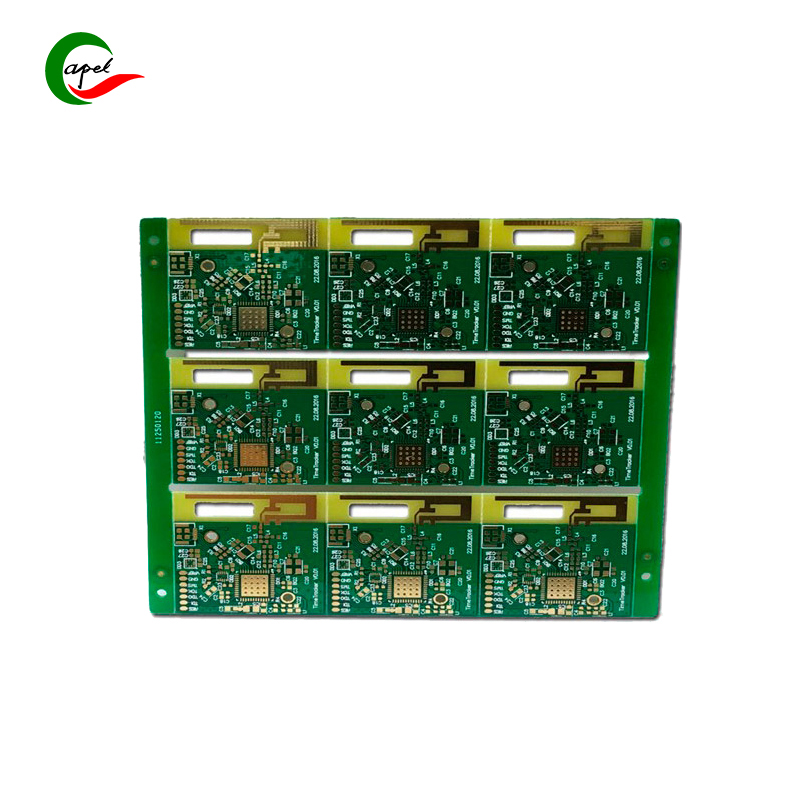

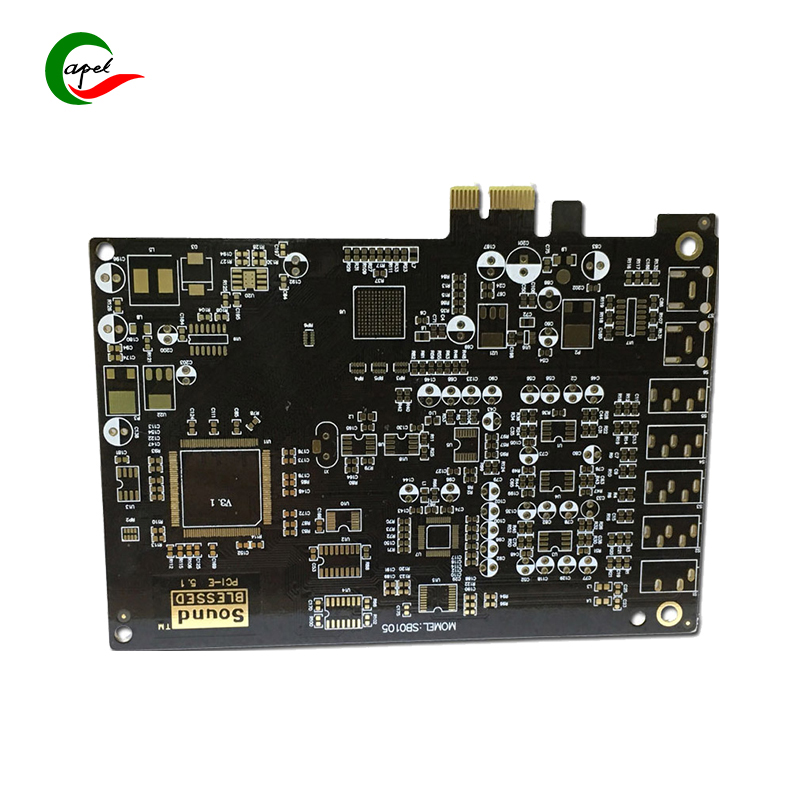

6 Layer PCB Circuit Boards Rapid Pcb Prototyping Pcb Manufacturer China

Matla a Ts'ebetso ea PCB

| Che. | Morero | Lipontšo tsa tekheniki |

| 1 | Lera | 1-60(lera) |

| 2 | Boholo ba sebaka sa ho sebetsa | 545 x 622 limilimithara |

| 3 | Botenya bo fokolang | 4(lera)0.40mm |

| 6(lera) 0.60mm | ||

| 8(lera) 0.8mm | ||

| 10(lera)1.0mm | ||

| 4 | Bophara bo fokolang ba mola | 0.0762 limilimithara |

| 5 | Sebaka se fokolang | 0.0762 limilimithara |

| 6 | Mocheso o fokolang oa ho bula | 0.15 limilimithara |

| 7 | Sekoti lebota botenya ba koporo | 0.015 limilimithara |

