Boemong ba nts'etsopele e potlakileng ea sebaka se secha sa matla, tlhokahalo ea liboto tse tsoetseng pele tsa taolo ea indasteri ea PCB e eketsehile, e tlisitseng menyetla le liphephetso tse kholo.Joalo ka moenjineri ea nang le boiphihlelo o thata oa PCB ea nang le boiphihlelo bo fetang lilemo tse 15 hotlhahiso ea PCB ea taolo ea indasteriindasteri, ke na le tokelo ea ho etella pele nts'etsopele le ts'ebetsong ea mekhoa ea theknoloji ea morao-rao ho finyella litlhoko tse ikhethang tsa lekala le lecha la matla.Sehloohong sena, re tla hlahloba litharollo tse ncha tse re nolofalletsang ho feta litekanyetso tsa indasteri le ho fana ka ts'ebetso e nepahetseng ho bareki ba rona, re tšehetsoa ke lithuto tse atlehileng tse totobatsang katleho ea mokhoa oa rona.

Mathata tšimong ea matla a macha

Lekala le lecha la eneji le akaretsa mefuta e mengata ea thekenoloji le lits'ebetso, ho kenyeletsoa litsamaiso tsa matla a tsosolositsoeng, lisebelisoa tsa polokelo ea matla, le meaho ea makoloi a motlakase, e 'ngoe le e' ngoe e na le mathata le litlhoko tsa eona.Ho ts'ehetsa ts'ebetso e se nang moeli le e sebetsang ea litsamaiso tsena, liboto tsa PCB tsa taolo ea indasteri li tlameha ho bonts'a ts'ebetso e ikhethang, ts'epahalo le ts'ebetso ha li ntse li hlola boholo, boima le meeli ea tšebeliso ea matla.Ho feta moo, maemo a thata a tikoloho eo lits'ebetso tsena li tobanang le tsona hangata li hloka meralo e thata e ka mamellang mocheso o feteletseng, ho thothomela le mongobo ntle le ho senya ts'ebetso.

Ha re tobane le liphephetso tsena, nts'etsopele e atlehileng le ho romelloa ha taolo ea indasteri ea PCB e itšetlehile ka tšebeliso ea theknoloji ea morao-rao ea moralo le kutloisiso e tebileng ea litlhoko tse khethehileng tsa tšimo e ncha ea matla.Joalo ka ha liphuputso tse latelang li bonts'a, kopanyo ea boitseanape le boqapi e bohlokoa molemong oa bokhoni ba rona ba ho fana ka litharollo tse ke keng tsa bapisoa ho bareki ba rona.

Thuto-pale ea 1: Ho ntlafatsa ts'ebetso ea lisebelisoa tsa matla a ka nchafatsoang

E mong oa bareki ba rona, mofani ea ka sehloohong oa litharollo tsa letsatsi, o ile a tla ho rona bakeng sa thuso ka tlhoko e potlakileng ea ho ntlafatsa ts'ebetso ea sesebelisoa sa hae sa letsatsi.Likaroloana tsena tsa bohlokoa li fetolela hajoale (DC) e hlahisoang ke liphanele tsa letsatsi hore e be alternating current (AC) e sebelisoang malapeng le likhoebong.Joalo ka pelo ea sistimi ea letsatsi, ts'ebetso le ts'epahalo ea inverter ke tsa bohlokoa molemong oa kakaretso oa tlhahiso ea matla a letsatsi.

Ka ho hlokomela bohlokoa ba phephetso ena, sehlopha sa rona se ile sa bula maliboho nts'etsopele ea moralo oa PCB o sa fetoheng o sa finyelleng litlhoko tse thata tsa ho sebetsana le motlakase le taolo ea mocheso empa hape o fana ka nako e telele e tšoarellang le bophelo bo atolositsoeng ba ts'ebeletso.Ka ho sebelisa lisebelisoa tse tsoetseng pele le mekhoa ea meralo, re ile ra etsa tharollo e ka kopanngoang ka mokhoa o tsitsitseng ho inverter ea letsatsi ha e ntse e fana ka ts'ebetso e phahameng ka ho fetisisa mabapi le katleho ea ho fetola matla le botsitso ba ts'ebetso.Ka ho nolofatsa meralo ea ka hare le ho ntlafatsa litsela tsa mats'oao, re fihlela lintlafatso tse bonahalang ho fehleng ha motlakase oa solar, ho feta tebello ea bareki le ho kenya letsoho ho amoheloeng hohle ha mahlale a matla a tsosolositsoeng.

