Li-PCB tsa High-Precision ke eng

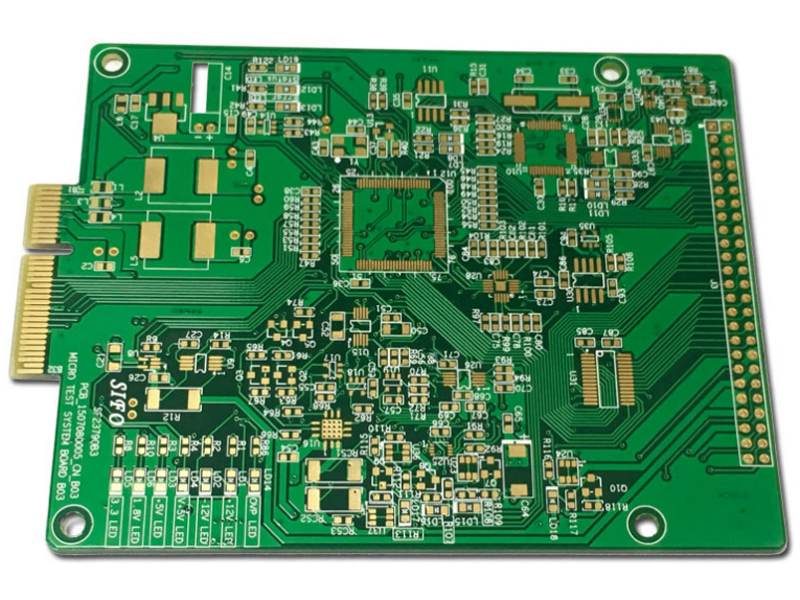

Boto ea potoloho e hatisitsoeng ka nepo e phahameng, e tsejoang hape e le boto ea potoloho e hatisitsoeng ka nepo,

ke karolo ea elektroniki e sebelisoang haholo lits'ebetsong tse hlokang lipotoloho tse nepahetseng le tse nepahetseng.

Li-PCB tsena li entsoe le ho etsoa ka tlhokomelo e kholo ho lintlha, ho netefatsa boemo bo phahameng ka ho fetisisa ba ho nepahala le ho tšepahala.

Li-PCB tse nepahetseng haholo li sebelisoa haholo liindastering tse kang sefofane, lisebelisoa tsa bongaka, likhokahano tsa mehala le likoloi. Li bohlokoa haholo lits'ebetsong tse hlokang ho nepahala ha matšoao a mats'oao, ts'ebetso ea maqhubu a holimo, mamello e tiileng, le kopanyo e tsoetseng pele ea theknoloji.

Li-PCB tsena ka tloaelo li etsoa ho sebelisoa lits'ebetso le mekhoa e tsoetseng pele joalo ka mehala e laoloang ea impedance, likarolo tse ntle tsa molumo, li-micro vias, li-vias tse foufetseng le tse patiloeng, le likhokahano tse phahameng tsa segokanyipalo. Li ka boela tsa kenyelletsa mekhahlelo e mengata, lipotoloho tse rarahaneng le lisebelisoa tse khethehileng ho finyella litlhoko tse khethehileng tsa kopo e reriloeng.

Mokhoa oa ho etsa li-PCB tse nepahetseng haholo o kenyelletsa mehato e tiileng ea taolo ea boleng, ho kenyeletsoa liteko tse matla le mekhoa ea ho hlahloba, ho netefatsa hore sehlahisoa sa ho qetela se kopana le lintlha tse hlokahalang. Ho nepahala le ho nepahala hona ho nolofalletsa ts'ebetso e sebetsang hantle le e ts'epahalang, haholo lits'ebetsong tse rarahaneng tsa elektroniki.

CAPEL High-Precision PCBs

Li-PCB tse nepahetseng haholo li etselitsoe ho fana ka likhokahano tsa motlakase tse tšepahalang le tse nepahetseng. Ba etsa lits'ebetso tse fapaneng tsa tlhahiso ea litsebi 'me ba latela moralo o tiileng le litekanyetso tsa liteko ho fihlela litlhoko tse ikhethileng tsa lits'ebetso tse hlokang liindasteri tse fapaneng.

Lisebelisoa tsa boleng bo holimo

Li-PCB tsa boleng bo holimo hangata li etsoa ka thepa ea boleng bo holimo, joalo ka lilaete tse khethehileng tsa lebelo le phahameng kapa lirafshoa tse tsoetseng pele. Lisebelisoa tsena li na le thepa e khethehileng e thusang ho ntlafatsa ts'ebetso ea motlakase ea PCB le botšepehi ba matšoao.

