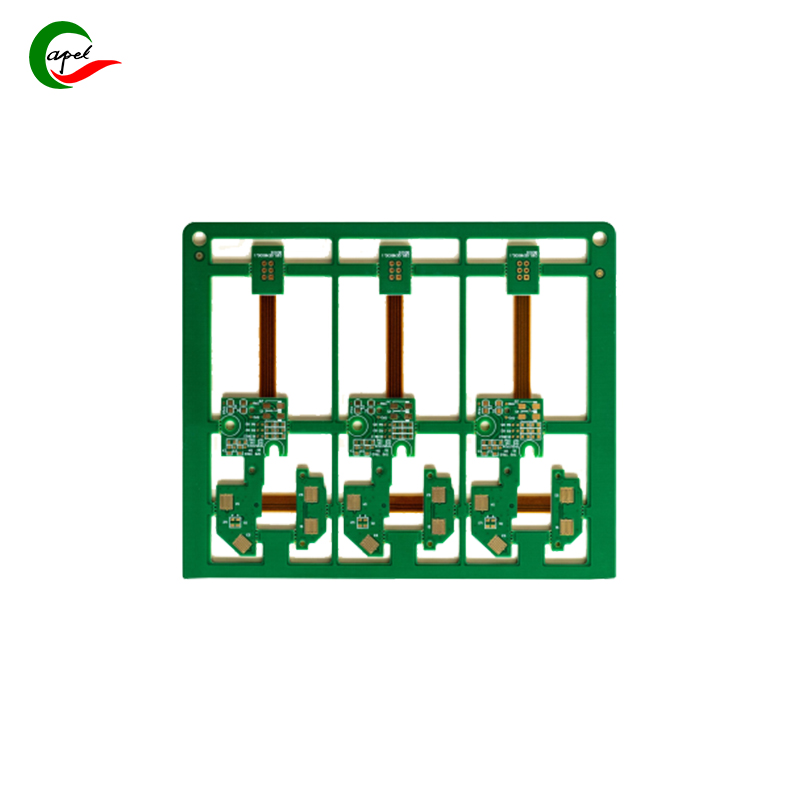

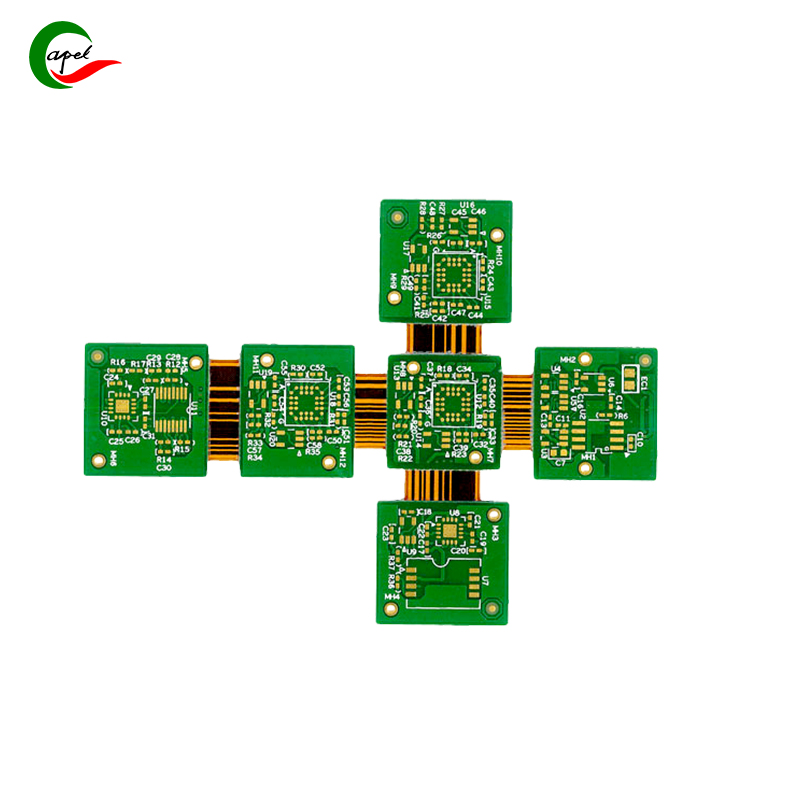

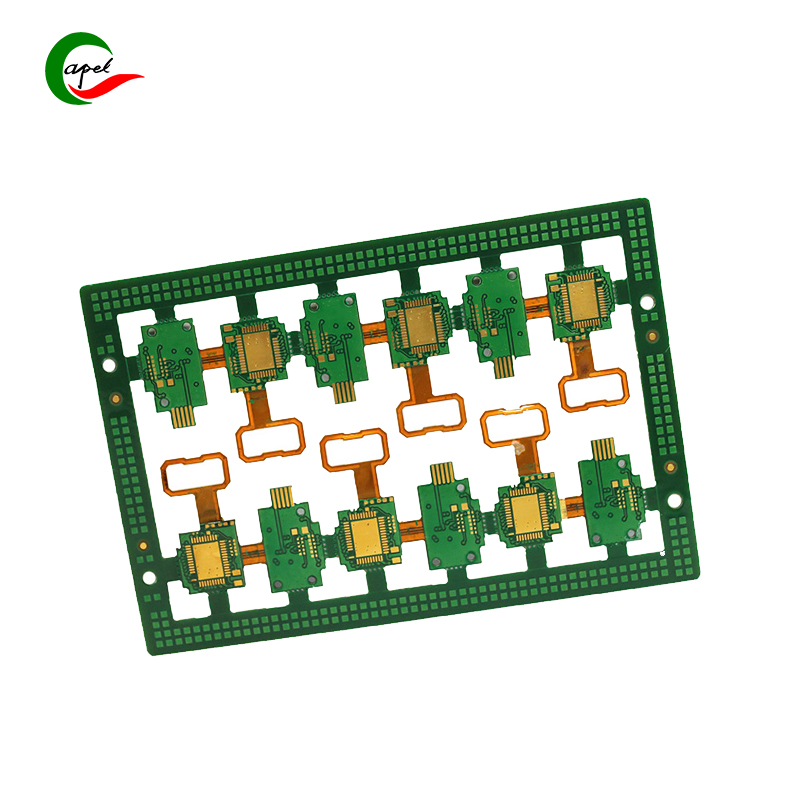

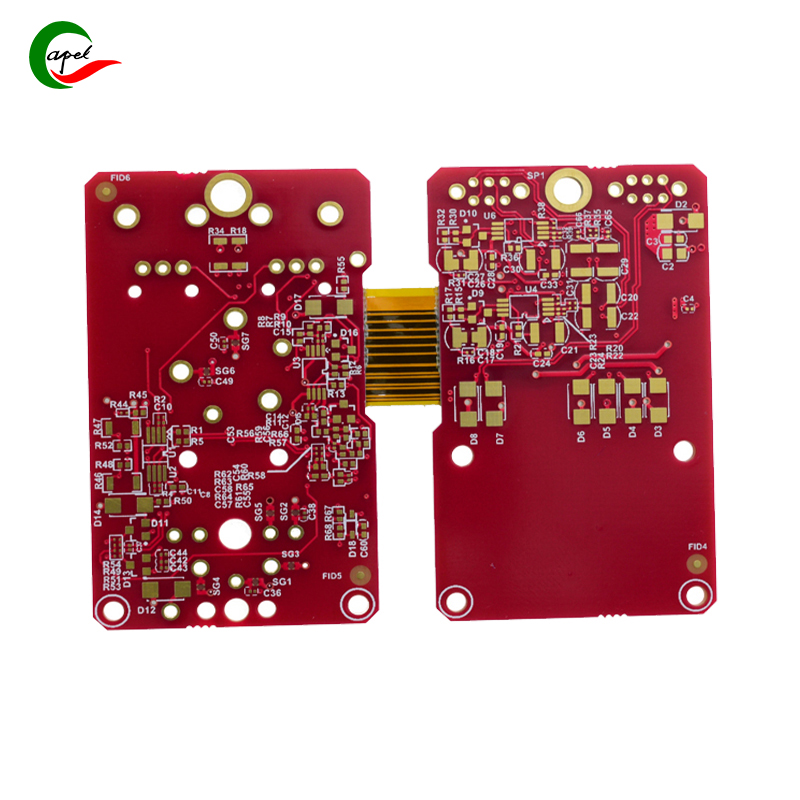

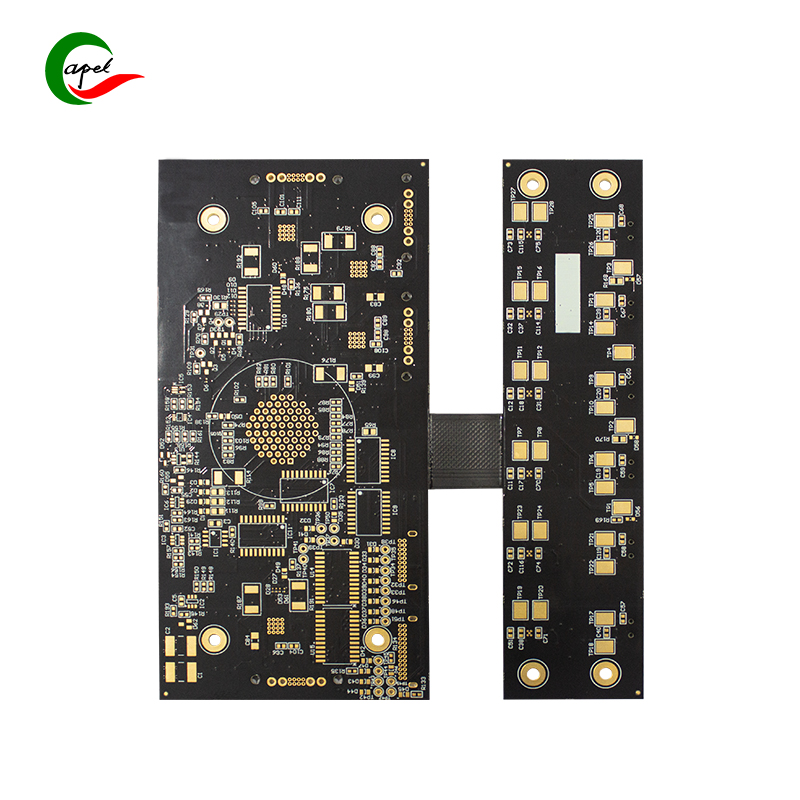

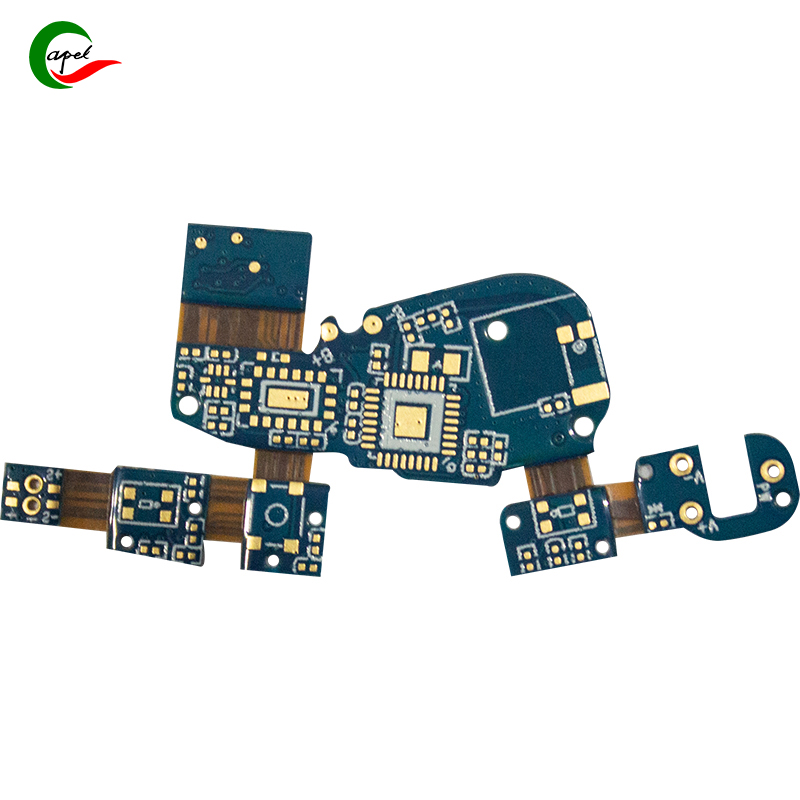

Ts'ebeletso ea Tlhahiso ea Rigid-Flex PCB

Sehlopha sa litsebi tsa theknoloji ea boto ea potoloho ea Capel ea lilemo tse 15 ea Rigid flexible flexible

- fana ka lintlha le tataiso ea bohlokoa ho bareki ba rona;

-kutloisiso e tebileng ea likarolo tsa tekheniki tsa thekenoloji ea rigid-flex board board e ba nolofalletsa ho fana ka tharollo e lumellanang le litlhoko tse ikhethang tsa moreki e mong le e mong.

-ho kopanya theknoloji ea morao-rao le melao-motheo ea moralo lihlahisoa tsa bona, ho netefatsa hore bareki ba Capel ba fumana liboto tsa potoloho tsa boemo bo holimo tse kopanang kapa tse fetang litekanyetso tsa indasteri.

Matla a tlhahiso ea li-PCB tse Rigid-Flex a ka fihla ho feta 70000sqm ka khoeli

--laola litaelo tse phahameng haholo 'me u kopane le linako tse thata tsa tlhahiso. Hore na o hloka palo e nyane kapa e kholo, re ka phethahatsa litlhoko tsa hau tsa odara kapele le ka nepo.

Support customized 2-32 lera phahameng-ho nepahala thata thata tenyetsehang pcb potoloho boto

-mahlale a tsoetseng pele, lisebelisoa le lits'ebetso ho netefatsa tlhahiso e nepahetseng le e tšepahalang. Tlhokomelo ea rona ho lintlha, mehato e thata ea taolo ea boleng, le liteko tse felletseng li re thusa ho fana ka li-PCB tse tenyetsehang tsa boleng bo holimo tse fihlelang maemo a holimo a indasteri.