Thuto-pale ea 2: Ho kenya tšebetsong litsamaiso tsa polokelo ea matla a matla a phahameng

Ketsahalong e 'ngoe e qobellang, k'hamphani e etelletseng pele ea theknoloji ea polokelo ea matla e ile ea batla tsebo ea rona ea ho nts'etsapele liboto tsa PCB tsa taolo ea indasteri bakeng sa sistimi ea eona e tsoetseng pele ea taolo ea betri ea lithium-ion.E tsepamisitse maikutlo ho holiseng matla a matla le polokeho ea ts'ebetso, bareki ba rona ba re file litlhoko tse rarahaneng, tse kenyelletsang ho itšehla thajana ho matla a phahameng, taolo e nepahetseng ea mocheso, le mekhoa e matla ea ho lemoha liphoso.Ho feta moo, tlhokahalo e ntseng e hola ea litharollo tsa polokelo ea matla a compact, a bobebe a hloka mokhoa oa moralo o ka amohelang matla a matla a ntseng a phahama ntle le ho beha ts'epo kapa polokeho.

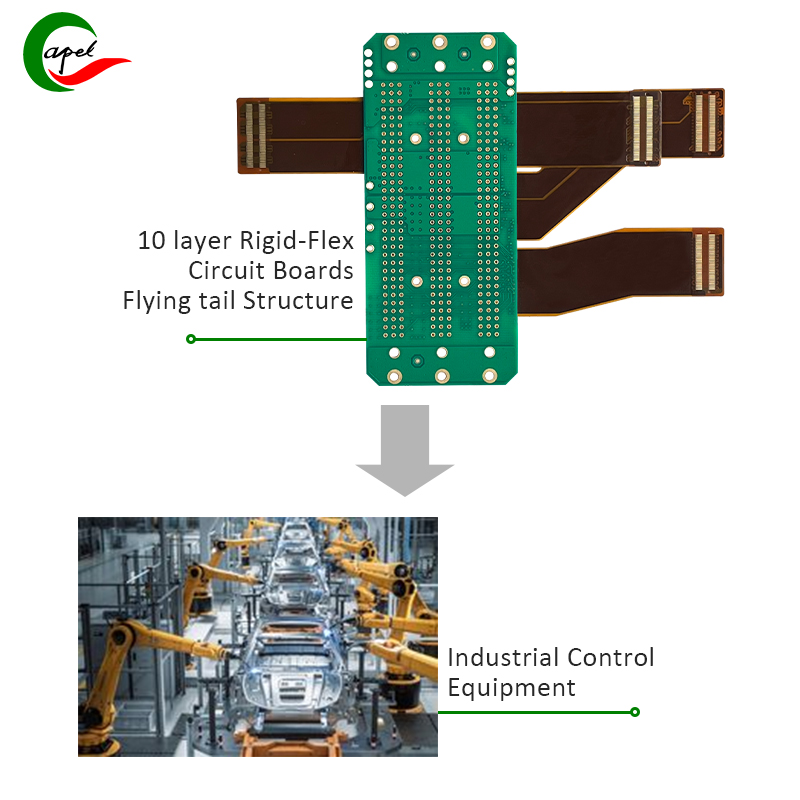

Ka ho sebelisa boiphihlelo ba rona bo pharaletseng ba moralo oa PCB o sebetsang hantle, re etsa tlhahlobo e felletseng ea lintlha tsa bareki ba rona le melaoana ea indasteri, ra rala motheo bakeng sa tharollo ea meralo e ncha e tsamaellanang le litlhoko tse ikhethang tsa lits'ebetso tsa polokelo ea matla.Ka ho sebelisa likhatelopele tsa morao-rao tsa theknoloji ea PCB ea li-multi-layer rigid-flex, re ralile meralo ea modular, e scalable e sa thuseng feela kopanyo e se nang moeli ka har'a sistimi ea taolo ea betri empa hape ntle le ho tela polokeho kapa ts'epahalo Matla a matla a ntlafatsoa haholo.Ka taolo e tsoetseng pele ea ts'ireletso, li-vias tsa mocheso, le ts'ebetso e hlokolosi ea sebopeho, ha rea ka ra nyenyefatsa feela boto ea PCB empa hape re ntlafalitse bokhoni ba eona ba ho sebetsana le litlhoko tse thata tsa litefiso tse phahameng le li-cycle tsa ho tsoa.

