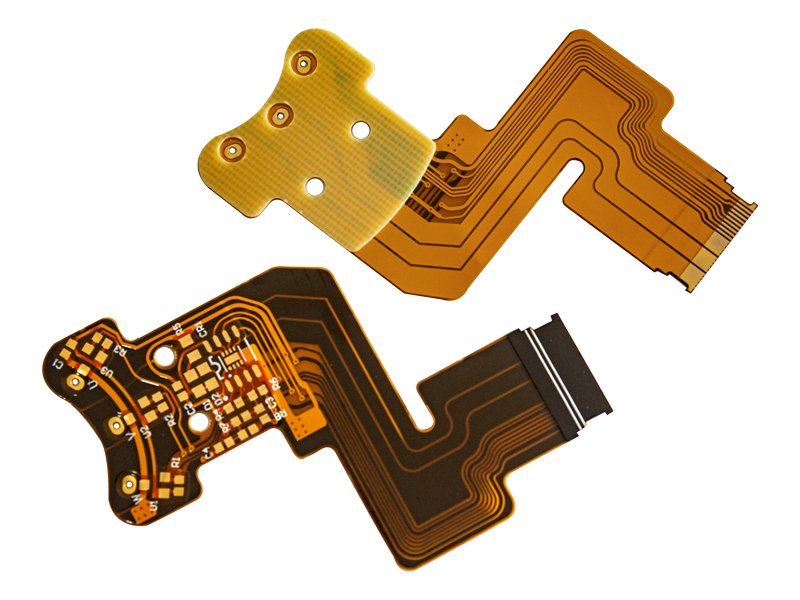

Li-PCB tse feto-fetohang li sebelisoa hangata indastering le lits'ebetsong tse fapaneng, ho kenyeletsoa lisebelisoa tsa elektroniki tsa bareki, lisebelisoa tsa elektroniki tsa likoloi, sebaka sa sefofane, lisebelisoa tsa bongaka, likhokahano tsa mehala le tse ling. Hangata li fumanoa ka lisebelisoa tse kang li-smartphone, matlapa, liaparo, lisebelisoa tsa ho laola likoloi, lisebelisoa tsa litšoantšo tsa bongaka le lipontšo tse bonolo.

Ho phaella ho tenyetseha, e tsoetseng pele flex PCB na le melemo e meng. Ba fokotsa boholo le boima ba lisebelisoa tsa elektroniki, ba ntlafatsa botsitso ba matšoao ka ho fokotsa tahlehelo ea mats'oao le tšitiso ea motlakase (EMI), ba ntlafatsa taolo ea mocheso ka ho qhala mocheso ka katleho, ba nolofatsa kopano le liteko, 'me ba eketsa nako e telele le ts'epahalo.

Ka kakaretso, li-PCB tse tsoetseng pele tsa flex li fana ka tharollo bakeng sa meralo ea elektroniki e hlokang ho tenyetseha, ho boloka sebaka, le ts'ebetso e tšepahalang maemong a thata. Ba fana ka mefuta e mengata ea melemo e ba etsang khetho e tsebahalang bakeng sa lits'ebetso tsa sejoale-joale tsa elektroniki.

HDI

Thekenoloji

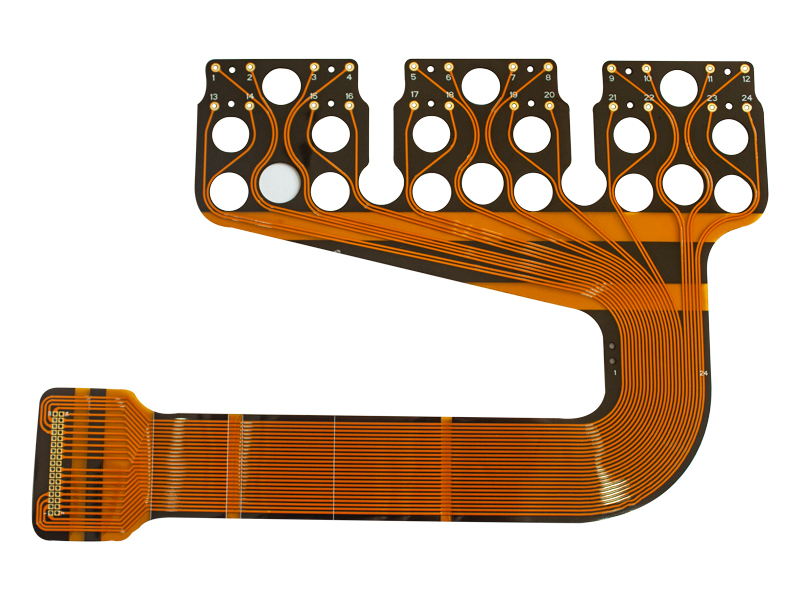

Theknoloji ea High-density interconnect (HDI) e ka sebelisoa ho li-PCB tse feto-fetohang, tse lumellang ho fokotsa likaroloana le tšebeliso ea liphutheloana tse hlakileng haholoanyane. Sena se etsa hore ho be le sekhahla se phahameng sa potoloho, ho fetisoa ha mats'oao ho ntlafalitsoeng le ts'ebetso e eketsehileng ka har'a sephutheloana se senyenyane.