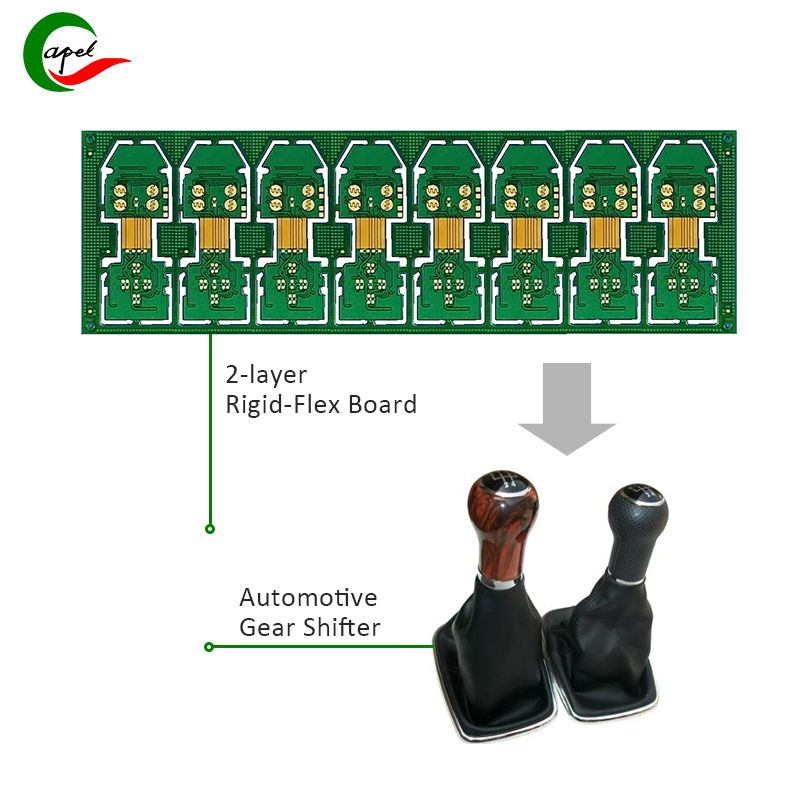

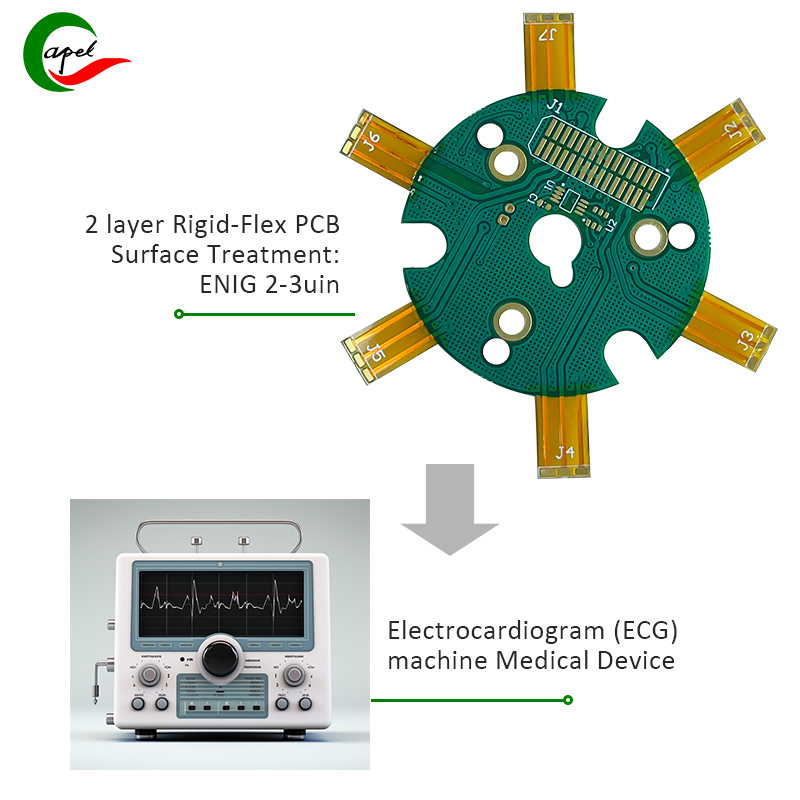

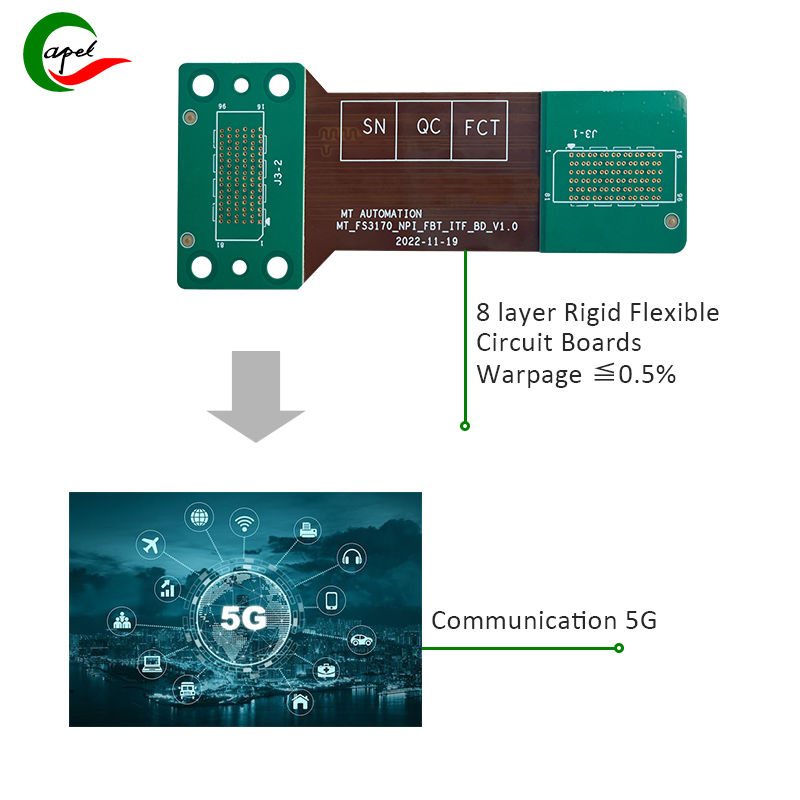

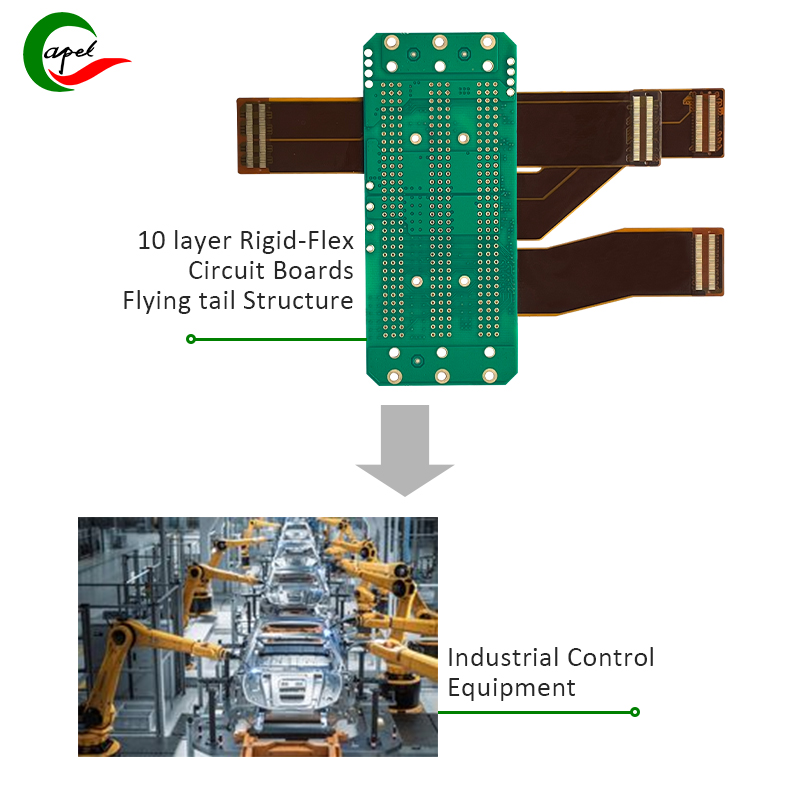

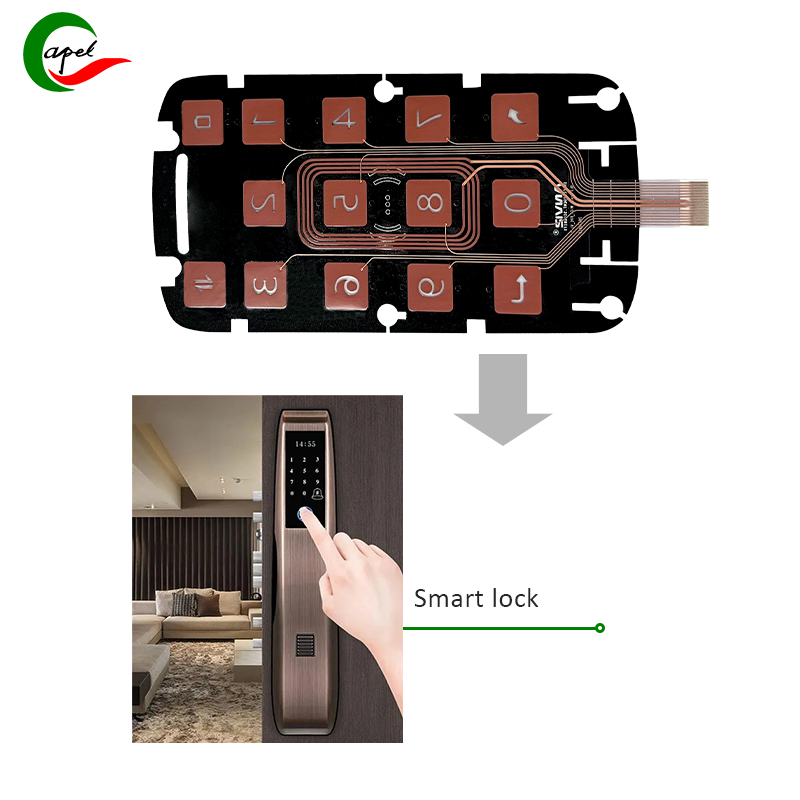

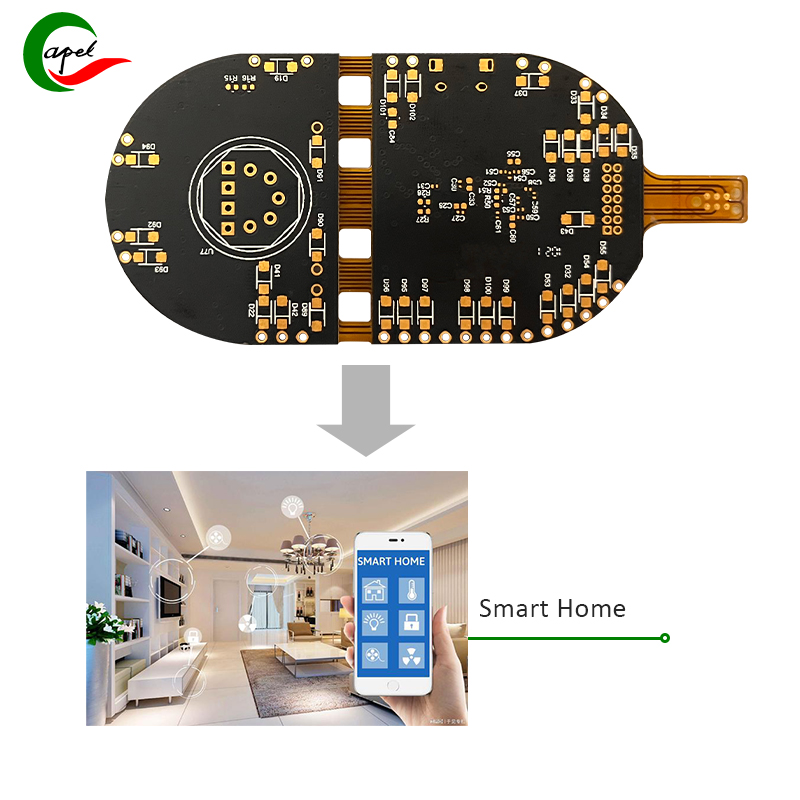

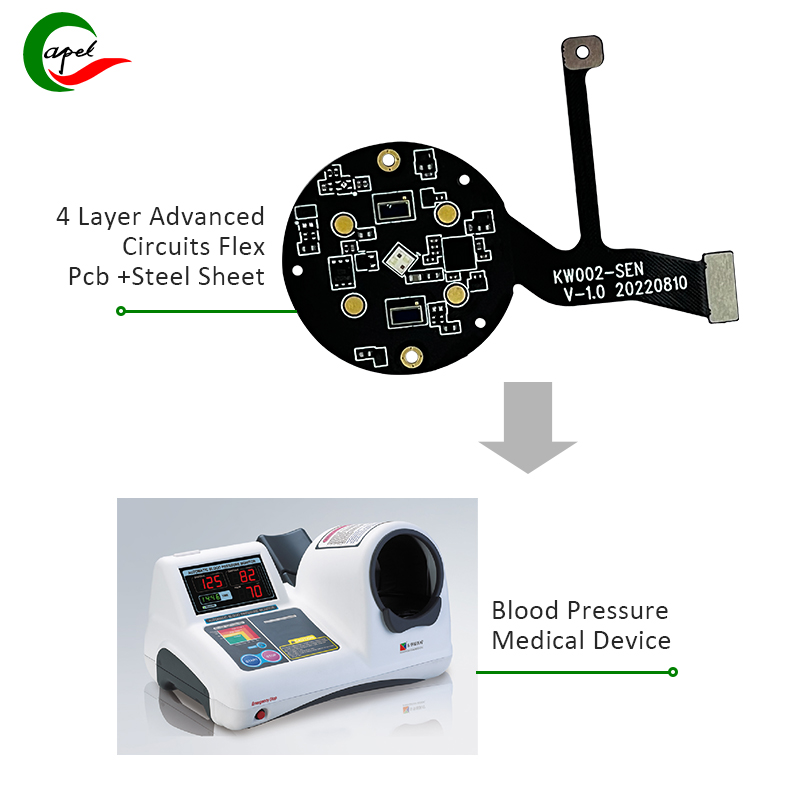

Linyeoe tsa Kopo Tsa Mapolanka a Potoloho a Rigid-Flex PCB

Fana ka litharollo tse ka tšeptjoang mabapi le ho etsa liboto tsa potoloho tse thata bakeng sa bareki ba lisebelisoa tse aparoang, lisebelisoa tsa bongaka, litsamaiso tsa sefofane le ts'ireletso, litsamaiso tsa likoloi, lisebelisoa tsa elektroniki tsa bareki, li-automation tsa indasteri le likhokahano tsa mehala.

- Li-PCB tse thata tse feto-fetohang tse lumellanang le litlhoko tsa tsona tse ikhethang;

-Ho itšetlehile ka litlhoko tse khethehileng tsa indasteri ea hau, re ka fana ka liboto tsa potoloho tse hatisitsoeng tse thata tse feto-fetohang tse nang le lisebelisoa tse khethehileng tse kang lisebelisoa tse hanyetsanang le mocheso o phahameng bakeng sa lisebelisoa tsa likoloi le tsa sefofane, hammoho le lisebelisoa tsa boemo ba bongaka bakeng sa lisebelisoa tsa lisebelisoa tsa bongaka. Re boetse re lula re nchafalitsoe ka theknoloji ea morao-rao e thata-thata ea ho etsa PCB ho fihlela litlhoko tse tsoelang pele tsa liindasteri tsena.