Ho romelloa ka katleho ha liboto tsa rona tse tsoetseng pele tsa PCB litsamaisong tsa polokelo ea matla a bareki ho ekelitse haholo matla ka kakaretso a matla le ts'ebetso ea sistimi, e ba lumellang ho fa bareki litharollo tse kopaneng le tse matla.Ho feta moo, mokhoa oa rona oa kopanelo oa ho sebetsana le melao le litaba tsa polokeho o totobatsa boitlamo ba rona ba ho fana ka litharollo tse felletseng tse tsamaellanang le maemo a ntseng a tsoela pele a indasteri e ncha ea matla.

Thuto-pale ea 3: Lisebelisuoa tsa motlakase bakeng sa lisebelisoa tsa ho tjhaja koloi ea motlakase

Lefapheng la likoloi tsa motlakase, ho ata ha likoloi tsa motlakase ho khanna tlhokahalo ea lisebelisoa tse matla le tse sebetsang tsa ho fana ka likoloi tsa motlakase (EVSE) le lisebelisoa tsa thepa ea thepa.Bokhoni ba theknoloji ea rona bo ile ba lekoa ha moetsi ea hlahelletseng oa liteishene tsa ho tjhaja likoloi tsa motlakase a batla ho ntlafatsa ts'ebetso le ts'epahalo ea litharollo tsa eona tsa ho tjhaja ka potlako ha a ntse a fokotsa mathata a amanang le kabo e phahameng ea matla le taolo ea mocheso.Ha botumo ba likoloi tsa motlakase bo ntse bo eketseha, tlhokahalo ea lisebelisoa tsa ho tjhaja ka potlako, e bolokehileng le e kotsi e ntse e bonahala haholoanyane, e totobatsang karolo ea bohlokoa ea liboto tsa PCB tsa taolo ea indasteri lits'ebetsong tsena.

E susumetsoa ke filosofi ea ho khanna mekhoa e mecha tsamaisong ea likoloi tsa motlakase, sehlopha sa rona se rala litharollo tsa PCB tsa motlakase o phahameng, tsa morao-rao tse hlophisang tšebelisano e rarahaneng ea lisebelisoa tsa elektroniki tsa motlakase, ho felloa ke mocheso le likhokahano tsa puisano ka har'a lisebelisoa tsa ho tjhaja.Ka ho matlafatsa boitseanape ba rona ba ho itšehla thajana, ho bapisa li-impedance, le likhokahano tse tšepahalang, re thehile meralo e ntlafalitsoeng ea PCB e ntlafatsang matla a seteishene sa ho tjhaja le ho bonts'a khanyetso e ntle khahlanong le likhatello tsa tikoloho le bokhoni ba ho khetholla ts'ebetso.