| 8 | Metallized aperture tolerance | ± 0.05 limilimithara |

| 9 | Mamello e se nang metale aperture | ± 0.025mm |

| 10 | Ho mamellana le lesoba | ± 0.05 limilimithara |

| 11 | Mamello ya dimensional | ± 0.076 limilimithara |

| 12 | Borokho bo fokolang ba solder | 0.08 limilimithara |

| 13 | Insulation resistance | 1E+12Ω (e tloaelehileng) |

| 14 | Karolelano ea botenya ba poleiti | 1:10 |

| 15 | Tšisinyeho ea mocheso | 288 ℃ (makhetlo a 4 ka metsotsoana e 10) |

| 16 | E khopamisitsoe ebile e kobehile | ≤0.7% |

| 17 | Matla a khahlanong le motlakase | ~1.3KV/mm |

| 18 | Matla a thibelang ho hlobola | 1.4N/mm |

| 19 | Solder hanela boima | ≥6H |

| 20 | Ho lieha ha lelakabe | 94V-0 |

| 21 | Taolo ea impedance | ±5% |

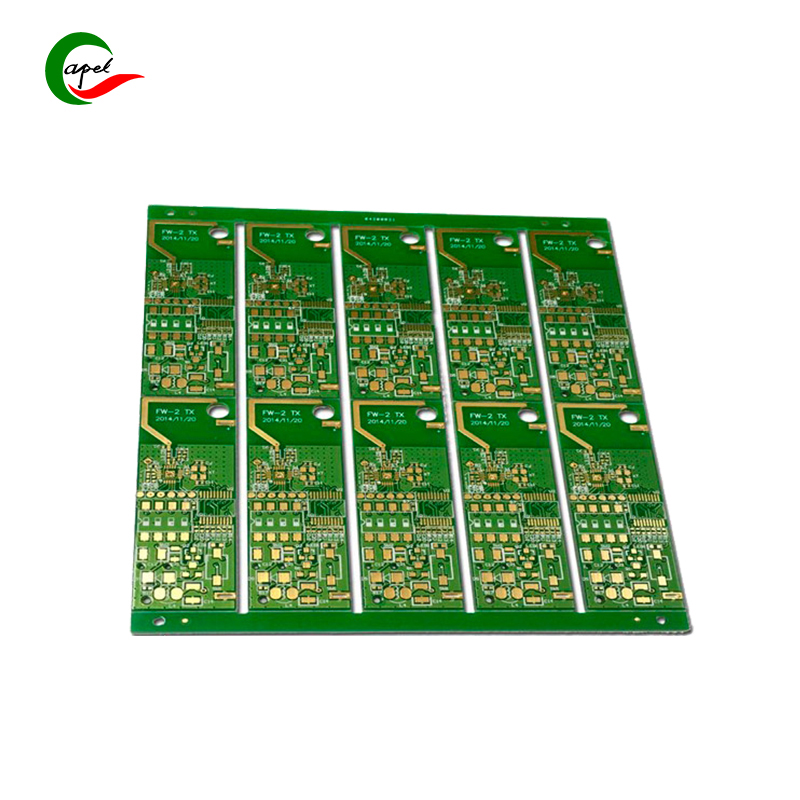

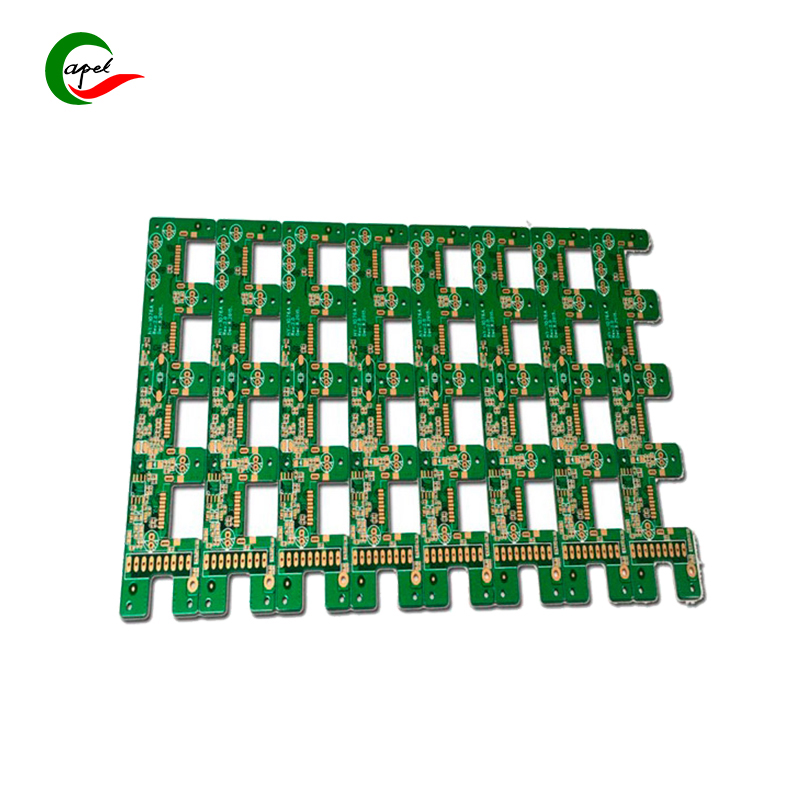

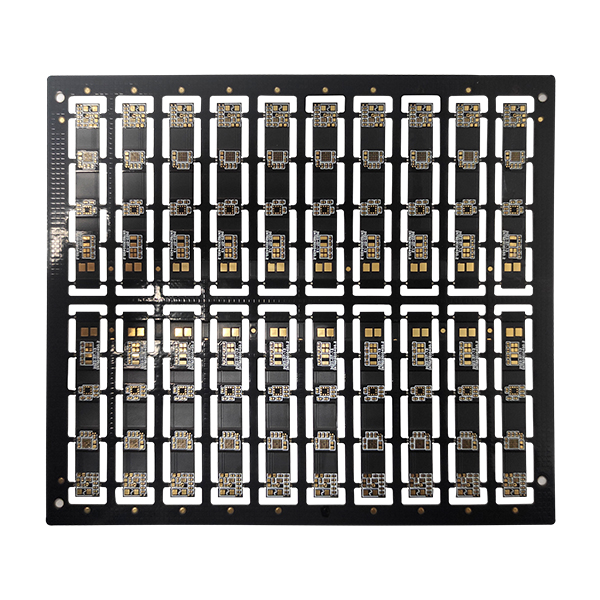

Re etsa mohlala oa liboto tsa potoloho ea PCB ka boiphihlelo ba lilemo tse 15 ka botsebi ba rona

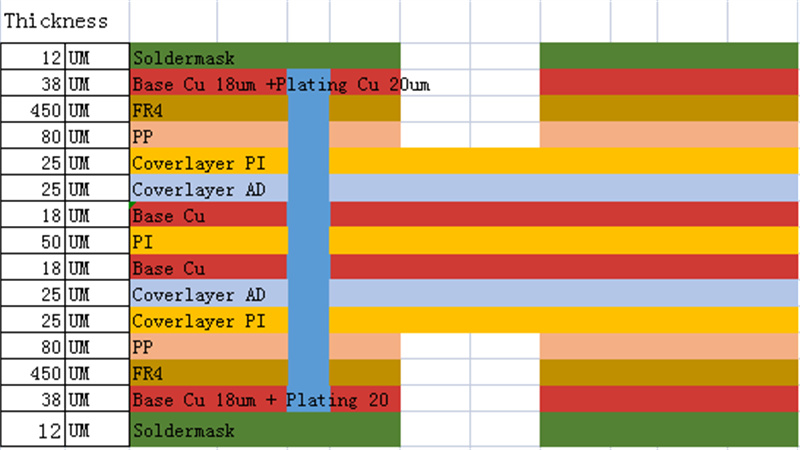

4 lera Flex-Rigid Boards

8 lera Rigid-Flex PCBs

8 lera HDI PCBs

Lisebelisoa tsa Teko le Tlhahlobo

Teko ea microscope

Tlhahlobo ea AOI

Teko ea 2D

Teko ea Impedance

Teko ea RoHS

Flying Probe

Horizontal Tester

Ho Kobeha Teste

PCB ea rona ea potoloho liboto prototype Service

. Fana ka tšehetso ea tekheniki Pele ho thekiso le ka mor'a thekiso;

