Theknoloji ea kopano ea mohlala ea PCB e bapala karolo ea bohlokoa tlhahisong le ho bokelleng liboto tsa potoloho.Litheknoloji tsena li netefatsa tlhahiso e sebetsang, ea boleng bo holimo le ea moruo ea liboto tsa potoloho ea prototype.Ka poso ena ea blog, re tla hlahloba mekhoa e meng e tloaelehileng ea ho kopanya prototyping ea PCB.Pele re kena lintlheng, a re ke re tsebiseng Capel ka bokhutšoanyane, k'hamphani e nang le phihlelo ea lilemo tse 15 indastering ea boto ea potoloho, e nang le sehlopha sa litsebi tsa setsebi, theknoloji e tsoetseng pele ea kopano ea potoloho, le fektheri ea eona ea tlhahiso le kopano.

Capel e bile moetapele indastering ea boto ea potoloho ka lilemo tse fetang 15, e ikemiselitseng ho fihlela litlhoko tse fapaneng tsa bareki ba eona.Khampani e na le sehlopha sa litsebi tse nang le phihlelo tse fumaneng tsebo ea bohlokoa ho hlahisa le ho kopanya liboto tsa potoloho.Theknoloji e tsoetseng pele ea kopano ea boto ea potoloho ea Capel e tiisa litekanyetso tsa boleng bo holimo le mekhoa e metle ea tlhahiso.

Ho ba le lihlahisoa tsa eona tsa boto ea potoloho le limela tsa kopano ho fa Capel monyetla oa tlhōlisano.Setupo sena se lumella k'hamphani ho laola hantle ts'ebetso ea tlhahiso, ho netefatsa phano e nakong le ho boloka taolo e ntle ea boleng.Ho feta moo, tsebo ea k'hamphani ea tlhahiso ea PCB le kopano e e nolofalletsa ho fana ka bareki ka litharollo tse pharaletseng le tse theko e tlaase.

Kaha joale re tloaelane le Capel le bokhoni ba eona, ha re hlahlobeng mekhoa ea kopano ea PCB e sebelisoang hangata

indasteri.

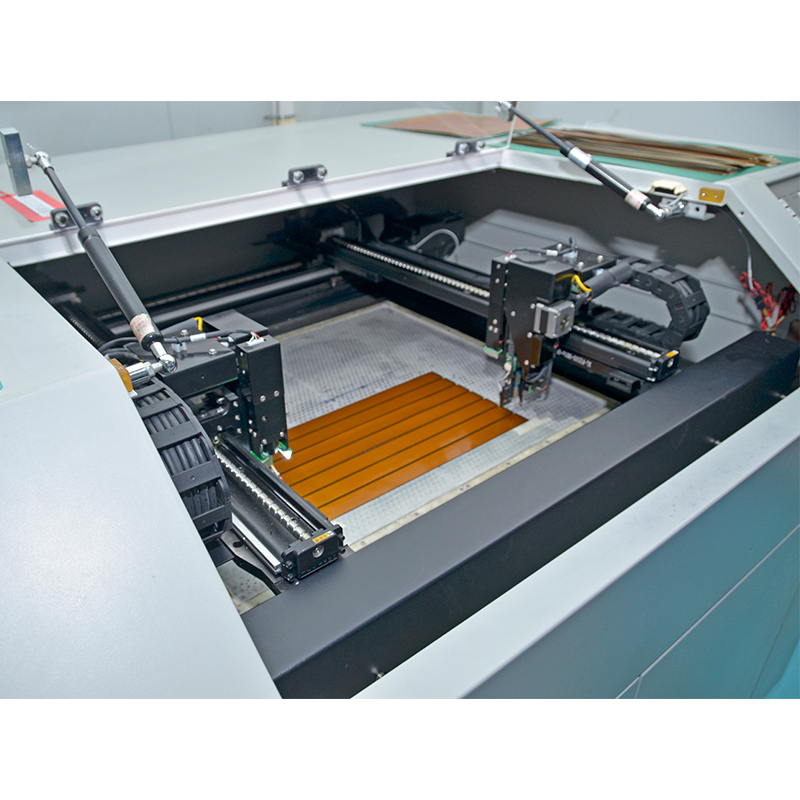

1. Theknoloji ea Surface Mount (SMT):

Theknoloji ea Surface Mount (SMT) ke e 'ngoe ea mekhoa e sebelisoang haholo ea ho kopanya PCB.E kenyelletsa ho kenya likarolo ka kotloloho ho PCB.SMT e fana ka melemo e mengata, ho kenyelletsa le bokhoni ba ho amohela likaroloana tse nyane, letsoalo le phahameng la likarolo, le ts'ebetso e ntlafalitsoeng ea motlakase.