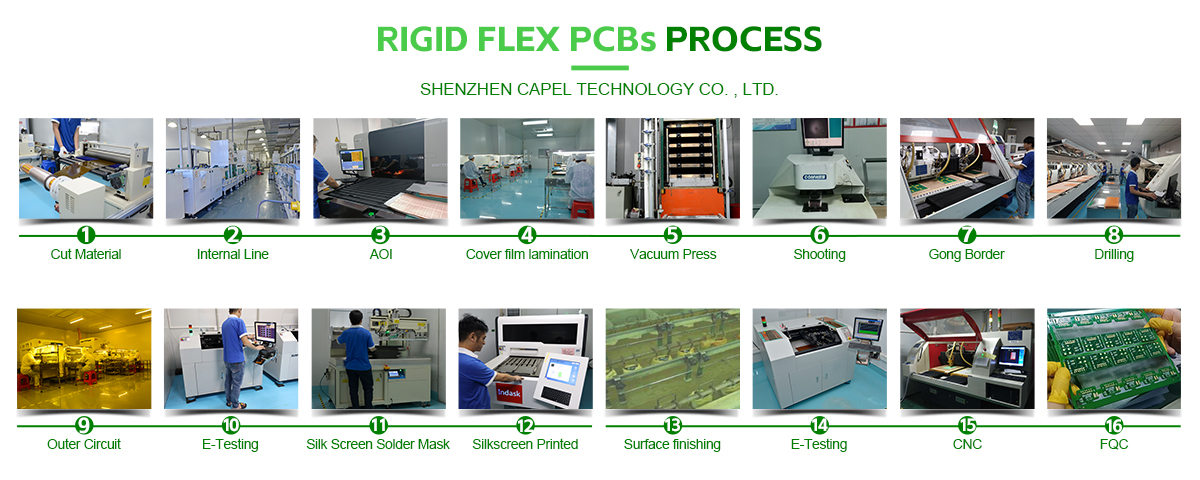

Mokhoa o thata oa ho etsa PCB oa ho etsa

1. Ho seha:Ho seha thepa ea motheo ea boto e thata: Seha sebaka se seholo sa boto e nang le koporo ka boholo bo hlokoang ke moralo.

2. Ho seha thepa ea motheo ea boto e tenyetsehang:Seha thepa ea mantlha ea moqolo (masebelisoa a motheo, sekhomaretsi se hloekileng, filimi e koahelang, PI reinforcement, joalo-joalo) ka boholo bo hlokoang ke moralo oa boenjiniere.

3. Ho cheka:Hlakola ka likoti bakeng sa likhokahano tsa potoloho.

4. Mokoti o motšo:Sebelisa potion ho etsa hore toner e khomarele lebota la lesoba, le phethang karolo e ntle mabapi le ho tsamaisa.

5. Ho roala koporo:Plate lera la koporo ka sekoting ho finyella conduction.

6. Ponahalo ea ho tsamaisana:Lokisetsa filimi (negative) tlas'a sebaka se tsamaisanang le lesoba moo filimi e omeletseng e kenngoeng ho netefatsa hore mohlala oa filimi o ka kopana hantle le bokaholimo ba boto. Mohlala oa filimi o fetisetsoa filiming e omeletseng holim'a boto ka holim'a molao-motheo oa litšoantšo tse khanyang.

7. Ntlafatso:Sebelisa potassium carbonate kapa sodium carbonate ho hlahisa filimi e omeletseng libakeng tse sa tsejoeng tsa mokhoa oa potoloho, ho siea mokhoa o omileng oa filimi sebakeng se pepeneneng.

8. Etching:Kamora hore mokhoa oa potoloho o ntlafatsoe, sebaka se pepeneneng sa bokaholimo ba koporo se koaheloa ke tharollo ea etching, se siea mohlala o koahetsoe ke filimi e omileng.

flex pcb kopano

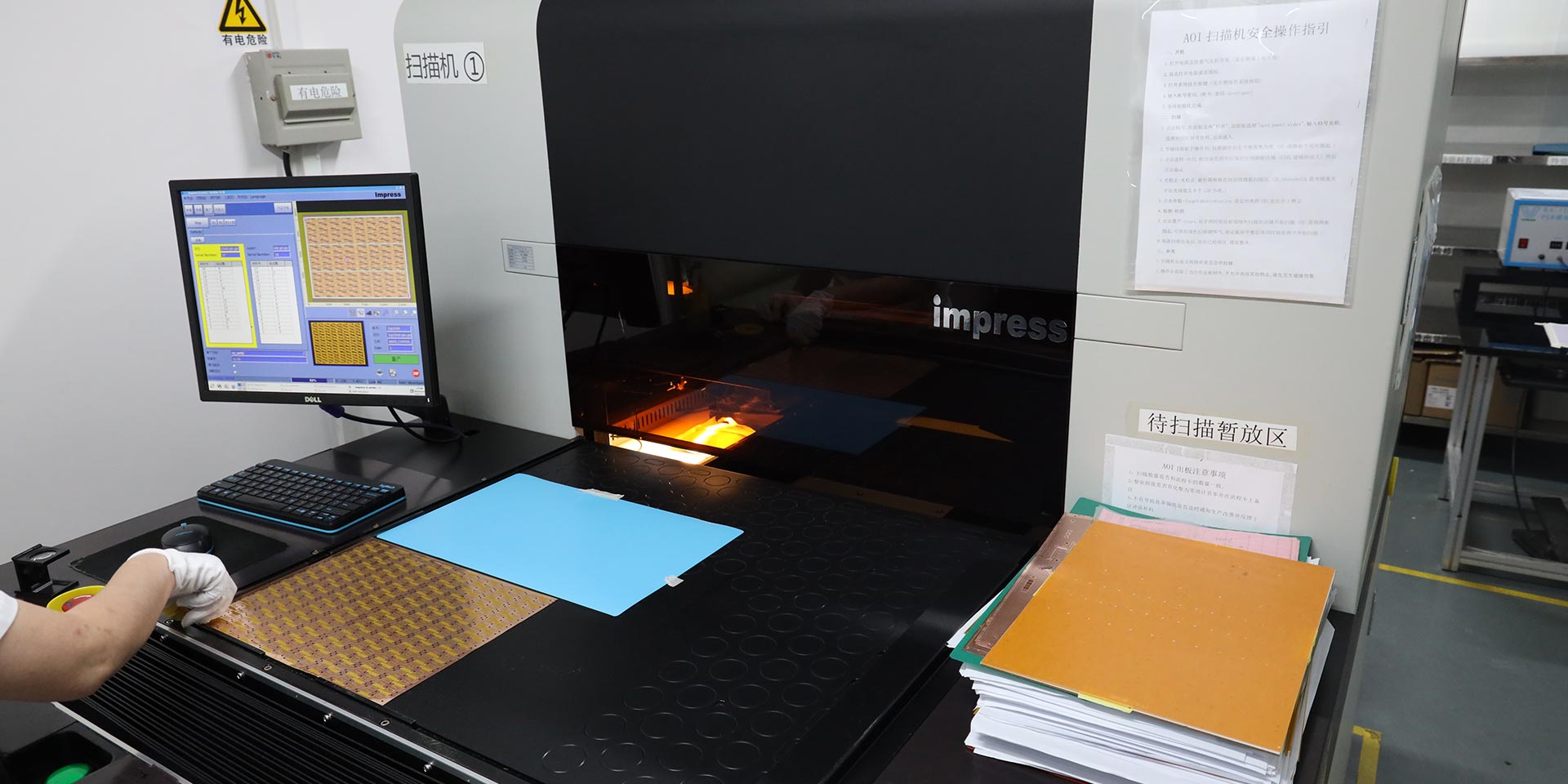

9. AOI:Tlhahlobo ea optical e iketsang. Ka molao-motheo oa ho bonahatsa optical, setšoantšo se fetisetsoa ho thepa ea ho sebetsa, 'me ha e bapisoa le data e behiloeng, mathata a potoloho a bulehileng le a khutšoanyane a mohala a fumanoa.

10. Lamination:Koahela potoloho ea foil ea koporo ka filimi e sireletsang ka holimo ho thibela oxidation ea potoloho kapa potoloho e khutšoanyane, 'me ka nako e ts'oanang e sebetsa e le ho kenya letsoho le ho kobeha ha lihlahisoa.

11. Laminating CV:Tobetsa filimi e kwahelang pele ho laminated le poleiti e matlafalitsoeng ka botlalo ka mocheso o phahameng le khatello e phahameng.

12. Hlakola:Sebelisa hlobo le matla a punch ea mochini ho phunya poleiti ea mosebetsi ka boholo ba thomello bo fihlelang litlhoko tsa tlhahiso ea moreki.

13. Lamination(boemo ba liboto tsa pcb tse thata-flex)

14. Ho hatella:Tlas'a maemo a vacuum, sehlahisoa se futhumatsoa butle-butle, 'me boto e bonolo le boto e thata li hatelloa hammoho ka ho hatella ho chesang.

15. Ho cheka ha bobeli:Sebetsa ka lesoba le kopanyang boto e bonolo le boto e thata.

16. Ho hloekisa plasma:Sebelisa plasma ho fihlela litlamorao tseo mekhoa e tloaelehileng ea ho hloekisa e ke keng ea li fihlela.

17. Koporo e qoelitsoeng (boto e thata):Lera la koporo e pentiloe ka sekoting ho finyella conduction.

18. Copper plating (hard board):Sebelisa electroplating ho tenya botenya ba lesoba koporo le holim'a koporo.

19. Potoloho (filimi e omileng):Beha lesela la lintho tse etsang photosensitive holim'a poleiti e entsoeng ka koporo ho sebetsa e le filimi bakeng sa phetisetso ea mohlala. Etching AOI wiring: Ho tlosa bokaholimo bohle ba koporo ntle le mohlala oa potoloho, ho hlahisa mokhoa o hlokahalang.

20. Mask ea solder (skrine ea silika):Koahela mela eohle le bokaholimo ba koporo ho sireletsa mela le ho insulate.

21. Maske a solder (ho pepeseha):Enke e etsa photopolymerization, 'me enke e sebakeng sa khatiso ea skrine e lula holim'a boto ebe e tiisa.