. Tloaelo ho fihla ho mekhahlelo e 40, 1-2days Phetoho e potlakileng ea prototyping, Theko ea likarolo, Kopano ea SMT;

. E fana ka lisebelisoa tse peli tsa Bongaka, Taolo ea Liindasteri, Likoloi, Lifofane, Tšireletso, IOT, UAV, Lipuisano joalo-joalo.

. Lihlopha tsa rona tsa baenjiniere le bafuputsi ba ikemiselitse ho phethahatsa litlhoko tsa hau ka ho nepahala le ka botsebi.

Mokhoa oa ho khetha moetsi ea nang le boiphihlelo le ea matla bakeng sa ho paka liboto tsa potoloho tse 6-layer.

1. Sheba lentsoe-ea-molomo le tlhahlobo: utloisisa tlhahlobo ea bareki ba bang le ho bua ka molomo ka moetsi.

Lintlha tse bohlokoa li ka fumanoa ka ho batla liforamu tsa marang-rang, mecha ea litaba ea sechaba kapa liforomo tsa litsebi bakeng sa litlhahlobo le maikutlo. Batla ba nang le botumo bo tiileng le boiphihlelo ba lilemo.

2. Boiphihlelo le botsebi: Etsa bonnete ba hore moetsi o na le phihlelo e ruileng le tsebo ea ho etsa liboto tsa potoloho tsa 6-layer.

Ithute ka nalane ea bona le semelo sa bona, ho kenyeletsoa hore na ba qetile nako e kae ba le indastering le palo ea merero eo ba e qetileng.

3. Bokhoni ba tekheniki le lisebelisoa: Hlahloba hore na moetsi o na le lisebelisoa tse tsoetseng pele le theknoloji ea ho etsa liboto tsa potoloho tse 6-layer.

Ithute ka bokhoni ba bona ba ho etsa liboto tse rarahaneng le likopano tse nang le sekhahla se phahameng ho netefatsa hore ba ka fihlela litlhoko tsa hau.

4. Taolo ea boleng: Utloisisa mokhoa oa ho laola boleng ba moetsi le ts'ebetso. Na ba na le litekanyetso tse thata tsa taolo ea boleng le lisebelisoa tse nepahetseng tsa tlhahlobo ho netefatsa boleng ba sehlahisoa, joalo ka hore na ba ka kenya tšebetsong sistimi ea taolo ea boleng ea ISO 9001.

5. Botšepehi le ho fana ka thepa: Lekola ho tšepahala le ho fana ka thepa ea mofani oa thepa. Na ba khona ho phetha merero ka nako le ho fana ka linako tse nepahetseng tsa ho fana. Botsa hore na ba na le leano la ho boloka lintho tsa tšohanyetso haeba ho ka ba le tieho kapa liketsahalo tse sa lebelloang.

6. Bua le bareki ba teng: Haeba ho khoneha, bua le bareki ba seng ba ntse ba le teng ba mofani oa thepa. Ithute ka phihlelo ea bona ea tšebelisano-'moho le khotsofalo, hammoho le boikutlo ba ho sebetsa ba moetsi le lebelo la karabo.

7. Puisano kapa buisana le bahlahisi: etsa lipuisano kapa buisana le bao e ka bang bahlahisi, 'me u ba botse ka litlhoko tsa bopaki le litlhoko tsa tekheniki. Sheba hore na likarabo tsa bona le litlhaloso tsa bona li nepahetse, li nepahetse, li nepahetse ebile lia khotsofatsa, e le hore u ka ahlola hore na ba na le phihlelo le matla ao u a hlokang.

8. Theko le tšebeletso: Qetellong, nahana ka theko le tšebeletso ea ka mor'a thekiso ka botlalo. Etsa bonnete ba hore theko e ea utloahala 'me e fana ka tšehetso e nepahetseng ka mor'a thekiso, joalo ka lipuisano tsa tekheniki, tlhahlobo ea tlhahiso le ho rarolla mathata, joalo-joalo.