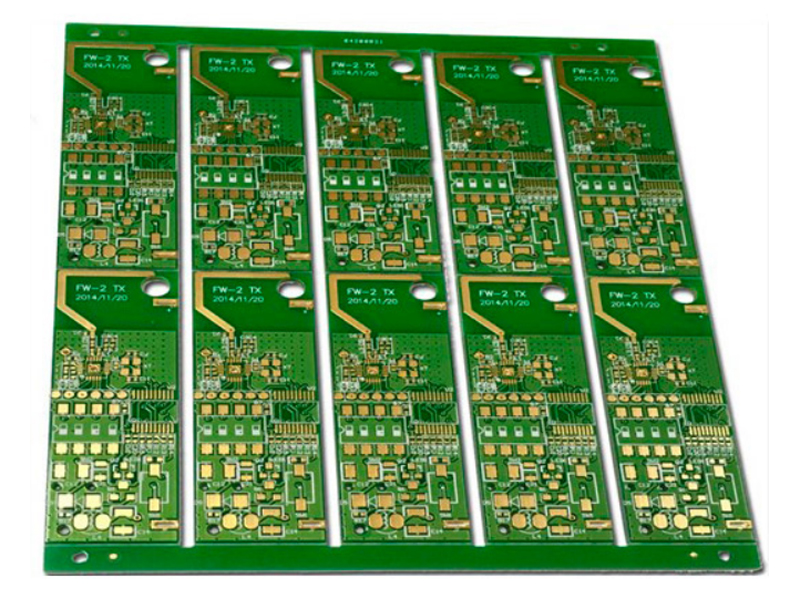

Multi-Layer Structure

Li-PCB tse nepahetseng haholo hangata li na le sebopeho sa mekhahlelo e mengata, se nolofalletsang meralo e rarahaneng le e teteaneng ea potoloho. Kaho e nang le mekhahlelo e mengata e thusa ho ntlafatsa ho itšehla thajana, ho fokotsa li-crosstalk le ho ntlafatsa kabo ea matla.

Fine Line le Space

Li-PCB tse nepahetseng haholo hangata li hloka mohala o motle haholo le bophara ba sebaka, hangata li lekantsoeng ka li-microns. Mesaletsa ena e moqotetsane e lumella ho tsamaisa mats'oao hantle le ho fokotsa tahlehelo kapa tšitiso.

Impedans e Laolang

Taolo ea impedance e bohlokoa bakeng sa ho boloka botšepehi ba matšoao lits'ebetsong tse potlakileng haholo. PCB e nepahetseng e laola tšitiso ea trace eohle hore e tsamaellane le semelo se hlokoang ke moralo.

Theknoloji e tsoetseng pele

Li-PCB tse nepahetseng haholo hangata li sebelisa mahlale a tsoetseng pele a tlhahiso joalo ka ho cheka ka laser le ho nka litšoantšo ka kotloloho. Ho cheka ka laser ho etsa hore ho be le tse nyane, tse nepahetseng haholoanyane ka litekanyo, ha litšoantšo tse tobileng li etsa hore ho ngolisoe maske a solder ka nepo.

Tlhahlobo le Tlhahlobo

Taolo ea boleng e bohlokoa bakeng sa li-PCB tse nepahetseng haholo. Mekhoa ea tlhahlobo e matla le tlhahlobo e kang automated Optical inspection (AOI) le tlhahlobo ea X-ray e sebelisoa ho hloaea mefokolo kapa mathata afe kapa afe le ho netefatsa hore PCB e kopana le lintlha tse hlokahalang.

Moralo bakeng sa Tlhahiso

Li-PCB tse nepahetseng haholo li hloka lintlha tse felletseng tsa DFM nakong ea moralo ho netefatsa hore meralo e ka etsoa ka bokhabane le ka nepo. Mekhoa ea DFM e thusa ho ntlafatsa moralo oa ts'ebetso ea tlhahiso le ho eketsa chai e akaretsang ea tlhahiso.

Likaroloana tsa Miniaturized

Li-PCB tse nepahetseng haholo hangata li etselitsoe ho amohela likaroloana tse nyane joalo ka lisebelisoa tsa holim'a metsi li-microelectromechanical system (MEMS). Ho beoa ka nepo le ho soasoa ha likaroloana tsena tse nyane ho kenya letsoho ho nepahala le tšebetso ea PCB ka kakaretso.