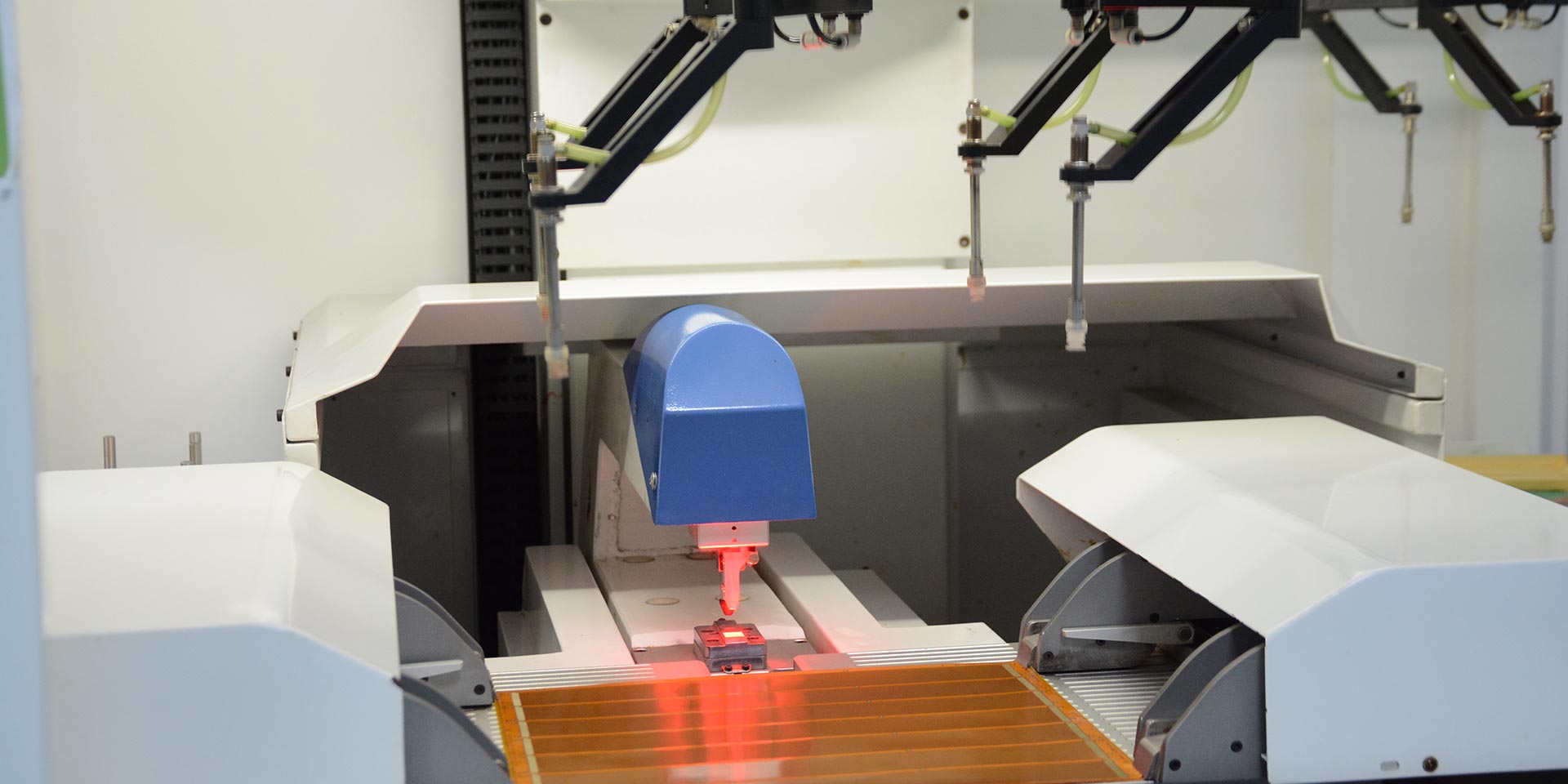

22. Ho sibolla laser:Sebelisa mochini oa ho itšeha oa laser ho etsa tekanyo e itseng ea ho itšeha ka laser sebakeng sa mela e thata-flex, ebola karolo e bonolo ea boto, 'me u pepese karolo e bonolo ea boto.

23. Kopano:Beha maqephe a tšepe kapa li-reinforcements libakeng tse tsamaellanang tsa boto ho tlama le ho eketsa boima ba likarolo tsa bohlokoa tsa FPC.

Regid tenyetsehang pcb kopano

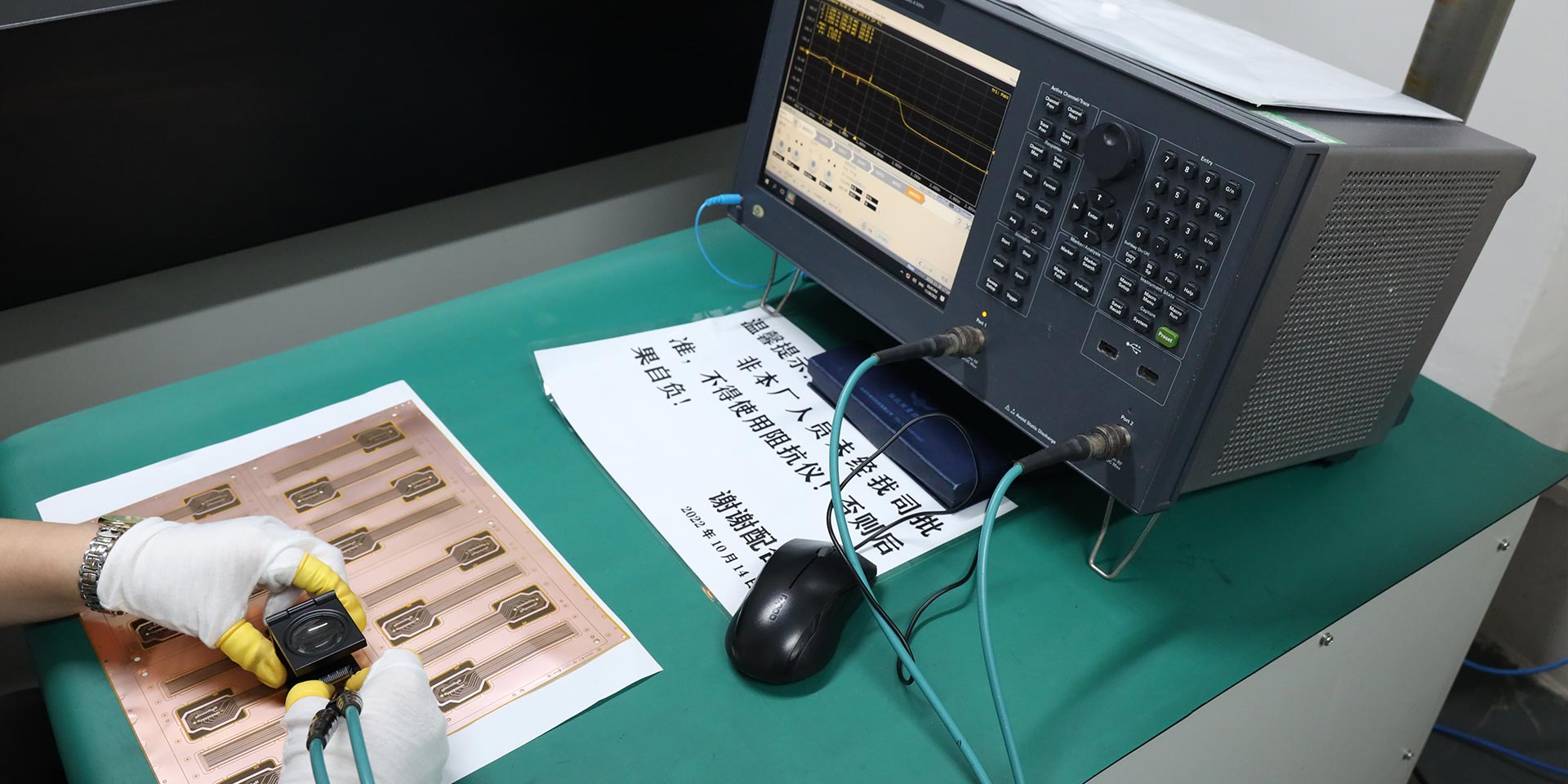

24. Teko:Sebelisa li-probe ho hlahloba hore na ho na le liphoso tse bulehileng / tse khuts'oane tsa potoloho ho netefatsa hore sehlahisoa se sebetsa.

