Tsebisa:

Ka poso ena ea blog, re tla hlahlobisisa lintlha tsa hore na likarolo tsa boto ea potoloho e thata-flex li hokahanngoa joang, ho hlahloba mekhoa e fapaneng e sebelisoang ts'ebetsong.

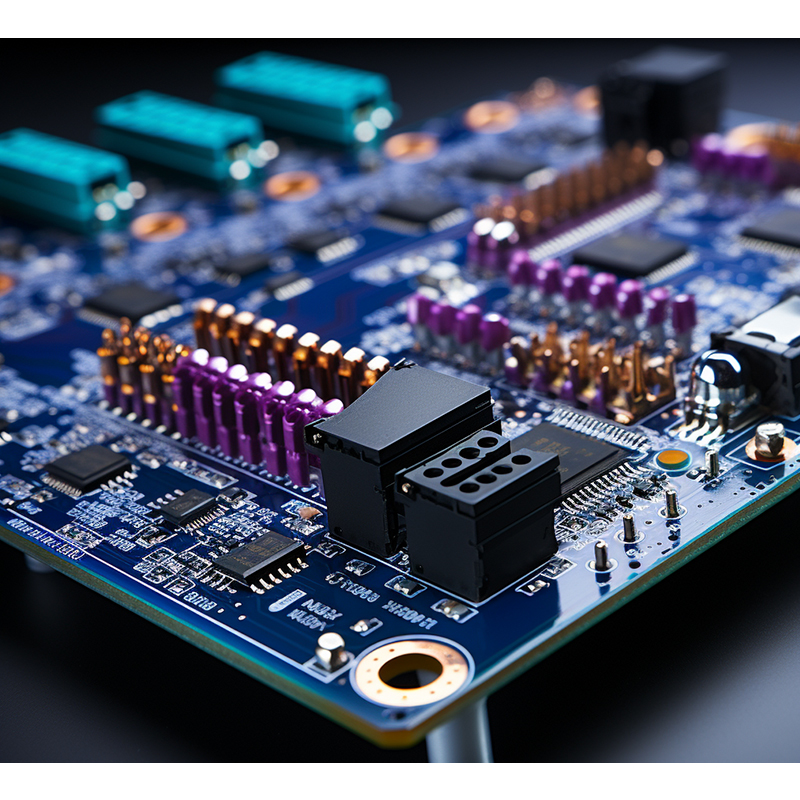

Li-circuits tsa rigid-flex li ratoa liindastering tse fapaneng ho kenyelletsa le sefofane, bongaka le lisebelisoa tsa elektroniki tsa bareki.Liboto tsena li ikhetha ka hore li kopanya li-circuits tse feto-fetohang le likarolo tse thata, tse fanang ka nako e telele le ho feto-fetoha ha maemo.E 'ngoe ea lintlha tsa bohlokoa tse netefatsang ts'ebetso le ts'epahalo ea liboto tse thata-flex ke theknoloji ea ho kopanya e sebelisetsoang ho hokahanya lihlopha tse fapaneng.

1. Theknoloji ea ho kopanya:

Theknoloji ea li-adhesive bonding e sebelisoa haholo tlhahisong ea boto ea potoloho e thata.E kenyelletsa tšebeliso ea sekhomaretsi se khethehileng se nang le sesebelisoa se phekolang mocheso.Likhomaretsi tsena li sebelisetsoa ho kopanya likarolo tse tenyetsehang le likarolo tse thata tsa liboto tsa potoloho.Sekhomaretsi ha se fane feela ka ts'ehetso ea meralo empa se boetse se tiisa likhokahano tsa motlakase lipakeng tsa lihlopha.

Nakong ea ts'ebetso ea tlhahiso, sekhomaretsi se sebelisoa ka mokhoa o laoloang 'me likarolo li tsamaisana hantle pele li etsoa laminated hammoho tlas'a mocheso le khatello.Sena se tiisa maqhama a matla pakeng tsa lihlopha, ho fella ka boto ea potoloho e thata-flex e nang le thepa e babatsehang ea mechine le ea motlakase.

2. Theknoloji ea Surface Mount (SMT):

Mokhoa o mong o tsebahalang oa ho kopanya likarolo tsa boto ea potoloho ea rigid-flex ke ho sebelisa theknoloji ea holim'a metsi (SMT).SMT e kenyelletsa ho beha likarolo tsa holim'a holim'a metsi ka kotloloho karolong e thata ea boto ea potoloho ebe o kopanya likarolo tsena ho li-pads.Theknoloji ena e fana ka mokhoa o ka tšeptjoang le o sebetsang oa ho hokahanya lihlopha ha o ntse o netefatsa likhokahano tsa motlakase pakeng tsa tsona.

Ho SMT, likarolo tse thata le tse tenyetsehang li entsoe ka li-vias le liphaephe tse tsamaellanang ho tsamaisa tšebetso ea soldering.Sebelisa pente ea solder sebakeng sa pad mme u behe karolo ka nepo.Ka mor'a moo, boto ea potoloho e kenngoa ka mokhoa oa reflow soldering, moo motsoako oa solder o qhibilihang ebe o kopanya lihlopha hammoho, ho theha maqhama a matla.

3. Ka ho phutlisa lesoba:

Ho fihlela matla a matla a mochini le khokahanyo ea motlakase, liboto tsa potoloho tse thata-flex hangata li sebelisa plating ea lesoba.Mokhoa ona o kenyelletsa ho phunya masoba ka har'a lihlopha le ho sebelisa lisebelisoa tse tsamaisang ka har'a masoba ao.Sesebelisuoa sa conductive (hangata koporo) se kenngoa ka electroplated holim'a marako a lesoba, ho netefatsa tlamo e matla le khokahanyo ea motlakase pakeng tsa lihlopha.

Ho roala ka lesoba ho fana ka tšehetso e eketsehileng ho liboto tse thata-thata le ho fokotsa kotsi ea delamination kapa ho hloleha maemong a khatello e phahameng ea maikutlo.Bakeng sa liphetho tse ntle ka ho fetisisa, masoba a ho cheka a hloka ho beoa ka hloko ho ikamahanya le li-vias le li-pads ka mekhahlelo e fapaneng ho fihlela khokahano e sireletsehileng.

Ha re phethela:

Theknoloji ea sekhomaretsi e sebelisoang libotong tsa li-circuit tsa rigid-flex e bapala karolo ea bohlokoa ho netefatsa hore sebopeho sa bona se tšepahala le ts'ebetso ea motlakase.Adhesion, thekenoloji ea holim'a holim'a metsi le ho roala ka lesoba ke mekhoa e sebelisoang haholo ho hokahanya likarolo tse fapaneng.Theknoloji e 'ngoe le e' ngoe e na le melemo ea eona 'me e khethoa ho latela litlhoko tse khethehileng tsa moralo le ts'ebeliso ea PCB.

Ka ho utloisisa mekhoa ea ho kopanya e sebelisoang libotong tsa potoloho tse thata-flex, bahlahisi le baqapi ba ka etsa likopano tsa elektronike tse matla le tse ka tšeptjoang.Liboto tsena tse tsoetseng pele tsa potoloho li kopana le litlhoko tse ntseng li eketseha tsa theknoloji ea sejoale-joale, tse lumellang ho kengoa tšebetsong ha lisebelisoa tsa elektronike tse tenyetsehang le tse tšoarellang liindastering tse fapaneng.

Nako ea poso: Sep-18-2023

Morao