Mahlakore Habeli Potoloho Boards Prototype Pcb Manufacturer

Bokhoni ba Ts'ebetso ea PCB

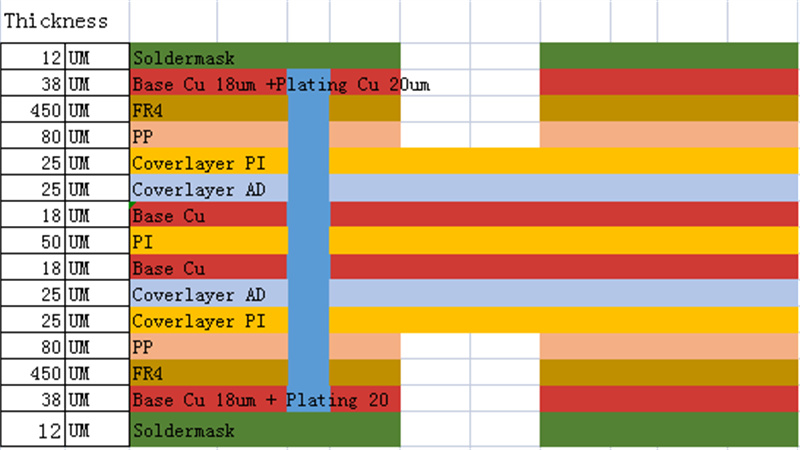

| Che. | Morero | Lipontšo tsa tekheniki |

| 1 | Lera | 1-60(lera) |

| 2 | Boholo ba sebaka sa ho sebetsa | 545 x 622 limilimithara |

| 3 | Botenya bo fokolang | 4(lera)0.40mm |

| 6(lera) 0.60mm | ||

| 8(lera) 0.8mm | ||

| 10(lera)1.0mm | ||

| 4 | Bophara bo fokolang ba mola | 0.0762 limilimithara |

| 5 | Sebaka se fokolang | 0.0762 limilimithara |

| 6 | Mocheso o fokolang oa ho bula | 0.15 limilimithara |

| 7 | Sekoti lebota botenya ba koporo | 0.015 limilimithara |

| 8 | Metallized aperture tolerance | ± 0.05 limilimithara |

| 9 | Mamello e se nang metallized aperture | ± 0.025 limilimithara |

| 10 | Ho mamellana le lesoba | ± 0.05 limilimithara |

| 11 | Mamello ya dimensional | ± 0.076 limilimithara |

| 12 | Borokho bo fokolang ba solder | 0.08 limilimithara |

| 13 | Insulation resistance | 1E+12Ω (e tloaelehileng) |

| 14 | Karolelano ea botenya ba poleiti | 1:10 |

| 15 | Tšisinyeho ea mocheso | 288 ℃ (makhetlo a 4 ka metsotsoana e 10) |

| 16 | E khopamisitsoe ebile e kobehile | ≤0.7% |

| 17 | Matla a khahlanong le motlakase | ~1.3KV/mm |

| 18 | Matla a thibelang ho hlobola | 1.4N/mm |

| 19 | Solder hanela boima | ≥6H |

| 20 | Ho lieha ha lelakabe | 94V-0 |

| 21 | Taolo ea impedance | ±5% |

Re etsa Circuit Boards Prototyping ka boiphihlelo ba lilemo tse 15 ka botsebi ba rona