25. Litlhaku:Hatisa matšoao a tšoaeang boto ho thusa ho kopanya le ho tsebahatsa lihlahisoa tse latelang.

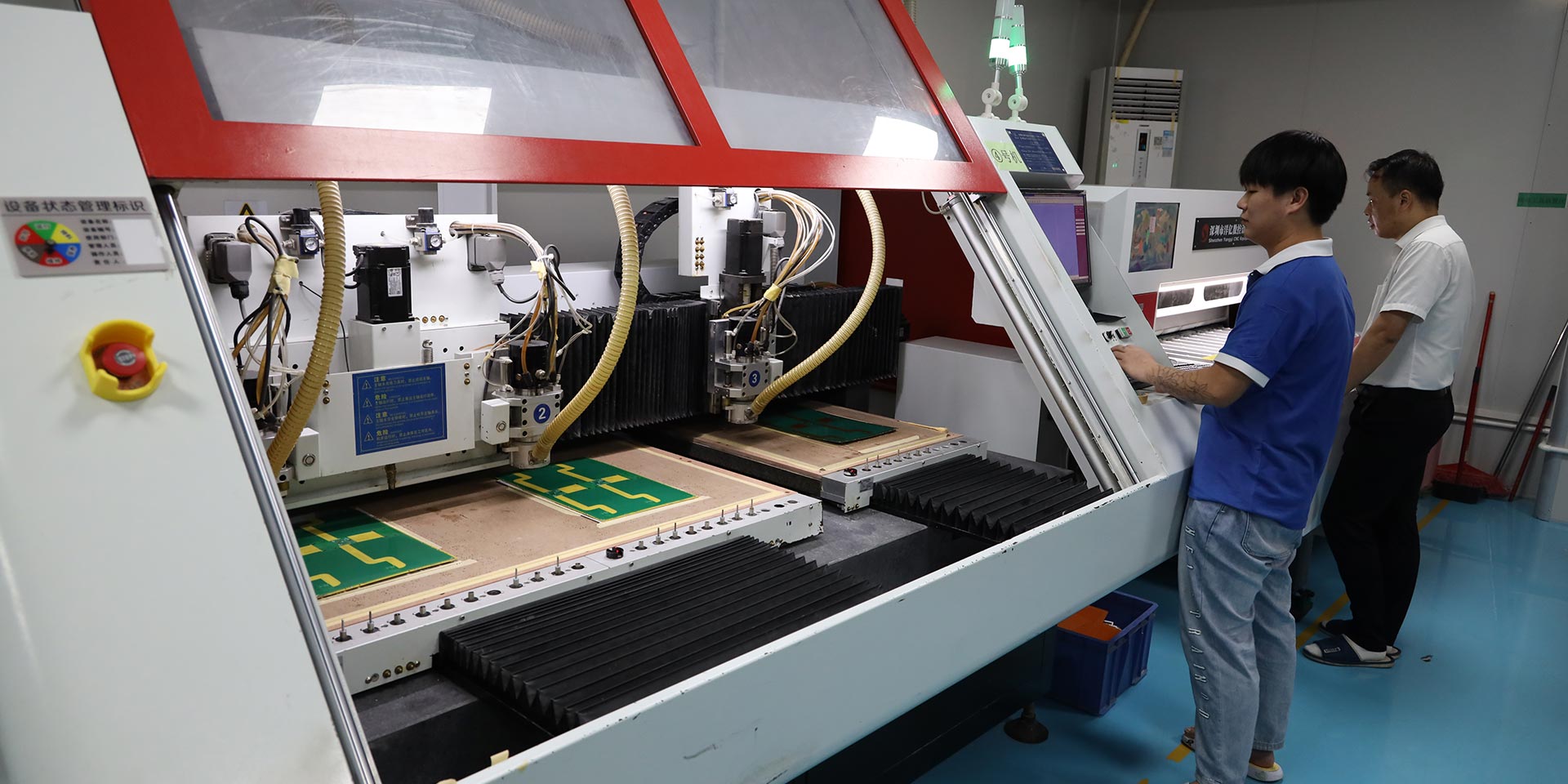

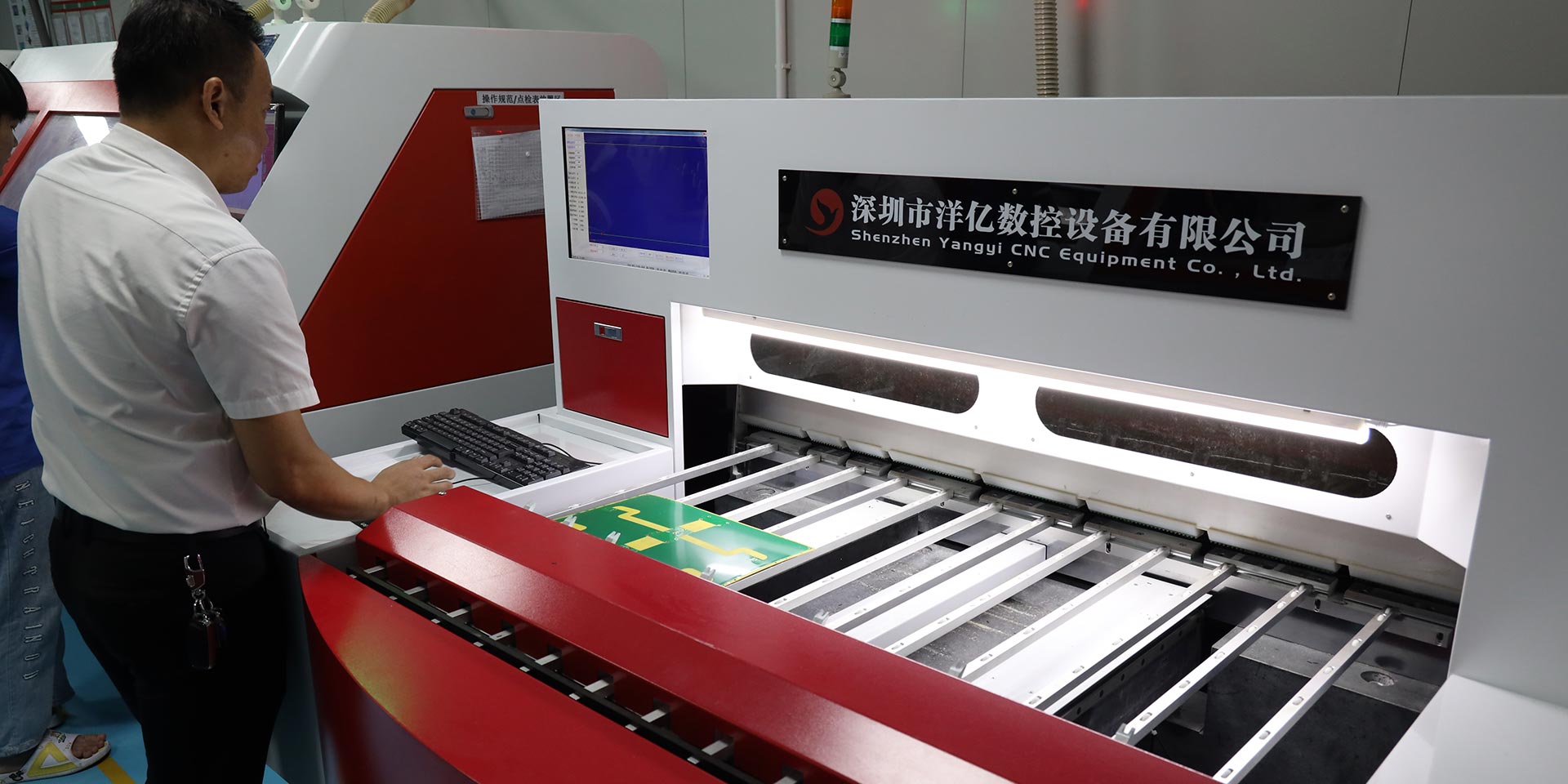

26. Letlapa la gong:Sebelisa lisebelisoa tsa mochini oa CNC ho hlahisa sebopeho se hlokahalang ho latela litlhoko tsa bareki.

27. FQC:Lihlahisoa tse feliloeng li tla hlahlojoa ka botlalo bakeng sa ponahalo ho latela litlhoko tsa bareki, 'me lihlahisoa tse nang le bothata li tla khethoa ho netefatsa boleng ba sehlahisoa.

28. Sephutheloana:Liboto tse fetisitseng tlhahlobo e felletseng li tla pakoa ho latela litlhoko tsa bareki ebe li romelloa ntlong ea polokelo.

Seboka sa Turkey se Rigid Flexible PCB

Fana ka boiphihlelo le thuso nakong ea moralo, ho thusa bareki ho ntlafatsa meralo ea bona

bakeng sa ts'ebetso, ts'epahalo, le ho boloka litšenyehelo;

Ho khona ho hlahisa likarolo tse nyane tsa li-prototypes tsa PCB tse thata ka nako e nepahetseng, ho lumella bareki ho lekola le ho netefatsa meralo ea bona pele ba tsoela pele ka tlhahiso ea bongata;

Boloka litokomane tse qaqileng ho pholletsa le ts'ebetso ea kopano, ho kenyeletsoa likoloto tsa thepa (BOM), litaelo tsa kopano, le litlaleho tsa liteko;

Ho fana ka nako ka nako (Capel e na le moralo o nepahetseng oa tlhahiso, taolo e sebetsang ea lisebelisoa, le tšebelisano e haufi le bareki nakong eohle ea tlhahiso.);

Shebana le mathata afe kapa afe a ka hlahang ka mor'a ho romelloa 'me u fane ka tšehetso ea tekheniki kapa litšebeletso tsa tiisetso ha ho hlokahala.