2. Theknoloji ea ho sebelisa likoti (THT):

Theknoloji ea ka-hole (THT) ke theknoloji ea khale ea ho kopanya e kenyelletsang lisebelisoa tse ntseng li eketseha ka ho kenya li-loto ka mekoting ea PCB le ho li kopanya ka lehlakoreng le leng.THT e atisa ho sebelisoa bakeng sa likarolo tse hlokang matla a eketsehileng a mochine kapa tse kholo haholo bakeng sa SMT.

3. Tlhahlobo ea optical e iketsang (AOI):

Automated Optical Inspection (AOI) ke theknoloji e sebelisoang ho hlahloba li-PCB tse kopaneng bakeng sa liphoso kapa liphoso.Litsamaiso tsa AOI li sebelisa lik'hamera le mekhoa ea ho lemoha litšoantšo ho hlahloba likarolo tse fapaneng tsa PCB, tse kang ho beha likarolo, li-solder, le polarity.Theknoloji ena e tiisa kopano ea boleng bo phahameng le ho fokotsa monyetla oa hore lihlahisoa tse nang le bokooa li fihle ho bareki.

4. Tlhahlobo ea X-ray:

Tlhahlobo ea X-ray ke theknoloji e sa senyeheng ea tlhahlobo e sebelisoang ho hlahloba li-PCB bakeng sa likarolo tse patiloeng, tse kang manonyeletso a solder kapa thepa e sa tlaleng tlas'a likarolo.Tlhahlobo ea X-ray e thusa ho lemoha mefokolo e kang solder e sa lekaneng, li-solder tse batang, kapa li-voids tse ka 'nang tsa se ke tsa bonahala ka ho hlahloba pono.

5. Sebetsa hape le ho lokisa:

Mekhoa ea ho lokisa le ho lokisa e bohlokoa ho lokisa mefokolo kapa ho nkela likarolo tse fosahetseng ho li-PCB tse kopaneng.Litsebi tse nang le litsebo li sebelisa lisebelisoa le lisebelisoa tse khethehileng ho senya le ho fetola likarolo ntle le ho baka tšenyo ho PCB.Mekhoa ena e fokotsa litšila le ho boloka mapolanka a nang le bokooa, ho boloka nako le lisebelisoa.

6. Khetho ea ho cheseletsa:

Selectional soldering ke mokhoa o sebelisoang ho solder ka har'a lesoba ho PCB ntle le ho ama likarolo tsa soldered surface mount.E fana ka ho nepahala ho hoholo le ho fokotsa monyetla oa ho senya likarolo tse haufi.

7. Teko ea Marang-rang (ICT):

Teko ea in-circuit (ICT) e sebelisa lisebelisoa tse khethehileng tsa tlhahlobo ho lekola tšebetso ea likarolo tsa potoloho ho PCB.E thusa ho lemoha likarolo tse fosahetseng, li-circuits tse bulehileng kapa tse khutšoanyane kapa litekanyetso tse fosahetseng tsa likarolo.ICT e fana ka maikutlo a bohlokoa ho ntlafatsa moralo le ts'ebetso ea ho kopanya.

Tsena ke tse ling tsa mekhoa e tloaelehileng ea kopano ea PCB e sebelisoang ke lik'hamphani tse kang Capel.Tsoelo-pele e tsoelang pele ea theknoloji e lumella bahlahisi ho hlahloba mekhoa e mecha le ho ntlafatsa tšimong ea kopano ea boto ea potoloho.

Phihlelo e pharalletseng ea Capel le boiphihlelo ba botekgeniki indastering ea boto ea potoloho, hammoho le theknoloji ea eona e tsoetseng pele ea kopano ea PCB, e e etsa molekane ea tšepahalang ho bareki ba eona.Boitlamo ba k'hamphani ba ho fana ka lits'ebeletso tse sebetsang hantle, tsa boleng bo holimo le tsa moruo tsa boto ea potoloho le likopano li e khetholla 'marakeng.

Ka kakaretso, ho utloisisa mekhoa e tloaelehileng ea kopano ea prototyping ea PCB ho bohlokoa ho bahlahisi le bareki.Likhamphani tse kang Capel li phahamisa tsebo ea tsona, boiphihlelo le theknoloji e tsoetseng pele ho fana ka tharollo ea boto ea potoloho le tharollo ea kopano.Ka ho khetha molekane ea ka tšeptjoang joaloka Capel, bareki ba rua molemo lits'ebetsong tse sebetsang hantle, taolo ea boleng bo phahameng le tharollo e theko e tlaase.

Nako ea poso: Oct-19-2023

Morao