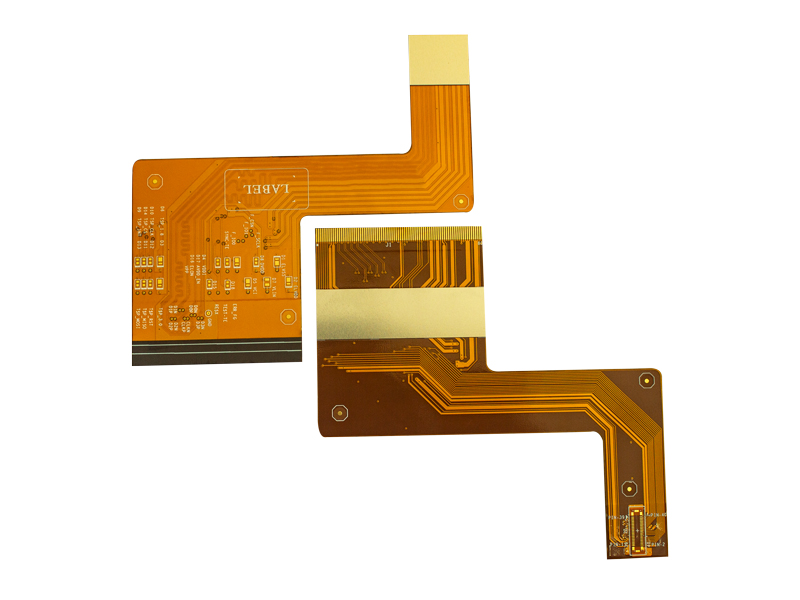

Theknoloji ea Flex-to-Install

E lumella PCB hore e kobehe pele kapa e mennoe nakong ea ts'ebetso ea tlhahiso, e nolofalletsa ho kenya le ho kena libakeng tse thata. Sena se bohlokoa haholo lits'ebetsong tse haelloang ke sebaka, joalo ka lisebelisoa tse ka roaloang, lisensara tsa IoT, kapa li-implants tsa bongaka.

Embedded Components

Kopanya likarolo tse kentsoeng joalo ka li-resistors, li-capacitor kapa lisebelisoa tse sebetsang ka kotloloho ho substrate e feto-fetohang. Ho kopanya hona ho boloka sebaka, ho fokotsa ts'ebetso ea kopano, le ho ntlafatsa botšepehi ba pontšo ka ho fokotsa bolelele ba ho hokahanya.

Tsamaiso ea Mocheso

E kopantsoe le theknoloji e tsoetseng pele ea tsamaiso ea mocheso ho felisa mocheso ka katleho. Sena se ka kenyelletsa tšebeliso ea lisebelisoa tse tsamaisang mocheso oa mocheso, li-vias tsa mocheso, kapa lisinki tsa mocheso. Tsamaiso e nepahetseng ea mocheso e tiisa hore likarolo tsa PCB li sebetsa ka har'a meeli ea mocheso oa tsona, ho ntlafatsa botšepehi le bophelo bohle.

Khanyetso ea Tikoloho

E mamella maemo a thata, ho kenyeletsoa mocheso o feteletseng, mongobo o phahameng, ho thothomela kapa ho pepesehela lik'hemik'hale. Sena se finyelloa ka tšebeliso ea lisebelisoa tse khethehileng le liphahlo tse eketsang ho hanyetsa lintlha tsena tsa tikoloho, ho etsa hore li-PCB li tšoanelehe bakeng sa likopo tsa likoloi, tsa indasteri kapa tsa ka ntle.

Moralo bakeng sa Tlhahiso

Ela hloko lintlha tse matla tsa DFM ho netefatsa tlhahiso e sebetsang hantle le e baballang chelete e ngata. Sena se kenyelletsa ho ntlafatsa boholo ba phanele, mekhoa ea ho kopanya le mekhoa ea tlhahiso ho fokotsa litšila, ho eketsa chai le ho fokotsa litšenyehelo tsa tlhahiso ka kakaretso.

Ho tšepahala le ho tšoarella

Ka tlhahlobo e matla le ts'ebetso ea taolo ea boleng ho netefatsa ho ts'epahala le ho tšoarella. Sena se kenyelletsa tlhahlobo ea ts'ebetso ea motlakase, ho tenyetseha ha mochini, ho solderability le likarolo tse ling ho netefatsa hore li-PCB li fihlela maemo a indasteri le litlhoko tsa bareki.

Dikgetho tsa ho itlhophisa

Fana ka likhetho tsa ho itlhophisa ho fihlela litlhoko tse ikhethileng tsa ts'ebeliso, ho kenyelletsa libopeho tse ikhethileng, boholo, meralo ea li-stackup le likarolo tse ikhethang tse ipapisitseng le litlhoko tsa sehlahisoa sa ho qetela.