Rigid Flexible PCB Fabrication Melemo

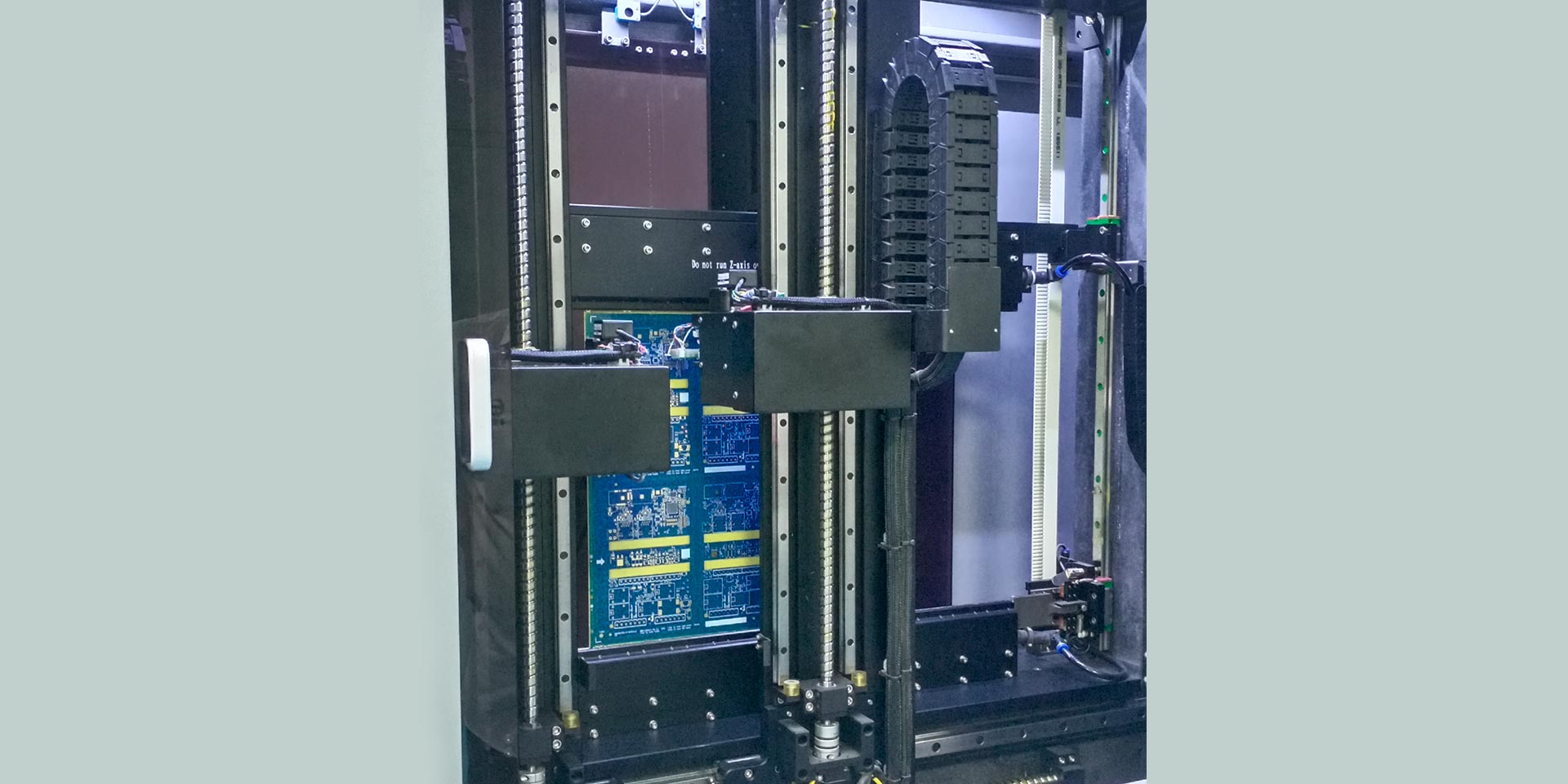

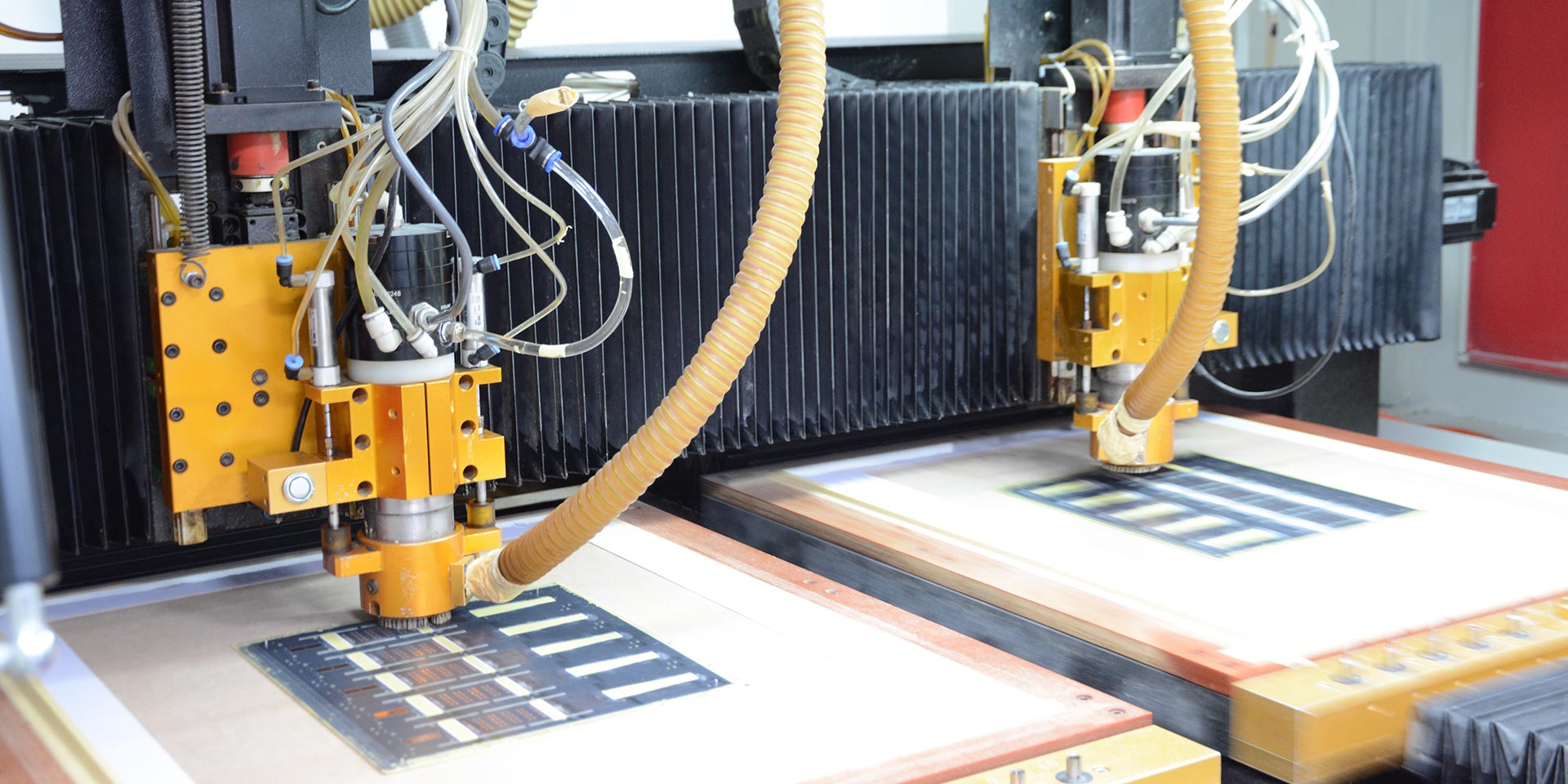

Lisebelisoa tsa tlhahiso tse ikemetseng le tse phahameng ka ho fetesisa

- fokotsa liphoso tsa batho, ho ntlafatsa katleho, le ho ntlafatsa boleng ba kakaretso ea liboto tsa rona tse thata tse hatisitsoeng tsa potoloho.

Capel e na le setsi sa eona sa R&D, feme ea tlhahiso, le feme ea patch bakeng sa liboto tsa potoloho tse thata

- Lipatlisiso le nts'etsopele e tsoelang pele ho theha litharollo tse ncha le ho ntlafatsa ts'ebetso ea lihlahisoa tsa bareki ba rona.

-Capel e na le taolo e felletseng mabapi le ts'ebetso ea tlhahiso, ho netefatsa taolo ea boleng le tlhahiso e sebetsang, e na le nako e khuts'oane ea ho etella pele le phano e potlakileng.

-Capel e khona ho sebetsana le litokiso le liphetoho ho liboto tsa potoloho tse thata-flex tseo ba li hlahisang, ho fana ka tšehetso ka mor'a ho rekisa le ho netefatsa khotsofalo ea bareki.

Tlhahiso e tsoelang pele ea theknoloji e tsoetseng pele le e tsoetseng pele ea ts'ebetso

-Re etelletsa boqapi le ntlafatso e sa feleng molemong oa rona oa ho etsa PCB o tenyetsehang, re ntse re hlahloba le ho amohela mahlale a macha le a tsoetseng pele, re u fa litharollo tsa maemo a holimo le ho netefatsa hore liboto tsa hau tse thata tse tenyetsehang tsa PCB li fihlela litekanyetso tsa morao-rao tsa tekheniki.

-Eketsa ts'ebetso ea tlhahiso ho ntlafatsa ts'ebetso le ho fokotsa litšenyehelo, ho fokotsa litšila tsa thepa, ho khutsufatsa linako tsa ho etella pele, le ho fana ka tharollo e theko e boima ho bareki ba rona.

Regid Flexible PCB Bokhoni ba Tlhahiso

| Sehlopha | Bokhoni ba Ts'ebetso | Sehlopha | Bokhoni ba Ts'ebetso |

| Mofuta oa Tlhahiso | Lera le le leng la FPC le flex PCB Mekhahlelo e habeli FPC flec PCB Multilayer FPC Aluminium PCB Regid-Flex PCB | Mekhahlelo Nomoro | 1-30 mekhahlelo FPC Flexible PCB 2-32 mekhahlelo e Rigid-FlexPCB 1-60 mekhahlelo e Rigid PCB HDI Boards |

| Max Tlhahiso Boholo | FPC e le 'ngoe ea 4000mm Doublelayers FPC 1200mm Mefuta e mengata ea FPC 750mm Regid-Flex PCB 750mm | Insulating Lera Botenya | 27.5um / 37.5/ 50um / 65/75um 100um / 125um / 150um |