Liboto tsa rona tse tsoetseng pele tsa PCB li kenyelelitsoe ka katleho litsing tsa ho tjhaja likoloi tsa motlakase, li ntlafatsa haholo ts'ebetso ea ho tjhaja le ts'epahalo ea sistimi, le ho fokotsa sebaka sa seteishene sa ho tjhaja ka kakaretso.Sena le sona se thusa katoloso e se nang moeli ea marang-rang a ho tjhaja likoloi tsa motlakase, ho fa bakhanni monyetla o bonolo oa ho fumana tharollo e potlakileng, e tšepahalang ea ho tjhaja.Boitlamo ba rona ba ho sutumelletsa meeli ea thekenoloji ea boto ea PCB ea liindasteri tse nang le mahlakore a mabeli likoloing tsa motlakase li bontša boitlamo ba rona bo sa sisinyeheng ba ho khanna phetoho e ntle tšimong e ncha ea matla.

Tsoela pele ho ea pele ka boqapi le ho tšepahala

Liphuputso tsena tse tlamang li bonts'a hore mekhoa ea morao-rao ea meralo bakeng sa tlhahiso ea PCB ea taolo ea indasteri e bapala karolo ea bohlokoa ho rarolleng liqholotso tse nang le likarolo tse ngata lekaleng le lecha la eneji.Ka ho matlafatsa boitseanape ba sebaka sa marang-rang, boqapi bo tsamaisoang ke lipatlisiso, le boitlamo bo sa thekeseleng ba ho fana ka ts'ebetso e phahameng, ha re fihlelle litlhoko tsa bareki ba rona feela empa hape re kenya letsoho ho nts'etsopele ea mahlale a phetoho a fetolang matla a matla.

Ho tloha ho ntlafatsa ts'ebetso ea lits'ebetso tsa matla a tsosolositsoeng ho isa ho ho nolofalletsa litharollo tsa polokelo ea matla a matla a phahameng ho tsamaisa katoloso ea meaho ea tjhaja ea likoloi tsa motlakase, boitlamo ba rona bo sa sisinyeheng ba ho sutumelletsa meeli ea lisebelisoa tsa taolo ea indasteri ea theknoloji ea PCB ea kopano e bonts'a boiteko ba rona ba ho ntšetsa pele taolo ea indasteri Ho laola thomo e tšoarellang. ya tsoelopele le botshepehi.Lekala le lecha la matla.Ha lebelo la boqapi le ntse le eketseha le tlhokahalo ea litharollo tse tšoarellang, tse sebetsang hantle haholo li ntse li eketseha, re tsitsitse morerong oa rona oa ho etsa bokhabane ba boenjiniere hobane rea tseba hore katleho e 'ngoe le e 'ngoe eo re e fihlelang e na le monyetla oa ho bopa bokamoso ba theknoloji ea matla.

taolo e phahameng e nepahetseng ea liindasteri flex pcb iqapetsoeng tshebetso

Ka kakaretso

Theknoloji ea morao-rao ea boto ea taolo ea liindasteri ea PCB e bonts'a matla a phetoho a boqapi, ho ts'epahala, le tšebelisano 'moho lebaleng le lecha la matla.Ha re ntse re shebana le mathata le menyetla ea kamoso, re ikemiselitse ho tsoela pele ho phethahatsa tšepiso ea Tiisetso e Ntle ea Ts'ebetso, ho fa bareki ba rona le balekane ba rona mahlale a mahlale a mahlale ao ba a hlokang hore ba atlehe mehleng ea phetoho le monyetla o neng o sa lebelloa.

Ka ho sebetsana ka sebete le liqholotso tse ka pel'a rona, re tiisa boitlamo ba rona ba ho fana ka litharollo tsa mantlha tse fetang tloaelo le ho khothatsa moloko o latelang oa mahlale a matla.Ha re qaleng leetong le khannoang ke boqapi, morero, le sepheo se sa thekeseleng sa bokhabane ba boenjiniere.Bokamoso ba matla bo re emetse, joalo ka moetsi oa PCBA oa taolo ea indasteri 'me re ikemiselitse ho e bopa ka theknoloji ea morao-rao ea meralo ea FR4 Industrial Control PCB Boards.

Nako ea poso: Dec-29-2023

Morao