The proofing process of a 6 layer PCB circuit boards

1. Etsa moralo oa setšoantšo sa potoloho le moralo: pele u qapa setšoantšo sa potoloho ea potoloho le moralo ho latela litlhoko tsa moralo oa potoloho. Ena ke mohato oa bohlokoa oa ho khetholla boholo ba boto, melao ea ho tsamaisa, ho beha lisebelisoa, le tse ling.

2. Etsa lifaele tsa boto ea potoloho: Sebelisa software ea moralo oa PCB ho fetolela meralo ea potoloho le meralo hore e be lifaele tsa boto ea potoloho.

Lifaele tsena hangata li kenyelletsa lifaele tsa Gerber, lifaele tsa drill, lifaele tsa soldermask, joalo-joalo.

3. Netefatsa moralo: Pele boto ea potoloho e etsoa, moralo oa potoloho o netefatsoa. Netefatsa hore moralo oa boto ea hau ha o na liphoso le mathata a tlhahiso ka ho etsa papiso ea potoloho le tlhahlobo ea DFM (Design for Manufacturability).

4. Fana ka taelo: Fana ka litokomane tsa boto le litlhoko tse tsamaellanang tsa tlhahiso ho moetsi oa boto. Hangata hoa hlokahala ho fana ka sebopeho sa faele, lisebelisoa tsa boto ea potoloho, palo ea likarolo, litlhoko tsa pad, 'mala oa mask oa solder, litlhoko tsa skrine ea silika, litlhoko tsa ts'ebetso, joalo-joalo.

5. Boto ea potoloho ea tlhahiso: Moetsi oa boto ea potoloho o hlahisa ho latela litokomane tse fanoeng.

Sena se kenyelletsa ho sebelisa lifilimi tse tšesaane ho etsa lipaterone tsa boto ea potoloho e hatisitsoeng, ho ts'oaroa ha lik'hemik'hale kapa machining ho tlosa likarolo tse sa batleheng tsa koporo, ho cheka, ho penta ka koporo, ho koahela (li-pads, soldermask, silkscreen), dicing le lits'ebetso tse ling.

6. Etsa tlhahlobo ea ts'ebetso: Etsa tlhahlobo ea ts'ebetso ho boto e le 'ngoe e entsoeng ho netefatsa ts'ebetso ea eona e tloaelehileng.

7. Bokella boto ea potoloho: kenya boto ea potoloho ka har'a lisebelisoa tse lumellanang bakeng sa tlhahlobo ea ts'ebetso kapa ts'ebeliso e sebetsang.

8. Lekola liphetho tsa bopaki: Kamora ho amohela boto ea potoloho ea bopaki, etsa tlhahlobo e felletseng.

Hlahloba hore na ponahalo le boholo ba boto ea potoloho li finyella litlhoko, hlahloba pad le boleng ba welding, 'me u leke hore na ts'ebetso le ts'ebetso ea boto ea potoloho li tloaelehile.

9. Phetoho le ho ntlafatsa: Etsa liphetoho tse hlokahalang le ho ntlafatsa ho latela liphetho tsa tlhahlobo.

Haeba boto ea potoloho e fumanoa e e-na le mathata kapa e hloka ho ntlafatsoa, lifaele tsa moralo li ka fetoloa ka tsela e nepahetseng.

10. Ho netefatsa hape: Haeba boto ea potoloho e na le palo e kholo ea phetoho kapa ho hlokahala ho pheta-pheta hangata, ho ka etsoa bopaki bo bocha.

Pheta mokhoa o fetileng, romella faele fekthering bakeng sa tlhahiso hape, 'me u hlahlobe le ho ntlafatsa hape.

11. Tlhahiso ea bongata: Ha moralo le ts'ebetso ea boto ea potoloho e khotsofatsa, tlhahiso ea bongata e ka etsoa. Bahlahisi ba hlahisa ho ea ka lifaele tsa ho qetela tsa moralo, 'me ba hlahisa liboto tse ngata tsa potoloho ho fana ka bareki.

12. Latela le ho laola ketane ea phepelo: Ho bohlokoa haholo ho latela le ho laola ketane ea phepelo nakong eohle ea ho paka le ho hlahisa lihlahisoa tse ngata.

Netefatsa phepelo ea thepa, ntlafatsa tsoelo-pele ea tlhahiso ka nako, litokisetso tsa thepa, joalo-joalo, 'me u netefatse hore ho tsamaisoa ka nako ea liboto tsa potoloho.