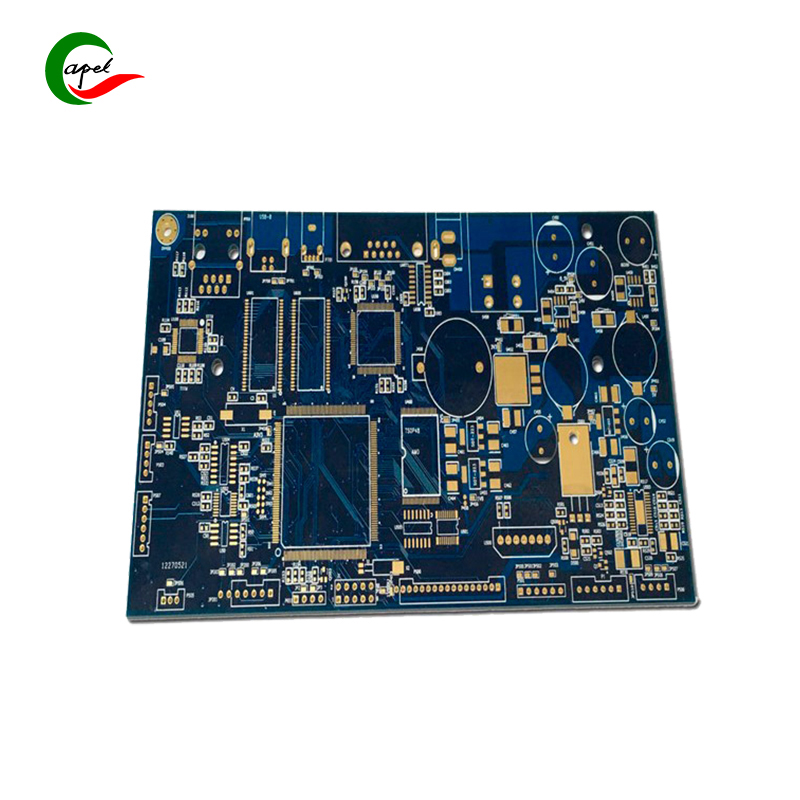

4 lera Flex-Rigid Boards

8 lera Rigid-Flex PCBs

8 lera HDI Printed Circuit Boards

Lisebelisoa tsa Teko le Tlhahlobo

Teko ea microscope

Tlhahlobo ea AOI

Teko ea 2D

Teko ea Impedance

Teko ea RoHS

Flying Probe

Horizontal Tester

Ho Kobeha Teste

Tšebeletso ea Prototyping ea Liboto tsa rona tsa Potoloho

. Fana ka tšehetso ea tekheniki Pele ho thekiso le ka mor'a thekiso;

. Tloaelo ho fihla ho mekhahlelo e 40, 1-2days Phetoho e potlakileng ea prototyping, Theko ea likarolo, Kopano ea SMT;

. E fana ka lisebelisoa tse peli tsa Bongaka, Taolo ea Liindasteri, Likoloi, Lifofane, Lisebelisoa tsa Bareki, IOT, UAV, Lipuisano joalo-joalo.

. Lihlopha tsa rona tsa baenjiniere le bafuputsi ba ikemiselitse ho phethahatsa litlhoko tsa hau ka ho nepahala le ka botsebi.

Mokhoa oa ho etsa liboto tsa boleng bo holimo tse nang le mahlakore a mabeli a potoloho?

1. Rala boto: Sebelisa software ea computer-aid design (CAD) ho etsa moralo oa boto. Netefatsa hore moralo o kopana le litlhoko tsohle tsa motlakase le tsa mochini, ho kenyeletsoa bophara ba sebaka, sebaka, le ho beoa ha likaroloana. Nahana ka lintlha tse kang botšepehi ba matšoao, kabo ea matla, le tsamaiso ea mocheso.

2. Prototyping le liteko: Pele ho tlhahiso ea bongata, ho bohlokoa ho theha boto ea prototype ho netefatsa moralo le ts'ebetso ea tlhahiso. Lekola li-prototype ka botlalo bakeng sa ts'ebetso, ts'ebetso ea motlakase, le tšebelisano ea mochini ho tseba mathata afe kapa afe a ka bang teng.

3. Khetho ea Lintho: Khetha thepa ea boleng bo holimo e lumellanang le litlhoko tsa hau tse khethehileng tsa boto. Likhetho tse tloaelehileng tsa thepa li kenyelletsa FR-4 kapa mocheso o phahameng oa FR-4 bakeng sa substrate, koporo bakeng sa mesaletsa ea conductive, le mask a solder ho sireletsa likarolo.

4. Etsa lera le ka hare: Qala ka ho lokisa lera le ka hare la boto, le kenyelletsang mehato e mengata:

a. Hloekisa le ho roughen ea koporo clad laminate.

b. Etsa kopo e tšesaane ea photosensitive e omeletseng filimi holim'a koporo.

c. Filimi e pepesetsoa khanya ea ultraviolet (UV) ka sesebelisoa sa lifoto se nang le mokhoa o lakatsehang oa potoloho.

d. Filimi e hlahisoa ho tlosa libaka tse sa tsejoeng, ho siea mokhoa oa potoloho.

e. Etch koporo e pepesitsoeng ho tlosa thepa e feteletseng e siea feela mesaletsa le lipache tse lakatsehang.