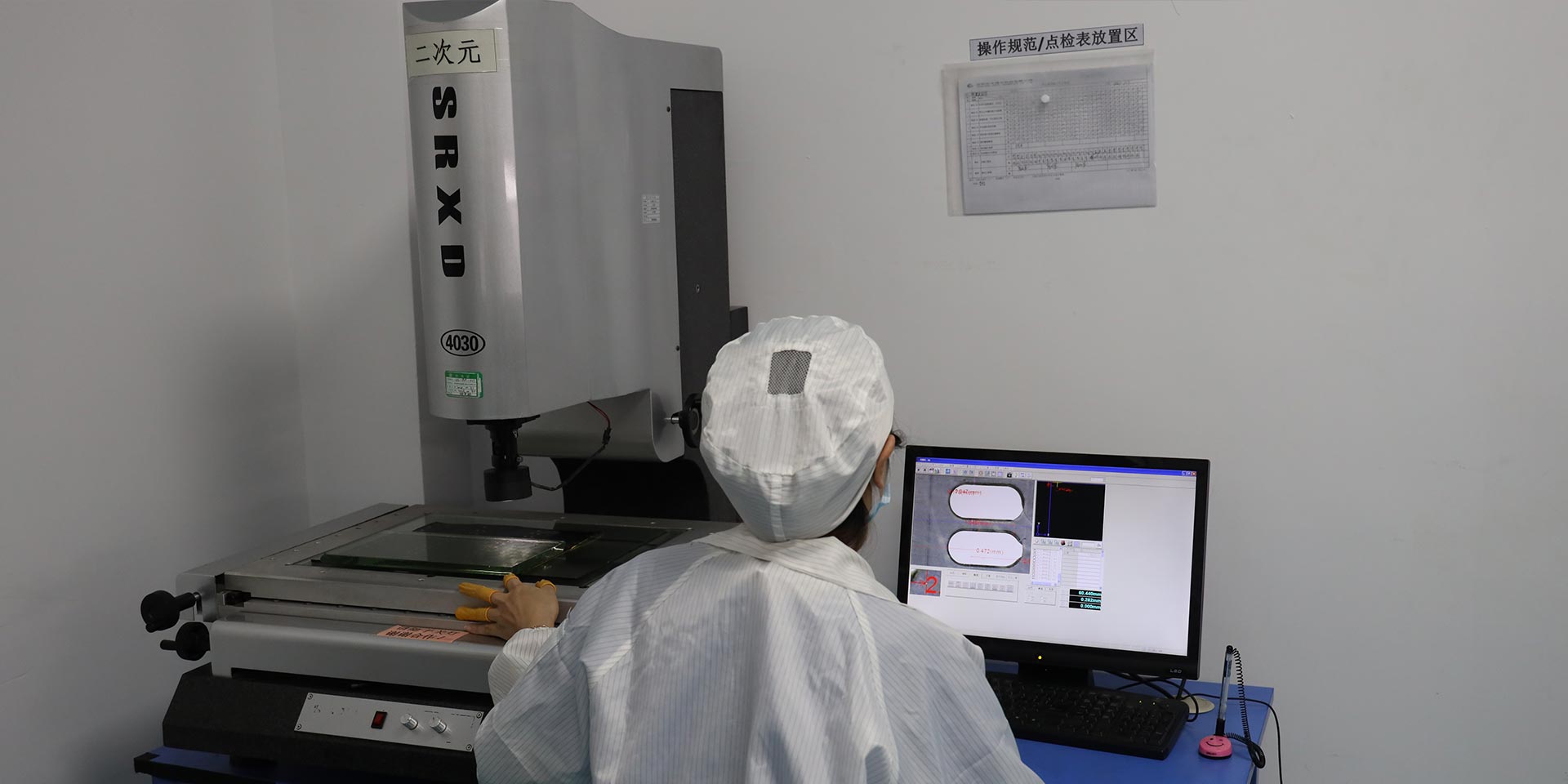

| Boto Botenya | FPC0.06mm-04mm Rigid-Flex PCB025-60mm | Mamello ea Boholo ba PTH | + 0.075 limilimithara |

| Bokaholimo Qetella | Ho inela Khauta/ Ho qoelisoa Silver/Gold Plating /Tin Plating/OSP | Stiffener | FR4 /PI/ PET /SUS /PSA/Alu |

| Semicircle Boholo ba Orifice | Ka tlase ho 0.4mm | Min Line Space bophara | 0.045mm/0.045mm |

| Botenya Mamello | + 0.03 limilimithara | Tšitiso | 500-1200 |

| Foil ea Koporo Botenya | 9um/12um/18um/ 35um/70um/100um | Tšitiso Laolwa Mamello | +10% |

| Mamello ot NPTH boholo | + 0.05 limilimithara | The Min Flush Width | 0.80 limilimithara |

| Min Via Hole | 0.1 limilimithara | phethahatsa Standard | GB/IPC-650/PC-6012IPC-01311/ IPC-601311 |

| Setifikeiti | ULand ROHS 5014001:2015 IS0 9001:2015 IATF16949:2016 | Patents | dipatente tsa mohlala boiqapelo dipatente |

Taolo ea Boleng bakeng sa Tlhahiso ea Rigid Flexible PCB

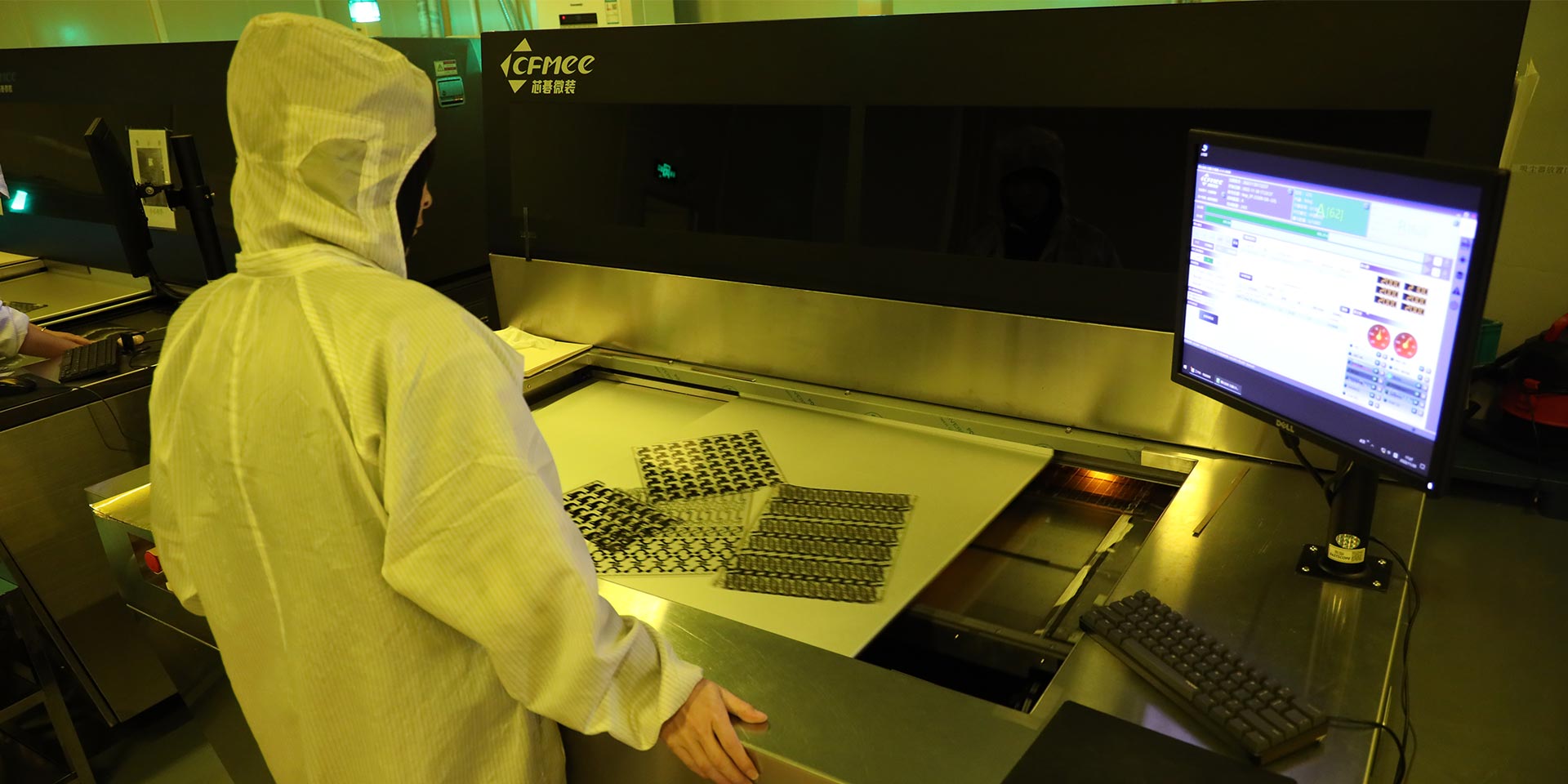

Tsamaiso e felletseng ea taolo ea boleng

- Re kentse tšebetsong sistimi e felletseng ea taolo ea boleng ho netefatsa litekanyetso tse phahameng ka ho fetisisa tsa tlhahiso ea PCB e tenyetsehang (tlhahlobo ea thepa, tlhahlobo ea ts'ebetso, tlhahlobo ea lihlahisoa le tlhahlobo)

Ts'ebetso ea rona ke ISO 14001:2015, ISO 9001:2015, IATF16949:2016 e netefalitsoeng

- boitlamo ba rona ho tsamaiso ea boleng, ts'ebetsong ea tikoloho, le ntlafatso e tsoelang pele, boitlamo ba rona ba ho fana ka liboto tsa potoloho tse tšepahalang le tsa boleng bo holimo.

Lihlahisoa tsa rona li tšoailoe ke UL le ROHS

-E netefatsa hore li-PCB tsa rona tse thata tse tenyetsehang li kopana le litekanyetso tsa polokeho le ho latela melao ea indasteri, e se nang lintho tse kotsi, e etsa hore e be botsoalle tikolohong le ho bolokeha ho sebelisoa lits'ebetsong tse fapaneng.

E fumane lipatente tse fetang 20 tsa mohlala oa utility le litokelo tsa boqapi

- tsepamiso ea rona ho nts'etsopele ea litharollo tse ikhethang le tse iqapetsoeng tsa tlhahiso ea PCB e thata, boitlamo ba rona ho boqapi bo netefatsa hore o fumana lihlahisoa tsa maemo a holimo tse fihlelang litlhoko tsa hau tse ikhethileng.

Quick Turn Rigid-Flex PCB Prototyping

Lihora tse 24 tse sa emeng tse thata tse feto-fetohang tsa boto ea tlhahiso ea litšebeletso tsa tlhahiso

Ho tlisoa ha liodara tse nyane hangata ho nka matsatsi a 5-7

Hangata tlhahiso ea lihlahisoa tse ngata e nka matsatsi a 10-15

| Tlhahiso | Palo ea lihlopha | Nako ea thomello (matsatsi a khoebo) | |||

| Mehlala | Tlhahiso ea 'Misa | ||||

| FPC | 1L | 3 | 6-7 | ||

| 2L | 4 | 7-8 | |||

| 3L | 5 | 8-10 | |||

| Bakeng sa li-PCB tse feto-fetohang tsa FPC tse nang le likarolo tse fetang 3, eketsa matsatsi a 2 a khoebo bakeng sa karolo ka 'ngoe e eketsehileng | |||||

| HDI e patoa foufetseng ka tsela PCB le Regid-Flex PCB | 2-3L | 7 | 10-12 | ||

| 4-5L | 8 | 12-15 | |||

| 6L | 12 | 16-20 | |||

| 8L | 15 | 20-25 | |||

| 10-20L | 18 | 25-30 | |||

| SMT: Kenya matsatsi a mang a 1-2 a khoebo ho nako e kaholimo ea thomello | |||||

| RFQ:2 lihora tsa ho sebetsa CS:24 lihora tsa ho sebetsa | |||||

| EQ: Lihora tse 4 tsa ho sebetsa Matla a tlhahiso: 80000m / khoeli | |||||

Khopolo ea Hang-hang bakeng sa Kopano ea Flexible PCB le Flex PCB

Capel e hlahisa fekthering ea eona 'me e laoloa ke sehlopha sa litsebi tse nang le phihlelo ea lilemo tse 15 ho netefatsa hore sehlahisoa se seng le se seng se tšoaneleha ka 100%.