F. Lekola lera le ka hare bakeng sa bofokoli leha e le bofe kapa ho kheloha moralong.

5. Laminates: Mekhahlelo e ka hare e kopantsoe le prepreg ka mochine oa khatiso. Mocheso le khatello li sebelisoa ho tlama lihlopha le ho theha phanele e matla. Etsa bonnete ba hore likarolo tse ka hare li hlophisitsoe hantle 'me li ngolisitsoe ho thibela ho se lumellane hofe kapa hofe.

6. Ho cheka: Sebelisa mochine o nepahetseng oa ho phunya ho phunya masoba bakeng sa ho kenya likarolo le ho hokahanya. Mefuta e fapaneng ea likotoana tsa ho cheka li sebelisoa ho latela litlhoko tse khethehileng. Netefatsa bonnete ba sebaka sa lesoba le bophara.

Mokhoa oa ho etsa liboto tsa boleng bo holimo tse nang le mahlakore a mabeli a potoloho?

7. Motlakase oa Koporo oa Motlakase: Sebelisa lesela le lesesaane la koporo libakeng tsohle tse ka hare tse pepeneneng. Mohato ona o netefatsa conductivity e nepahetseng 'me o thusa mokhoa oa ho roala ka mehato e latelang.

8. Litšoantšo tse ka ntle tsa lera: Ho tšoana le mokhoa o ka hare oa lera, filimi e omeletseng ea photosensitive e koahetsoe holim'a lera le ka ntle la koporo.

E pepese leseli la UV ka sesebelisoa se holimo sa lifoto 'me u ntlafatse filimi ho hlahisa mokhoa oa potoloho.

9. Etching ea ka ntle ea lera: Tlosa koporo e sa hlokahaleng holim'a lera le ka ntle, u siee mesaletsa le lipache tse hlokahalang.

Sheba lera le ka ntle bakeng sa mefokolo kapa liphapang.

10. Solder Mask le Legend Printing: Sebelisa lisebelisoa tsa mask a solder ho sireletsa mesaletsa ea koporo le liphaephe ha u tloha sebakeng sa ho kenya likarolo. Hatisa litšōmo le matšoao holim'a likarolo tse ka holimo le tse ka tlase ho bontša sebaka sa likarolo, polarity, le lintlha tse ling.

11. Boitokisetso ba Bokaholimo: Ho lokisoa ha bokaholimo ho sebelisoa ho sireletsa bokaholimo ba koporo bo pepeneng ho tsoa ho oxidation le ho fana ka sebaka se solderable. Likhetho li kenyelletsa hot air leveling (HASL), electroless nickel mersion gold (ENIG), kapa liphetho tse ling tse tsoetseng pele.

12. Tsamaiso le Ho Theha: Liphanele tsa PCB li khaoloa ka liboto ka bomong ho sebelisa mochini oa ho tsamaisa kapa mokhoa oa V-scribing.

Etsa bonnete ba hore mathōko a hloekile le litekanyo li nepahetse.

13. Teko ea Motlakase: Etsa tlhahlobo ea motlakase e kang tlhahlobo ea ho tsoela pele, litekanyo tsa ho hanyetsa, le ho hlahloba ho itšehla thajana ho netefatsa hore ho sebetsa le ho tšepahala ha mapolanka a entsoeng.

14. Taolo ea Boleng le Tlhahlobo: Liboto tse felileng li hlahlojoa ka botlalo bakeng sa mefokolo leha e le efe ea tlhahiso e kang marikhoe a makgutshwane, a bulang, a sa nepahalang kapa a nang le mefokolo. Ho kenya ts'ebetsong mekhoa ea ho laola boleng ho etsa bonnete ba ho lateloa ke melao le litekanyetso.

15. Ho Paka le ho Romela: Ka mor'a hore boto e fetise tlhahlobo ea boleng, e phuthetsoe ka mokhoa o sireletsehileng ho thibela tšenyo nakong ea ho romelloa.

Etsa bonnete ba ho ngola le litokomane tse nepahetseng ho latela le ho khetholla liboto ka nepo.